- [Korean]

- Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

-

Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

-

J Powder Mater. 2025;32(1):16-22. Published online February 28, 2025

-

DOI: https://doi.org/10.4150/jpm.2024.00444

-

-

Abstract Abstract

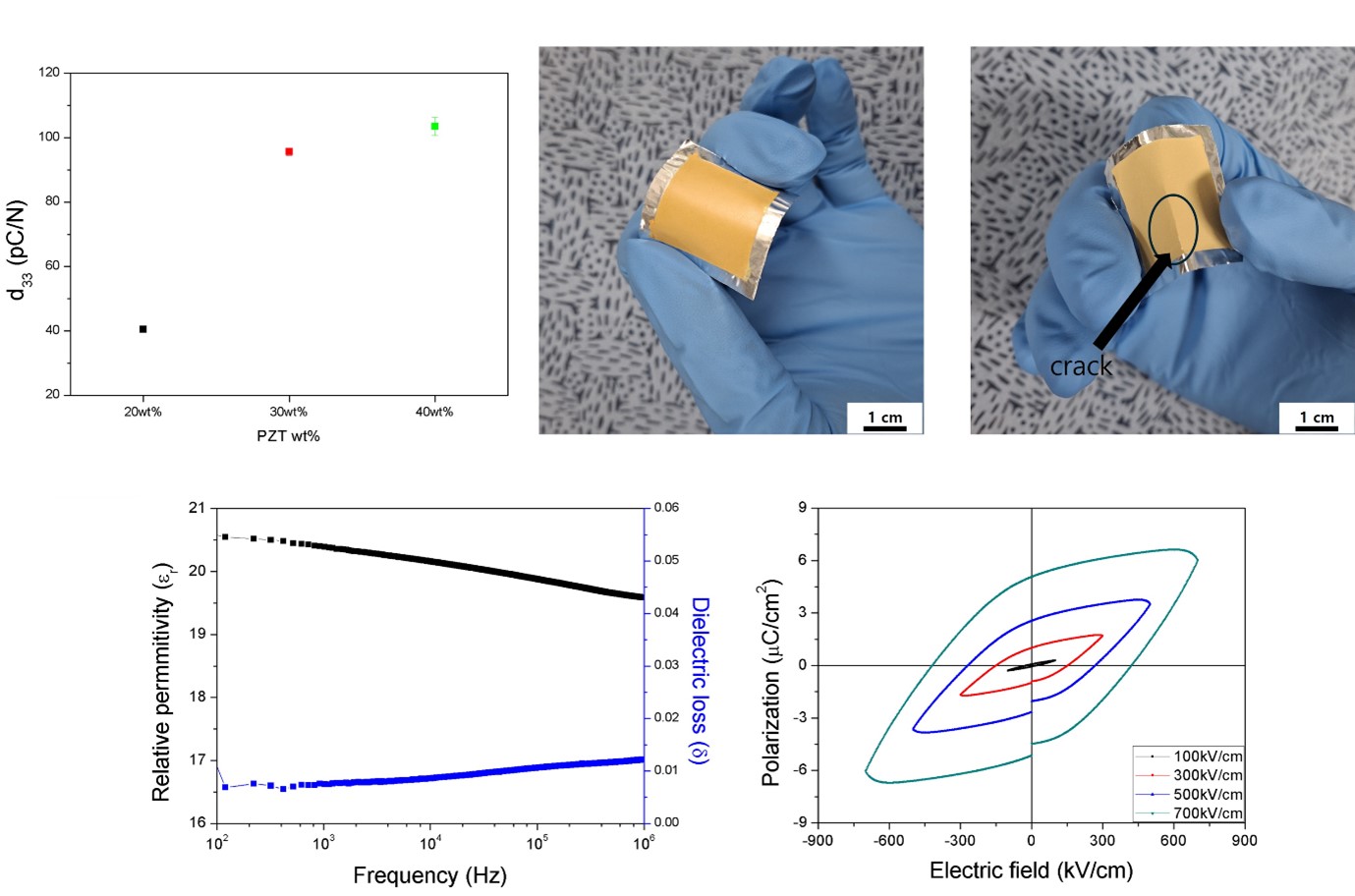

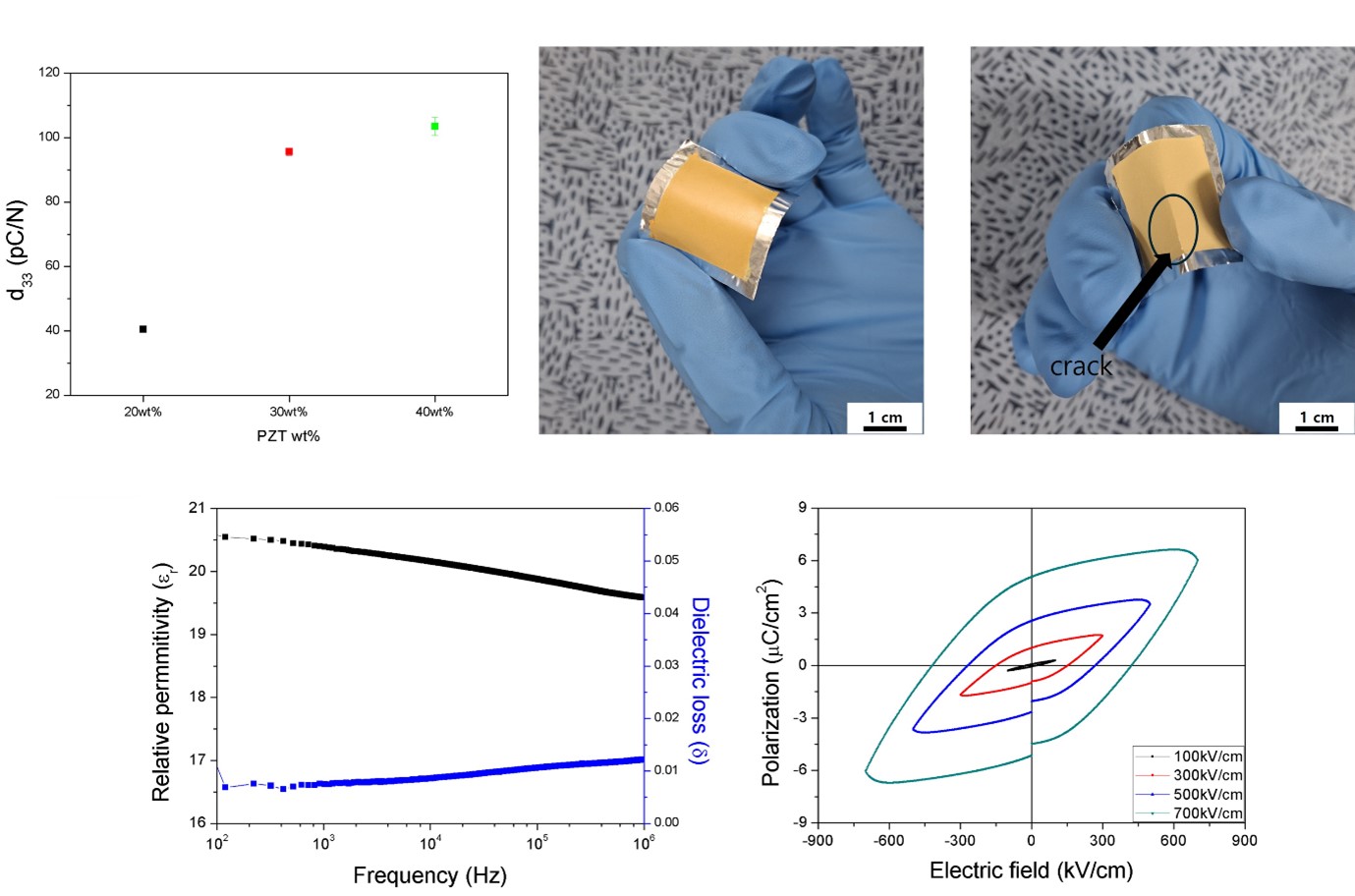

PDF PDF

- Piezoelectric composites have attracted significant research interest as sustainable power sources for electronic devices due to their high mechanical stability and electrical output characteristics. This study investigated the optimal processing conditions for fabricating a flexible piezoelectric energy harvester based on Pb(Zr,Ti)O₃ (PZT) powder and a polyimide (PI) matrix composite. Various parameters, including the optimal mixing ratio of PI/PZT, ultrasonic treatment, homogenization, vacuum oven, and UV/O₃ treatment, were optimized to achieve a uniform piezoelectric composite. A PZT content of 30 wt% and 20 minutes of homogenization were identified as the most effective conditions for increasing the uniformity of the composite. The optimized composite exhibited a high piezoelectric coefficient, a typical P-E hysteresis loop, and dielectric properties, exhibiting a voltage output that adjusts in response to variations in the applied touch force. This study provides foundational data for the uniform fabrication of flexible piezoelectric energy harvesters and next-generation miniaturized electronic devices.

- [English]

- Eco-Friendly Powder and Particles-Based Triboelectric Energy Harvesters

-

Rayyan Ali Shaukat, Jihun Choi, Chang Kyu Jeong

-

J Powder Mater. 2023;30(6):528-535. Published online December 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.6.528

-

-

1,812

View

-

36

Download

-

5

Citations

-

Abstract Abstract

PDF PDF

Since their initial development in 2012, triboelectric nanogenerators (TENGs) have gained popularity worldwide as a desired option for harnessing energy. The urgent demand for TENGs is attributed to their novel structural design, low cost, and use of large-scale materials. The output performance of a TENG depends on the surface charge density of the friction layers. Several recycled and biowaste materials have been explored as friction layers to enhance the output performance of TENGs. Natural and oceanic biomaterials have also been investigated as alternatives for improving the performance of TENG devices. Moreover, structural innovations have been made in TENGs to develop highly efficient devices. This review summarizes the recent developments in recycling and biowaste materials for TENG devices. The potential of natural and oceanic biowaste materials is also discussed. Finally, future outlooks for the structural developments in TENG devices are presented. -

Citations

Citations to this article as recorded by  - Triboelectric Nanogenerators for Future Space Missions

Rayyan Ali Shaukat, Muhammad Muqeet Rehman, Maryam Khan, Rui Chang, Carlo Saverio Iorio, Yarjan Abdul Samad, Yijun Shi

Nano-Micro Letters.2026;[Epub] CrossRef - Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System

Saba Ejaz, Imran Shah, Shahid Aziz, Gul Hassan, Ahmed Shuja, Muhammad Asif Khan, Dong-Won Jung

Micromachines.2025; 16(2): 230. CrossRef - Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

Journal of Powder Materials.2025; 32(1): 16. CrossRef - Sustainable Triboelectric Nanogenerator from Abalone Shell Powder for Self-Powered Humidity Sensing

Yunsook Yang, Farhan Akhtar, Shahzad Iqbal, Muhammad Muqeet Rehman, Woo Young Kim

Sensors.2025; 25(24): 7584. CrossRef - Research Trends in Magneto-Mechano-Electric (MME) Energy Harvesting Devices

So Ie Jeong, Geon-Tae Hwang

Journal of Powder Materials.2025; 32(6): 529. CrossRef

|