Most viewed

- Page Path

- HOME > Browse Articles > Most viewed

Most-read articles are from the articles published in 2023 during the last three month.

- [English]

- A Review of Inorganic Solid Electrolytes for All-Solid-State Lithium Batteries: Challenges and Progress

- Seul Ki Choi, Jaehun Han, Gi Jeong Kim, Yeon Hee Kim, Jaewon Choi, MinHo Yang

- J Powder Mater. 2024;31(4):293-301. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00206

- 4,875 View

- 135 Download

- 3 Citations

-

Abstract

Abstract

PDF

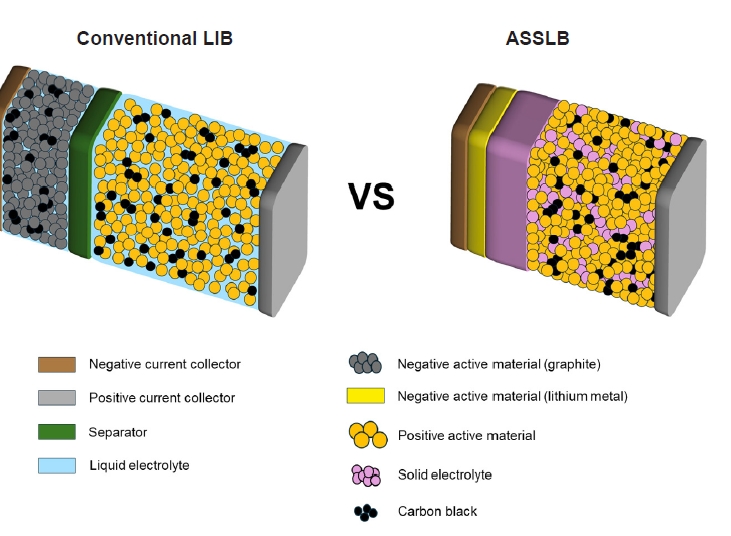

PDF - All-solid-state lithium batteries (ASSLBs) are receiving attention as a prospective next-generation secondary battery technology that can reduce the risk of commercial lithium-ion batteries by replacing flammable organic liquid electrolytes with non-flammable solid electrolytes. The practical application of ASSLBs requires developing robust solid electrolytes that possess ionic conductivity at room temperature on a par with that of organic liquids. These solid electrolytes must also be thermally and chemically stable, as well as compatible with electrode materials. Inorganic solid electrolytes, including oxide and sulfide-based compounds, are being studied as promising future candidates for ASSLBs due to their higher ionic conductivity and thermal stability than polymer electrolytes. Here, we present the challenges currently facing the development of oxide and sulfide-based solid electrolytes, as well as the research efforts underway aiming to resolve these challenges.

-

Citations

Citations to this article as recorded by- A facile synthesis of bulk LiPON in solution for solid-state electrolytes

Osma J. Gomez, Adam Antar, Alex T. Hall, Leopoldo Tapia-Aracayo, Joshua Seo, Nam Kim, Zihan Sun, Ryan Lim, Fu Chen, Yue Li, John Cumings, Gary Rubloff, Sang Bok Lee, David Stewart, Yang Wang

Journal of Materials Chemistry A.2025; 13(34): 28368. CrossRef - Uniform lithium deposition using Cu teepee structures for anode-free lithium metal batteries

Seo Yun Jung, Jaehun Han, Seul Ki Choi, Se Youn Cho, Jong Ho Won, Jaewon Choi, Minho Yang

Chemical Engineering Journal.2025; 522: 167302. CrossRef - Garnet-type LLZO electrolytes for solid-state lithium batteries: Interfaces, conductivity, in-situ processing, and industrial prospects

Kaleab Habtamu Ayalew, Nithyadharseni Palaniyandy, Mkhulu K. Mathe, Phumlani F. Msomi

Chemical Engineering Journal.2025; : 168098. CrossRef

- A facile synthesis of bulk LiPON in solution for solid-state electrolytes

- [English]

- Recent Advances in Thermoelectric Materials and Devices: Improving Power Generation Performance

- Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Kwi-Il Park

- J Powder Mater. 2025;32(1):1-15. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00395

- 5,119 View

- 136 Download

- 1 Citations

-

Abstract

Abstract

PDF

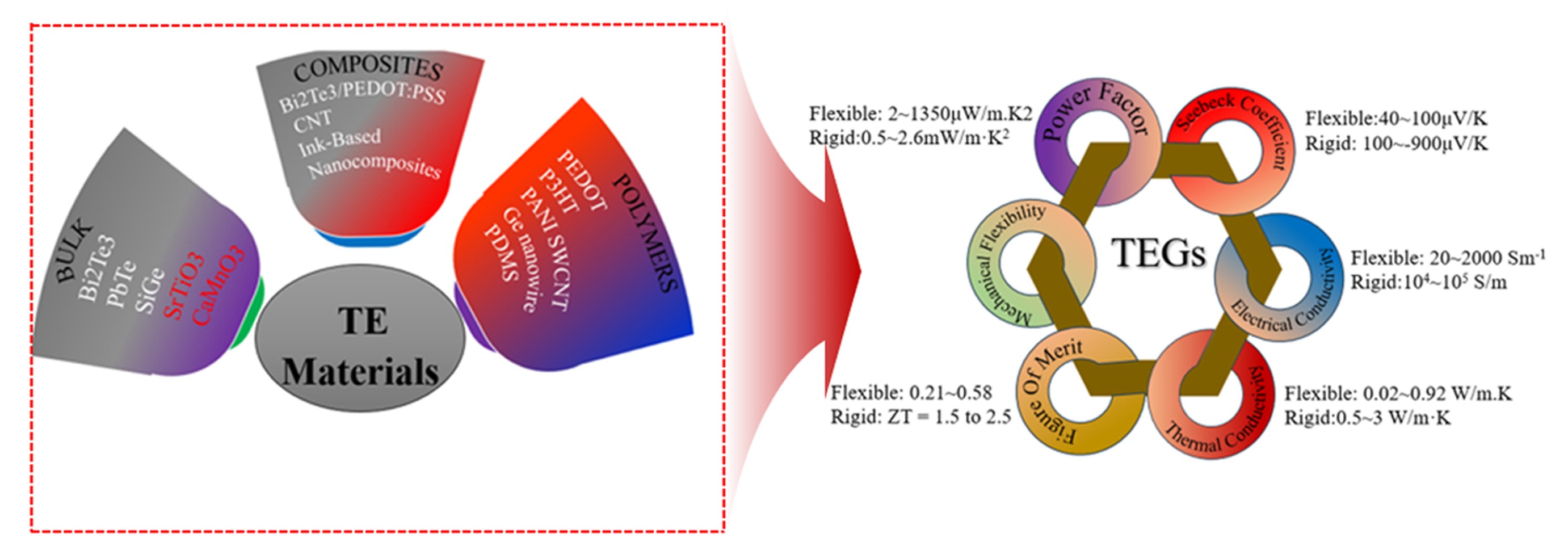

PDF - Thermoelectric materials have been the focus of extensive research interest in recent years due to their potential in clean power generation from waste heat. Their conversion efficiency is primarily reflected by the dimensionless figure of merit, with higher values indicating better performance. There is a pressing need to discover materials that increase output power and improve performance, from the material level to device fabrication. This review provides a comprehensive analysis of recent advancements, such as Bi2Te3-based nanostructures that reduce thermal conductivity while maintaining electrical conductivity, GeTe-based high entropy alloys that utilize multiple elements for improved thermoelectric properties, porous metal-organic frameworks offering tunable structures, and organic/hybrid films that present low-cost, flexible solutions. Innovations in thermoelectric generator designs, such as asymmetrical geometries, segmented modules, and flexible devices, have further contributed to increased efficiency and output power. Together, these developments are paving the way for more effective thermoelectric technologies in sustainable energy generation.

-

Citations

Citations to this article as recorded by- Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

Muhammad Sohaib Tahir, Xue Dong, Muhammad Mansoor Khan

Results in Engineering.2025; 27: 106344. CrossRef

- Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

- [English]

- Research Trends in Electromagnetic Shielding using MXene-based Composite Materials

- Siyeon Kim, Jongmin Byun

- J Powder Mater. 2024;31(1):57-76. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.57

- 5,133 View

- 131 Download

- 3 Citations

-

Abstract

Abstract

PDF

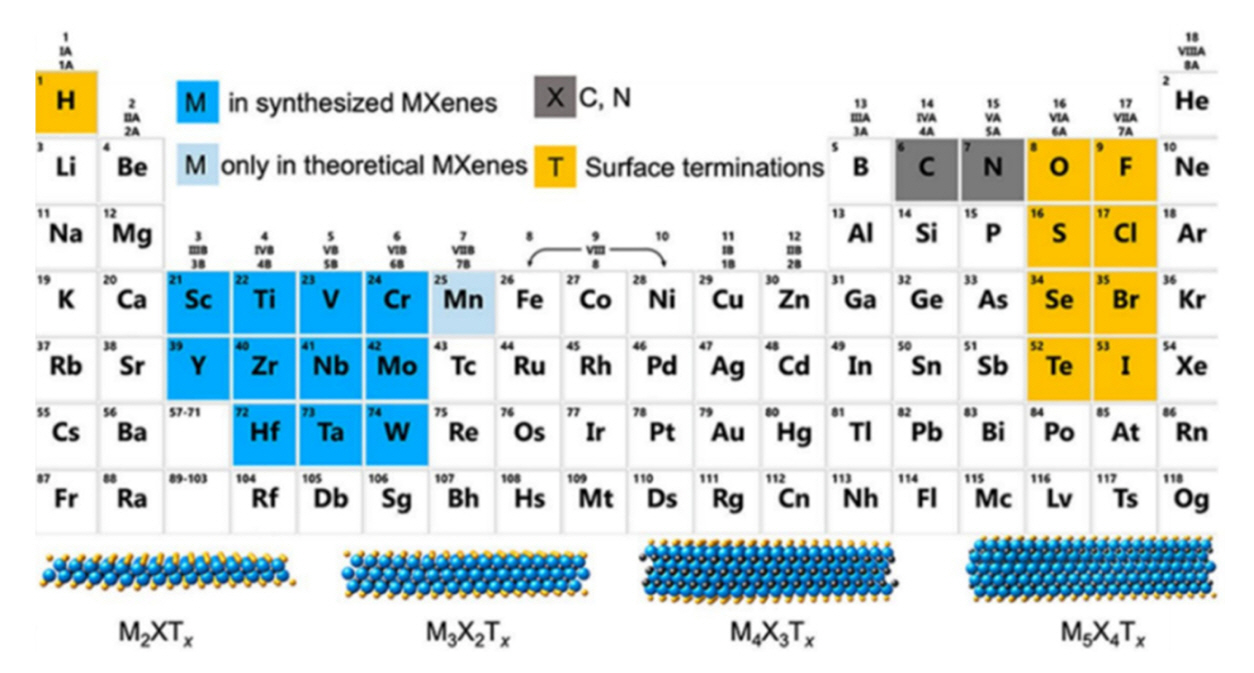

PDF Recent advancements in electronic devices and wireless communication technologies, particularly the rise of 5G, have raised concerns about the escalating electromagnetic pollution and its potential adverse impacts on human health and electronics. As a result, the demand for effective electromagnetic interference (EMI) shielding materials has grown significantly. Traditional materials face limitations in providing optimal solutions owing to inadequacy and low performance due to small thickness. MXene-based composite materials have emerged as promising candidates in this context owing to their exceptional electrical properties, high conductivity, and superior EMI shielding efficiency across a broad frequency range. This review examines the recent developments and advantages of MXene-based composite materials in EMI shielding applications, emphasizing their potential to address the challenges posed by electromagnetic pollution and to foster advancements in modern electronics systems and vital technologies.

-

Citations

Citations to this article as recorded by- Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

Pramod D. Mhase, Varsha C. Pujari, Santosh S. Jadhav, Abdullah G. Al-Sehemi, Sarah Alsobaie, Sunil M. Patange

Composites Communications.2025; 54: 102284. CrossRef - Microstructure tailoring of Nb-based MAX phase by low temperature synthesis with layer-structured Nb2C powder and molten salt method

Chaehyun Lim, Wonjune Choi, Jongmin Byun

Materials Characterization.2025; 225: 115106. CrossRef - Fabrication of MOF@MXene composites via surface modification of MXene under acidic conditions

Ji-Haeng Jeong, Woong-Ryeol Yu

Functional Composites and Structures.2025; 7(2): 025006. CrossRef

- Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

- [English]

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

- J Powder Mater. 2025;32(3):179-190. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00094

- 2,348 View

- 92 Download

-

Abstract

Abstract

PDF

PDF - Area-selective atomic layer deposition (AS-ALD) is a bottom-up process that selectively deposits thin films onto specific areas of a wafer surface. The surface reactions of AS-ALD are controlled by blocking the adsorption of precursors using inhibitors such as self-assembled monolayers (SAMs) or small molecule inhibitors. To increase selectivity during the AS-ALD process, the design of both the inhibitor and the precursor is crucial. Both inhibitors and precursors vary in reactivity and size, and surface reactions are blocked through interactions between precursor molecules and surface functional groups. However, challenges in the conventional SAM-based AS-ALD method include thermal instability and potential damage to substrates during the removal of residual SAMs after the process. To address these issues, recent studies have proposed alternative inhibitors and process design strategies.

- [English]

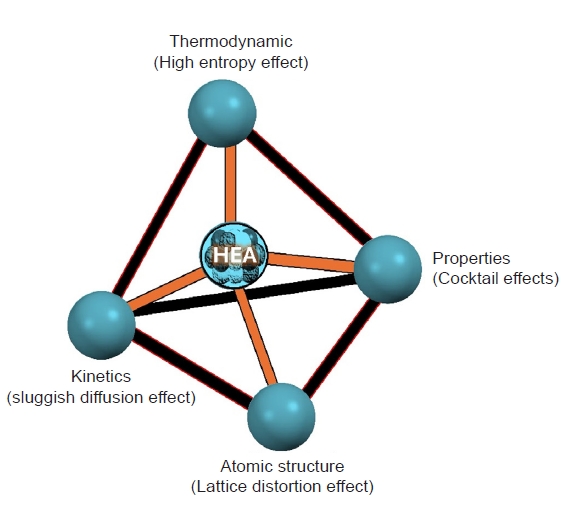

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 2,027 View

- 66 Download

- 1 Citations

-

Abstract

Abstract

PDF

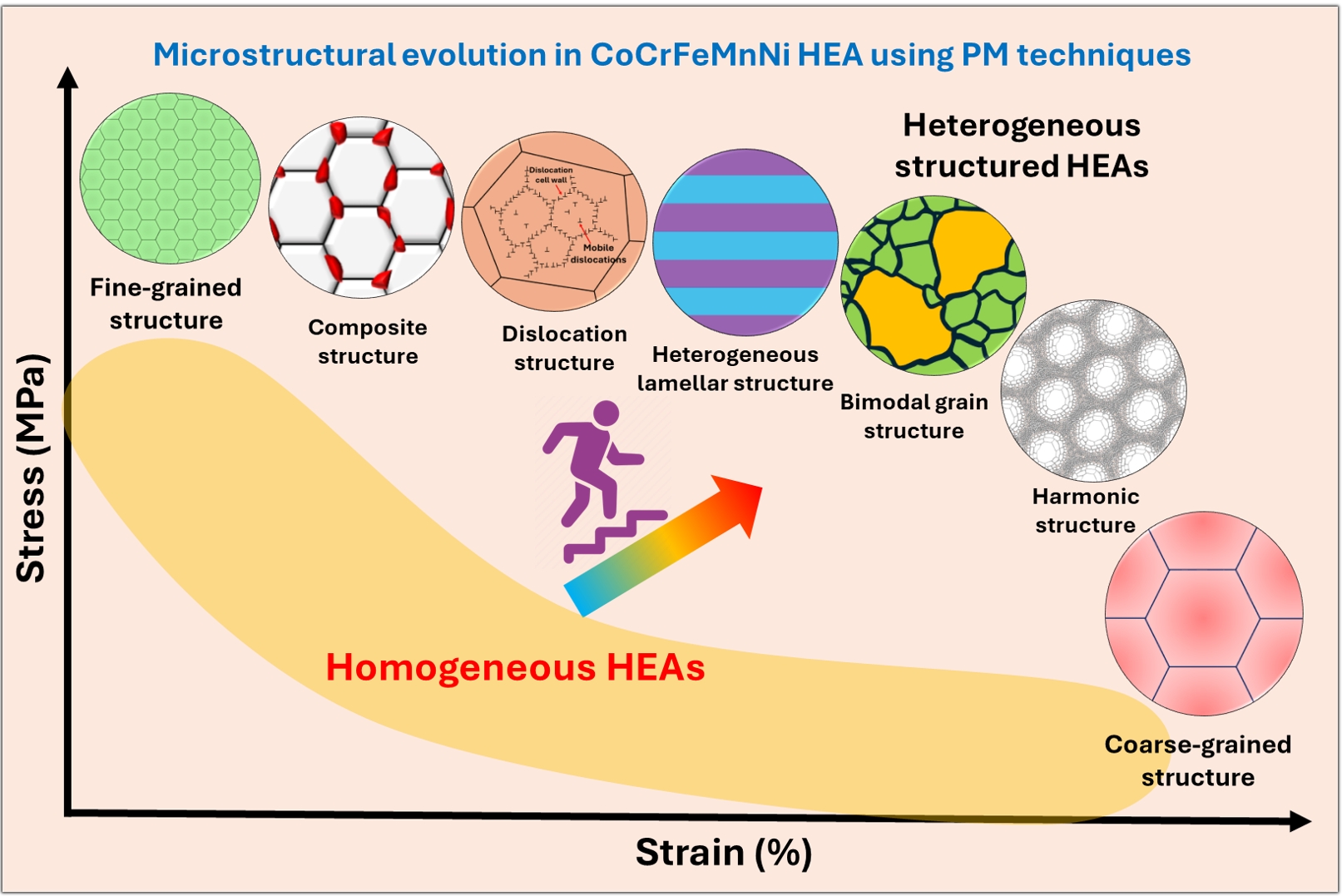

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- [English]

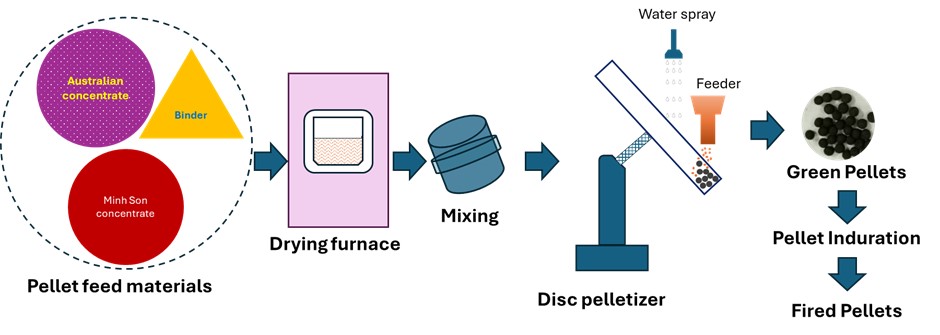

- Enhanced Compressive Strength of Fired Iron Ore Pellets: Effects of Blending Fine and Coarse Particle Concentrates

- Ngo Quoc Dung, Tran Xuan Hai, Nguyen Minh Thuyet, Nguyen Quang Tung, Arvind Barsiwal, Nguyen Hoang Viet

- J Powder Mater. 2025;32(4):315-329. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00129

- 1,256 View

- 63 Download

-

Abstract

Abstract

PDF

PDF - This study investigated the effects of oxidative firing parameters and raw material characteristics on the pelletization of Australian and Minh Son (Vietnam) iron ore concentrates. The influence of firing temperature (1050°C–1150°C) and holding time (15–120 min) on pellet compressive strength was examined, focusing on microstructural changes during consolidation. Green pellets were prepared using controlled particle size distributions and bentonite as a binder. Scanning electron microscopy and energy-dispersive X-ray spectroscopy analyses revealed that grain boundary diffusion, liquid phase formation, and densification significantly improved mechanical strength. X-ray diffraction confirmed the complete oxidation of magnetite to hematite at elevated temperatures, a critical transformation for metallurgical performance. Optimal firing conditions for both single and blended ore compositions yielded compressive strengths above 250 kgf/pellet, satisfying the requirements for blast furnace applications. These results provide valuable guidance for improving pellet production, promoting the efficient utilization of diverse ore types, and enhancing the overall performance of ironmaking operations.

- [English]

- Advances in Powder Metallurgy for High-Entropy Alloys

- Sheetal Kumar Dewangan, Cheenepalli Nagarjuna, Hansung Lee, K. Raja Rao, Man Mohan, Reliance Jain, Byungmin Ahn

- J Powder Mater. 2024;31(6):480-492. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00297

- 2,604 View

- 113 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) represent a revolutionary class of materials characterized by their multi-principal element compositions and exceptional mechanical properties. Powder metallurgy, a versatile and cost-effective manufacturing process, offers significant advantages for the development of HEAs, including precise control over their composition, microstructure, and mechanical properties. This review explores innovative approaches integrating powder metallurgy techniques in the synthesis and optimization of HEAs. Key advances in powder production, sintering methods, and additive manufacturing are examined, highlighting their roles in improving the performance, advancement, and applicability of HEAs. The review also discusses the mechanical properties, potential industrial applications, and future trends in the field, providing a comprehensive overview of the current state and future prospects of HEA development using powder metallurgy.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [English]

- Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

- Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

- J Powder Mater. 2024;31(1):1-7. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.1

- 4,243 View

- 116 Download

- 7 Citations

-

Abstract

Abstract

PDF

PDF This study explores the profound impact of varying oxygen content on microstructural and mechanical properties in specimens HO and LO. The higher oxygen concentration in specimen HO is found to significantly influence alpha lath sizes, resulting in a size of 0.5-1 μm, contrasting with the 1-1.5 μm size observed in specimen LO. Pore fraction, governed by oxygen concentration, is high in specimen HO, registering a value of 0.11%, whereas specimen LO exhibits a lower pore fraction (0.02%). Varied pore types in each specimen further underscore the role of oxygen concentration in shaping microstructural morphology. Despite these microstructural variations, the average hardness remains consistent at ~370 HV. This study emphasizes the pivotal role of oxygen content in influencing microstructural features, contributing to a comprehensive understanding of the intricate interplay between elemental composition and material properties.

-

Citations

Citations to this article as recorded by- Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

Hadiseh Esmaeilpoor, Mahdi Aghaahmadi, Hyun Jong Yoo, Chan Woong Park, Tae Jin Jang, Seok Su Sohn, Jeoung Han Kim

Journal of Materials Science & Technology.2025; 213: 223. CrossRef - High-integrity diffusion bonding of laser powder bed fused, forged, and rolled Ti–6Al–4V alloys

Seoyeon Jeon, Hyunjong Ha, Dong Jun Lee, Hyeonil Park, Yong Nam Kwon, Hyunjoo Choi, Hyokyung Sung

Journal of Materials Research and Technology.2025; 35: 2108. CrossRef - Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Obtaining functionally-graded metal-matrix materials Ti‒6Al‒4V + WC in the process of 3D printing by the method of additive plasma-arc deposition

V. Korzhyk, A. Grynyuk, O. Babych, O. Berdnikova, Ye. Illiashenko, O. Bushma

The Paton Welding Journal.2025; 2025(8): 29. CrossRef - Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

Journal of Powder Materials.2024; 31(5): 365. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

- [English]

- Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

- Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

- J Powder Mater. 2024;31(2):137-145. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00038

- 2,807 View

- 81 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In order to predict the process window of laser powder bed fusion (LPBF) for printing metallic components, the calculation of volumetric energy density (VED) has been widely calculated for controlling process parameters. However, because it is assumed that the process parameters contribute equally to heat input, the VED still has limitation for predicting the process window of LPBF-processed materials. In this study, an explainable machine learning (xML) approach was adopted to predict and understand the contribution of each process parameter to defect evolution in Ti alloys in the LPBF process. Various ML models were trained, and the Shapley additive explanation method was adopted to quantify the importance of each process parameter. This study can offer effective guidelines for fine-tuning process parameters to fabricate high-quality products using LPBF.

-

Citations

Citations to this article as recorded by- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- [Korean]

- Recent Studies on Area Selective Atomic Layer Deposition of Elemental Metals

- Min Gyoo Cho, Jae Hee Go, Byung Joon Choi

- J Powder Mater. 2023;30(2):156-168. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.156

- 1,967 View

- 52 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The semiconductor industry faces physical limitations due to its top-down manufacturing processes. High cost of EUV equipment, time loss during tens or hundreds of photolithography steps, overlay, etch process errors, and contamination issues owing to photolithography still exist and may become more serious with the miniaturization of semiconductor devices. Therefore, a bottom-up approach is required to overcome these issues. The key technology that enables bottom-up semiconductor manufacturing is area-selective atomic layer deposition (ASALD). Here, various ASALD processes for elemental metals, such as Co, Cu, Ir, Ni, Pt, and Ru, are reviewed. Surface treatments using chemical species, such as self-assembled monolayers and small-molecule inhibitors, to control the hydrophilicity of the surface have been introduced. Finally, we discuss the future applications of metal ASALD processes.

-

Citations

Citations to this article as recorded by- Selective Atomic Layer Deposition of Co Thin Films Using Co(EtCp)2 Precursor

Sujeong Kim, Yong Tae Kim, Jaeyeong Heo

Korean Journal of Materials Research.2024; 34(3): 163. CrossRef

- Selective Atomic Layer Deposition of Co Thin Films Using Co(EtCp)2 Precursor

- [Korean]

- Thermal Atomic Layer Etching of the Thin Films: A Review

- Hyeonhui Jo, Seo Hyun Lee, Eun Seo Youn, Ji Eun Seo, Jin Woo Lee, Dong Hoon Han, Seo Ah Nam, Jeong Hwan Han

- J Powder Mater. 2023;30(1):53-64. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.53

- 3,277 View

- 172 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Atomic layer etching (ALE) is a promising technique with atomic-level thickness controllability and high selectivity based on self-limiting surface reactions. ALE is performed by sequential exposure of the film surface to reactants, which results in surface modification and release of volatile species. Among the various ALE methods, thermal ALE involves a thermally activated reaction by employing gas species to release the modified surface without using energetic species, such as accelerated ions and neutral beams. In this study, the basic principle and surface reaction mechanisms of thermal ALE?processes, including “fluorination-ligand exchange reaction”, “conversion-etch reaction”, “conversion-fluorination reaction”, “oxidation-fluorination reaction”, “oxidation-ligand exchange reaction”, and “oxidation-conversion-fluorination reaction” are described. In addition, the reported thermal ALE processes for the removal of various oxides, metals, and nitrides are presented.

-

Citations

Citations to this article as recorded by- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

Journal of Powder Materials.2025; 32(3): 179. CrossRef

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- [English]

- Stretch-Flangeability of Laser Powder Bed Fusion-Processed 316L Stainless Steel

- Rae Eon Kim, Yeon Taek Choi, Sang Guk Jeong, Do Won Lee, Hyoung Seop Kim

- J Powder Mater. 2025;32(2):87-94. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00017

- 1,498 View

- 18 Download

-

Abstract

Abstract

PDF

PDF Supplementary Material

Supplementary Material - Metal additive manufacturing (AM) facilitates the production of complex geometries with enhanced functionality. Among various AM techniques, laser powder bed fusion (LPBF) is distinguished by its precision and exceptional mechanical properties achieved via laser fusion deposition. Recent advancements in AM have focused on combining LPBF with post-processing methods such as cold rolling, high-pressure torsion, and forming processes. Therefore, understanding the forming behavior of LPBF-processed materials is essential for industrial adoption. This study investigates the stretch-flangeability of LPBF-fabricated 316L stainless steel, emphasizing its anisotropic microstructure and mechanical properties. Hole expansion tests were employed to assess stretch-flangeability in comparison to wrought 316L stainless steel. The results demonstrate that LPBF-processed samples exhibit significant anisotropic behavior, demonstrating the influence of microstructural evolution on formability. These findings contribute valuable insights into optimizing LPBF materials for industrial forming applications.

- [English]

- Epsilon Iron Oxide (ε-Fe2O3) as an Electromagnetic Functional Material: Properties, Synthesis, and Applications

- Ji Hyeong Jeong, Hwan Hee Kim, Jung-Goo Lee, Youn-Kyoung Baek

- J Powder Mater. 2024;31(6):465-479. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00290

- 1,613 View

- 62 Download

-

Abstract

Abstract

PDF

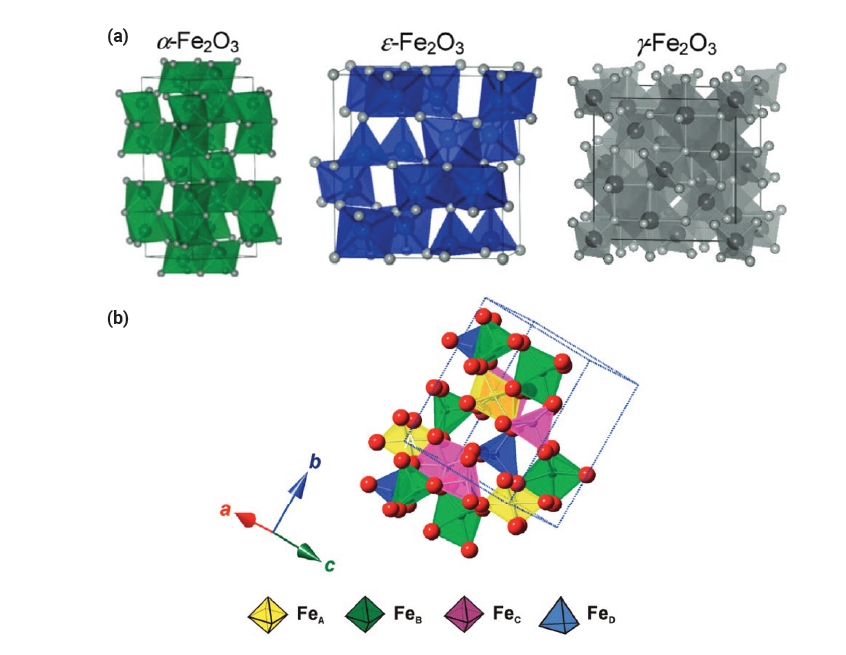

PDF - Iron oxide (ε-Fe₂O₃) is emerging as a promising electromagnetic material due to its unique magnetic and electronic properties. This review focuses on the intrinsic properties of ε-Fe₂O₃, particularly its high coercivity, comparable to that of rare-earth magnets, which is attributed to its significant magnetic anisotropy. These properties render it highly suitable for applications in millimeter wave absorption and high-density magnetic storage media. Furthermore, its semiconducting behavior offers potential applications in photocatalytic hydrogen production. The review also explores various synthesis methods for fabricating ε-Fe₂O₃ as nanoparticles or thin films, emphasizing the optimization of purity and stability. By exploring and harnessing the properties of ε-Fe₂O₃, this study aims to contribute to the advancement of next-generation electromagnetic materials with potential applications in 6G wireless telecommunications, spintronics, high-density data storage, and energy technologies.

- [English]

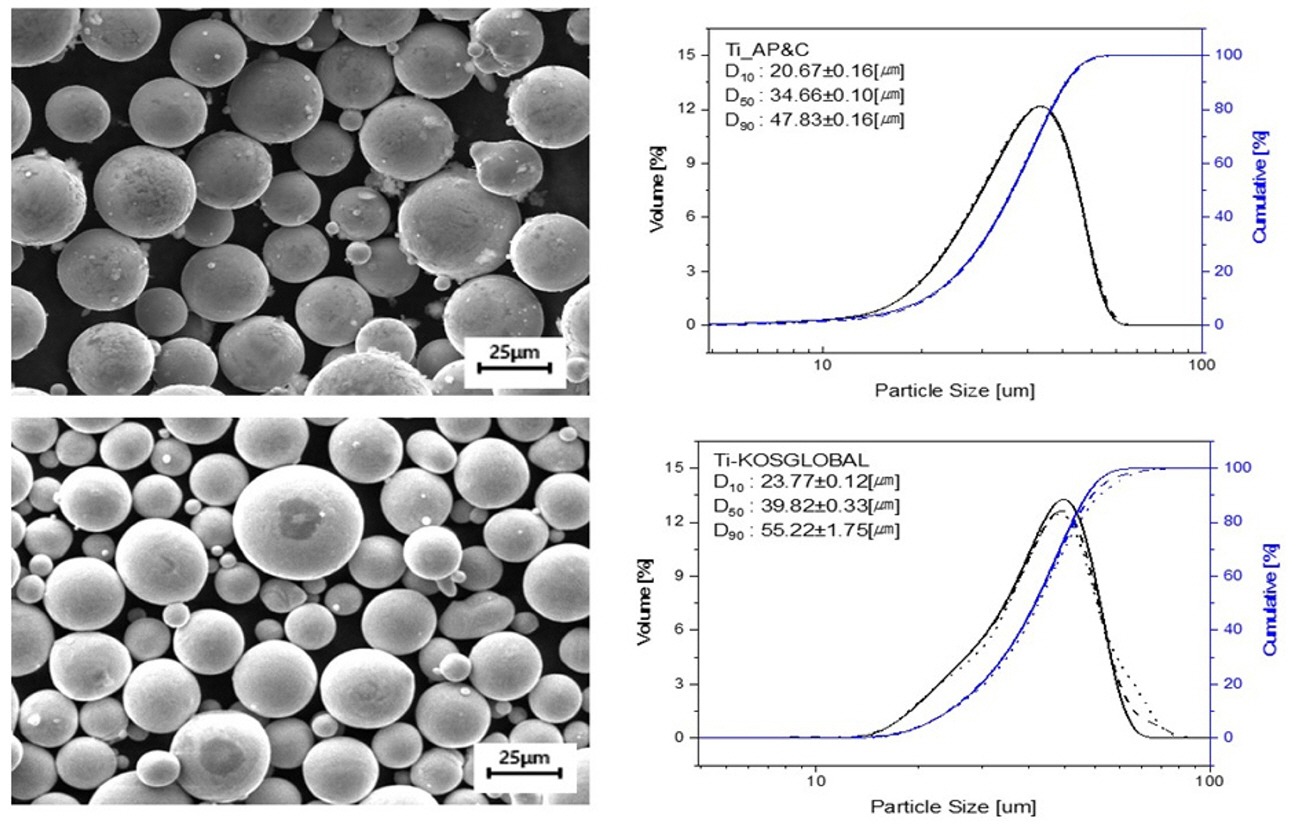

- Cost-effective Fabrication of Near β-Ti Alloy via L-PBF: Process Optimization of In-situ Alloying Ti-3Fe

- Sehun Kim, Ukju Gim, Taehu Kang, Jongik Lee, Sanghee Jeong, Jimin Han, Bin Lee

- J Powder Mater. 2025;32(4):288-298. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00213

- 708 View

- 12 Download

-

Abstract

Abstract

PDF

PDF - This study presents a cost-effective approach to fabricating near β-Ti alloys via in-situ alloying during laser powder bed fusion (L-PBF). A blend of non-spherical pure Ti, 3 wt.% Fe, and 0.1 wt.% SiO2 nanoparticles was used to induce β-phase stabilization and improve flowability. Twenty-five process conditions were evaluated across a volumetric energy density range of 31.75-214.30 J/mm3, achieving a maximum relative density of 99.21% at 89.29 J/mm3. X-ray diffraction analysis revealed that the β-Ti phase was partially retained at room temperature, accompanied by lattice contraction in the α’-Ti structure, indicating successful Fe incorporation. Elemental mapping confirmed that the Fe distribution was homogeneous, without significant segregation. Compared to pure Ti, the Ti-3Fe sample exhibited a 49.2% increase in Vickers hardness and notable improvements in yield and ultimate tensile strengths. These results demonstrate the feasibility of in-situ alloying with low-cost elemental powders to produce high-performance near β-Ti alloys using L-PBF.

- [English]

- Laser Processing of an Al0.1CoCrFeNi High Entropy Alloy + Cu Composite Powders via Laser Powder Bed Fusion

- Kwangtae Son, Ji-Woon Lee, Soon-Jik Hong, Somayeh Pasebani

- J Powder Mater. 2025;32(4):277-287. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00101

- 689 View

- 13 Download

-

Abstract

Abstract

PDF

PDF - This study examined process–structure relationships in laser powder bed fusion of Al₀.₁CoCrFeNi + Cu composites, focusing on densification, elemental distribution, and solidification cracking. Mechanically mixed Al₀.₁CoCrFeNi and Cu powders were processed across a range of laser powers (100–250 W) and scan speeds (200–800 mm/s). Increased volumetric energy density (VED) improved densification, with a plateau near 200 J/mm³ yielding ~96% relative density; however, this value was still below application-grade thresholds. At low VED, insufficient thermal input and short melt pool residence times promoted Cu segregation, while higher VED facilitated improved elemental mixing. Elemental mapping showed partial co-segregation of Ni with Cu at low energies. Solidification cracks were observed across all processing conditions. In high VED regimes, cracking exhibited a minimal correlation with segregation behavior and was primarily attributed to steep thermal gradients, solidification shrinkage, and residual stress accumulation. In contrast, at low VED, pronounced Cu segregation appeared to exacerbate cracking through localized thermal and mechanical mismatch.

TOP

kpmi

kpmi

First

First Prev

Prev