Current issue

- Page Path

- HOME > Browse Articles > Current issue

Research Articles

- [English]

- Laser Processing of an Al0.1CoCrFeNi High Entropy Alloy + Cu Composite Powders via Laser Powder Bed Fusion

- Kwangtae Son, Ji-Woon Lee, Soon-Jik Hong, Somayeh Pasebani

- J Powder Mater. 2025;32(4):277-287. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00101

- 689 View

- 13 Download

-

Abstract

Abstract

PDF

PDF - This study examined process–structure relationships in laser powder bed fusion of Al₀.₁CoCrFeNi + Cu composites, focusing on densification, elemental distribution, and solidification cracking. Mechanically mixed Al₀.₁CoCrFeNi and Cu powders were processed across a range of laser powers (100–250 W) and scan speeds (200–800 mm/s). Increased volumetric energy density (VED) improved densification, with a plateau near 200 J/mm³ yielding ~96% relative density; however, this value was still below application-grade thresholds. At low VED, insufficient thermal input and short melt pool residence times promoted Cu segregation, while higher VED facilitated improved elemental mixing. Elemental mapping showed partial co-segregation of Ni with Cu at low energies. Solidification cracks were observed across all processing conditions. In high VED regimes, cracking exhibited a minimal correlation with segregation behavior and was primarily attributed to steep thermal gradients, solidification shrinkage, and residual stress accumulation. In contrast, at low VED, pronounced Cu segregation appeared to exacerbate cracking through localized thermal and mechanical mismatch.

- [English]

- Cost-effective Fabrication of Near β-Ti Alloy via L-PBF: Process Optimization of In-situ Alloying Ti-3Fe

- Sehun Kim, Ukju Gim, Taehu Kang, Jongik Lee, Sanghee Jeong, Jimin Han, Bin Lee

- J Powder Mater. 2025;32(4):288-298. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00213

- 708 View

- 12 Download

-

Abstract

Abstract

PDF

PDF - This study presents a cost-effective approach to fabricating near β-Ti alloys via in-situ alloying during laser powder bed fusion (L-PBF). A blend of non-spherical pure Ti, 3 wt.% Fe, and 0.1 wt.% SiO2 nanoparticles was used to induce β-phase stabilization and improve flowability. Twenty-five process conditions were evaluated across a volumetric energy density range of 31.75-214.30 J/mm3, achieving a maximum relative density of 99.21% at 89.29 J/mm3. X-ray diffraction analysis revealed that the β-Ti phase was partially retained at room temperature, accompanied by lattice contraction in the α’-Ti structure, indicating successful Fe incorporation. Elemental mapping confirmed that the Fe distribution was homogeneous, without significant segregation. Compared to pure Ti, the Ti-3Fe sample exhibited a 49.2% increase in Vickers hardness and notable improvements in yield and ultimate tensile strengths. These results demonstrate the feasibility of in-situ alloying with low-cost elemental powders to produce high-performance near β-Ti alloys using L-PBF.

- [English]

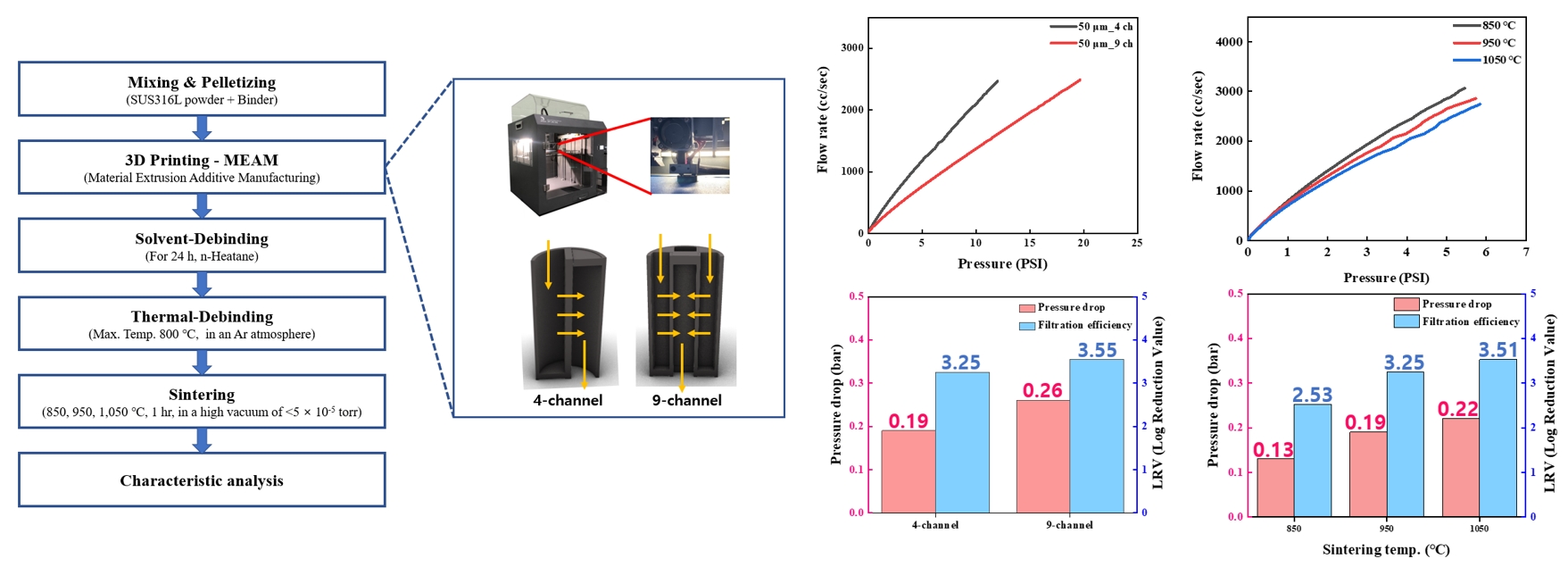

- Fabrication and Pore Characteristics of Metal Powder Filters with a Cross-Sealed Honeycomb Shape Using Material Extrusion Additive Manufacturing

- Minji Kim, Min-Jeong Lee, Su-Jin Yun, Poong-Yeon Kim, Hyeon Ju Kim, Juyong Kim, Jung Woo Lee, Jung-Yeul Yun

- J Powder Mater. 2025;32(4):299-308. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00234

- 676 View

- 18 Download

-

Abstract

Abstract

PDF

PDF - The development of high-performance metal filters is essential for maintaining ultra-clean environments in semiconductor manufacturing. In this study, cross-sealed honeycomb filters were fabricated using STS316L powder via material extrusion additive manufacturing (MEAM) for semiconductor gas filtration. The effects of filter geometry (4 or 9 channels) and sintering temperature (850°C, 950°C, or 1,050°C) on performance were examined. First, 4-channel and 9-channel filters sintered at the same temperature (950°C) exhibited similar porosities of 50.08% and 50.57%, but the 9-channel filter showed a higher pressure-drop (0.26 bar) and better filtration-efficiency (3.55 LRV) than the 4-channel filter (0.19 bar and 3.25 LRV, respectively). Second, for filters with the same geometry (4-channel) increasing the sintering temperature reduced porosity from 64.52% to 40.33%, while the pressure-drop increased from 0.13 bar to 0.22 bar and filtration-efficiency improved from 2.53 LRV to 3.51 LRV. These findings demonstrate that filter geometry and sintering temperature are key factors governing the trade-off between air permeability, pressure-drop, and filtration efficiency. This work provides insights and data for optimizing MEAM-based high-performance metal powder filter design.

- [Korean]

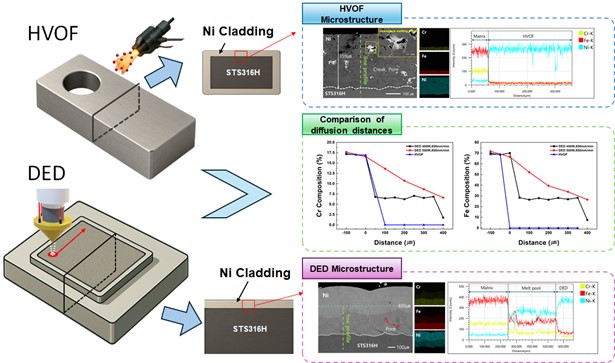

- Evaluation of Mechanical Properties of Pure Ni Coatings on a Type 316H Stainless Steel Substrate via High-Velocity Oxy-fuel and Directed Energy Deposition Processes

- Won Chan Lee, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

- J Powder Mater. 2025;32(4):309-314. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00185

- 628 View

- 3 Download

-

Abstract

Abstract

PDF

PDF - This study compares pure Ni coatings deposited on type 316H stainless steel using high-velocity oxy-fuel (HVOF) and directed energy deposition (DED) processes. Microstructural analysis showed that DED produced more uniform claddings with fewer pores, while HVOF resulted in incomplete melting and cracks. Elemental diffusion of Cr and Fe from the substrate into the cladding was evident in DED samples, especially at higher laser power, but minimal in HVOF due to low heat input. Vickers hardness testing revealed that DED claddings had higher hardness near the interface, which was attributed to solid solution strengthening and reduced porosity. Although HVOF better suppressed diffusion, it exhibited inferior mechanical properties due to internal defects. Overall, the DED process demonstrated superior coating quality and mechanical performance, suggesting its suitability for corrosion-resistant applications requiring both structural integrity and thermal stability, such as molten salt reactors.

- [English]

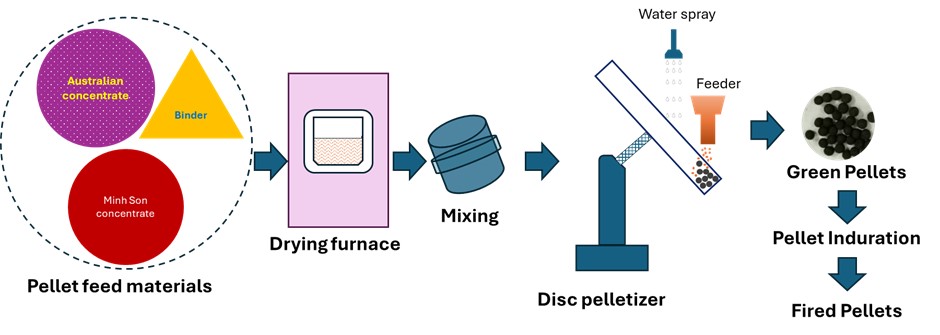

- Enhanced Compressive Strength of Fired Iron Ore Pellets: Effects of Blending Fine and Coarse Particle Concentrates

- Ngo Quoc Dung, Tran Xuan Hai, Nguyen Minh Thuyet, Nguyen Quang Tung, Arvind Barsiwal, Nguyen Hoang Viet

- J Powder Mater. 2025;32(4):315-329. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00129

- 1,256 View

- 63 Download

-

Abstract

Abstract

PDF

PDF - This study investigated the effects of oxidative firing parameters and raw material characteristics on the pelletization of Australian and Minh Son (Vietnam) iron ore concentrates. The influence of firing temperature (1050°C–1150°C) and holding time (15–120 min) on pellet compressive strength was examined, focusing on microstructural changes during consolidation. Green pellets were prepared using controlled particle size distributions and bentonite as a binder. Scanning electron microscopy and energy-dispersive X-ray spectroscopy analyses revealed that grain boundary diffusion, liquid phase formation, and densification significantly improved mechanical strength. X-ray diffraction confirmed the complete oxidation of magnetite to hematite at elevated temperatures, a critical transformation for metallurgical performance. Optimal firing conditions for both single and blended ore compositions yielded compressive strengths above 250 kgf/pellet, satisfying the requirements for blast furnace applications. These results provide valuable guidance for improving pellet production, promoting the efficient utilization of diverse ore types, and enhancing the overall performance of ironmaking operations.

- [Korean]

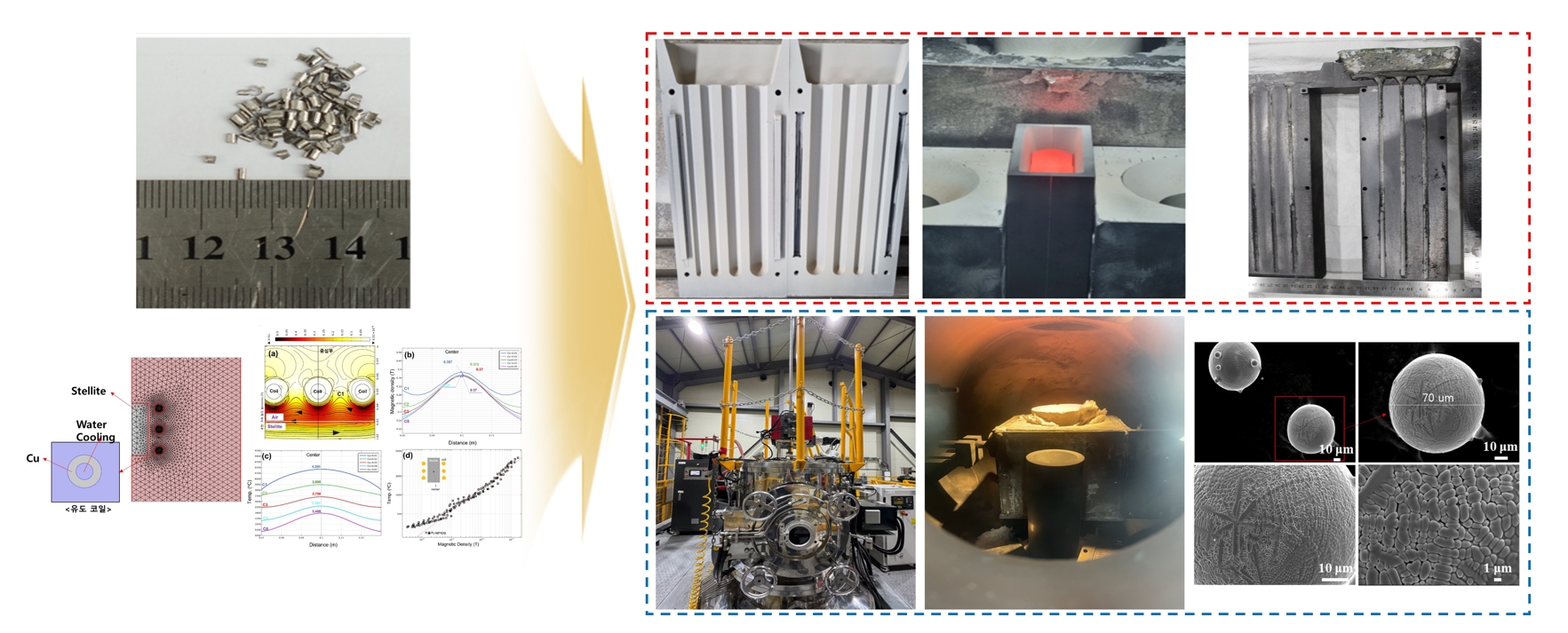

- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

- YongKwan Lee, Hyun-chul Kim, Myungsuk Kim, Soong Ju Oh, Kyoungtae Park, JaeJin Sim

- J Powder Mater. 2025;32(4):330-343. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00136

- 646 View

- 8 Download

-

Abstract

Abstract

PDF

PDF - Co-Cr alloys are widely used in cutting tools and turbine components due to their high strength and resistance against wear and corrosion. However, scrap generated during hardfacing is often discarded due to impurities and oxidation, and research on its recycling remains limited. This study aimed to optimize the recycling process of Stellite 6 scrap to reduce waste and minimize costs while maintaining material quality. Melting, casting, and powdering processes were designed using HSC Chemistry, FactSage, and COMSOL Multiphysics, with optimization of key parameters such as the crucible material and temperature control. The recycled alloy and powder were analyzed using X-ray fluorescence analysis, inductively coupled plasma optical emission spectroscopy, and X-ray diffractometry, showing mechanical and chemical properties comparable to commercial Stellite 6. The Co and Cr contents were maintained, with a slight increase in Fe. These findings demonstrate the potential for producing high-quality recycled Stellite 6 materials, contributing to the sustainable utilization of metal resources in high-performance applications.

- [Korean]

- Influence of Powder Particle Size on the Microstructure of UO2 Fuel Pellets with High Gd2O3 Content

- Ji-Hwan Lee, Jae Ho Yang, Ji-Hae Yoon, Dong-Joo Kim, Dong-wook Shin, Dong Seok Kim

- J Powder Mater. 2025;32(4):344-353. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00178

- 655 View

- 13 Download

-

Abstract

Abstract

PDF

PDF - The recent development of small modular reactors (SMRs) and the adoption of higher-enrichment fuels have intensified the need for advanced burnable absorbers to ensure effective reactivity control and extended fuel cycles. Among various designs, UO2 fuels with high Gd2O3 (gadolinium oxide) content provide notable benefits; in particular, they are compatible with established fabrication methods for burnable absorber fuels. However, achieving a homogeneous dispersion of Gd2O3 at high loading levels remains challenging, and the frequent occurrence of phase segregation and non-uniform microstructures can limit fuel reliability and performance. Overcoming these limitations requires an understanding of the powder characteristics and mixing behaviors during fabrication. In this study, we investigate the effects of the initial particle size and mixing method of UO2 and Gd2O3 powders on the microstructure and mixing homogeneity of high-Gd2O3-content fuels. The findings indicate that both the mixing method and the preparation state of the starting powders significantly affect the resulting microstructure and mixing uniformity.

- [Korean]

- Effect of Fe and Cr on ω Phase Formation in Metastable β-Ti Alloy

- Sun-Young Park, Young-Bum Chun

- J Powder Mater. 2025;32(4):354-360. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00220

- 669 View

- 7 Download

-

Abstract

Abstract

PDF

PDF - This study investigated the effects of Fe and Cr contents on ω phase formation and transformation during solution treatment and the subsequent aging process, for which four model alloys with varying Fe and Cr contents but keeping Mo equivalent of ~ 12.6 were prepared by plasma arc melting and fabricated into plates by hot forging followed by hot-rolling. The atherrmal ω phase was observed in all Ti alloys after solution treatment followed by water quenching through XRD and TEM analysis. The largest volume fraction of athermal ω phase is formed in Ti alloy with only Fe 4 wt.% among all Ti alloys, leading to the highest Vickers value due to hardening effect ω phase. It was found that not only Mo equivalent but also each characteristic of β stabilizing elements should be considered to understand a microstructure evolution and mechanical properties.

TOP

kpmi

kpmi

First

First Prev

Prev