- [English]

- Preparation of Flake-shape Cobalt Powders by High-Energy Ball Milling for rSOC Current Collectors

-

Poong-Yeon Kim, Min-Jeong Lee, Hyeon Ju Kim, Su-Jin Yun, Si Young Chang, Jung-Yeul Yun

-

J Powder Mater. 2025;32(5):383-389. Published online October 31, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00241

-

-

Abstract Abstract

PDF PDF

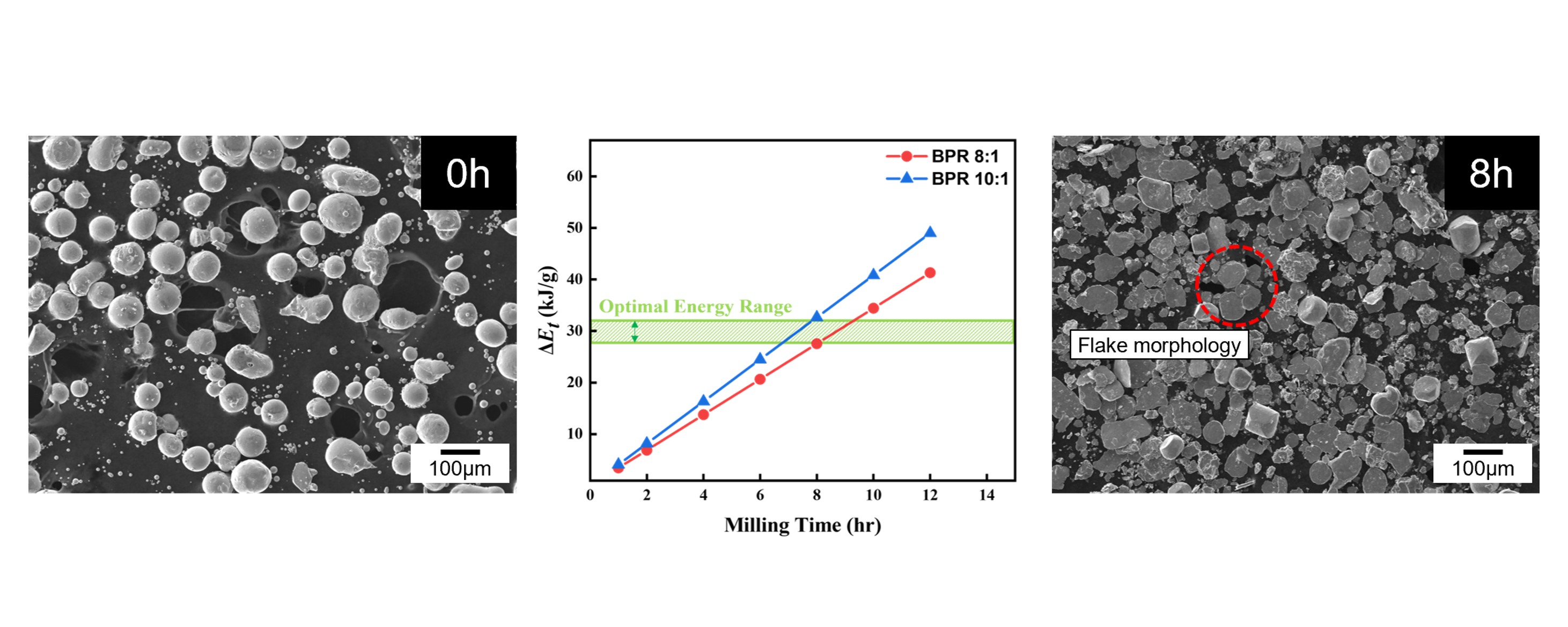

- Reversible solid oxide cells (rSOCs), which enable two-way conversion between electricity and hydrogen, have gained attention with the rise of hydrogen energy. However, foam-type current collectors in rSOC stacks exhibit poor structural controllability and limited electrode contact area. To address these limitations, this study aimed to convert spherical cobalt powders into flake-type morphology via high-energy ball milling, as a preliminary step toward fabricating flake-based current collectors.

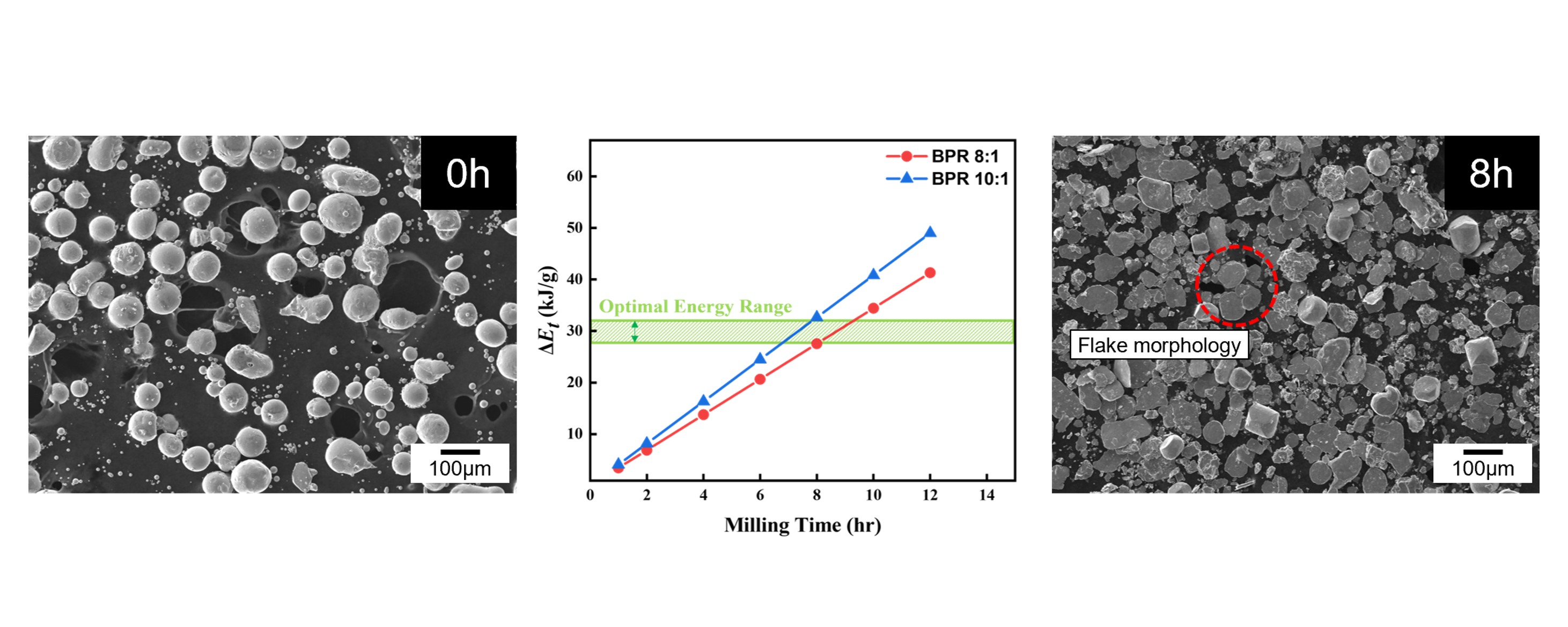

Milling parameters—specifically, the ball-to-powder ratio (BPR), milling time, and process control agent (PCA) content—were varied. At an 8:1 BPR, over 90% of the powder became flake-shaped after 8 hours, while extended milling caused cold welding. In contrast, a 10:1 BPR resulted in dominant fragmentation. The Burgio–Rojac model quantified energy input and defined the optimal range for flake formation. Increasing the PCA to 4 wt% delayed flake formation to 16 hours and induced cold welding, as shown by bimodal particle size distributions. These results support the development of Co-based current collectors for use in rSOCs.

- [English]

- Spark Plasma Sintering of Stainless Steel Powders Fabricated by High Energy Ball Milling

-

Si Young Chang, Sung-Tag Oh, Myung-Jin Suk, Chan Seok Hong

-

J Korean Powder Metall Inst. 2014;21(2):97-101. Published online April 1, 2014

-

DOI: https://doi.org/10.4150/KPMI.2014.21.2.97

-

-

1,062

View

-

9

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

The 304 stainless steel powders were prepared by high energy ball milling and subsequently sintered by spark plasma sintering, and the microstructural characteristics and micro-hardness were investigated. The initial size of the irregular shaped 304 stainless steel powders was approximately 42 μm. After high energy ball milling at 800 rpm for 5h, the powders became spherical with a size of approximately 2 μm, and without formation of reaction compounds. From TEM analysis, it was confirmed that the as-milled powders consisted of the aggregates of the nano-sized particles. As the sintering temperature increased from 1073K to 1573K, the relative density and micro-hardness of sintered sample increased. The sample sintered at 1573K showed the highest relative density of approximately 95% and a micro-hardness of 550 Hv. -

Citations

Citations to this article as recorded by  - Investigating molybdenum’s sulphur scavenging ability for MoS2 formation in preventing pitting corrosion of stainless steels

Kai Xiang Kuah, Daniel J. Blackwood

npj Materials Degradation.2023;[Epub] CrossRef

|