- [English]

- Finite Element and Discrete Element Analyses of Anisotropic Powder Compaction for Axial Flux Motor Cores

-

Jeong Ah Lee, Do Won Lee, , Hyojeong Ha, Ki Hyuk Kwon, Eon Byeong Park, Taeyoung Kim, Hyoung Seop Kim

-

J Powder Mater. 2025;32(6):451-458. Published online December 31, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00409

-

-

Abstract Abstract

PDF PDF

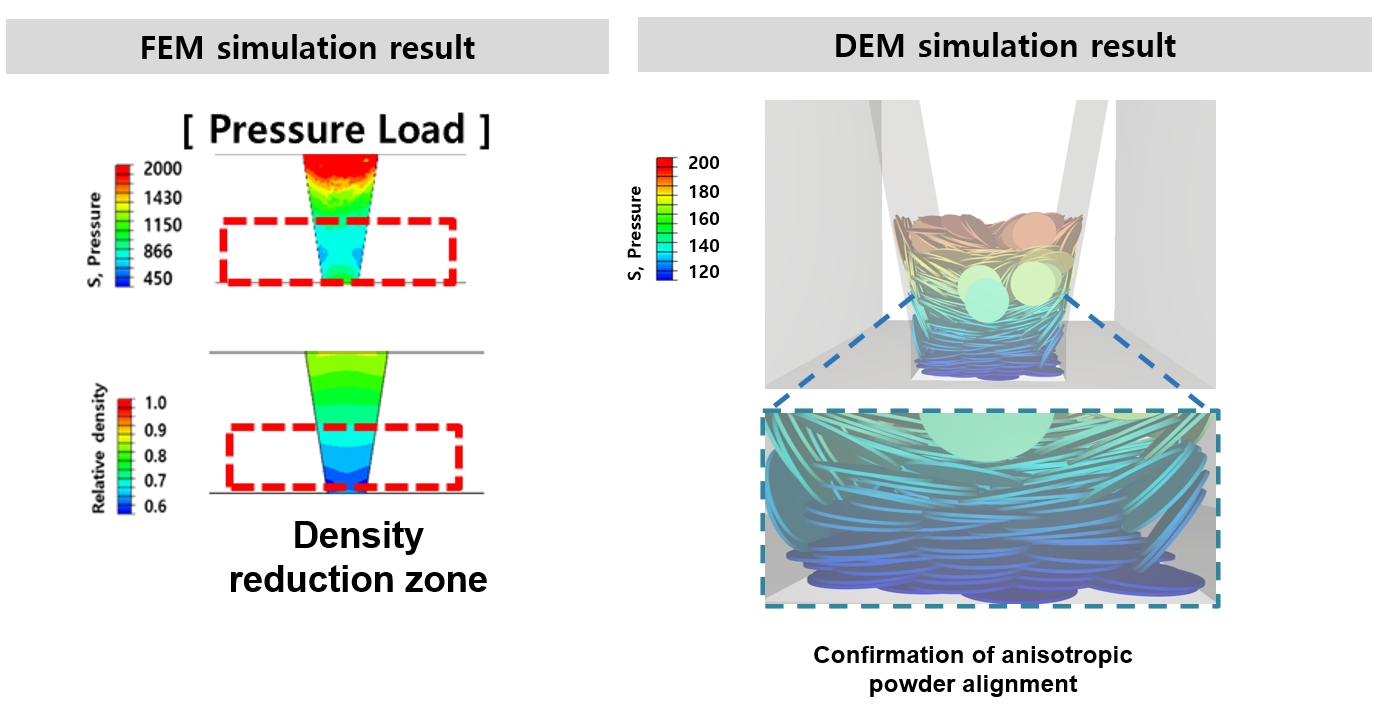

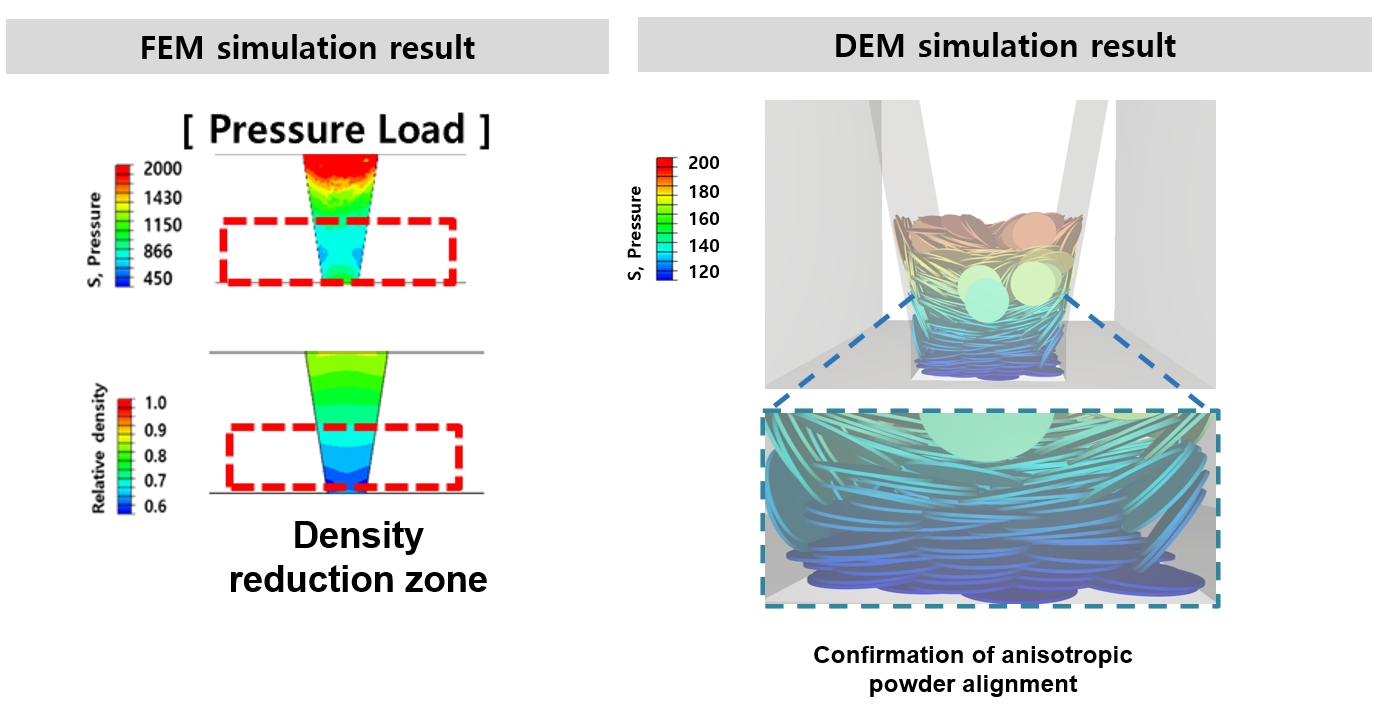

- This study investigates the compaction behavior of anisotropic, plate-like powders used in axial flux motor cores through a combined FEM–DEM approach. A porous continuum FEM model captures stress and density evolution during die pressing, revealing strong gradients along the compaction direction, with higher stress and densification near the upper punch and reduced compaction in the lower region. Guided by these results, DEM simulations examine particle packing, orientation, and contact pressure in representative zones. The DEM analysis shows that higher local pressure promotes denser packing and in-plane particle alignment near the upper punch, while the lower region exhibits more random orientations and lower contact forces. As a result, the multi-scale FEM–DEM framework clarifies how anisotropic particle behavior governs local densification and offers practical guidance for die design and process optimization to achieve more uniform density and controlled magnetic-property-relevant particle alignment in axial flux motor cores.

- [Korean]

- Prediction of Martensite Fraction in the Sintering Hardening Process of Ni/Mo Alloy Powder (FLC-4608) Using the Finite Element Method

-

Hyo Wook Park, Soo-Hyun Joo, Eon Sik Lee, Ki Hyuk Kwon, Hyong Seop Kim

-

J Korean Powder Metall Inst. 2015;22(1):10-14. Published online February 1, 2015

-

DOI: https://doi.org/10.4150/KPMI.2015.22.1.10

-

-

Abstract Abstract

PDF PDF

In recent years, industrial demands for superior mechanical properties of powder metallurgy steel components with low cost are rapidly growing. Sinter hardening that combines sintering and heat treatment in continuous one step is cost-effective. The cooling rate during the sinter hardening process dominates material microstructures, which finally determine the mechanical properties of the parts. This research establishes a numerical model of the relation between various cooling rates and microstructures in a sinter hardenable material. The evolution of a martensitic phase in the treated microstructure during end quench tests using various cooling media of water, oil, and air is predicted from the cooling rate, which is influenced by cooling conditions, using the finite element method simulations. The effects of the cooling condition on the microstructure of the sinter hardening material are found. The obtained limiting size of the sinter hardening part is helpful to design complicate shaped components.

|