- [Korean]

- Effect of the Initial Porosity of Needle Coke-Pitch Carbonized Blocks on Impregnation-Related Physical Properties

-

U-Sang Youn, Sang-Hye Lee, Jae-Seung Roh

-

J Powder Mater. 2025;32(2):138-144. Published online April 30, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00038

-

-

Abstract Abstract

PDF PDF

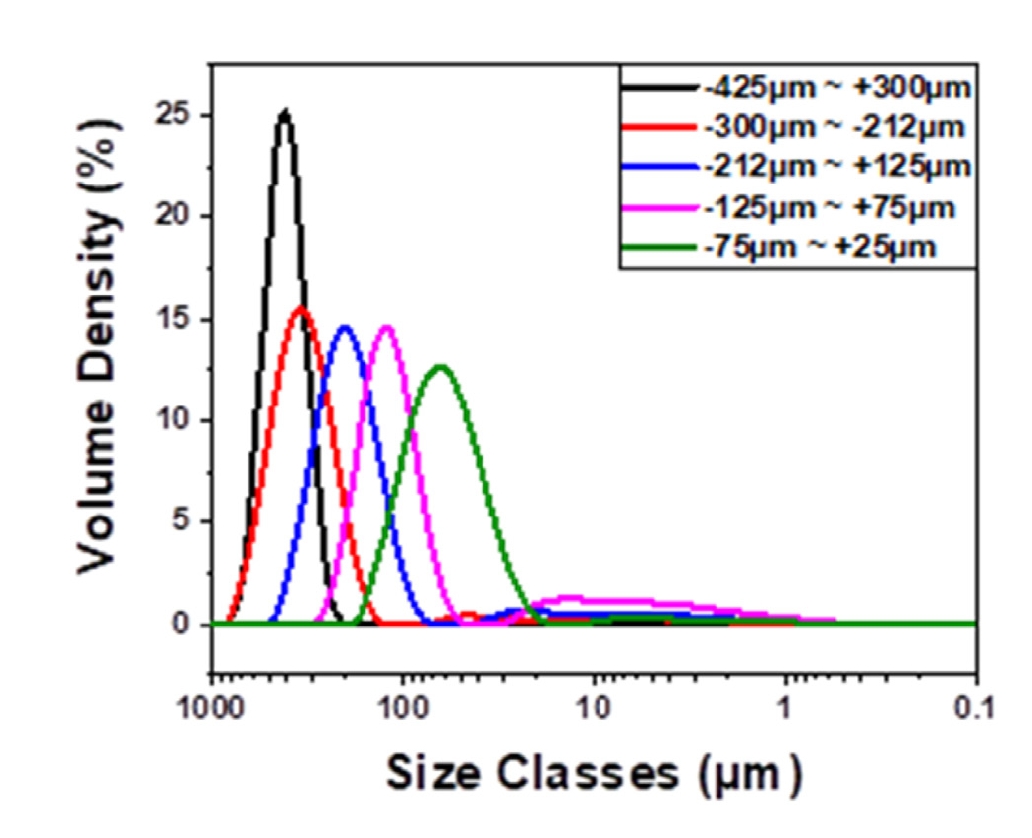

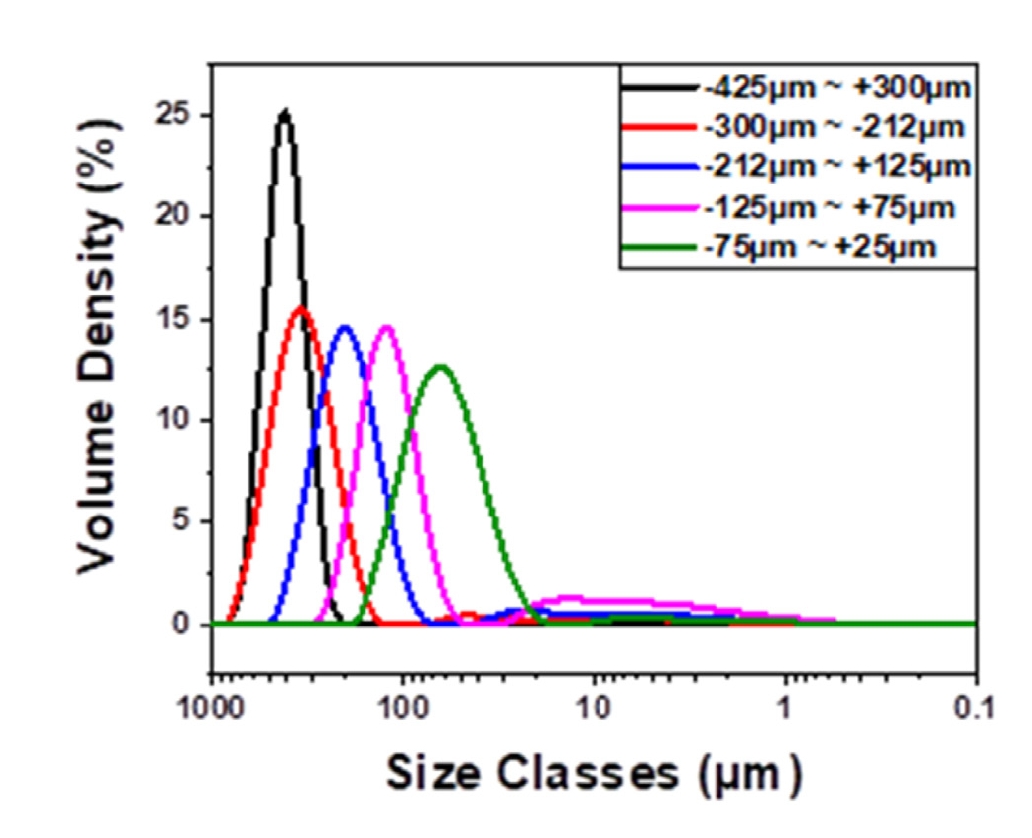

- Carbonized blocks with different porosities were prepared by varying the particle size of the filler and subsequent impregnation. The impregnated carbonized blocks were re-carbonized. The use of smaller particles in the filler in the carbonized block was associated with larger porosity, smaller pore size, and a higher impregnation ratio. The block with the smallest average particle size (53 μm), CB-53, had a porosity of 35.9% and pores of approximately 40 μm, while the block with the largest average particle size (413 μm), CB-413, had a porosity of 30.5% and pores of approximately 150 μm. CB-53 had the highest bulk density, electrical resistivity, flexural strength, and impregnation ratio. This is due to the large porosity, which is believed to be due to the presence of more interfaces between particles during the re-carbonization of the impregnated carbonized block, resulting in a better pore-filling effect.

- [Korean]

- Changes in Mechanical and Electrical Properties as a Function of Unidirectional Pressure Changes in Preforming While Isostatic Pressing

for Graphite Block Fabrication

-

Tae-Sub Byun, Dong-Pyo Jeon, Sang-Hye Lee, Sang-Woo Lee, Jae-Seung Roh

-

J Powder Mater. 2023;30(1):35-40. Published online February 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.1.35

-

-

1,611

View

-

9

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

In this study, a graphite block is fabricated using artificial graphite processing byproduct and phenolic resin as raw materials. Mechanical and electrical property changes are confirmed due to the preforming method. After fabricating preforms at 50, 100, and 150 MPa, CIP molding at 150 MPa is followed by heat treatment to prepare a graphite block. 150UP-CIP shows a 12.9% reduction in porosity compared with the 150 MPa preform. As the porosity is decreased, the bulk density, flexural strength, and shore hardness are increased by 14.9%, 102.4%, and 13.7%, respectively; and the deviation of density and electrical resistivity are decreased by 51.9% and 34.1%, respectively. Therefore, as the preforming pressure increases, the porosity decreases, and the electrical and mechanical properties improve. -

Citations

Citations to this article as recorded by  - Effect of Microstructural Change under Pressure during Isostatic Pressing on Mechanical and Electrical Properties of Isotropic Carbon Blocks

Tae-Sub Byun, Sang-Hye Lee, Suk-Hwan Kim, Jae-Seung Roh

Materials.2024; 17(2): 387. CrossRef - Effect of Pressure and Holding Time during Compression Molding on Mechanical Properties and Microstructure of Coke-Pitch Carbon Blocks

Sun-Ung Gwon, Sang-Hye Lee, U-Sang Youn, Jae-Seung Roh

Applied Sciences.2024; 14(2): 772. CrossRef

- [Korean]

- Effect of Change in Open Porosity as a Function of Uniaxial Molding Pressure on Density Improvement After Impregnation

-

Sang-Min Lee, Sang-Hye Lee, Jae-Seung Roh

-

J Korean Powder Metall Inst. 2021;28(1):7-12. Published online February 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.1.7

-

-

1,614

View

-

23

Download

-

3

Citations

-

Abstract Abstract

PDF PDF

The change in the open porosity of bulk graphite as a function of the uniaxial molding pressure during manufacturing is studied using artificial graphite powder. Subsequently, the graphite is impregnated to determine the effect of the open porosity on the impregnation efficiency and to improve the density of the final bulk graphite. Bulk graphite is manufactured with different uniaxial molding pressures after mixing graphite powder, which is the by-product of processing the final graphite products and phenolic resin. The bulk density and open porosity are measured using the Archimedes method. The bulk density and open porosity of bulk graphite increase as the molding pressure increases. The open porosity of molded bulk graphite is 25.35% at 30 MPa and 29.84% at 300 MPa. It is confirmed that the impregnation efficiency increases when the impregnation process is performed on a specimen with large open porosity. In this study, the bulk density of bulk graphite molded at 300 MPa is 11.06% higher than that before impregnation, which is the highest reported increase. Therefore, it is expected that the higher the uniaxial pressure, the higher the density of bulk graphite. -

Citations

Citations to this article as recorded by  - Improving the packing and mechanical properties of graphite blocks by controlling filler particle-size distribution

Hye in Hwang, Ji Hong Kim, Ji Sun Im

Advanced Composite Materials.2024; 33(5): 762. CrossRef - Effect of Pressure and Holding Time during Compression Molding on Mechanical Properties and Microstructure of Coke-Pitch Carbon Blocks

Sun-Ung Gwon, Sang-Hye Lee, U-Sang Youn, Jae-Seung Roh

Applied Sciences.2024; 14(2): 772. CrossRef - Correlation between Pitch Impregnation Pressure and Pore Sizes of Graphite Block

Changkyu Kim, Woong Kwon, Moon Hee Lee, Jong Seok Woo, Euigyung Jeong

Materials.2022; 15(2): 561. CrossRef

|