- [English]

- Finite Element and Discrete Element Analyses of Anisotropic Powder Compaction for Axial Flux Motor Cores

-

Jeong Ah Lee, Do Won Lee, , Hyojeong Ha, Ki Hyuk Kwon, Eon Byeong Park, Taeyoung Kim, Hyoung Seop Kim

-

J Powder Mater. 2025;32(6):451-458. Published online December 31, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00409

-

-

Abstract Abstract

PDF PDF

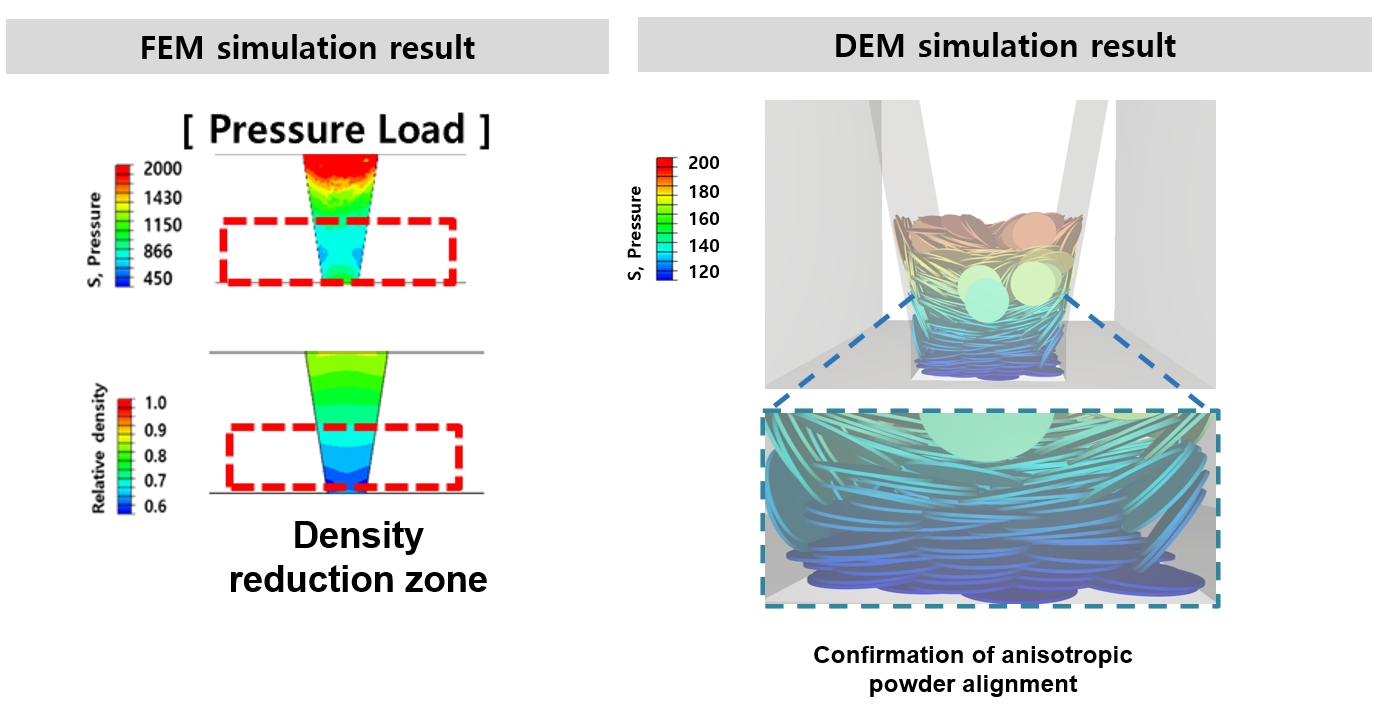

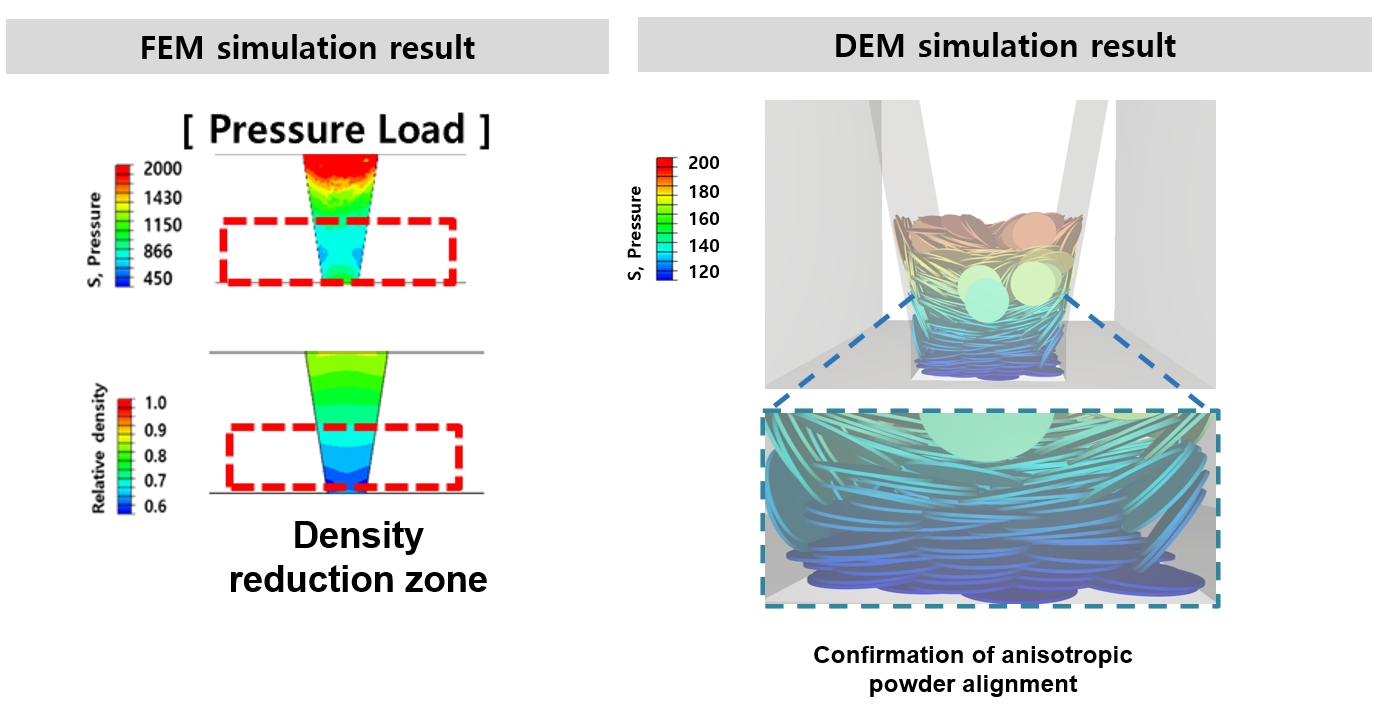

- This study investigates the compaction behavior of anisotropic, plate-like powders used in axial flux motor cores through a combined FEM–DEM approach. A porous continuum FEM model captures stress and density evolution during die pressing, revealing strong gradients along the compaction direction, with higher stress and densification near the upper punch and reduced compaction in the lower region. Guided by these results, DEM simulations examine particle packing, orientation, and contact pressure in representative zones. The DEM analysis shows that higher local pressure promotes denser packing and in-plane particle alignment near the upper punch, while the lower region exhibits more random orientations and lower contact forces. As a result, the multi-scale FEM–DEM framework clarifies how anisotropic particle behavior governs local densification and offers practical guidance for die design and process optimization to achieve more uniform density and controlled magnetic-property-relevant particle alignment in axial flux motor cores.

- [Korean]

- Property of the Spheroidized Zr Powder by Radio Frequency Plasma Treatment

-

Yukyeong Lee, Mi-Sun Choi, Eon Byeong Park, Jeong Seok Oh, Taehyun Nam, Jung Gi Kim

-

J Korean Powder Metall Inst. 2021;28(2):97-102. Published online April 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.2.97

-

-

Abstract Abstract

PDF PDF

Powder quality, including high flowability and spherical shape, determines the properties of additively manufactured products. Therefore, the cheap production of high-quality powders is critical in additive manufacturing. Radio frequency plasma treatment is an effective method to fabricate spherical powders by melting the surface of irregularly shaped powders; in the present work, mechanically milled Zr powders are spheroidized by radio frequency plasma treatment and their properties are compared with those of commercial Zircaloy-2 alloy powder. Spherical Zr particles are successfully fabricated by plasma treatment, although their flowability and impurity contents are poorer than those of the commercial Zircaloy-2 alloy powder. This result shows that radio-frequency plasma treatment with mechanically milled powders requires further research and development for manufacturing low-cost powders for additive manufacturing.

|