Search

- Page Path

- HOME > Search

- [Korean]

- Effect of TiO2 Content on High-Temperature Degradation Behavior of Nd2O3 and Yb2O3 Doped YSZ Composite Materials

- Gye-Won Lee, Seonung Choi, Tae-jun Park, Jong-il Kim, In-hwan Lee, Yoon-seok Oh

- J Powder Mater. 2024;31(5):431-436. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00269

- 668 View

- 12 Download

-

Abstract

Abstract

PDF

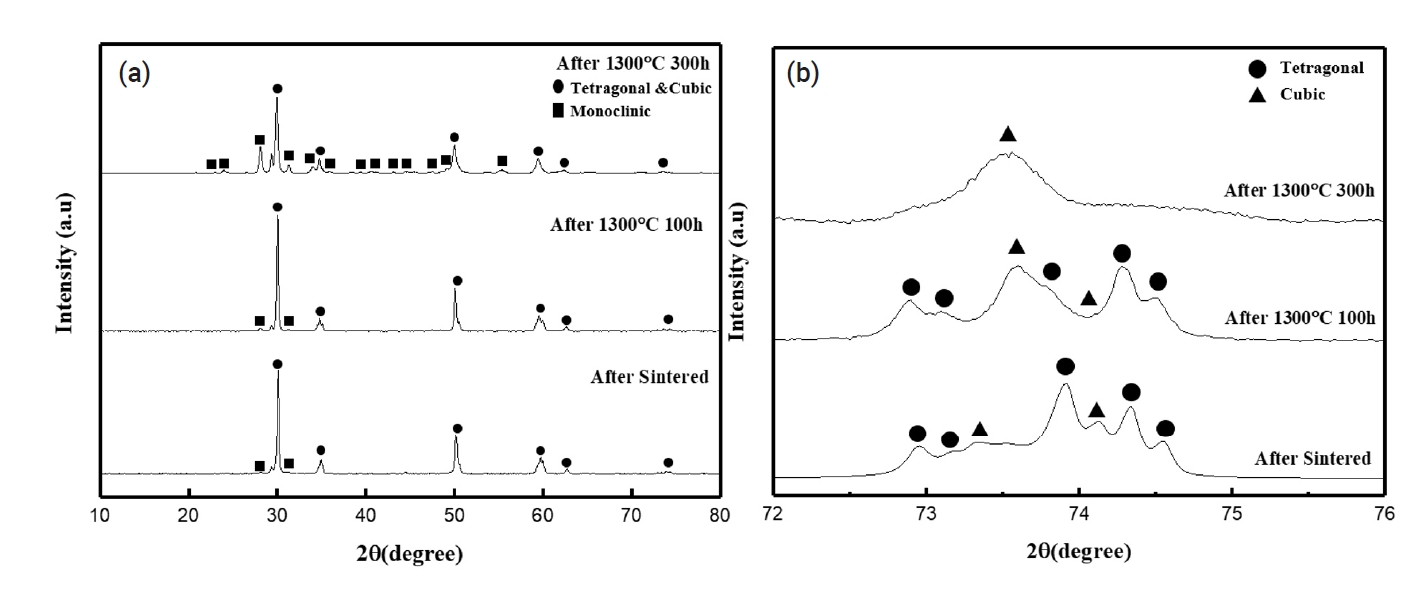

PDF - Hot section components of gas turbines are exposed to a high operating temperature environment. To protect these components, thermal barrier coatings (TBC) are applied to their surfaces. Yttria-stabilized zirconia (YSZ), which is widely used as a TBC material, faces limitations at temperatures above 1200℃. To mitigate these issues, research has focused on adding lanthanide rare earth oxides and tetravalent oxides to prevent the phase-transformation of the monoclinic phase in zirconia. This study investigated the effects of varying TiO2 content in Nd2O3 and Yb2O3 co-doped YSZ composites. Increasing TiO2 content effectively suppressed formation of the monoclinic phase and increased the thermal degradation resistance compared to YSZ in environments over 1200℃. These findings will aid in developing more thermally stable and efficient TBC materials for application in high-temperature environments.

- [English]

- Effect of SiC and WC additon on Oxidation Behavior of Spark-Plasma-Sintered ZrB2

- Chang-Yeoul Kim, Jae-Seok Choi, Sung-Churl Choi

- J Korean Powder Metall Inst. 2019;26(6):455-462. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.455

- 1,160 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF ZrB2 ceramic and ZrB2 ceramic composites with the addition of SiC, WC, and SiC/WC are successfully synthesized by a spark plasma sintering method. During high-temperature oxidation, SiC additive form a SiO2 amorphous outer scale layer and SiC-deplete ZrO2 scale layer, which decrease the oxidation rate. WC addition forms WO3 during the oxidation process to result in a ZrO2/WO3 liquid sintering layer, which is known to improve the antioxidation effect. The addition of SiC and WC to ZrB2 reduces the oxygen effective diffusivity by one-fifth of that of ZrB2. The addition of both SiC and WC shows the formation of a SiO2 outer dense glass layer and ZrO2/WO3 layer so that the anti-oxidation effect is improved three times as much as that of ZrB2. Therefore, SiC- and WC-added ZrB2 has a lower two-order oxygen effective diffusivity than ZrB2; it improves the anti-oxidation performance 3 times as much as that of ZrB2.

-

Citations

Citations to this article as recorded by- Role of TiC and WC Addition on the Mechanism and Kinetics of Isothermal Oxidation and High-Temperature Stability of ZrB2–SiC Composites

Pradyut Sengupta, Indranil Manna

High Temperature Corrosion of Materials.2024; 101(S1): 57. CrossRef

- Role of TiC and WC Addition on the Mechanism and Kinetics of Isothermal Oxidation and High-Temperature Stability of ZrB2–SiC Composites

TOP

KPMI

KPMI

First

First Prev

Prev