Funded articles

- Page Path

- HOME > Browse Articles > Funded articles

Research Articles

- [Korean]

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- Eunhyo Song, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00059

- Funded: National Research Foundation of Korea

- 423 View

- 16 Download

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

- [English]

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

- J Powder Mater. 2025;32(3):179-190. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00094

- Funded: National Research Foundation of Korea

- 2,348 View

- 92 Download

-

Abstract

Abstract

PDF

PDF - Area-selective atomic layer deposition (AS-ALD) is a bottom-up process that selectively deposits thin films onto specific areas of a wafer surface. The surface reactions of AS-ALD are controlled by blocking the adsorption of precursors using inhibitors such as self-assembled monolayers (SAMs) or small molecule inhibitors. To increase selectivity during the AS-ALD process, the design of both the inhibitor and the precursor is crucial. Both inhibitors and precursors vary in reactivity and size, and surface reactions are blocked through interactions between precursor molecules and surface functional groups. However, challenges in the conventional SAM-based AS-ALD method include thermal instability and potential damage to substrates during the removal of residual SAMs after the process. To address these issues, recent studies have proposed alternative inhibitors and process design strategies.

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- Funded: National Research Foundation of Korea

- 410 View

- 32 Download

-

Abstract

Abstract

PDF

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [English]

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang Oanh, , Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

- J Powder Mater. 2025;32(3):191-201. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00143

- Funded: Ministry of Education and Training of Vietnam

- 846 View

- 49 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) exhibit complex phase formation behavior, challenging conventional predictive methods. This study presents a machine learning (ML) framework for phase prediction in HEAs, using a curated dataset of 648 experimentally characterized compositions and features derived from thermodynamic and electronic descriptors. Three classifiers—random forest, gradient boosting, and CatBoost—were trained and validated through cross-validation and testing. Gradient boosting achieved the highest accuracy, and valence electron concentration (VEC), atomic size mismatch (δ), and enthalpy of mixing (ΔHmix) were identified as the most influential features. The model predictions were experimentally verified using a non-equiatomic Al₃₀Cu₁₇.₅Fe₁₇.₅Cr₁₇.₅Mn₁₇.₅ alloy and the equiatomic Cantor alloy (CoCrFeMnNi), both of which showed strong agreement with predicted phase structures. The results demonstrate that combining physically informed feature engineering with ML enables accurate and generalizable phase prediction, supporting accelerated HEA design.

-

Citations

Citations to this article as recorded by- Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

Jiacheng Tong, Jun Wang, Huimin Zhang, Haoran Liu, Youchang Sun, Zhiguo Li, Wenyi Zhang, Zhe Wang, Yanli Chang, Zhao Yuan, Henry Hu

Metallurgical and Materials Transactions B.2025;[Epub] CrossRef - Recent progresses on high entropy alloy development using machine learning: A review

Abhishek Kumar, Nilay Krishna Mukhopadhyay, Thakur Prasad Yadav

Computational Materials Today.2025; : 100038. CrossRef

- Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

- [Korean]

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

- J Powder Mater. 2025;32(3):244-253. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00087

- Funded: Korean Institute of Materials Science, Ministry of Trade, Industry, and Energy, Ministry of Trade, Industry, and Energy, Ministry of Trade, Industry, and Energy

- 512 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - Ti-6Al-4V alloy is widely utilized in aerospace and medical sectors due to its high specific strength, corrosion resistance, and biocompatibility. However, its low machinability makes it difficult to manufacture complex-shaped products. Advancements in additive manufacturing have focused on producing high-performance, complex components using the laser powder bed fusion (LPBF) process, which is a specialized technique for customized geometries. The LPBF process exposes materials to extreme thermal conditions and rapid cooling rates, leading to residual stresses within the parts. These stresses are intensified by variations in the thermal history across regions of the component. These variations result in differences in microstructure and mechanical properties, causing distortion. Although support structure design has been researched to minimize residual stress, few studies have conducted quantitative analyses of stress variations due to different support designs. This study investigated changes in the residual stress and mechanical properties of Ti-6Al-4V alloy fabricated using LPBF, focusing on support structure design.

- [English]

- SnF2-Induced LiF Interphase for Stable Lithium Metal Anodes with Suppressed Dendrite Growth

- Yeong Hoon Jeon, Seul Ki Choi, Yun Seung Nah, Wonil Shin, Yong-Ho Choa, Minho Yang

- J Powder Mater. 2025;32(3):212-221. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00164

- Funded: National Research Foundation of Korea, National Research Foundation of Korea

- 640 View

- 22 Download

-

Abstract

Abstract

PDF

PDF - Lithium (Li) metal is a promising anode for next-generation batteries due to its high capacity, low redox potential, and low density. However, dendrite growth and interfacial instability limit its use. In this study, an artificial solid electrolyte interphase layer of LiF and Li-Sn (LiF@Li-Sn) was fabricated by spray-coating SnF2 onto Li. The LiF@Li-Sn anode exhibited improved air stability and electrochemical performance. Electrochemical impedance spectroscopy indicated a charge transfer resistance of 25.2 Ω after the first cycle. In symmetric cells, it maintained a low overpotential of 27 mV after 250 cycles at 2 mA/cm2, outperforming bare Li. In situ microscopy confirmed dendrite suppression during plating. Full cells with NMC622 cathodes and LiF@Li-Sn anodes delivered 130.8 mAh/g with 79.4% retention after 300 cycles at 1 C and 98.8% coulombic efficiency. This coating effectively stabilized the interface and suppressed dendrites, with promising implications for practical lithium metal batteries.

- [English]

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- Funded: Agency for Defense Development

- 607 View

- 34 Download

-

Abstract

Abstract

PDF

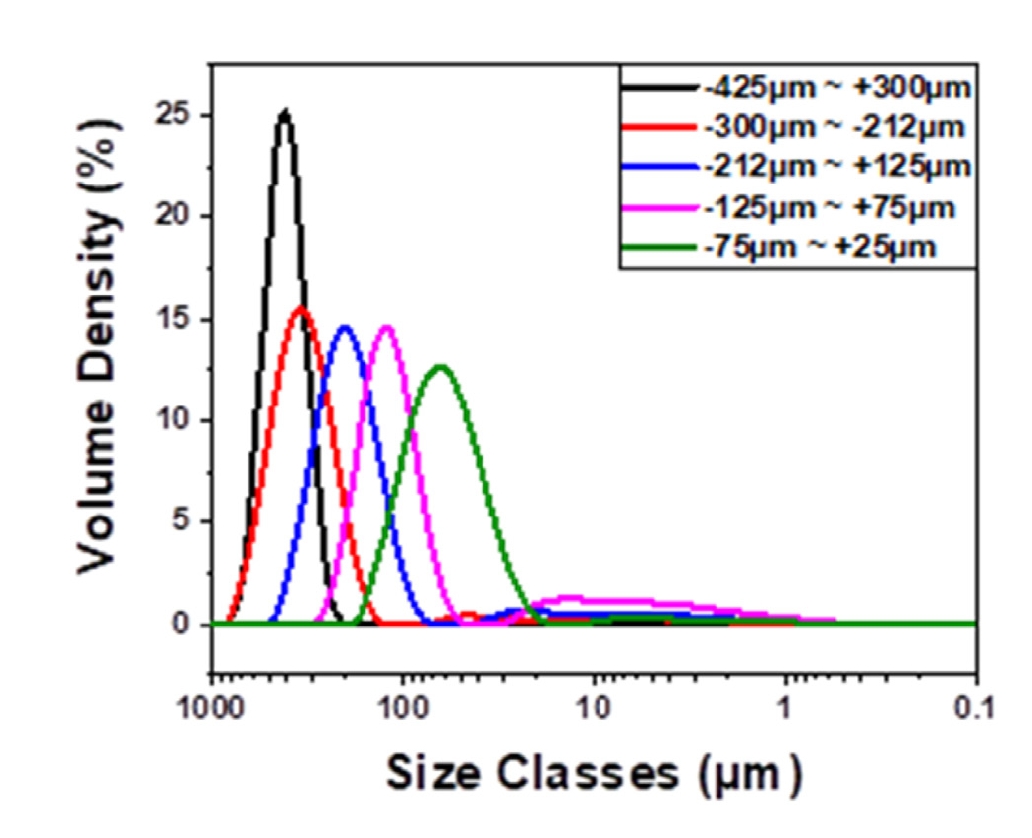

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

- [Korean]

- The Manufacturing Process of Clean Ni-Cr-Co-Based Superalloy Powder Using a Plasma Rotating Electrode

- Kyu-Sik Kim, Dae Woong Kim, Yeontae Kim, Jung Hyo Park

- J Powder Mater. 2025;32(3):222-231. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00171

- Funded: Agency for Defense Development

- 414 View

- 19 Download

-

Abstract

Abstract

PDF

PDF - Ni-based superalloys are widely used for critical components in aerospace, defense, industrial power generation systems, and other applications. Clean superalloy powders and manufacturing processes, such as compaction and hot isostatic pressing, are essential for producing superalloy discs used in turbine engines, which operate under cyclic rotating loads and high-temperature conditions. In this study, the plasma rotating electrode process (PREP), one of the most promising methods for producing clean metallic powders, is employed to fabricate Ni-based superalloy powders. PREP leads to a larger powder size and narrower distribution compared to powders produced by vacuum induction melt gas atomization. An important finding is that highly spheroidized powders almost free of satellites, fractured, and deformed particles can be obtained by PREP, with significantly low oxygen content (approximately 50 ppm). Additionally, large grain size and surface inclusions should be further controlled during the PREP process to produce high-quality powder metallurgy parts.

- [Korean]

- Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

- Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

- J Powder Mater. 2025;32(2):104-112. Published online March 4, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00458

- Funded: National Research Foundation of Korea, National Research Foundation of Korea

- 653 View

- 24 Download

-

Abstract

Abstract

PDF

PDF - A hybrid energy harvester that consisted of thermoelectric (TE) composite film and electrospun piezoelectric (PE) polymeric membranes was constructed. TE composites were fabricated by dispersing inorganic TE powders inside polyvinylidene fluoride elastomer using a drop-casting technique. The polyvinylidene fluoride-trifluoroethylene, which was chosen due to its excellent chemical resistance, mechanical stability, and biocompatibility, was electrospun onto an aluminum foil to fabricate the ultra-flexible PE membranes. To create a hybrid energy harvester that can simultaneously convert heat and mechanical energy resources into electricity, the TE composite films attached to the PE membrane were encapsulated with protective polydimethylsiloxane. The fabricated energy harvester converted the outputs with a maximum voltage of 4 V (PE performance) and current signals of 0.2 μA (TE performance) under periodical heat input and mechanical bending in hybrid modes. This study demonstrates the potential of the hybrid energy harvester for powering flexible and wearable electronics, offering a sustainable and reliable power source.

- [Korean]

- Effect of the Initial Porosity of Needle Coke-Pitch Carbonized Blocks on Impregnation-Related Physical Properties

- U-Sang Youn, Sang-Hye Lee, Jae-Seung Roh

- J Powder Mater. 2025;32(2):138-144. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00038

- Funded: Kumoh National Institute of Technology

- 386 View

- 8 Download

-

Abstract

Abstract

PDF

PDF - Carbonized blocks with different porosities were prepared by varying the particle size of the filler and subsequent impregnation. The impregnated carbonized blocks were re-carbonized. The use of smaller particles in the filler in the carbonized block was associated with larger porosity, smaller pore size, and a higher impregnation ratio. The block with the smallest average particle size (53 μm), CB-53, had a porosity of 35.9% and pores of approximately 40 μm, while the block with the largest average particle size (413 μm), CB-413, had a porosity of 30.5% and pores of approximately 150 μm. CB-53 had the highest bulk density, electrical resistivity, flexural strength, and impregnation ratio. This is due to the large porosity, which is believed to be due to the presence of more interfaces between particles during the re-carbonization of the impregnated carbonized block, resulting in a better pore-filling effect.

Critical Review

- [English]

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- Funded: National Research Foundation of Korea

- 2,027 View

- 66 Download

- 1 Citations

-

Abstract

Abstract

PDF

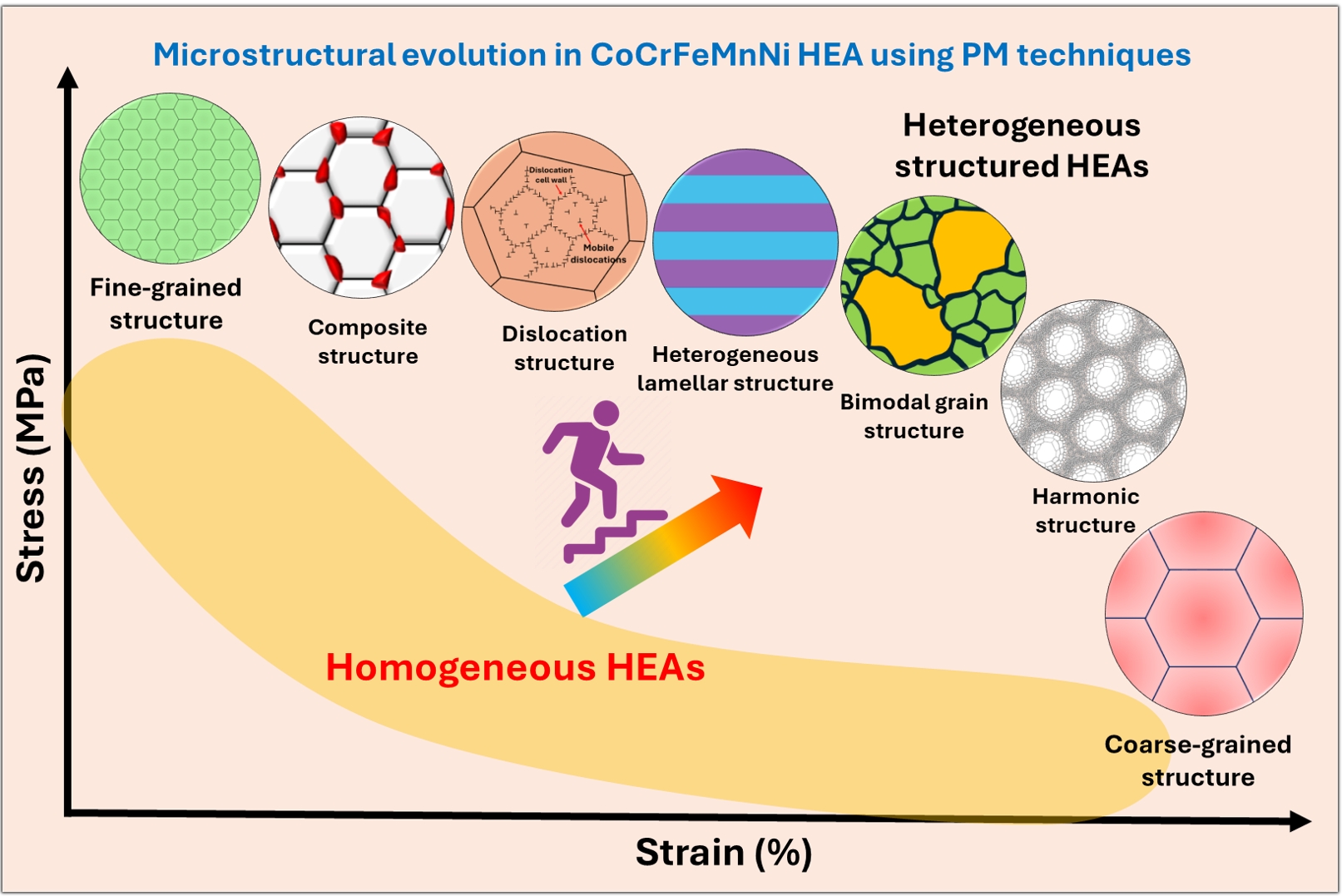

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Research Articles

- [English]

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- Funded: Korea Institute of Materials Science, National Research Foundation of Korea

- 780 View

- 39 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

-

Citations

Citations to this article as recorded by- Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

Seon-Keun Oh, Sang-Hun Shim, Young-Kyun Kim, Young-Sang Na

Materials Science and Engineering: A.2025; 945: 148989. CrossRef

- Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

- [Korean]

- Effect of Cellulose Fiber Density Variation on Energy Harvesting Performance in a Hydrovoltaic Generator

- Seung-Hwan Lee, So Hyun Baek, Hyun-Woo Lee, Yongbum Kwon, Kanghyuk Lee, Kee-Ryung Park, Yoseb Song, Bum Sung Kim, Ji Young Park, Yong-Ho Choa, Da-Woon Jeong

- J Powder Mater. 2025;32(2):113-121. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00052

- Funded: Korea Institute of Industrial Technology, Development of DLE-type carbon-neutral next-generation lithium-ion concentration technology

- 742 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - Energy harvesting has become a crucial technology for sustainable energy solutions; in particular, the utilization of ambient water movement in hydrovoltaic generators has emerged as a promising approach. However, optimizing performance requires an understanding of structural factors affecting energy harvesting, particularly capillary effects. This study aimed to improve hydrovoltaic generator performance by adjusting internal fiber density, which influences water transport and ion mobility. Using cold isostatic pressing, cellulose acetate (CA) loading in a urethane mold was varied to optimize internal density. As CA loading increased, the fiber arrangement became denser, narrowing capillary pathways and reducing proton mobility. While open-circuit voltage (VOC) remained stable, short-circuit current (ISC) decreased with higher CA mass. The sample with a loading of 0.3 g exhibited the highest energy harvesting efficiency, achieving ISC = 107.2 μA, VOC = 0.15 V, and power (P) = 16.7 μW. This study provides insights into methods of improving hydrovoltaic generator efficiency through internal structural modifications.

- [Korean]

- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

- Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):131-137. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00080

- Funded: Korea Institute of Materials Science, National Research Foundation of Korea

- 537 View

- 17 Download

-

Abstract

Abstract

PDF

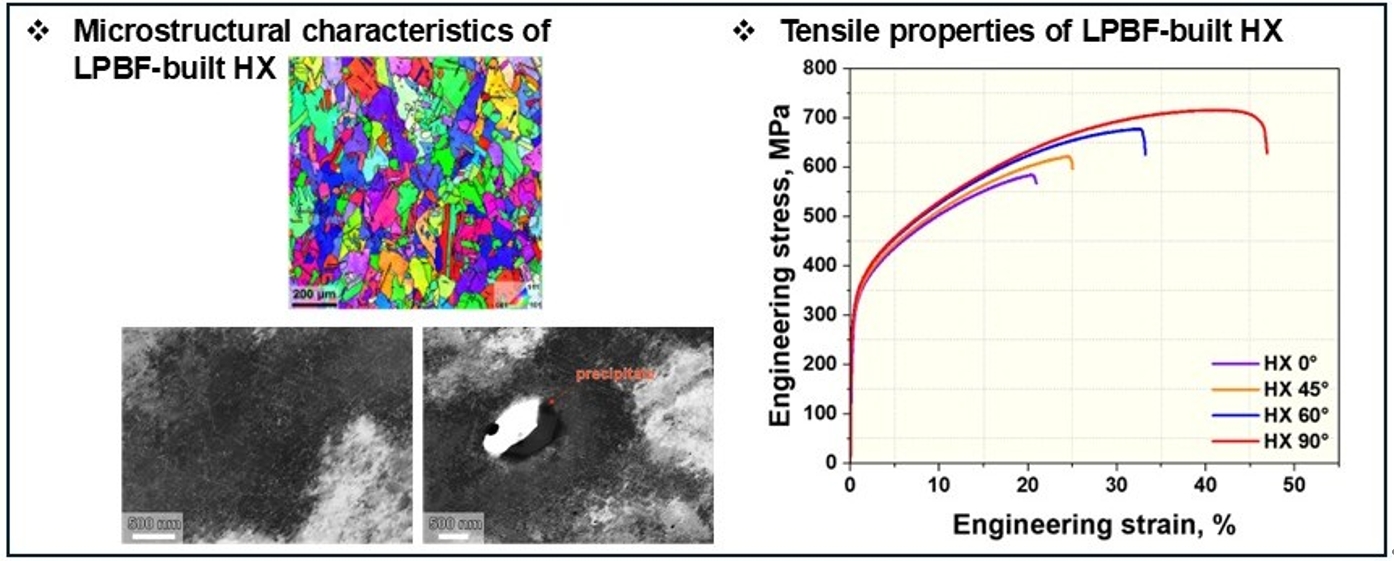

PDF - In this study, the effect of build orientation on the mechanical properties of Hastelloy X fabricated by laser powder bed fusion (LPBF) process was investigated. Initial microstructural analysis revealed an equiaxed grain structure with random crystallographic orientation and annealing twins. Intragranular precipitates identified as Cr-rich M23C6 and Mo-rich M6C carbides were observed, along with a dense dislocation network and localized dislocation accumulation around the carbides. Mechanical testing showed negligible variation in yield strength with respect to build orientation; however, both ultimate tensile strength and elongation exhibited a clear increasing trend with higher build angles. Notably, the specimen built at 90° exhibited approximately 22% higher tensile strength and more than twice the elongation compared to the 0° specimen.

- [Korean]

- Extraction of MgSO4 from dolomite and synthesis of Mg(OH)2 in Bittern

- HyunSeung Shim, Jiyeon Kim, Areum Choi, Nuri Oh, YooJin Kim

- J Powder Mater. 2025;32(2):122-130. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00073

- Funded: Ministry of Trade, Industry and Energy

- 466 View

- 23 Download

-

Abstract

Abstract

PDF

PDF - We synthesized magnesium hydroxide using bittern and dolomite, which are domestic resources. In Bittern, there is a high concentration of Mg2+ ions, but the impurity Ca2+ ion content is also significant, requiring a purification process to remove it. There are two main methods for this purification. Firstly, there is a separation method that utilizes the difference in solubility between Mg2+ ions and Ca2+ ions by using sulfuric acid on dolomite. Adding MgSO4 solution from dolomite to Bittern removes Ca2+ ions as CaSO4. This process simultaneously purifies Ca impurities and increases the Mg/Ca ratio by adding extra Mg2+ ions. In this study, purified bittern was obtained by using dolomite and sulfuric acid to extract MgSO4, which was then used to purify Ca2+ ions. High-purity Mg(OH)2 was synthesized by optimizing the NaOH and NH4OH ratio as an alkaline precipitant.

TOP

kpmi

kpmi

First

First Prev

Prev