Articles

- Page Path

- HOME > J Powder Mater > Volume 32(2); 2025 > Article

-

Research Article

- Stretch-Flangeability of Laser Powder Bed Fusion-Processed 316L Stainless Steel

- Rae Eon Kim1, Yeon Taek Choi2, Sang Guk Jeong3, Do Won Lee2, Hyoung Seop Kim1,2,3,*

-

Journal of Powder Materials 2025;32(2):87-94.

DOI: https://doi.org/10.4150/jpm.2025.00017

Published online: April 30, 2025

1Graduate Institute of Ferrous & Eco Materials Technology, Pohang University of Science and Technology (POSTECH), Pohang 37673, Republic of Korea

2Department of Materials Science and Engineering, Pohang University of Science and Technology (POSTECH), Pohang 37673, Republic of Korea

3Tohoku University Advanced Institute for Materials Research (WPI-AIMR), Sendai Miyagi 980-8577, Japan

- *Corresponding Author: Hyoung Seop Kim, TEL: +82-10-4366-6596, E-mail: hskim@postech.ac.kr

- -직위: 김래언: 학생, 최연택: 학생, 정상국: 교수, 이도원: 학생, 김형섭: 교수

© The Korean Powder Metallurgy & Materials Institute

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 2,270 Views

- 23 Download

Abstract

- Metal additive manufacturing (AM) facilitates the production of complex geometries with enhanced functionality. Among various AM techniques, laser powder bed fusion (LPBF) is distinguished by its precision and exceptional mechanical properties achieved via laser fusion deposition. Recent advancements in AM have focused on combining LPBF with post-processing methods such as cold rolling, high-pressure torsion, and forming processes. Therefore, understanding the forming behavior of LPBF-processed materials is essential for industrial adoption. This study investigates the stretch-flangeability of LPBF-fabricated 316L stainless steel, emphasizing its anisotropic microstructure and mechanical properties. Hole expansion tests were employed to assess stretch-flangeability in comparison to wrought 316L stainless steel. The results demonstrate that LPBF-processed samples exhibit significant anisotropic behavior, demonstrating the influence of microstructural evolution on formability. These findings contribute valuable insights into optimizing LPBF materials for industrial forming applications.

- Metal additive manufacturing (AM) is an advanced technology that facilitates the production of intricate structures with multifunctional capabilities [1]. Among various AM techniques, laser-based processes like laser powder bed fusion (LPBF), which utilize laser fusion deposition, stand out for their high dimensional precision and superior mechanical properties [2-4]. In LPBF, a high-energy laser beam scans a powder bed selectively, inducing localized melting and solidification layer by layer. This process provides unparalleled design flexibility, enabling geometric optimization tailored to specific service conditions. Additionally, the rapid heating and cooling cycles inherent to LPBF, along with its localized thermal effects, result in the formation of non-equilibrium microstructures. These microstructures are characterized by dislocation cell structures and heterogeneous grain morphologies [5]. Such unique features significantly enhance the strength and performance of LPBF-processed materials. Lemarquis et al. suggested that applying cold rolling on the AMed samples enhances mechanical properties [6, 7]. Similarly, Al-Zubaydi et al also proposed that severe plastic deformation via high-pressure torsion results in exceptional mechanical performance [8-10]. Therefore, the postprocessing of high deformation on the AMed sample holds a high potential for achieving excellent mechanical properties, which was not obtainable in conventional materials. These hybrid approaches necessitate additional forming processes to produce parts with customized shapes. Furthermore, the low productivity issues of the AM process can be complemented by combining the AM process with sheet metal forming [11, 12]. The hybrid fabrication approaches that integrate sheet metal forming with AM have recently been proposed [11, 12]. Therefore, as the use of AM materials spreads, it is increasingly important to study the forming processes applicable to these materials to fully harness their potential. While these methods sacrifice some of the design freedom inherent to AM, they successfully enhance the mechanical properties of the final components. Moreover, hybrid fabrication approaches that integrate sheet metal forming with AM have recently been proposed [11, 12]. This approach offers two key advantages: the high productivity of sheet metal forming and the design flexibility of additive manufacturing, paving the way for broader industrial applications. However, further research on the formability of AM-processed materials is necessary to fully unlock their potential in industrial settings.

- Formability is a critical parameter for the industrial application of structural materials, enabling the efficient production of components with complex geometries through high-productivity stamping processes [13]. Among the various formability factors, stretch-flangeability is particularly important, as it is closely linked to edge cracking during forming operations. Edge cracking occurs when substrates with sheared edges undergo forming, resulting in crack initiation and propagation due to pre-existing damage at the edges [14]. This mode of failure is especially challenging because it cannot be predicted using traditional forming limit diagrams [14]. Paul et al. [15] reported the relationship between the hole expansion ratio and the tensile properties including yield strength, ultimate strength, normal anisotropy, total elongation, and post elongation. Generally, high coefficient normal anisotropy and excellent post-uniform elongation are reported to have a superior hole expansion ratio. Meanwhile, Yoon et al. [16] suggest a clear correlation between hole expansion ratio and fracture toughness rather than tensile properties. Their studies directly examined the relationship between fracture toughness and HER, confirming a linear correlation. They attributed this to the fact that materials with higher fracture toughness demand greater energy for crack initiation and propagation, making through-thickness crack formation more challenging.

- To address this issue, stretch-flangeability is commonly evaluated using hole expansion tests (HET). The resulting hole expansion ratio (HER) serves as a quantitative metric to measure the resistance of a material to edge cracking. This study aims to investigate the interplay between the unique microstructure of LPBF-processed materials and their stretch-flangeability, offering valuable insights for their broader industrial adoption.

1. Introduction

- 2.1. Fabrication

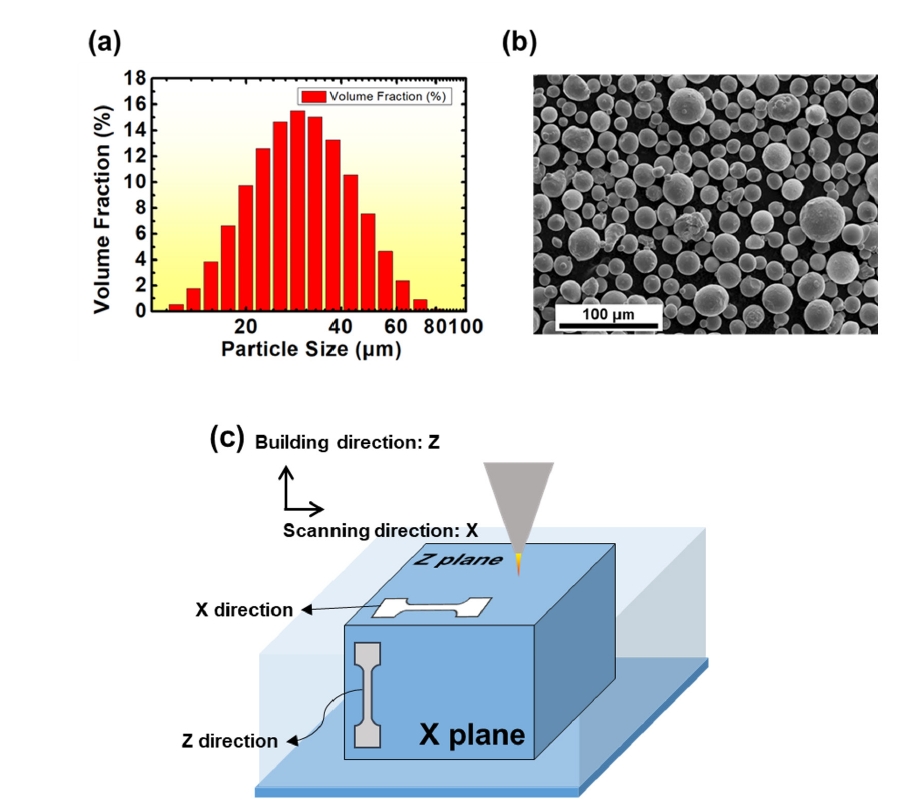

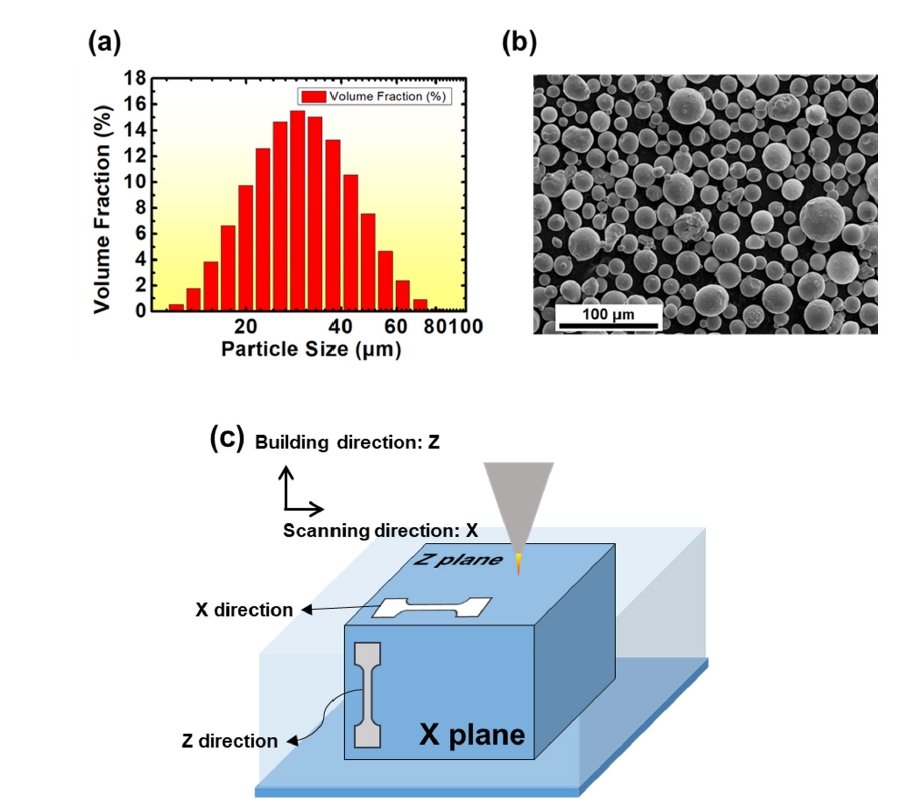

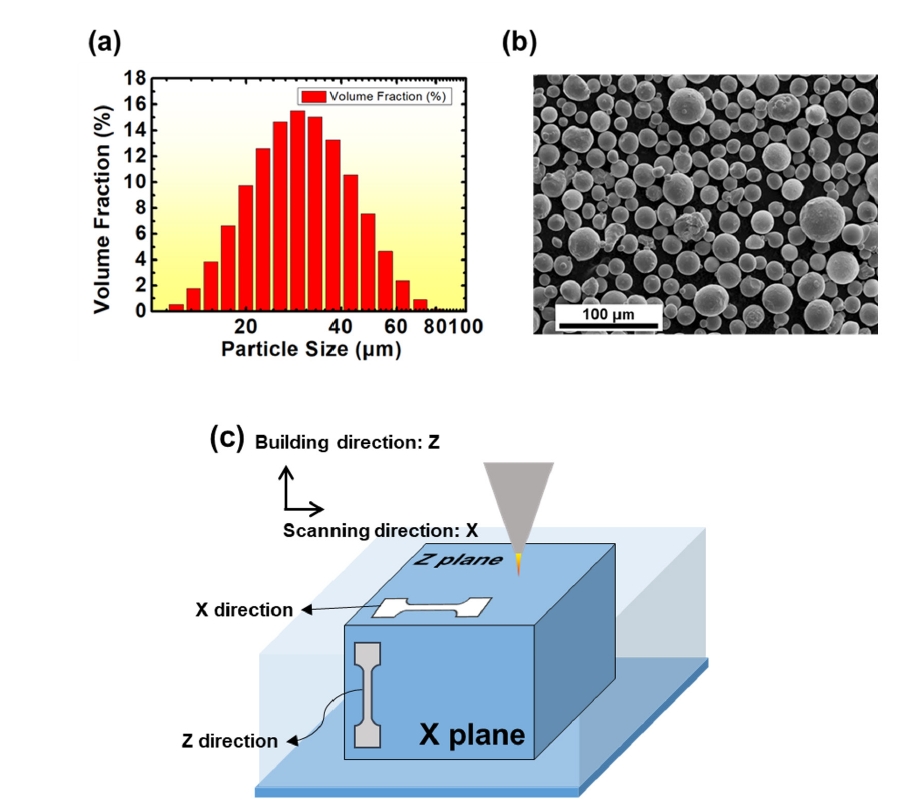

- An M2 series 5 LPBF machine was utilized to fabricate 316L stainless steel samples from the stainless steel powders. The spherical powders, produced via gas atomization, had an average particle size of ~31.8 μm and were suitable for LPBF processing (Fig. 1). The LPBF processing parameters are as follows: a laser power of 370 W, a hatch spacing of 0.09 μm, a laser scan speed of 1350 mm/s, a layer thickness of 50 μm, and a 67° rotation between layers. These LPBF-processing samples are referred to as the LPBF sample. For comparison, a wrought 316L stainless steel plate was annealed at 1050°C for 30 min, referred to as the wrought sample. Fig. 1c. illustrates the directions for the present samples.

- 2.2. Microstructural analysis

- For microstructural analysis, specimens were polished with SiC papers up to 1200 grit and then 0.04 μm colloidal silica suspension. Electron backscatter diffraction (EBSD) and backscattered scanning electron (BSE) analysis were performed using a field emission scanning electron microscope (FE-SEM). The EBSD data were interpreted using TSL-OIM 7 software.

- 2.3. Mechanical tests

- Uniaxial tensile tests were at a quasi-static strain rate of 1×10-3 along the rolling direction using a instron 1361 universal testing machine. The tensile samples were prepared with a flat dog-bone shape with dimensions of 5 mm gauge length and 2.5 mm width. The strain was measured with a ARAMIS digital image correlation system.

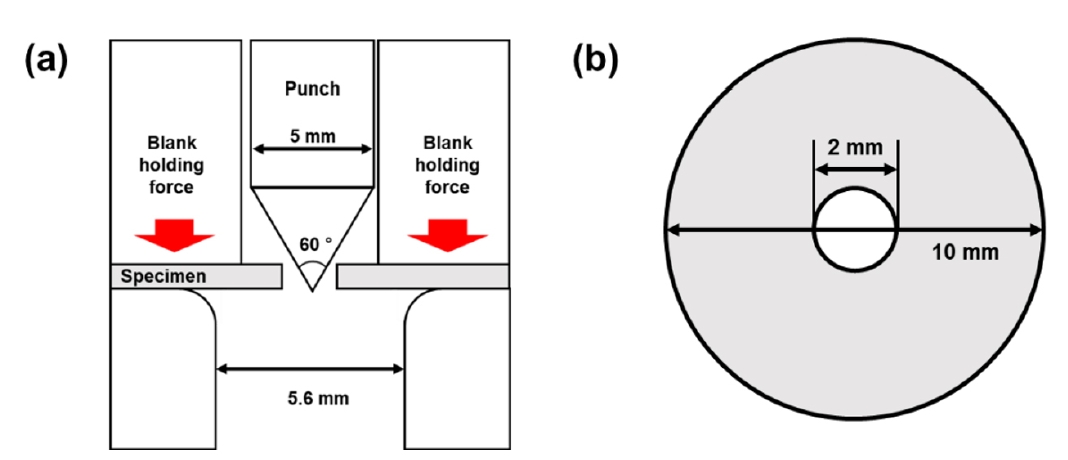

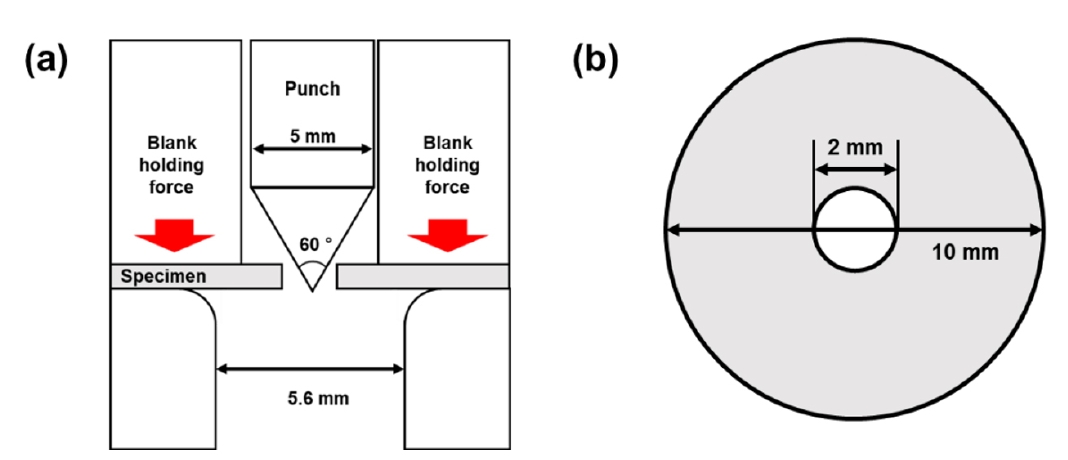

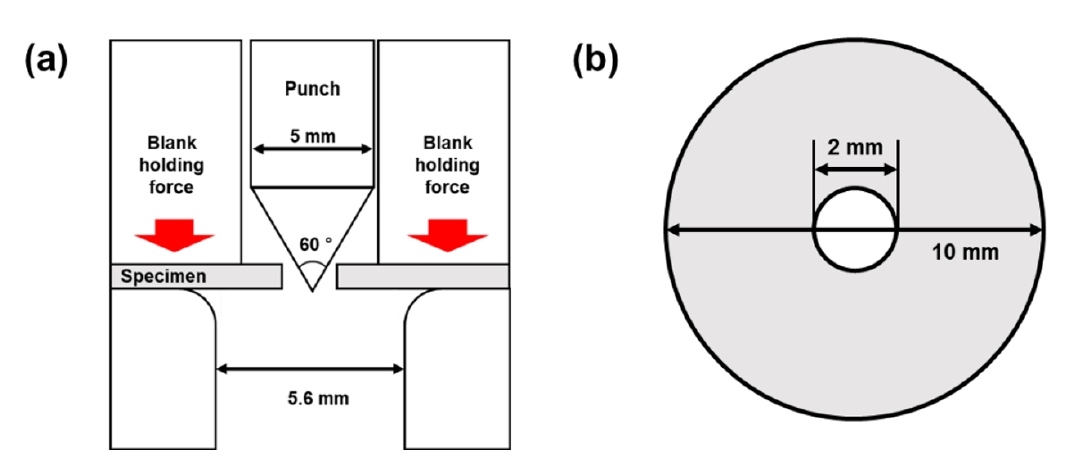

- Hole expansion tests (HET) were conducted using a scaled-down testing system mounted on a universal testing machine [13, 14]. Figure 2 illustrates the HET system and the specimen dimensions. The circular specimens, 10 mm in diameter and 0.5 mm thick, were punched with a 2 mm center hole. Before hole punching, to prevent the effect of surface roughness, the specimen surfaces were polished with SiC papers up to 1200 grit. The HETs were carried out with a conical punch at a punch speed of 1 mm/min. The final diameter was measured until the crack fully propagated through the thickness on the hole edge. The hole expansion ratio (HER) was calculated using the equation [17]:

- where d0 and df represent the initial and final hole diameters, respectively. The hole expansion tests were conducted on five samples of each alloy.

2. Experimental

- 3.1. Microstructure

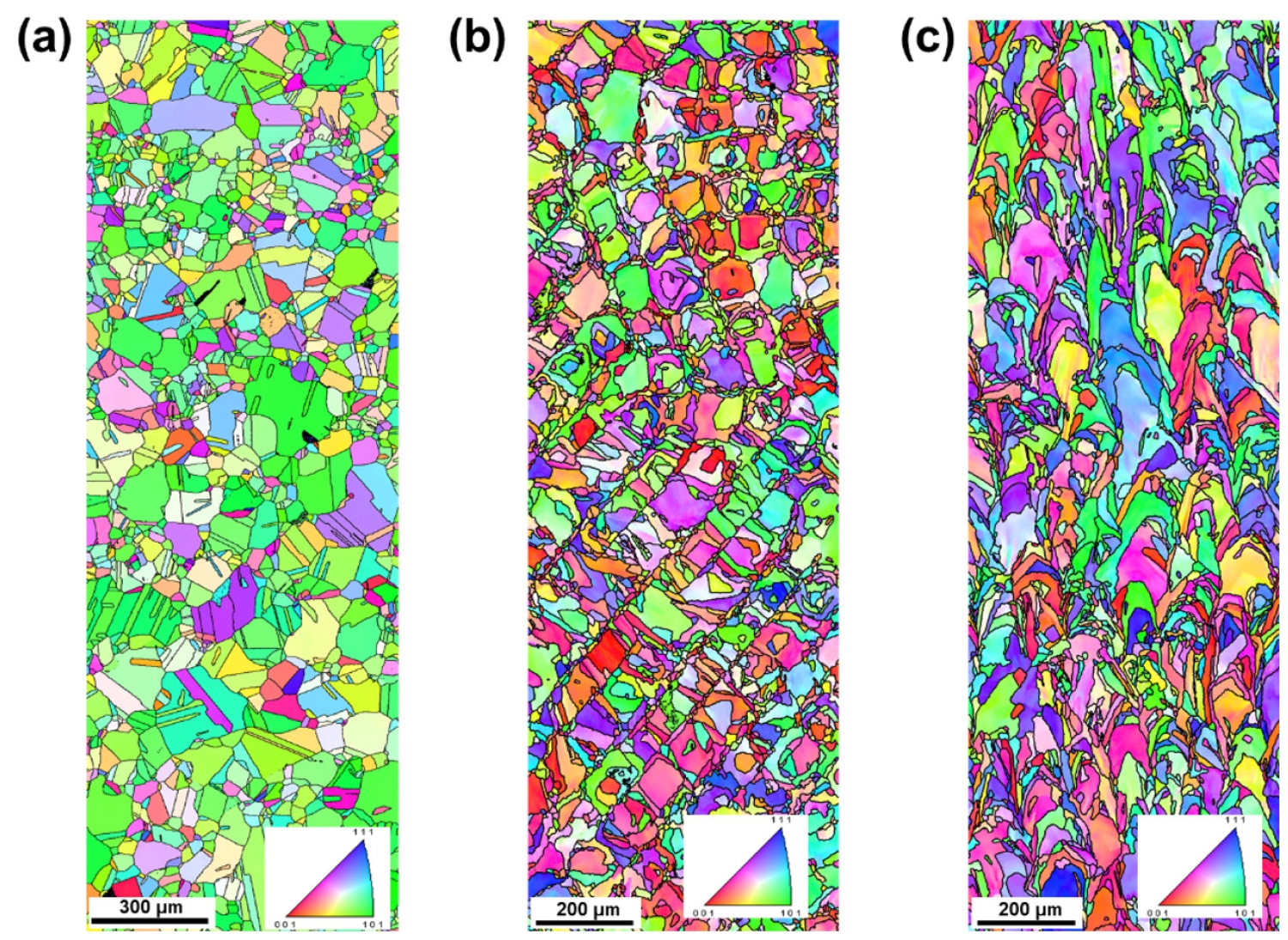

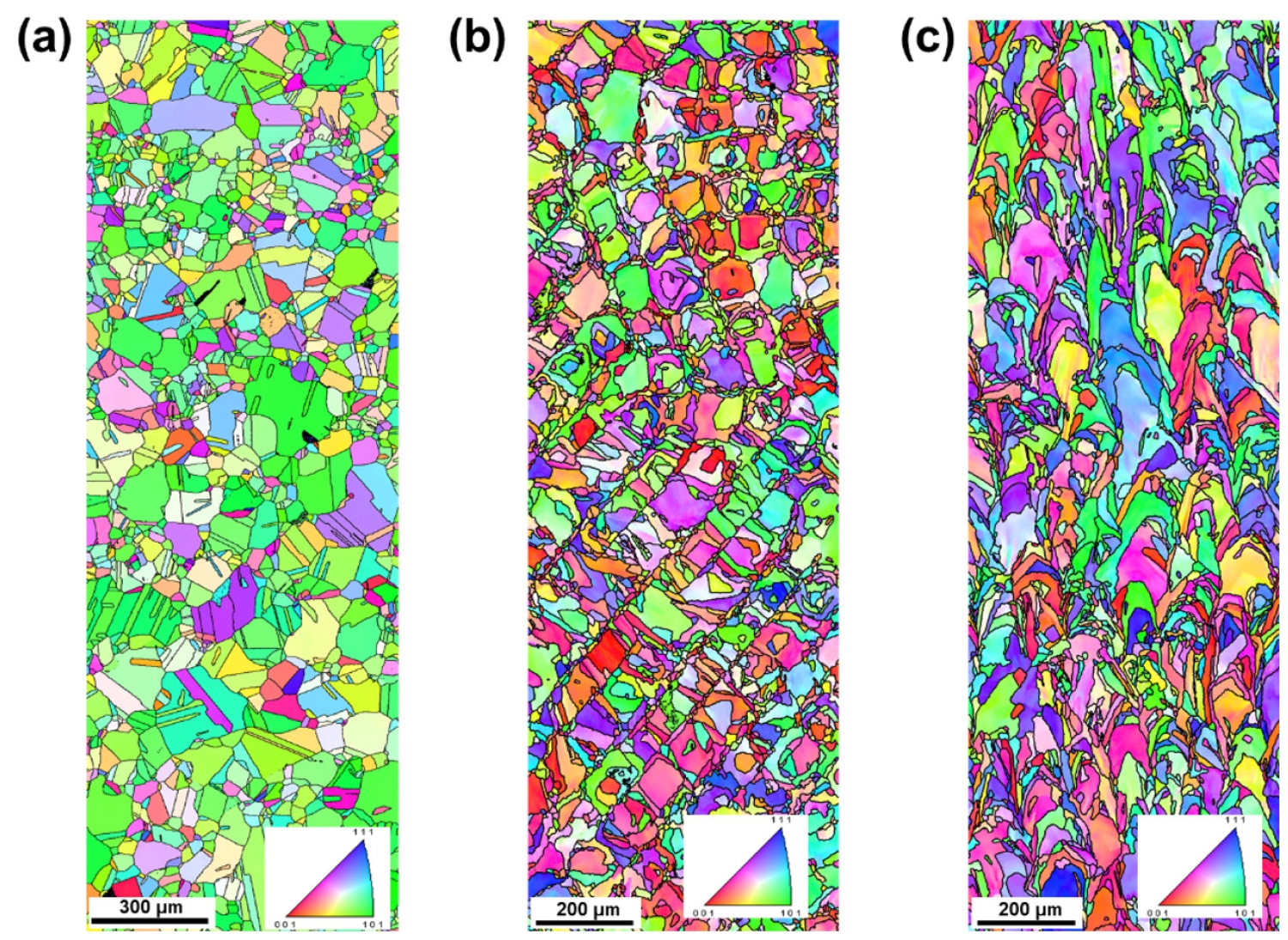

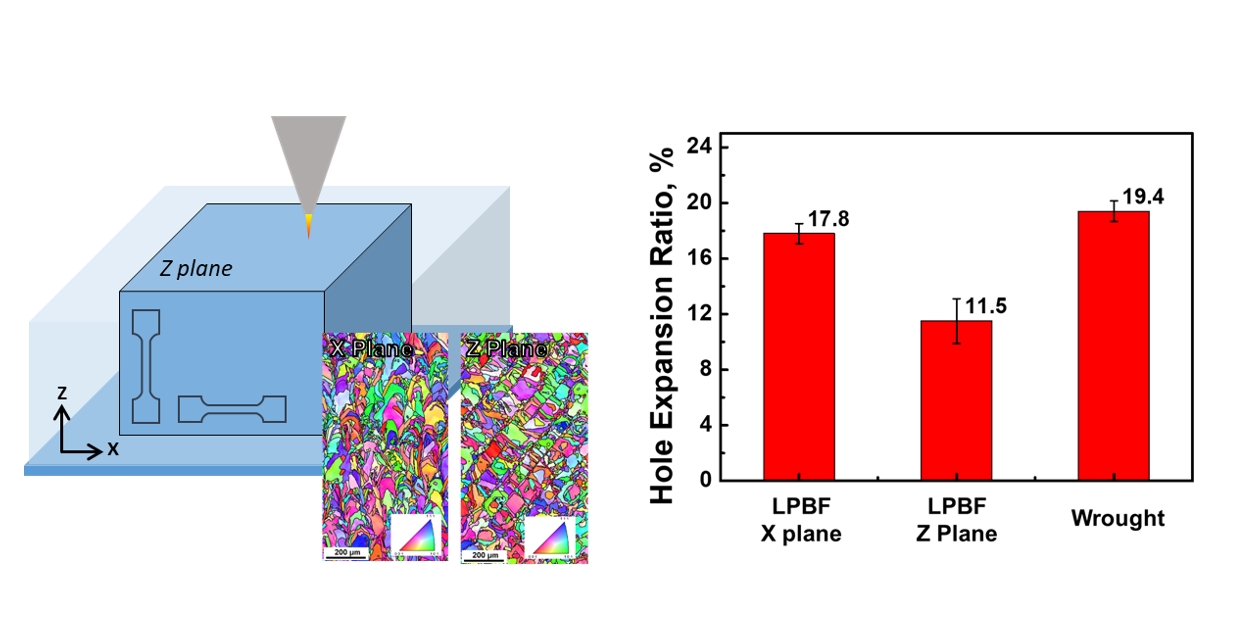

- EBSD-inverse pole figure (IPF) of the LPBF and wrought samples are shown in Fig. 3. The X and Z directions represent scanning and building directions, respectively. The wrought sample shows fully recrystallized, exhibiting equiaxed FCC grains, with an average grain size of 115.4±6.8 μm and a low GND density of ~4.5×1012 m-2. The grain boundaries act as the sites of crack initiation and propagation during plastic deformation, potentially deteriorating the stretch-flangeability. Interestingly, the LPBF-processed two samples show the unique microstructural evolution with high anisotropic microstructure, due to the non-uniform heat source of laser fabrication. The microstructure of the X-plane exhibited a semi-elliptical grain morphology perpendicular to the build direction. This is attributed to the heat flow of the molten powder during the LPBF process, radiating outward from the center of the laser scan. In The X-plane of the LPBF sample, the average grain size was ~58.0±33.0 μm with a GND density of ~1.1×1013 m-2. Meanwhile, the Z plane shows the bimodal grain morphology with an average grain size of ~45.4±26.5 μm and GND density of ~1.2×1013 m-2. The grain size distribution of the LPBF sample on the Z plane shows the two peaks indicating that the bimodal grain morphology (Supplementary Fig. S1). The higher GND density of the LPBF sample than the wrought sample arises from the high thermal stress during laser deposition.

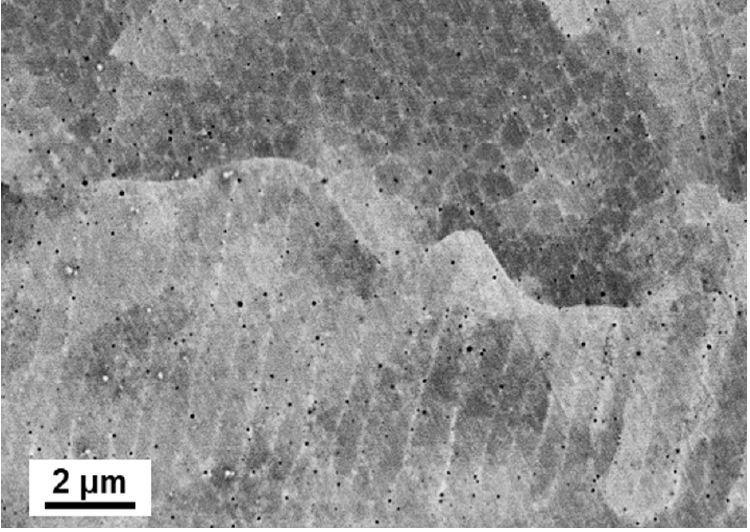

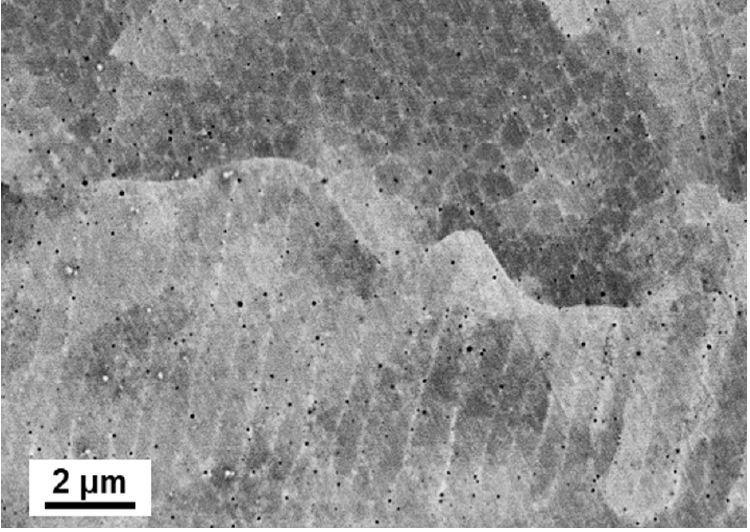

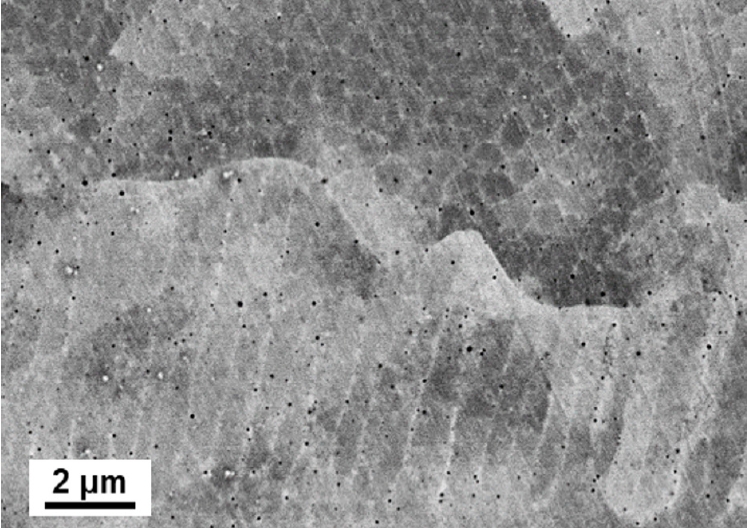

- The BSE image shows the presence of cellular structure in the LPBF sample, as shown in Fig. 4. It is attributed to the cellular solidification due to ultrafast cooling rate, deformation-induced dislocations from thermal stress, and geometrically necessary dislocations (GND) by the thermal heterogeneity. During solidification of AM, solute elements are rejected and segregate into the inter-cellular dendritic regions, leading to a microstructure where cell boundaries contain a higher concentration of solute elements compared to the cell interiors [18]. Additionally, localized melting and solidification lead to dynamic tension/compression cycles [18]. The thermal stresses during laser deposition induce dislocation formation. The elevated temperature of the deposited material reduces yield strength, promoting easier plastic deformation [18].

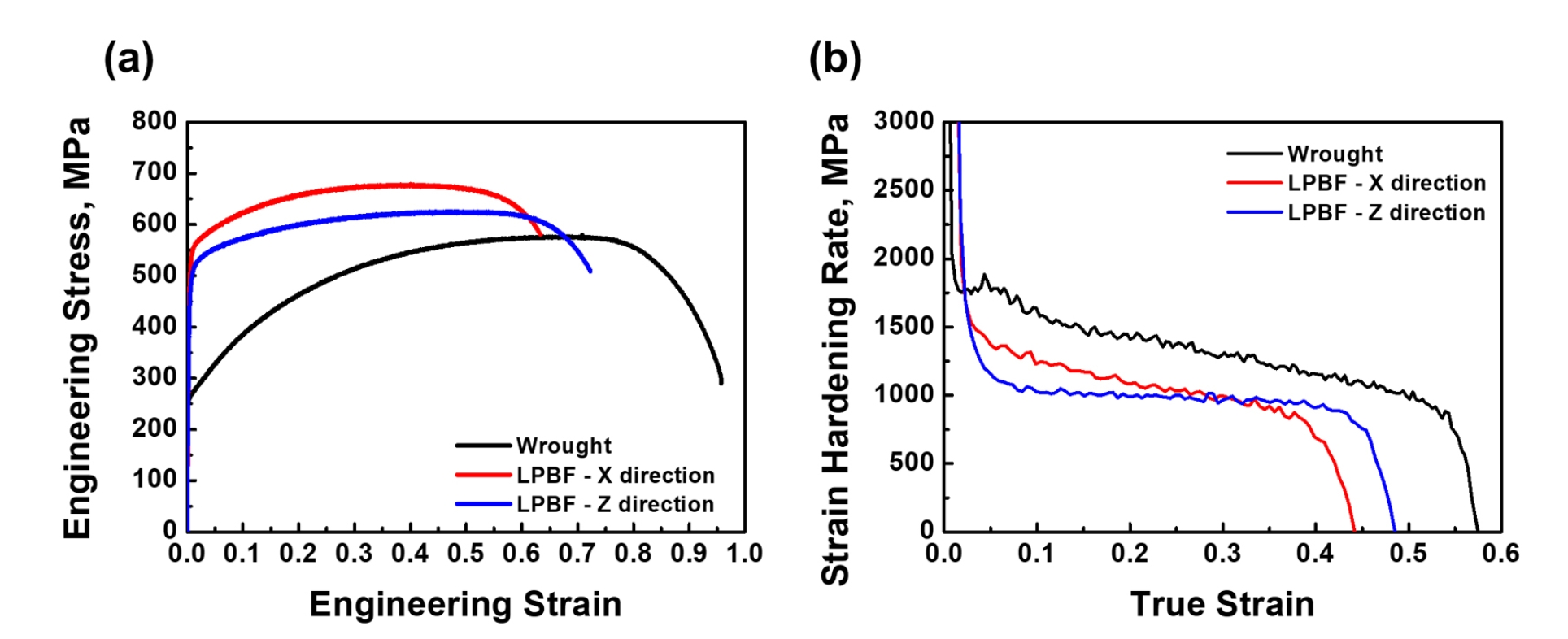

- 3.2. Mechanical properties

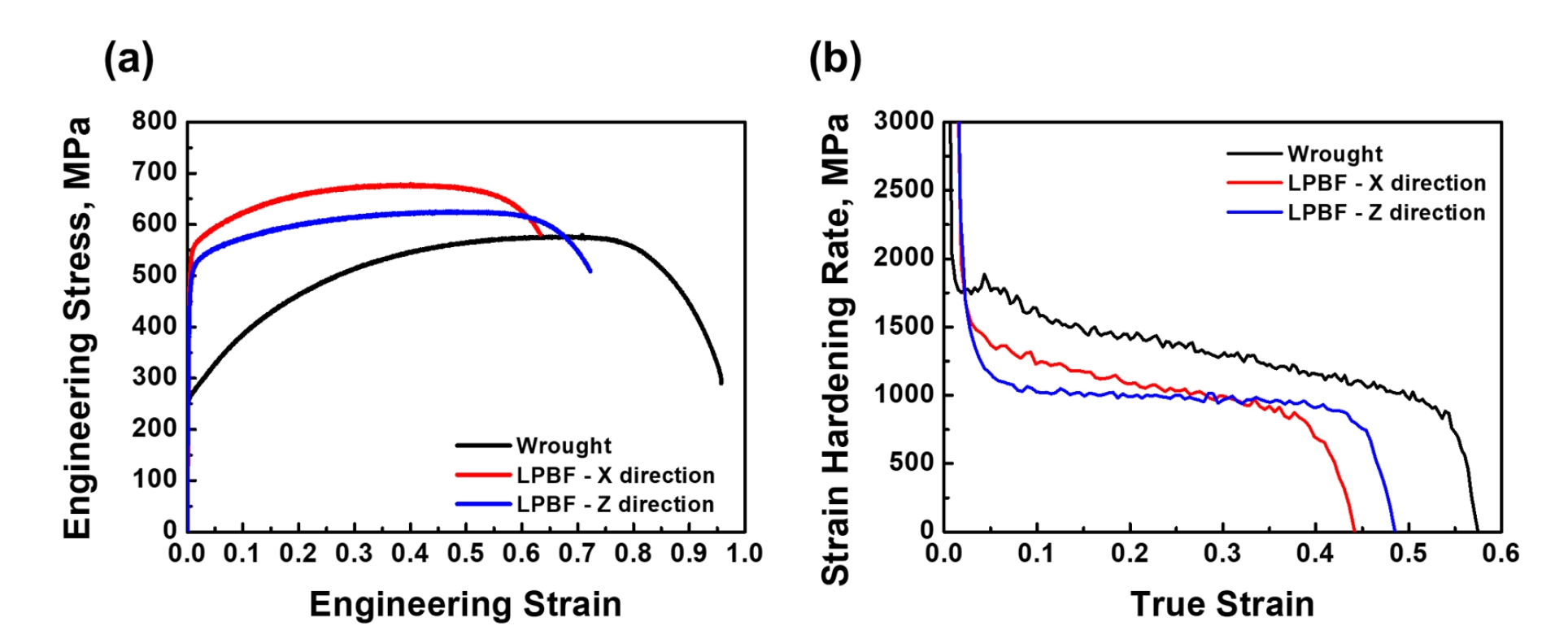

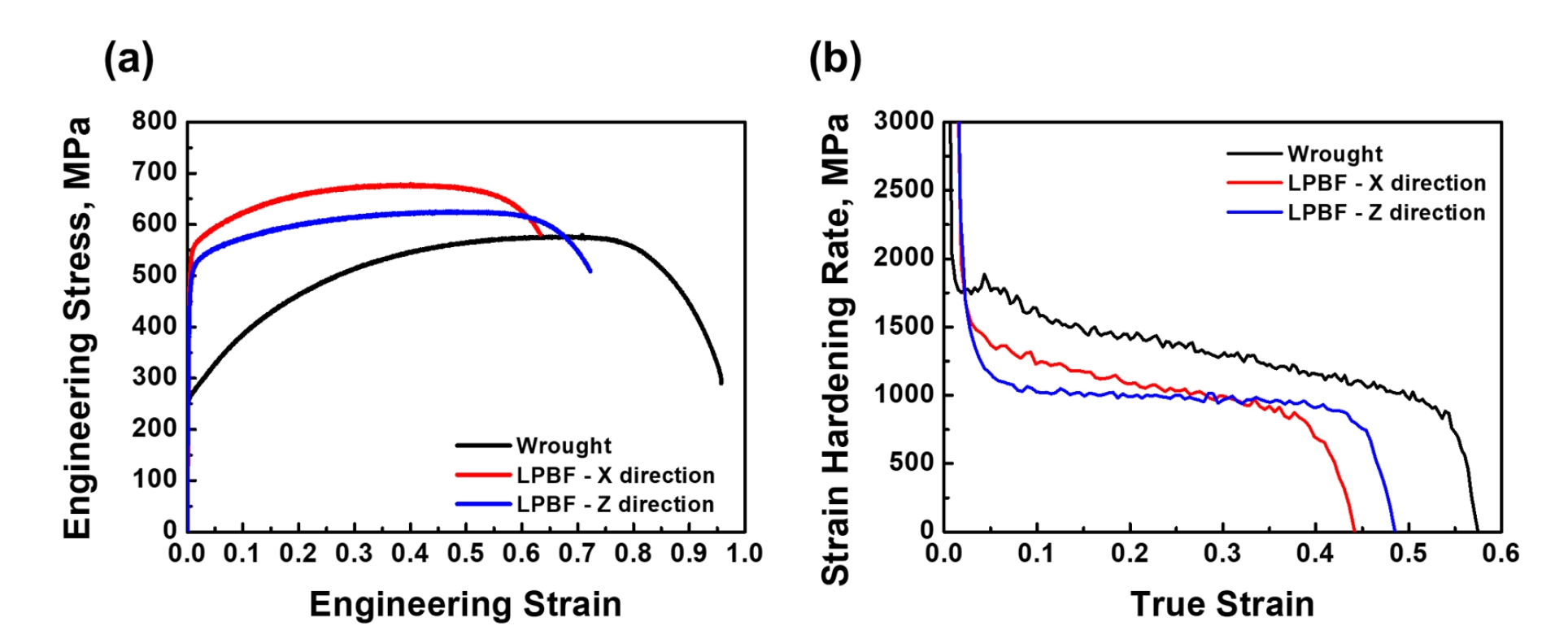

- Fig. 5a displays the engineering stress-strain curves of the present samples. The wrought sample shows a lower yield strength of ~254 MPa with high ductility (~0.96 of total elongation) owing to full recrystallization. Notably, both tensile samples of LPBF exhibited superior tensile strength compared to the wrought sample. This is attributed to the hierarchical microstructure, which combines heterogeneous grain morphology and a sub-structured cellular structure, enhancing the material's strength [5]. The LPBF sample exhibits anisotropic mechanical properties [9]. Specifically, the sample along the X direction demonstrates higher strength compared to the Z direction, which is attributed to its finer grain size and high GND density.

- Strain hardening rate (SHR) curves of each sample are plotted in Fig. 5b. The two drop regions in SHR are associated with easy glide and dynamic recovery. The wrought sample shows superior strain hardenability with stable deformation. This is because of the recrystallized grains with coarse grain size and low GND density.

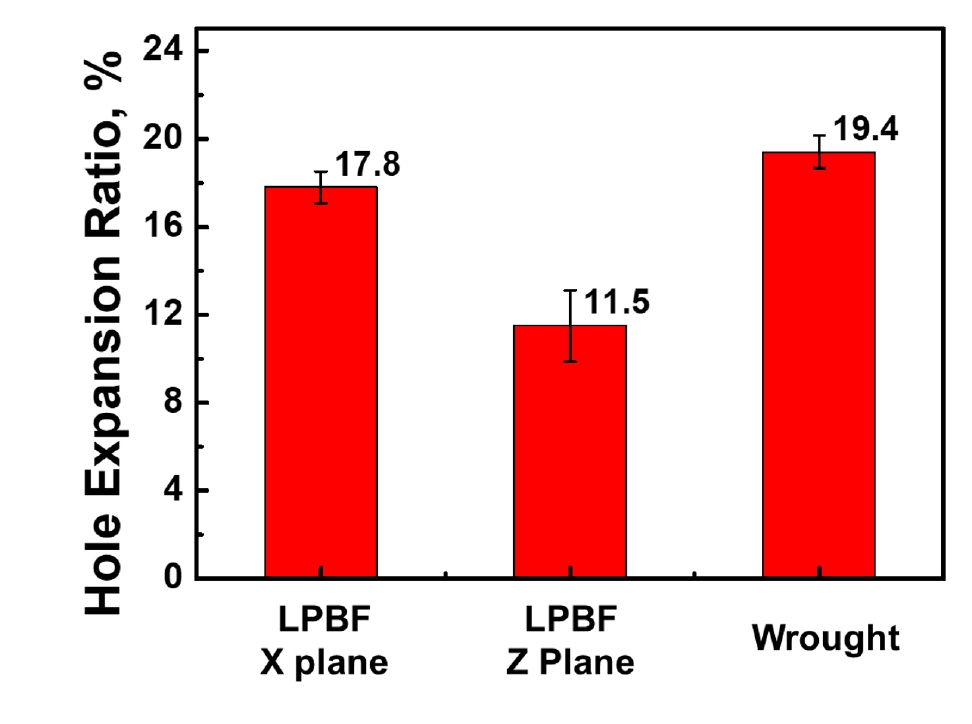

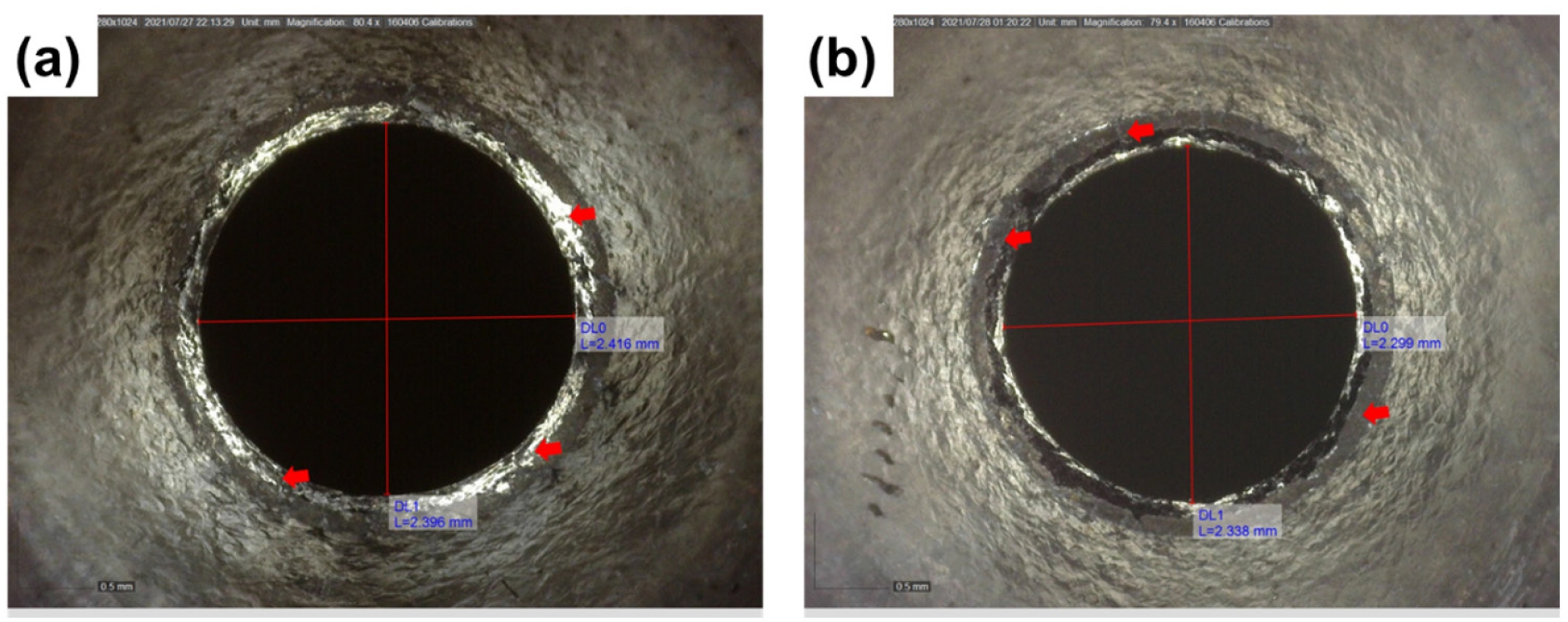

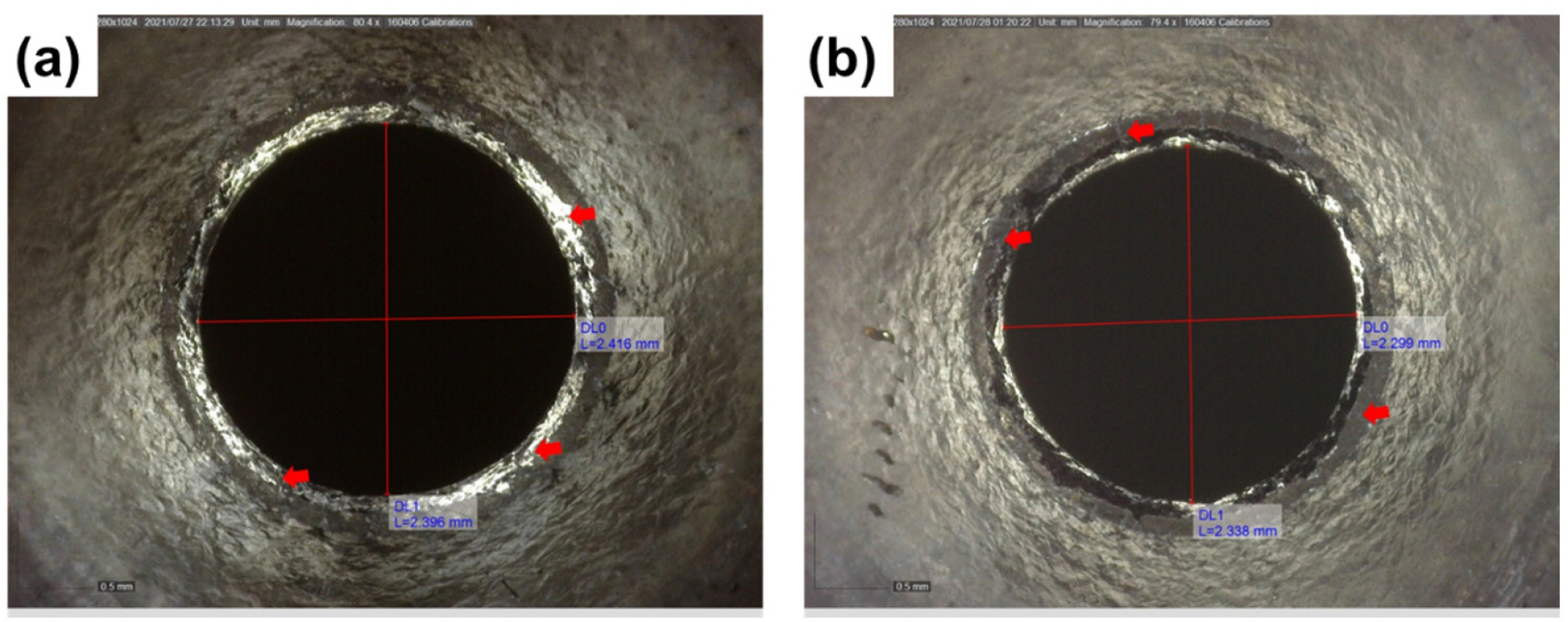

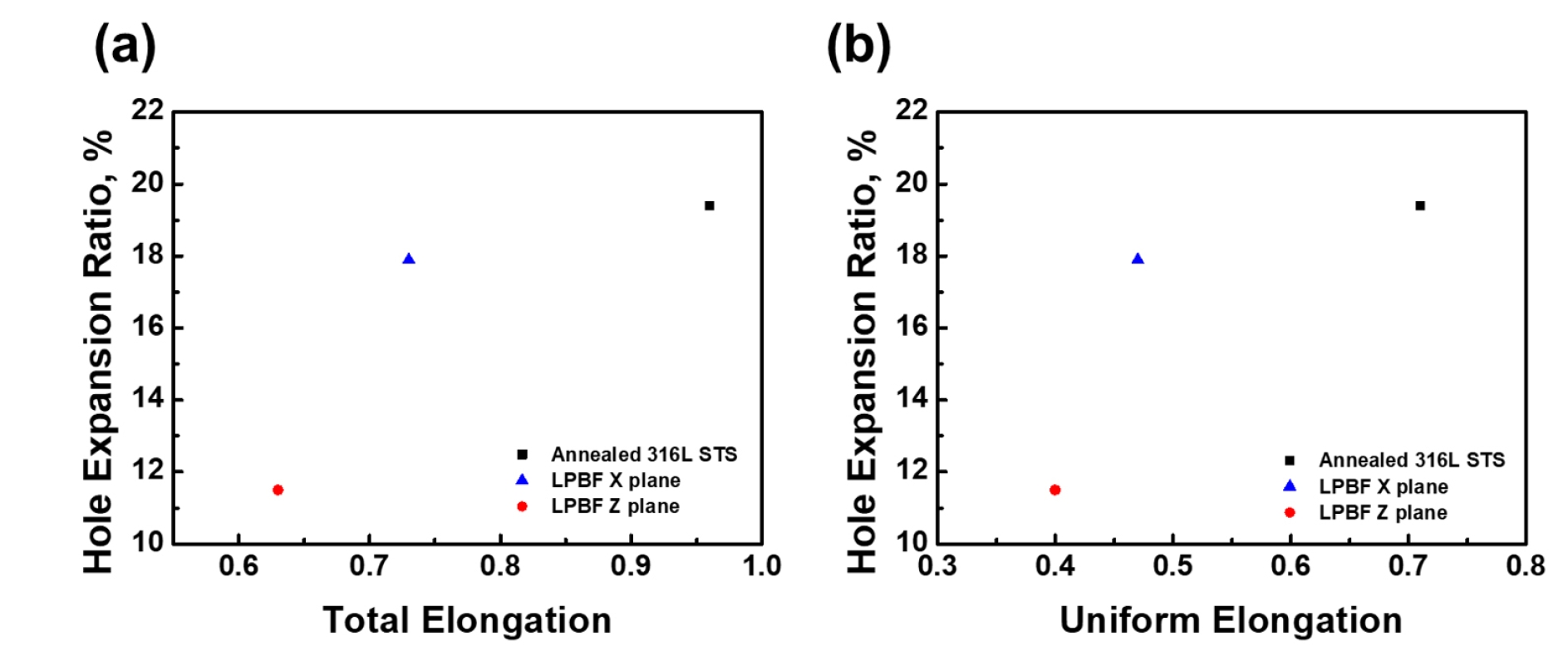

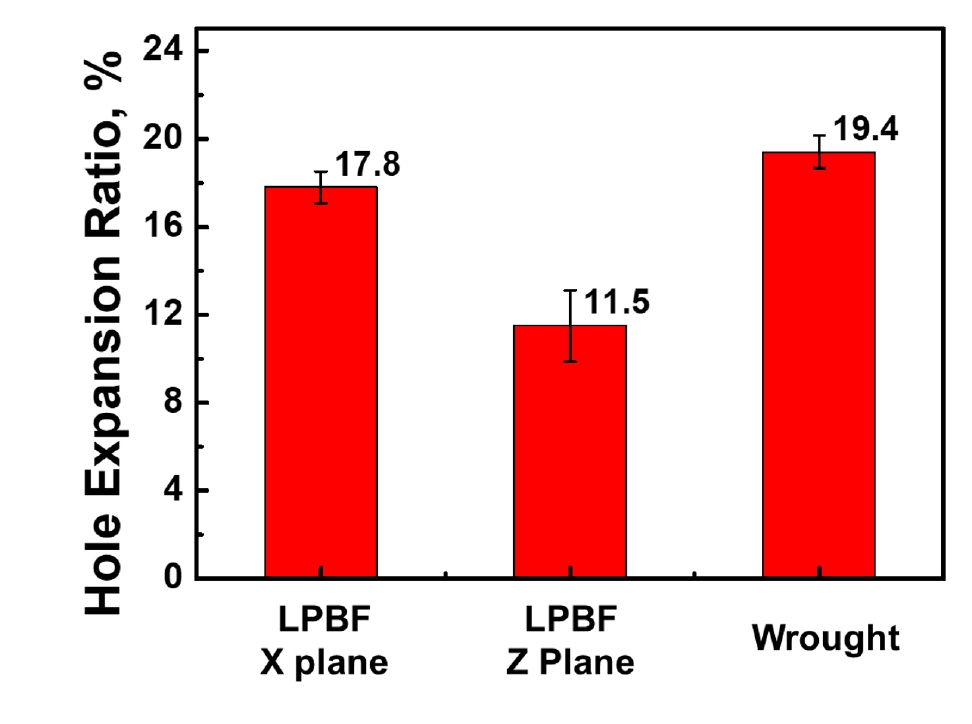

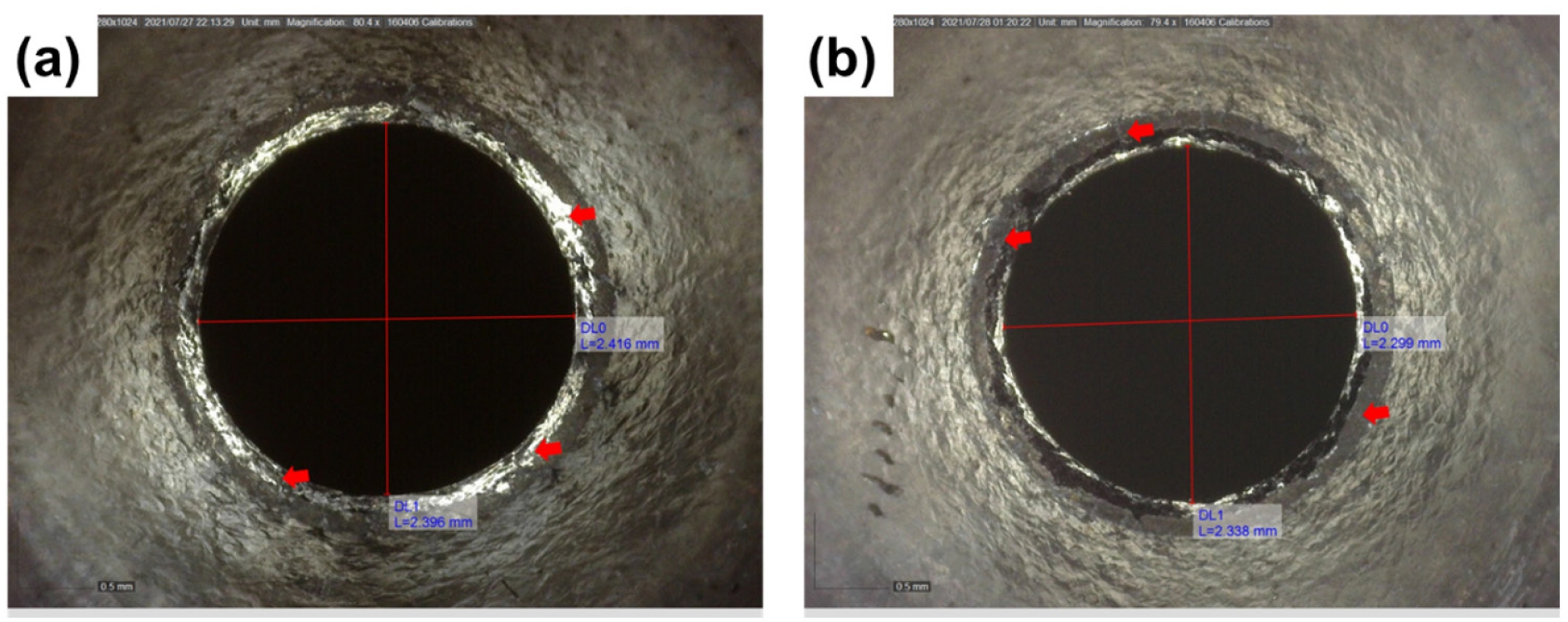

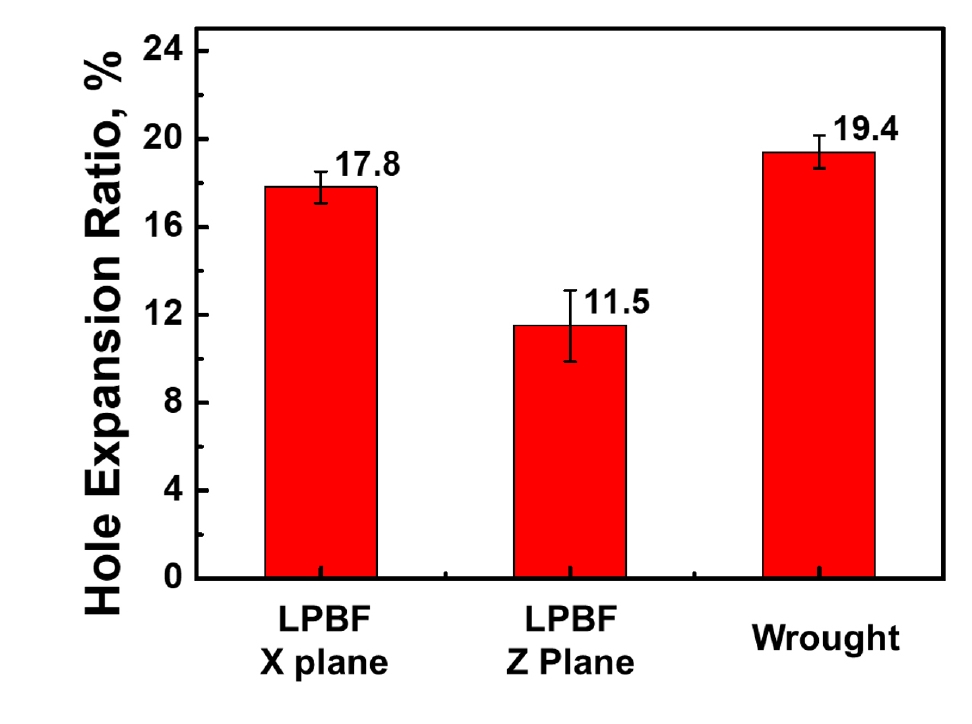

- The results of hole expansion tests are shown in Fig. 6. As shown in Fig. 7, the crack is fully propagated through the thickness of the specimens. The wrought sample exhibited the highest HER of ~19.4. The high elongation and coarse grains generally lead to excellent stretch-flangeability. Interestingly, significant HER differences were observed depending on the direction in the LPBF sample. It indicates that the microstructural anisotropy significantly influences stretch flangeability. The bimodal structure on the Z plane of the LPBF sample produces the strain partitioning between the fine and coarse grains, generating stress concentration and damage evolution [19-21]. Therefore, the strain partitioning from bimodal grains may result in an inferior resistance to crack initiation and propagation during the forming. To understand the anisotropic behavior of forming, the fracture mechanism in two cases needs to be further investigated. Consequently, it is recommended to perform forming operations on the X plane of the LPBF-processed building parts.

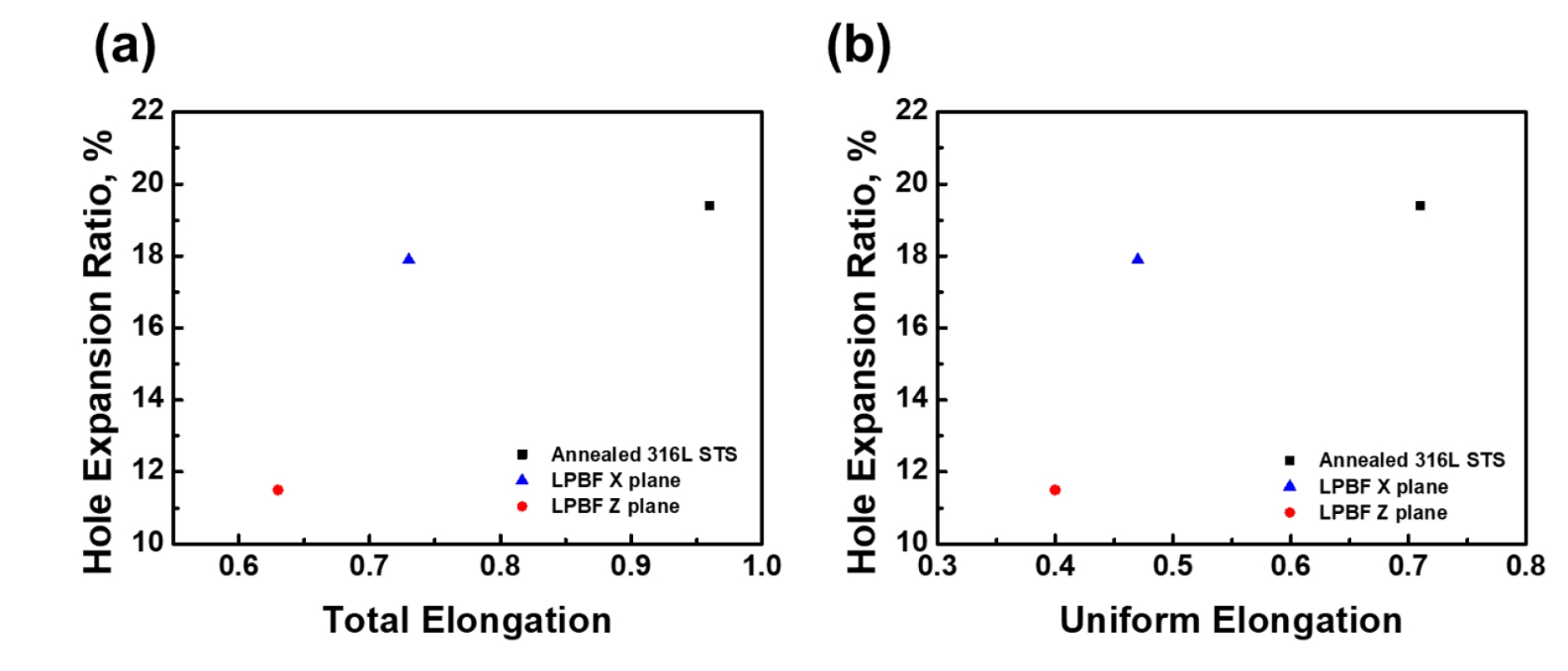

- The deformation path in the hole expansion test closely resembles that of a uniaxial tensile test. Specifically, when considering the major strain (ε1) versus minor strain (ε2) during deformation, the strain path for conical punching follows a uniaxial tensile mode (ε1 =−2ε2) [15]. The hole expansion ratio can be linked to the mechanical properties obtained from tensile testing. The crack-resistant properties during the forming test can be correlated with tensile properties in the direction on the plane of HET specimens, when considering the direction of major strain (Figs. 2 and 3) [15]. For instance, X-plane HET samples experience major strain on the X plane, which is related to the Z direction in tensile samples (Fig. 1c).

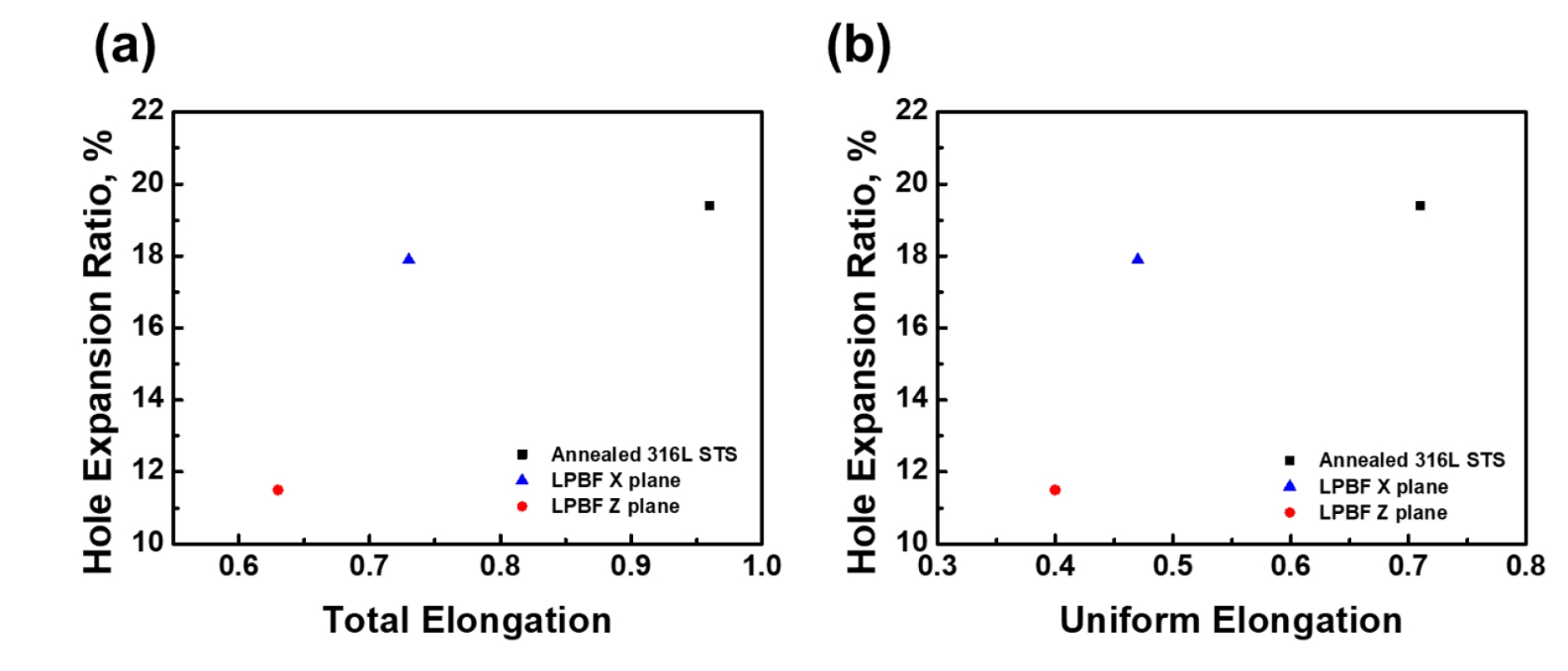

- Figure 8 displays the relationship between ductility and hole expansion ratio. The high ductility of the sample generally leads to a high hole expansion ratio. LPBF Z plane shows the inferior hole expansion ratio related to its ductility, which is attributed to its bimodal grain morphology. During the deformation of heterostructured materials, the stress concentration occurs at the interface, leading to damage evolution [20, 21]. Therefore, the interface between coarse and fine grains in the Z plane is vulnerable to cracking, which deteriorates the crack initiation and propagation resistances.

3. Results and Discussion

- Recent studies have demonstrated the potential of hybrid strategies combining additive manufacturing (AM) with processes such as cold rolling, high-pressure torsion, and forming processes to enhance material properties. Therefore, for AM materials to gain broader industrial acceptance, further investigation into their formability is essential. This study examines the metal-forming behavior of laser powder bed fusion (LPBF)-processed 316L stainless steel to address this gap. Hole expansion tests (HET) were performed on both wrought and LPBF samples in two orientations: the scan direction and the building direction. The results reveal pronounced anisotropy in the stretch-flangeability of LPBF materials, which can be attributed to their unique anisotropic microstructure. These findings provide valuable insights into the relationship between the microstructural characteristics of LPBF materials and their forming performance, emphasizing the importance of directional properties in industrial forming operations. By understanding and addressing the anisotropic behavior of LPBF materials, their potential for broader industrial applications can be further unlocked.

4. Conclusion

-

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT of Korea (2021R1A2C3006662).

-

Conflict of Interest

The authors have no conflicts of interest to declare.

-

Data Availability Statement

The datasets used during the current study available from the corresponding author on reasonable request.

-

Author Information and Contribution

Rae Eon Kim: Ph.D candidate; project administration, conceptualization, writing–original draft. Yeon Teak Choi: Ph.D; investigation. Sang Guk Jeong: Professor; investigation. Do Won Lee: Ph.D candidate; investigation. Hyoung Seop Kim: Professor; writing-review & editing, funding acquisition, supervision.

-

Acknowledgments

None.

Article information

Supplementary Materials

Supplementary Fig. S1.

- 1. J.-Y. Lee, J. An and C. K. Chua: Appl. Mater. Today, 7 (2017) 120–133.Article

- 2. R. E. Kim, S. G. Jeong, H. Ha, Y.-U. Heo, A. Amanov, G. H. Gu, D. J. Lee, J. Moon and H. S. Kim: Mater. Sci. Eng. A, 909 (2024) 146820.Article

- 3. J. Y. Park, B. J. Kim and J. G. Kim: Met. Mater. Int., 29 (2023) 3521.ArticlePDF

- 4. A. Jalali, A. Nikniazi, H. Gholamzadeh, S. Yin, M. Malekan, S. Y. Ahn, H. S. Kim, L. Balogh, L. Ravkov, S. Y. Persaud and V. Fallah: Met. Mater. Int., 30 (2024) 3370.ArticlePDF

- 5. Y. M. Wang, T. Voisin, J. T. McKeown, J. Ye, N. P. Calta, Z. Li, Z. Zeng, Y. Zhang, W. Chen and T. T. Roehling: Nat. Mater., 17 (2018) 63.ArticlePDF

- 6. L. Lemarquis, P. Giroux, H. Maskrot, B. Barkia, O. Hercher and P. Castany: J. Mater. Res. Technol., 15 (2021) 4725.Article

- 7. L. Jinlong, Z. Zhiping and H. Jin: Mater. Lett., 357 (2024) 135813.Article

- 8. A. S. Al-Zubaydi, N. Gao, J. Džugan, N. Gao, P. Podaný, Y. Chen and P. A. Reed: Mater. Sci. Technol., (2024) 22.Article

- 9. P. Snopiński: J. Alloys Compd., 941 (2023) 168984.Article

- 10. S. Mohd Yusuf, Y. Chen, S. Yang and N. Gao: Adv. Eng. Mater., 22 (2020) 2000052.Article

- 11. T. Ge, Y. Li, D. Gao, C. Yang and F. Li: J. Manuf. Process., 124 (2024) 345.Article

- 12. J. Ferchow, M. Bühler, M. Schlüssel, L. Zumofen, C. Klahn, U. Hofmann, A. Kirchheim and M. Meboldt: Int. J. Adv. Manuf. Technol., 119 (2022) 7947.ArticlePDF

- 13. Y. T. Choi, P. Asghari-Rad, J. W. Bae and H. S. Kim: Mater. Sci. Eng. A, 852 (2022) 143683.Article

- 14. Y. T. Choi, J. W. Bae, J. M. Park, H. H. Lee, H. Kwon, S. Son, D.-H. Ahn and H. S. Kim: Mater. Sci. Eng. A, 814 (2021) 141241.Article

- 15. S. K. Paul: Materialia, 9 (2020) 100566.Article

- 16. J. I. Yoon, J. Jung, S.-H. Joo, T. J. Song, K.-G. Chin, M. H. Seo, S.-J. Kim, S. Lee and H. S. Kim: Mater. Lett., 180 (201) 322.Article

- 17. IO Standardization, Metallic Materials-Sheet and Strip-Method of Hole Expanding Test, (2009).

- 18. G. M. Karthik, E. S. Kim, P. Sathiyamoorthi, A. Zargaran, S. G. Jeong, R. Xiong, S. H. Kang, J.-W. Cho and H. S. Kim: Addit. Manuf., 47 (2021) 102314.Article

- 19. J. Zhou, Y. Wang, G. Zhi and L. He: Met. Mater. Int., 30 (2024) 240.ArticlePDF

- 20. H.K. Park, K. Ameyama, J. Yoo, H. Hwang and H. S. Kim: Mater. Res. Lett., 6 (2018) 261.Article

- 21. R. E. Kim, G. H. Gu, H. Kwon, S. Y. Ahn, J. Kwon, J. A. Lee, Y. T. Choi, M. H. Seo and H. S. Kim: J. Mater. Res. Technol., 21 (2022) 3514.Article

References

Figure & Data

References

Citations

Fig. 1.

Fig. 2.

Fig. 3.

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Graphical abstract

TOP

KPMI

KPMI

ePub Link

ePub Link Cite this Article

Cite this Article