Search

- Page Path

- HOME > Search

Critical Review

- [Korean]

- Smelting and Recycling of Niobium

- Ho-Sang Sohn

- J Powder Mater. 2025;32(6):517-528. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00367

- 480 View

- 5 Download

-

Abstract

Abstract

PDF

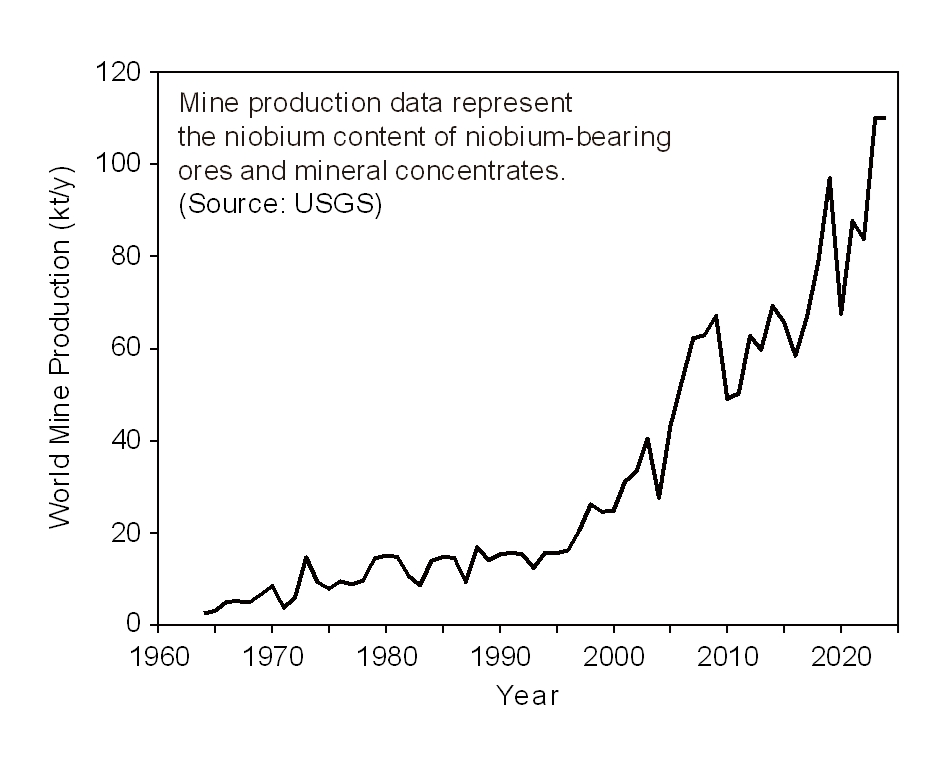

PDF - Global annual production of niobium is only around 100,000 tonnes; however, it is a critical metal for modern industry and is mined in only a limited number of regions. This study reviews the current status of niobium smelting and recycling technologies. Approximately 90% of niobium is produced as ferroniobium (FeNb) for use in steel alloys, although niobium is also utilized in superalloys, superconductors, capacitors, semiconductors, and other applications. Niobium coexists with tantalum in columbite and tantalite ores. These ores are decomposed by hydrofluoric acid digestion or alkali fusion, followed by solvent extraction to separate Nb2O5 and Ta2O5. Niobium metal and FeNb are produced from Nb2O5 primarily via aluminothermic reduction, although metallic niobium can also be manufactured by thermal reduction using Mg, Ca, or C, as well as by molten salt electrolysis. Crude niobium is subsequently refined into high-purity niobium through molten salt electrolytic refining, high-temperature vacuum treatment, and electron beam melting. Because most niobium is used as an alloying element in stainless steel and high-strength low-alloy steel, recycling practices for niobium remain poorly documented.

TOP

KPMI

KPMI

First

First Prev

Prev