Search

- Page Path

- HOME > Search

- [English]

- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

- Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

- J Powder Mater. 2024;31(2):119-125. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00045

- 3,138 View

- 80 Download

- 6 Citations

-

Abstract

Abstract

PDF

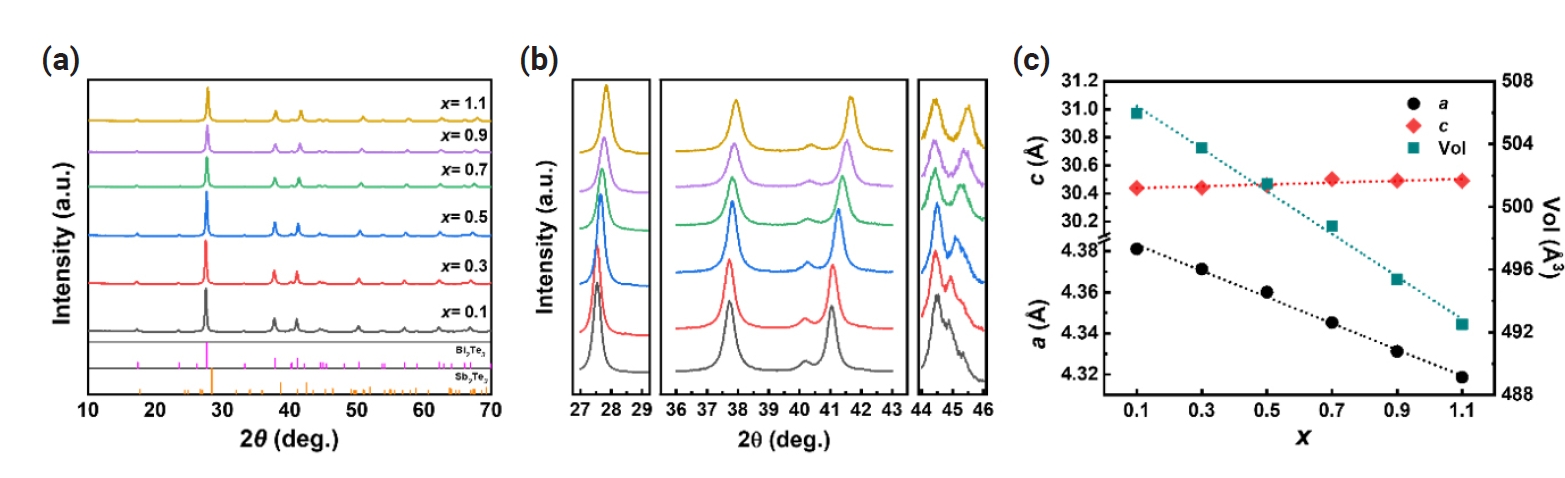

PDF - The n-type Bi2-xSbxTe3 compounds have been of great interest due to its potential to achieve a high thermoelectric performance, comparable to that of p-type Bi2-xSbxTe3. However, a comprehensive understanding on the thermoelectric properties remains lacking. Here, we investigate the thermoelectric transport properties and band characteristics of n-type Bi2-xSbxTe3 (x = 0.1 – 1.1) based on experimental and theoretical considerations. We find that the higher power factor at lower Sb content results from the optimized balance between the density of state effective mass and nondegenerate mobility. Additionally, a higher carrier concentration at lower x suppresses bipolar conduction, thereby reducing thermal conductivity at elevated temperatures. Consequently, the highest zT of ~ 0.5 is observed at 450 K for x = 0.1 and, according to the single parabolic band model, it could be further improved by ~70 % through carrier concentration tuning.

-

Citations

Citations to this article as recorded by- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef - Enhanced energy harvesting performance of bendable thermoelectric generator enabled by trapezoidal-shaped legs

Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Journal of Power Sources.2025; 631: 236254. CrossRef - Flexible hybrid thermoelectric films made of bismuth telluride-PEDOT:PSS composites enabled by freezing-thawing process and simple chemical treatment

Cheol Min Kim, Seoha Kim, Nagamalleswara Rao Alluri, Bitna Bae, Momanyi Amos Okirigiti, Gwang Hyun Kim, Hyeon Jun Park, Haksu Jang, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Materials Today Chemistry.2025; 44: 102532. CrossRef - Enhanced Electrical Properties of 3D Printed Bi2Te3-Based Thermoelectric Materials via Hot Isostatic Pressing

Seungki Jo

Ceramist.2025; 28(1): 126. CrossRef - Hot isostatic pressing-driven fine-tuning of electrical properties in p- and n-type (Bi,Sb)2Te3 thermoelectric materials

Seungki Jo, Jeong Min Park, Linh Ba Vu, Haeum Park, Soo Ho Jung, Jinhee Bae, Jong Min Park, Jungho Choe, Kyung Tae Kim

Ceramics International.2025; 51(26): 51107. CrossRef - Compensation of increased carrier concentration and thermal conductivity in enhancing thermoelectric efficiency in Sn-doped Sb-In-Te alloys

Yunjae Kim, Seungwoo Ha, Gyujin Chang, Gwan Hyeong Lee, Jaewoo Park, Chanwoo Ju, Se Yun Kim, TaeWan Kim, Sang-il Kim

Journal of the Korean Ceramic Society.2025;[Epub] CrossRef

- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

- [Korean]

- Influence of Si-rich Phase Morphologies on Mechanical Properties of AlSi10Mg Alloys p rocessed by S elective L aser M elting a nd P ost-Heat Treatment

- Jung-woo Nam, Yeong Seong Eom, Kyung Tae Kim, Injoon Son

- J Korean Powder Metall Inst. 2021;28(2):134-142. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.134

- 736 View

- 0 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, AlSi10Mg powders with average diameters of 44 μm are additively manufactured into bulk samples using a selective laser melting (SLM) process. Post-heat treatment to reduce residual stress in the as-synthesized sample is performed at different temperatures. From the results of a tensile test, as the heat-treatment temperature increases from 270 to 320°C, strength decreases while elongation significantly increases up to 13% at 320°C. The microstructures and tensile properties of the two heat-treated samples at 290 and 320°C, respectively, are characterized and compared to those of the as-synthesized samples. Interestingly, the Si-rich phases that network in the as-synthesized state are discontinuously separated, and the size of the particle-shaped Si phases becomes large and spherical as the heat-treatment temperature increases. Due to these morphological changes of Si-rich phases, the reduction in tensile strengths and increase in elongations, respectively, can be obtained by the post-heat treatment process. These results provide fundamental information for the practical applications of AlSi10Mg parts fabricated by SLM.

-

Citations

Citations to this article as recorded by- Wear behavior of aluminum-matrix particle (TiH2 and ZrH2)-reinforced composite foam additively manufactured using directed energy deposition

Hwa-Jeong Kim, Gwang-Yong Shin, Ki-Yong Lee, Do-Sik Shim

Journal of Materials Research and Technology.2023; 25: 222. CrossRef - Effect of Microstructural Evolution on Mechanical Properties and Fracture Modes of AlSi10Mg Blocks Fabricated by Selective Laser Melting after Stress Relief Annealing

Jianzhu Li, Yujie Li, Zhe Wang, Changguang Li, Hai Yuan, Yun Hao

Advanced Engineering Materials.2022;[Epub] CrossRef

- Wear behavior of aluminum-matrix particle (TiH2 and ZrH2)-reinforced composite foam additively manufactured using directed energy deposition

- [Korean]

- Influence of Powder Size on Properties of Selectively Laser-Melted- AlSi10Mg Alloys

- Yeong Seong Eom, Dong Won Kim, Kyung Tae Kim, Sang Sun Yang, Jungho Choe, Injoon Son, Ji Hun Yu

- J Korean Powder Metall Inst. 2020;27(2):103-110. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.103

- 1,132 View

- 3 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Aluminum (Al) - based powders have attracted attention as key materials for 3D printing because of their excellent specific mechanical strength, formability, and durability. Although many studies on the fabrication of 3Dprinted Al-based alloys have been reported, the influence of the size of raw powder materials on the bulk samples processed by selective laser melting (SLM) has not been fully investigated. In this study, AlSi10Mg powders of 65 μm in average particle size, prepared by a gas atomizing process, are additively manufactured by using an SLM process. AlSi10Mg powders of 45 μm average size are also fabricated into bulk samples in order to compare their properties. The processing parameters of laser power and scan speed are optimized to achieve densified AlSi10Mg alloys. The Vickers hardness value of the bulk sample prepared from 45 μm-sized powders is somewhat higher than that of the 65 μm-sized powder. Such differences in hardness are analyzed because the reduction in melt pool size stems from the rapid melting and solidification of small powders, compared to those of coarse powders, during the SLM process. These results show that the size of the powder should be considered in order to achieve optimization of the SLM process.

-

Citations

Citations to this article as recorded by- Laser Soldering Process Optimization of MEMS Probe of Probe Card for Semiconductor Wafer Test

Myeongin Kim, Won Sik Hong, Mi-Song Kim

Journal of Welding and Joining.2022; 40(3): 271. CrossRef - Investigation on Interfacial Microstructures of Stainless Steel/Inconel Bonded by Directed Energy Deposition of alloy Powders

Yeong Seong Eom, Kyung Tae Kim, Soo-Ho Jung, Jihun Yu, Dong Yeol Yang, Jungho Choe, Chul Yong Sim, Seung Jun An

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 219. CrossRef

- Laser Soldering Process Optimization of MEMS Probe of Probe Card for Semiconductor Wafer Test

- [Korean]

- The Effects of Hexamethylenetetramine Concentration on the Structural and Electrochemical Performances of Ni(OH)2 Powder for Pseudocapacitor Applications

- Dong Yeon Kim, Young-Min Jeong, Seong-Ho Baek, Injoon Son

- J Korean Powder Metall Inst. 2019;26(3):231-236. Published online June 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.3.231

- 1,167 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Ni hydroxides (Ni(OH)2) are synthesized on Ni foam by varying the hexamethylenetetramine (HMT) concentration using an electrodeposition process for pseudocapacitor (PC) applications. In addition, the effects of HMT concentration on the Ni(OH)2 structure and the electrochemical properties of the PCs are investigated. HMT is the source of amine-based OH− in the solution; thus, the growth rate and morphological structure of Ni(OH)2 are influenced by HMT concentration. When Ni(OH)2 is electrodeposited at a constant voltage mode of -0.85 V vs. Ag/AgCl, the cathodic current and the number of nucleations are significantly reduced with increasing concentration of HMT from 0 to 10 mM. Therefore, Ni(OH)2 is sparsely formed on the Ni foam with increasing HMT concentration, showing a layered double-hydroxide structure. However, loosely packed Ni(OH)2 grains that are spread on Ni foam maintain a much greater surface area for reaction and result in the effective utilization of the electrode material due to the steric hindrance effect. It is suggested that the Ni(OH)2 electrodes with HMT concentration of 7.5 mM have the maximum specific capacitance (1023 F/g), which is attributed to the facile electrolyte penetration and fast proton exchange via optimized surface areas.

-

Citations

Citations to this article as recorded by- Review of Domestic Research Trends on Layered Double Hydroxide (LDH) Materials: Based on Research Articles in Korean Citation Index (KCI)

Seon Yong Lee, YoungJae Kim, Young Jae Lee

Economic and Environmental Geology.2023; 56(1): 23. CrossRef

- Review of Domestic Research Trends on Layered Double Hydroxide (LDH) Materials: Based on Research Articles in Korean Citation Index (KCI)

- [English]

- Synthesis and Thermoelectric Properties of Carbon Nanotube-Dispersed Bi2Te3 Matrix Composite Powders by Chemical Routes

- Kyung Tae Kim, Injoon Son, Gook Hyun Ha

- J Korean Powder Metall Inst. 2013;20(5):345-349.

- DOI: https://doi.org/10.4150/KPMI.2013.20.5.345

- 1,065 View

- 2 Download

- 6 Citations

-

Abstract

Abstract

PDF

PDF - Carbon nanotube-dispersed bismuth telluride matrix (CNT/Bi_2Te_3) nanopowders were synthesized by chemical routes followed by a ball-milling process. The microstructures of the synthesized CNT/Bi_2Te_3 nanopowders showed the characteristic microstructure of CNTs dispersed among disc-shaped Bi_2Te_3 nanopowders with as an average size of 500 nm in-plane and a few tens of nm in thickness. The prepared nanopowders were sintered into composites with a homogeneous dispersion of CNTs in a Bi_2Te_3 matrix. The dimensionless figure-of-merit of the composite showed an enhanced value compared to that of pure Bi_2Te_3 at the room temperature due to the reduced thermal conductivity and increased electrical conductivity with the addition of CNTs.

-

Citations

Citations to this article as recorded by- Effect of Surface Roughness and Electroless Ni–P Plating on the Bonding Strength of Bi–Te-based Thermoelectric Modules

Sung Hwa Bae, Sungsoon Kim, Seong Hoon Yi, Injoon Son, Kyung Tae Kim, Hoyong Chung

Coatings.2019; 9(3): 213. CrossRef - Simple approach to synthesize CNTs uniformly coated Bi2Te3 nanocomposites by mechanical alloying

Balaji Ketharachapalli, Raj Kishora Dash

Applied Nanoscience.2018; 8(8): 1887. CrossRef - Fabrication of flexible SWCNTs-Te composite films for improving thermoelectric properties

Changcun Li, Pengliang Sun, Congcong Liu, Jingkun Xu, Tongzhou Wang, Wenfang Wang, Jian Hou, Fengxing Jiang

Journal of Alloys and Compounds.2017; 723: 642. CrossRef - Effects of Hydrogen Reduction in Microstructure, Mechanical and Thermoelectric Properties of Gas Atomized <italic>n</italic>-type Bi2Te2.7 Se0.3 Material

Pradip Rimal, Sang-Min Yoon, Eun-Bin Kim, Chul-Hee Lee, Soon-Jik Hong

journal of Korean Powder Metallurgy Institute.2016; 23(2): 126. CrossRef - High thermoelectric performance of Bi-Te alloy: Defect engineering strategy

Jong Gil Park, Young Hee Lee

Current Applied Physics.2016; 16(9): 1202. CrossRef - Investigation on the Thermoelectric Properties of Bismuth Telluride Matrix Composites by Addition of Graphene Oxide Powders

Kyung Tae Kim, Taesik Min, Dong Won Kim

Journal of Korean Powder Metallurgy Institute.2016; 23(4): 263. CrossRef

- Effect of Surface Roughness and Electroless Ni–P Plating on the Bonding Strength of Bi–Te-based Thermoelectric Modules

TOP

KPMI

KPMI

First

First Prev

Prev