- [English]

- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

-

Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

-

J Powder Mater. 2024;31(2):119-125. Published online April 30, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00045

-

-

3,179

View

-

81

Download

-

6

Citations

-

Abstract Abstract

PDF PDF

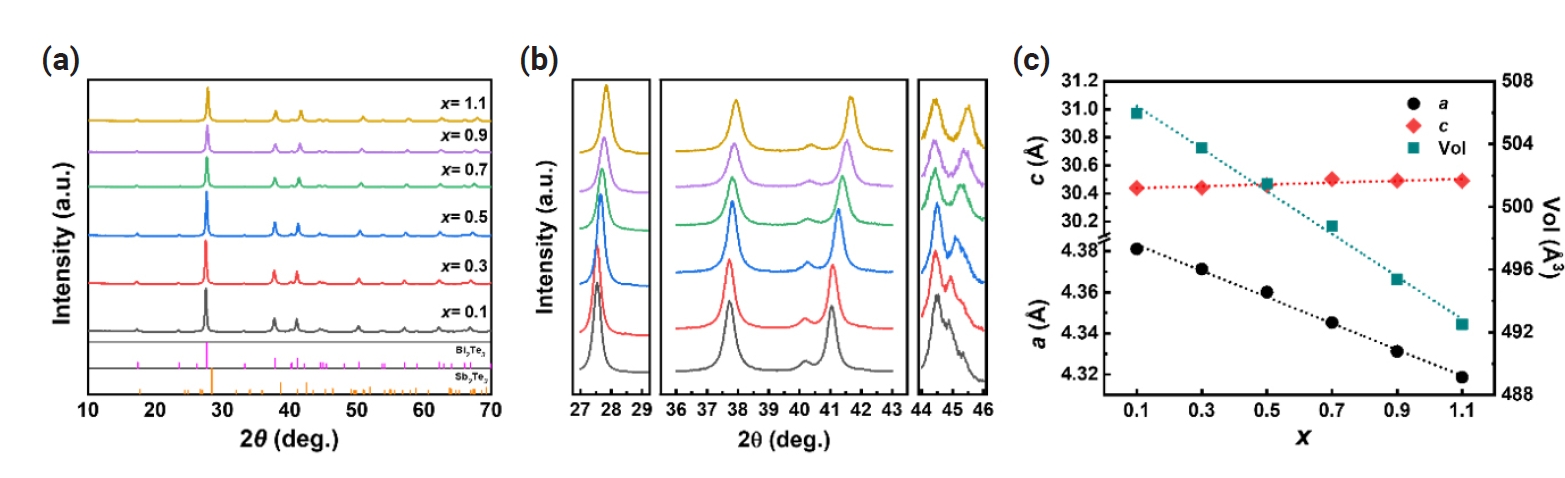

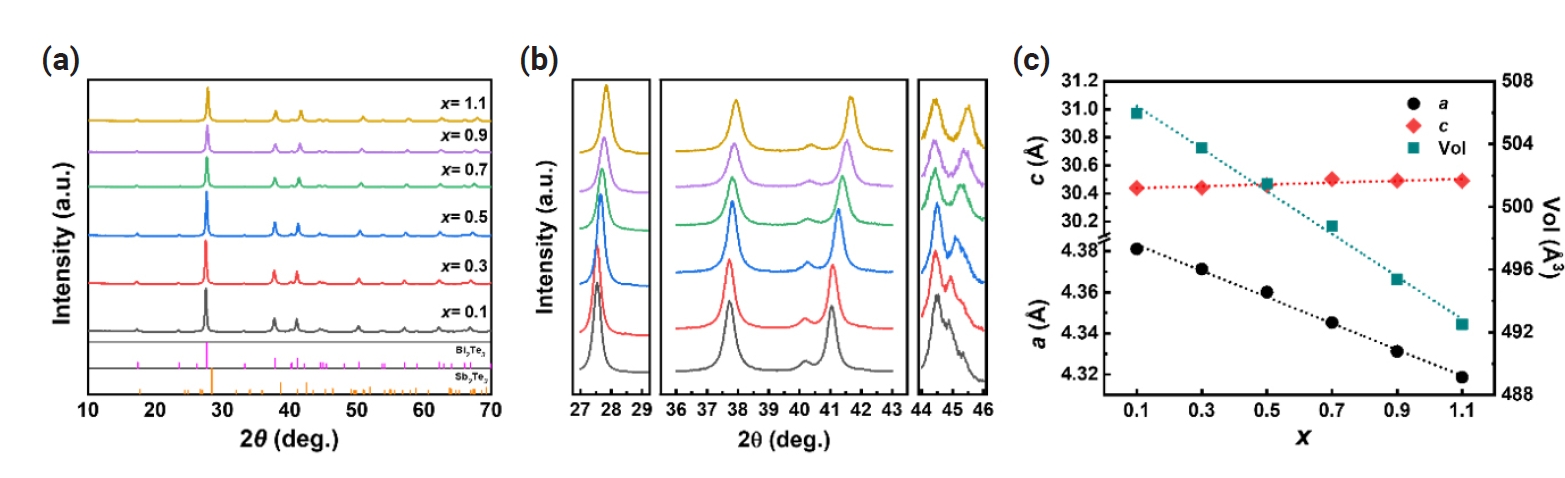

- The n-type Bi2-xSbxTe3 compounds have been of great interest due to its potential to achieve a high thermoelectric performance, comparable to that of p-type Bi2-xSbxTe3. However, a comprehensive understanding on the thermoelectric properties remains lacking. Here, we investigate the thermoelectric transport properties and band characteristics of n-type Bi2-xSbxTe3 (x = 0.1 – 1.1) based on experimental and theoretical considerations. We find that the higher power factor at lower Sb content results from the optimized balance between the density of state effective mass and nondegenerate mobility. Additionally, a higher carrier concentration at lower x suppresses bipolar conduction, thereby reducing thermal conductivity at elevated temperatures. Consequently, the highest zT of ~ 0.5 is observed at 450 K for x = 0.1 and, according to the single parabolic band model, it could be further improved by ~70 % through carrier concentration tuning.

-

Citations

Citations to this article as recorded by  - Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef - Enhanced energy harvesting performance of bendable thermoelectric generator enabled by trapezoidal-shaped legs

Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Journal of Power Sources.2025; 631: 236254. CrossRef - Flexible hybrid thermoelectric films made of bismuth telluride-PEDOT:PSS composites enabled by freezing-thawing process and simple chemical treatment

Cheol Min Kim, Seoha Kim, Nagamalleswara Rao Alluri, Bitna Bae, Momanyi Amos Okirigiti, Gwang Hyun Kim, Hyeon Jun Park, Haksu Jang, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Materials Today Chemistry.2025; 44: 102532. CrossRef - Enhanced Electrical Properties of 3D Printed Bi2Te3-Based Thermoelectric Materials via Hot Isostatic Pressing

Seungki Jo

Ceramist.2025; 28(1): 126. CrossRef - Hot isostatic pressing-driven fine-tuning of electrical properties in p- and n-type (Bi,Sb)2Te3 thermoelectric materials

Seungki Jo, Jeong Min Park, Linh Ba Vu, Haeum Park, Soo Ho Jung, Jinhee Bae, Jong Min Park, Jungho Choe, Kyung Tae Kim

Ceramics International.2025; 51(26): 51107. CrossRef - Compensation of increased carrier concentration and thermal conductivity in enhancing thermoelectric efficiency in Sn-doped Sb-In-Te alloys

Yunjae Kim, Seungwoo Ha, Gyujin Chang, Gwan Hyeong Lee, Jaewoo Park, Chanwoo Ju, Se Yun Kim, TaeWan Kim, Sang-il Kim

Journal of the Korean Ceramic Society.2025;[Epub] CrossRef

- [Korean]

- Enhancement of Thermoelectric Performance in Spark Plasma Sintered p-Type Bi0.5Sb1.5Te3.0 Compound via Hot Isostatic Pressing (HIP) Induced Reduction of Lattice Thermal Conductivity

-

Soo-Ho Jung, Ye Jin Woo, Kyung Tae Kim, Seungki Jo

-

J Powder Mater. 2023;30(2):123-129. Published online April 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.2.123

-

-

1,613

View

-

9

Download

-

4

Citations

-

Abstract Abstract

PDF PDF

High-temperature and high-pressure post-processing applied to sintered thermoelectric materials can create nanoscale defects, thereby enhancing their thermoelectric performance. Here, we investigate the effect of hot isostatic pressing (HIP) as a post-processing treatment on the thermoelectric properties of p-type Bi0.5Sb1.5Te3.0 compounds sintered via spark plasma sintering. The sample post-processed via HIP maintains its electronic transport properties despite the reduced microstructural texturing. Moreover, lattice thermal conductivity is significantly reduced owing to activated phonon scattering, which can be attributed to the nanoscale defects created during HIP, resulting in an ~18% increase in peak zT value, which reaches ~1.43 at 100°C. This study validates that HIP enhances the thermoelectric performance by controlling the thermal transport without having any detrimental effects on the electronic transport properties of thermoelectric materials. -

Citations

Citations to this article as recorded by  - Enhanced Electrical Properties of 3D Printed Bi2Te3-Based Thermoelectric Materials via Hot Isostatic Pressing

Seungki Jo

Ceramist.2025; 28(1): 126. CrossRef - Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

journal of Korean Powder Metallurgy Institute.2024; 31(2): 119. CrossRef - Investigation of the Thermal-to-Electrical Properties of Transition Metal-Sb Alloys Synthesized for Thermoelectric Applications

Jong Min Park, Seungki Jo, Sooho Jung, Jinhee Bae, Linh Ba Vu, Kwi-Il Park, Kyung Tae Kim

journal of Korean Powder Metallurgy Institute.2024; 31(3): 236. CrossRef - Enhancing Electrical Properties of N-type Bismuth Telluride Alloys through Graphene Oxide Incorporation in Extrusion 3D Printing

Jinhee Bae, Seungki Jo, Kyung Tae Kim

journal of Korean Powder Metallurgy Institute.2023; 30(4): 318. CrossRef

- [Korean]

- Investigation on Interfacial Microstructures of Stainless Steel/Inconel Bonded by Directed Energy Deposition of alloy Powders

-

Yeong Seong Eom, Kyung Tae Kim, Soo-Ho Jung, Jihun Yu, Dong Yeol Yang, Jungho Choe, Chul Yong Sim, Seung Jun An

-

J Korean Powder Metall Inst. 2020;27(3):219-225. Published online June 1, 2020

-

DOI: https://doi.org/10.4150/KPMI.2020.27.3.219

-

-

1,668

View

-

4

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

The directed energy deposition (DED) process of metal 3D printing technologies has been treated as an effective method for welding, repairing, and even 3-dimensional building of machinery parts. In this study, stainless steel 316L (STS316L) and Inconel 625 (IN625) alloy powders are additively manufactured using the DED process, and the microstructure of the fabricated STS316L/IN625 sample is investigated. In particular, there are no secondary phases in the interface between STS316L and the IN625 alloy. The EDS and Vickers hardness results clearly show compositionally and mechanically transient layers a few tens of micrometers in thickness. Interestingly, several cracks are only observed in the STS 316L rather than in the IN625 alloy near the interface. In addition, small-sized voids 200–400 nm in diameter that look like trapped pores are present in both materials. The cracks present near the interface are formed by tensile stress in STS316L caused by the difference in the CTE (coefficient of thermal expansion) between the two materials during the DED process. These results can provide fundamental information for the fabrication of machinery parts that require joining of two materials, such as valves. -

Citations

Citations to this article as recorded by  - Microstructures and mechanical properties of 316LSi/IN625 FGMs manufactured by CMT-WAAM

Jiang Aimin, Ahmad Baharuddin Abdullah, Shahir Mohd Yusuf

Advances in Mechanical Engineering.2025;[Epub] CrossRef

|