Search

- Page Path

- HOME > Search

Research Article

- [English]

- Machine Learning Modeling of the Mechanical Properties of Al2024-B4C Composites

- Maurya A. K., Narayana P. L., Wang X.-S., Reddy N. S.

- J Powder Mater. 2024;31(5):382-389. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00234

- 951 View

- 24 Download

-

Abstract

Abstract

PDF

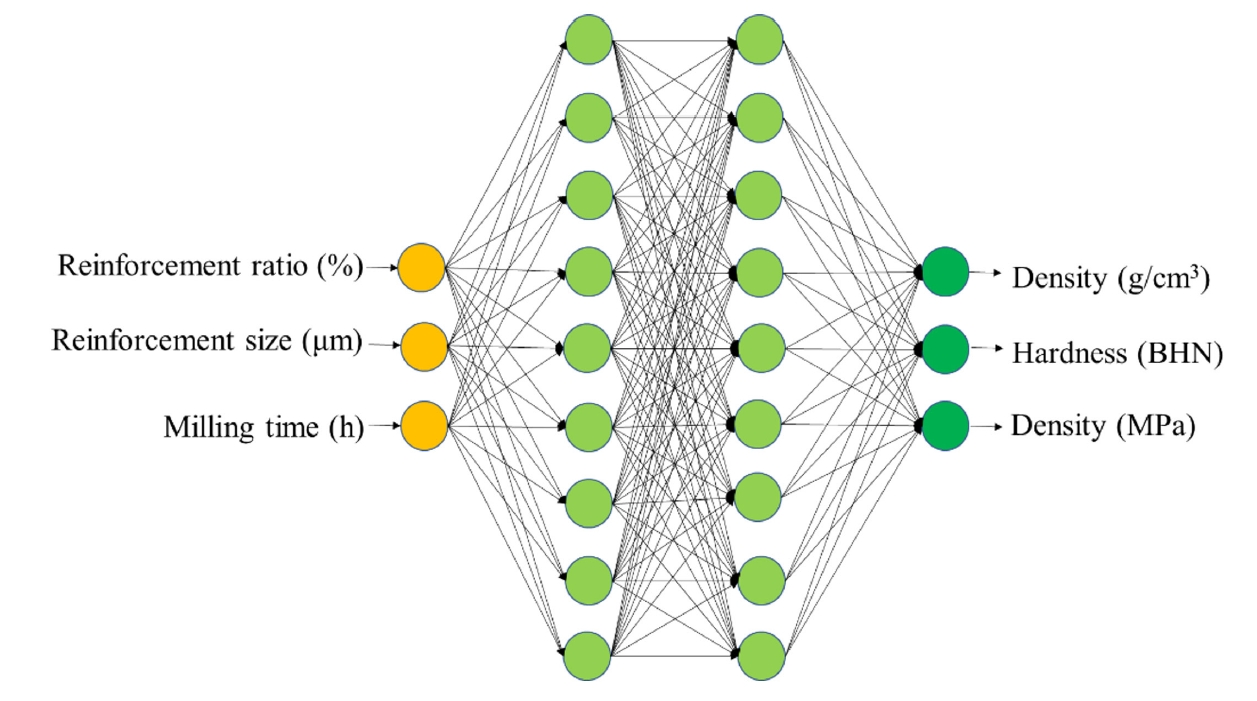

PDF - Aluminum-based composites are in high demand in industrial fields due to their light weight, high electrical conductivity, and corrosion resistance. Due to its unique advantages for composite fabrication, powder metallurgy is a crucial player in meeting this demand. However, the size and weight fraction of the reinforcement significantly influence the components' quality and performance. Understanding the correlation of these variables is crucial for building high-quality components. This study, therefore, investigated the correlations among various parameters—namely, milling time, reinforcement ratio, and size—that affect the composite’s physical and mechanical properties. An artificial neural network model was developed and showed the ability to correlate the processing parameters with the density, hardness, and tensile strength of Al2024-B4C composites. The predicted index of relative importance suggests that the milling time has the most substantial effect on fabricated components. This practical insight can be directly applied in the fabrication of high-quality Al2024-B4C composites.

TOP

KPMI

KPMI

First

First Prev

Prev