- [Korean]

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

-

Eunhyo Song, Hansung Lee, Byungmin Ahn

-

J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00059

-

-

666

View

-

23

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

- High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

-

Citations

Citations to this article as recorded by  - Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef

- [English]

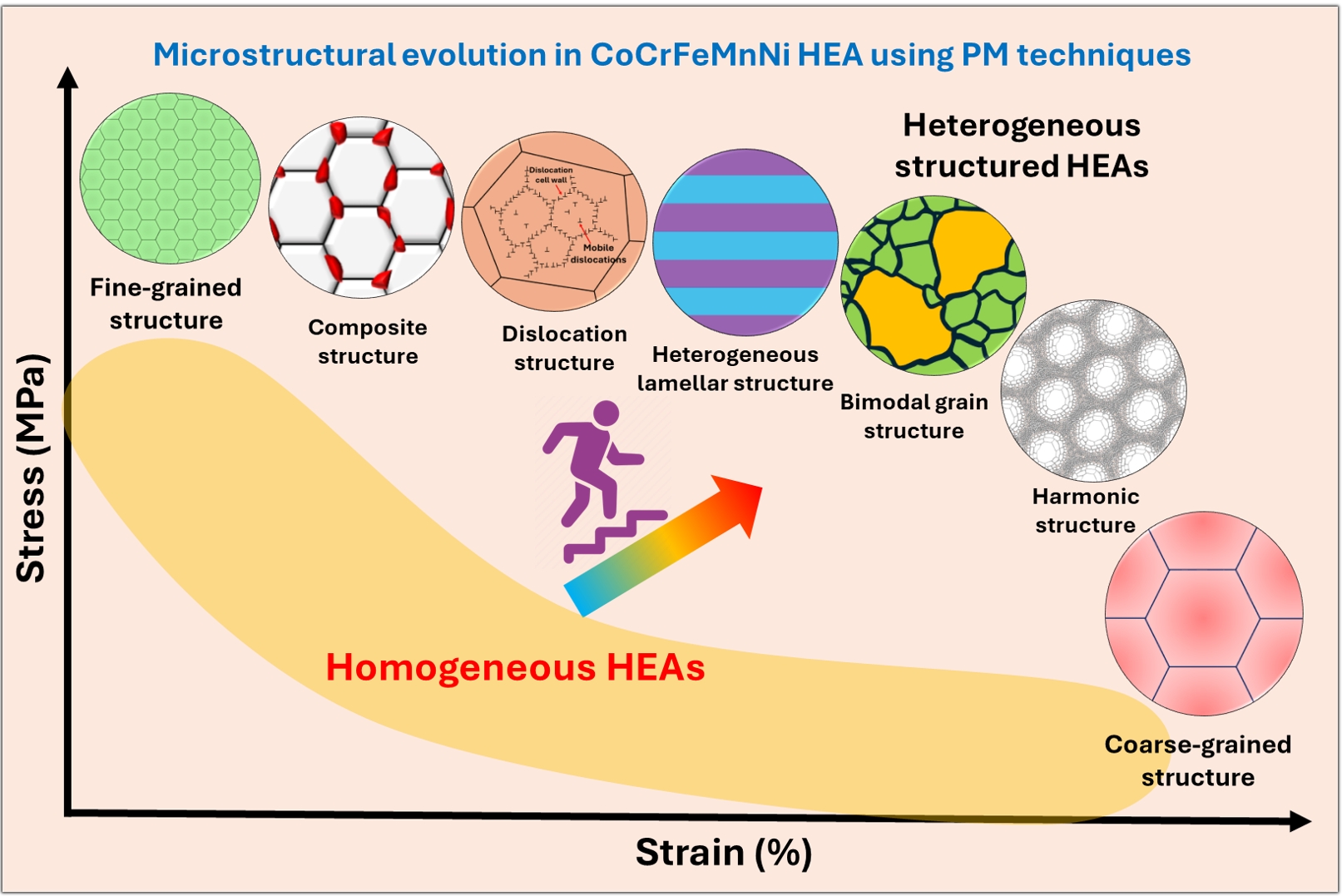

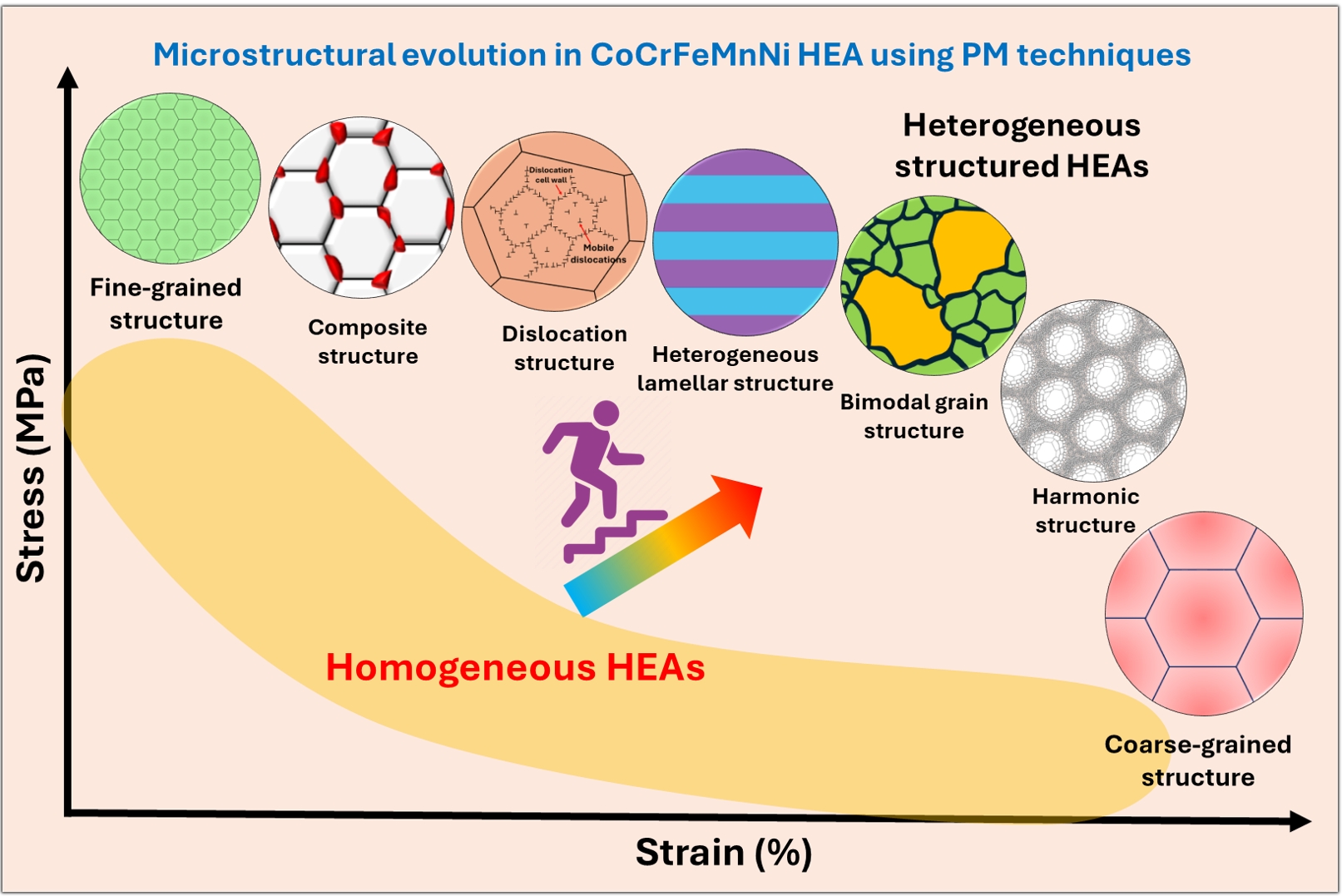

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

-

Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

-

J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

-

DOI: https://doi.org/10.4150/jpm.2024.00430

-

-

4,526

View

-

118

Download

-

4

Citations

-

Abstract Abstract

PDF PDF

- In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by  - Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- [Korean]

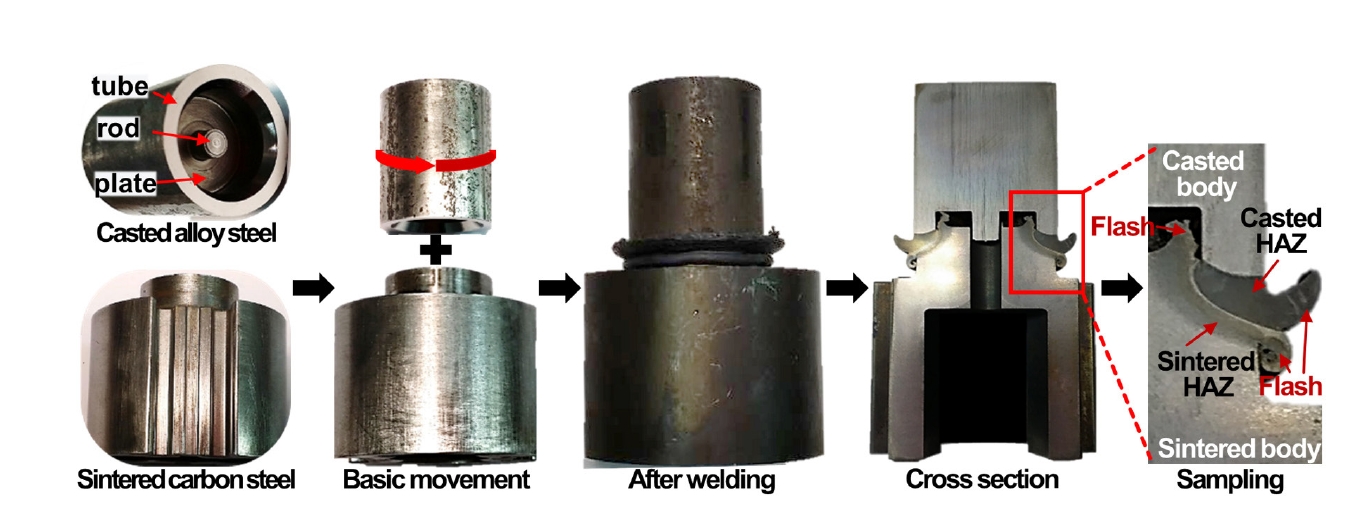

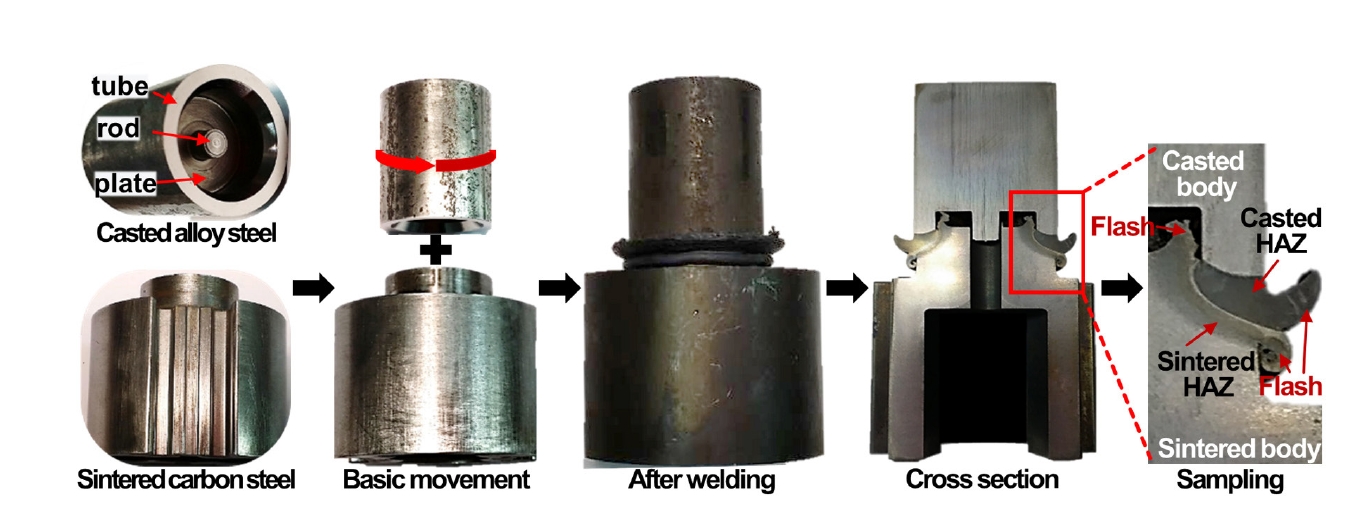

- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

-

Jisung Lee, Hansung Lee, Eunhyo Song, Byungmin Ahn

-

J Powder Mater. 2024;31(5):414-421. Published online October 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00311

-

-

Abstract Abstract

PDF PDF

- Friction welding, which uses heat and plastic flow to join metals, is expanding across industries due to its ability to weld heterogeneous alloys and simple process. However, process research is essential for materials with complex geometries, and limited research has been conducted on friction welding between cast and sintered metals. This study analyzed the mechanical properties and microstructural evolution of the joint by controlling the rotational speed and friction pressure, which affect the removal of the heat-affected zone in friction welding of casted SCM440 and sintered F-05-140. Hardness mapping and microstructure observations with material transition were performed to investigate the correlation between phase behavior and welding conditions. These results are anticipated to reduce costs and improve the mechanical properties of key mobility components.

|