Articles

- Page Path

- HOME > J Powder Mater > Volume 31(5); 2024 > Article

-

Research Article

SCM440 주조재와 F-05-140 소결재의 이종재료 마찰용접 및 공정 조건에 따른 접합 특성 연구 - 이지성1,†, 이한성2,†, 송은효3, 안병민2,3,*

- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

- Jisung Lee1,†, Hansung Lee2,†, Eunhyo Song3, Byungmin Ahn2,3,*

-

Journal of Powder Materials 2024;31(5):414-421.

DOI: https://doi.org/10.4150/jpm.2024.00311

Published online: October 31, 2024

1서한이노빌리티 구매본부

2아주대학교 첨단신소재공학과

3아주대학교 에너지시스템학과

1Purchasing Division, Seohan Innobility, Jincheon, 27850, Republic of Korea

2Department of Materials Science and Engineering, Ajou University, Suwon, 16499, Republic of Korea

3Department of Energy Systems Research, Ajou University, Suwon, 16499, Republic of Korea

- *Corresponding Author: Byungmin Ahn, TEL: +82-31-219-3531, FAX: +82-31-219-1613, E-mail: byungmin@ajou.ac.kr

- †These authors have contributed equally to this work.

© The Korean Powder Metallurgy & Materials Institute

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 909 Views

- 15 Download

Abstract

- Friction welding, which uses heat and plastic flow to join metals, is expanding across industries due to its ability to weld heterogeneous alloys and simple process. However, process research is essential for materials with complex geometries, and limited research has been conducted on friction welding between cast and sintered metals. This study analyzed the mechanical properties and microstructural evolution of the joint by controlling the rotational speed and friction pressure, which affect the removal of the heat-affected zone in friction welding of casted SCM440 and sintered F-05-140. Hardness mapping and microstructure observations with material transition were performed to investigate the correlation between phase behavior and welding conditions. These results are anticipated to reduce costs and improve the mechanical properties of key mobility components.

- 마찰용접(friction welding)은 회전을 통한 열 발생과 함께 소성 유동으로 두 표면의 금속을 접합하기 위해 가압 접촉을 일으키는 고상 용접 방법이다[1, 2]. 마찰용접은 공업 기술이 발달됨에 따라 공정이 단순하고, 미숙련공도 쉽게 기술을 습득함으로써 높은 생산 효율성을 가지며, 용접 시 유해가스가 발생하지 않아 친환경적임과 동시에 이종재료의 접합이 가능하여 제품적용부에 따른 설계를 통한 경제성을 보유하고 있다[3-5]. 이는 고효율, 친환경, 신뢰성을 요구하는 산업현장의 수요에 적합하여 품질 개선 및 생산성 향상을 위한 연구가 증가하고 있으며, 제품생산 적용이 점진적으로 확대되고 있다[2, 4]. 이러한 이점을 가지는 마찰용접은 공정 중 발생하는 접촉 단면의 열에너지로 형성되는 취약부인 열영향부(heat affected zone, HAZ)가 회전 후 가압을 통해 플래시로 방출되며, 열-기계적영향부(thermo-mechanically affected zone, TMAZ)만 남김으로써 용접부의 기계적 물성이 우수하다는 특징 또한 가진다[3, 6].

- 하지만, 마찰용접은 재료의 형상에 제한을 받으며, 회전이 가능한 형태의 부품이더라도 불 균일한 마찰에너지가 표면에 전달되는 형태의 복잡한 형상을 보유한 경우 마찰 특성을 확인하기 위한 연구가 선행되어야 한다[7]. 마찰 공정에 따른 플래시의 형성과 열영향부 및 열-기계적영향부의 거동과 관련된 용접 특성 정립을 통해 신뢰도를 확보할 필요가 있다[8]. 또한, 마찰용접은 이종재료의 접합이 가능하나, 마찰용접의 이점을 최대화할 수 있는 커넥팅 로드, 실린더 블록 등과 같이 주조 부품과 소결 부품이 동시에 사용되는 공정에 적용하기에 주조재와 소결재의 이종 접합과 관련된 연구 사례는 미미하다[9-11].

- 본 연구에서는 강도 및 인성, 내마모성이 우수하여 자동차의 핵심 부품에 사용되는 SCM440 합금강과[12] 기계 가공이 용이하고, 진동 감쇠능 및 피로 물성이 우수하며, 저렴한 가격으로 경제성이 우수한 F-05-140 분말소결재의[13, 14] 마찰용접 공정을 연구하였다. 마찰용접 공정에서 접합부의 기계적 물성과 열영향부 방출의 핵심 인자인 회전속도와 마찰압력을[15] 변수로 기계적 물성 및 미세조직을 분석하고, 상관관계를 규명함으로써 공정에 따른 접합 특성을 고찰하였다. 이를 통해 선박 및 자동차와 같은 수송기 핵심 부품의 생산단가 절감 및 기계적 물성 개선을 달성하고자 하였다.

1. Introduction

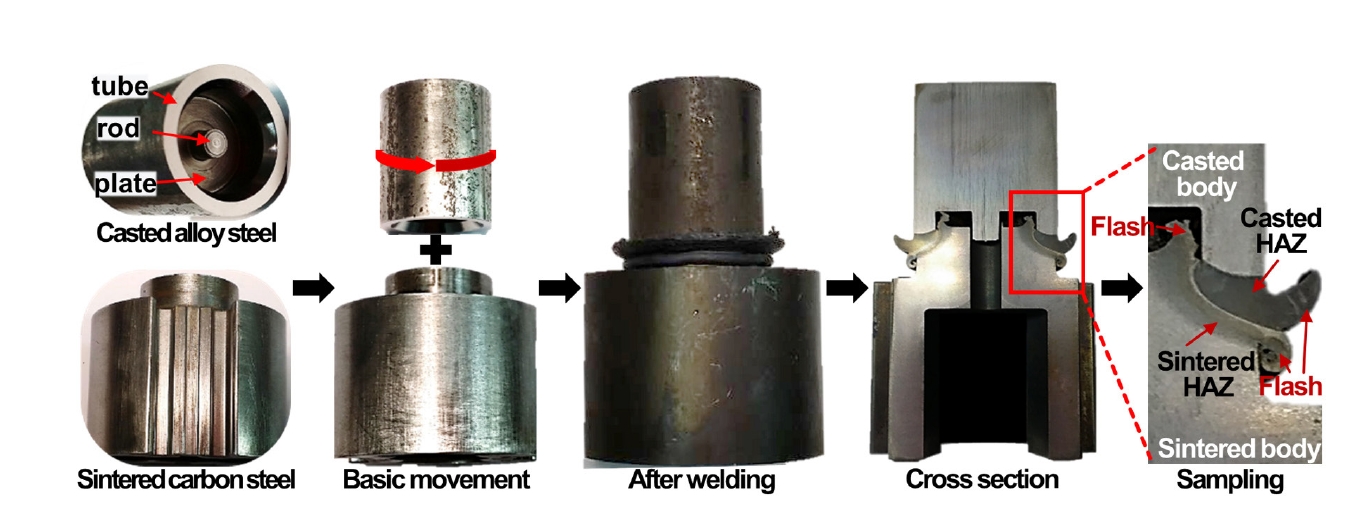

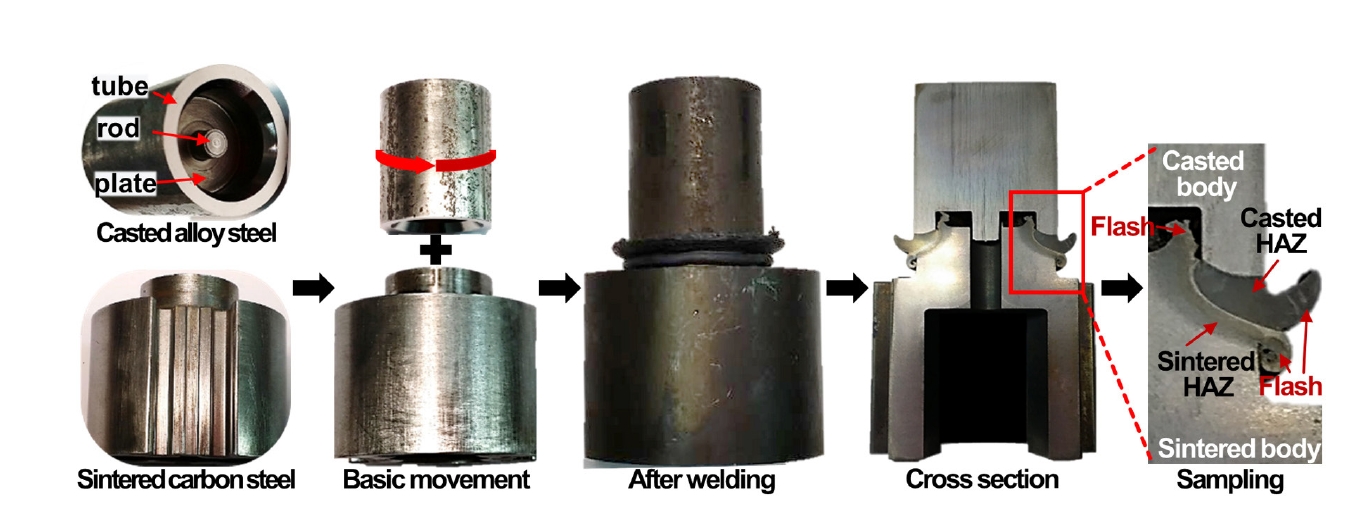

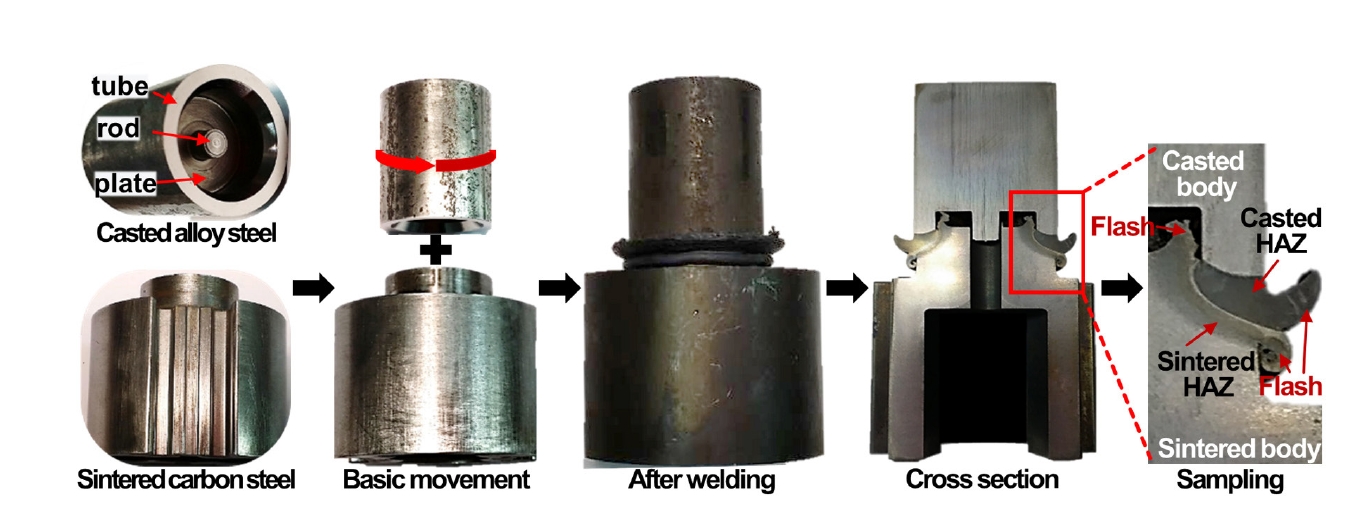

- 본 연구는 F-05-140 분말소결재 탄소강과 SCM440 주조재 합금강의 이종재료 마찰용접 시, 접합부 물성을 향상하기 위해 마찰용접공정에 따른 미세조직과 기계적 물성의 상관성을 연구하였다. F-05-140 분말소결재 탄소강은 순철 분말과 탄소 분말을 혼합하여 800 MPa로 유압 성형 후 질소 분위기에서 1130°C로 소결하였으며, 다양한 형태의 접합부(봉(rod), 관(tube), 판(plate))가 공존하게 제조되었다. SCM440 주조재 합금강은 연속 주조 후 인발 공정으로 제조하였으며, 소결재의 접합부에 맞게 제작되었다. SCM440 주조재와 F-05-140 분말소결재의 조성은 표 1과 같으며, 마찰용접 전 시편과 용접 후 샘플은 그림 1에 나타내었다.

- F-05-140 분말소결재와 SCM400 주조재의 이종재료 접합은 마찰용접기(friction welder, FW, F-250, Nitto Seiki, Japan)를 이용하였고, 접합 후 풀림 처리(620°C, 2h) 및 표면 연삭을 수행하여 샘플을 제조하였으며, 마찰용접의 공정 조건은 표 2와 같다. 또한, 용접 공정 조건에 따른 접합 형상을 확인하기 위해 식각(etching) 후 광학카메라(optical camera, RS-IMX333, Sony, Japan)로 관찰하였으며(그림 1(e)), 광학현미경(optical microscope, OM, BX51M, Olympus, Japan) 및 전계방사형 주사전자현미경(field-emission scanning electron microscope, FE-SEM, JSM 7500F, Jeol, Japan)-에너지분산분광기(energy-dispersive X-ray spectroscope, EDS, INCA x-act, Oxford, UK)를 이용하여 미세조직을 분석하였다. 용접면 원소재부와 열영향부의 면적 비교 및 기계적 물성을 확인하기 위해 마이크로 비커스 경도계(micro-Vickers hardness tester, HM-200, Mitutoyo, Japan)로 각 영역별 경도 측정 및 경도 매핑을 수행하였으며, 이종재료 마찰용접에서 공정에 따른 미세조직 및 기계적 물성의 상관성을 분석하였다.

2. Experimental

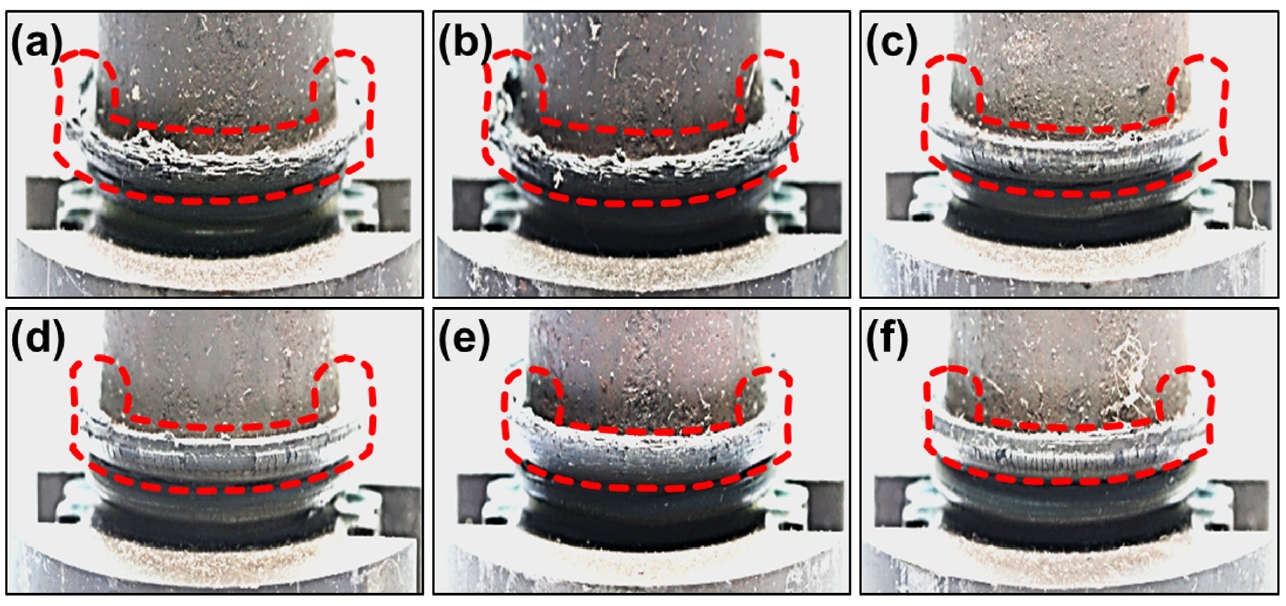

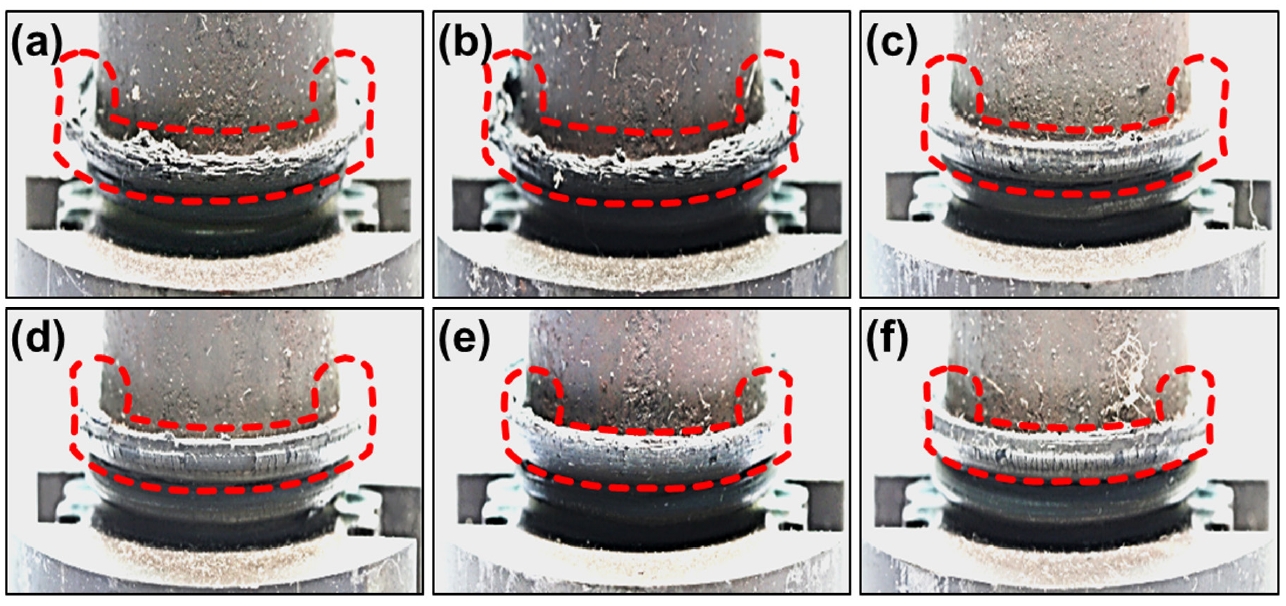

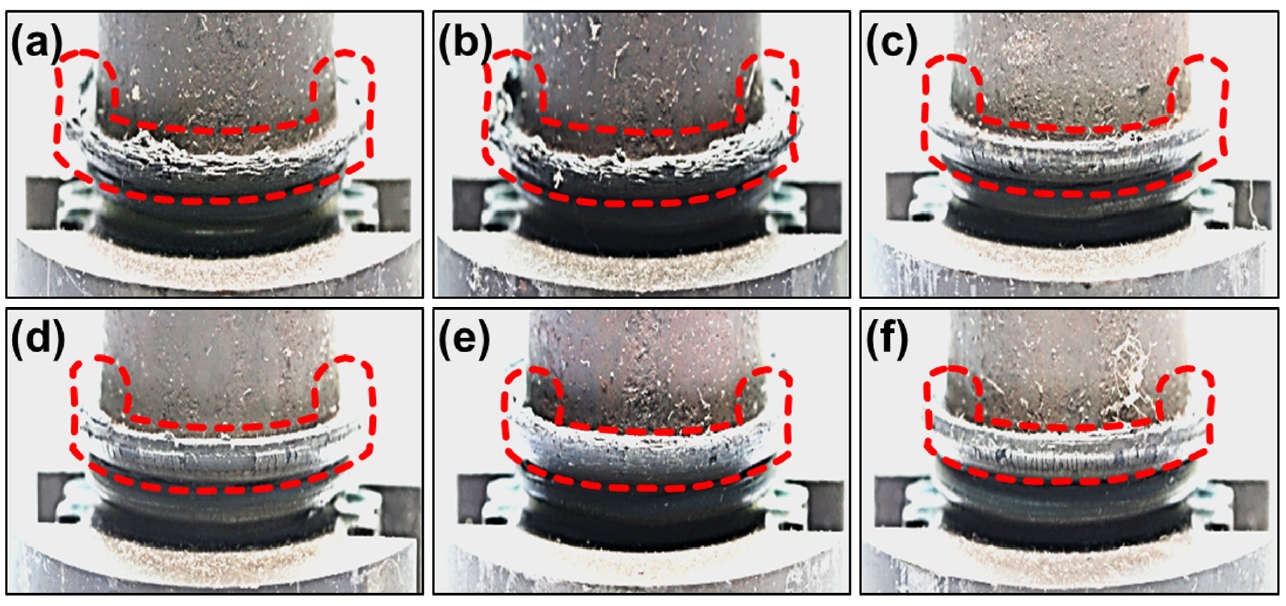

- 본 연구는 탄소강과 주조재 합금강을 다양한 마찰용접 형상에 맞게 가공하여 이종재료 마찰용접을 수행하였으며, 상대적으로 취약 미세조직이 발생할 확률이 높음과 동시에 낮은 기계적 물성을 가지는 용접부(welding zone)를 최소화하는 이종재료 마찰용접을 달성하기 위해 공정 조건 중 회전속도와 마찰압력을 제어하여 공정 설계에 따른 미세조직과 기계적 물성을 연구하였다. 이종재료 마찰용접 후 용접부가 플래시(flash)로 배출되는 형상을 확인하기 위해 광학 카메라로 용접 부위의 외부 형상을 관찰하였으며, 그림 2는 그 결과이다.

- 상대적으로 낮은 회전속도에서 이종재료 마찰용접을 수행하였을 때, 플래시의 형상은 불규칙하며, 용접 부위 바깥으로 불균일하게 방출되는 형태를 나타냈다(그림 2(a-c)). 반면, 2000RPM에서 수행된 마찰용접에서 플래시는 SCM440 합금강 방향으로 균일한 두께로 밀려나는 형태로 방출되었으며, 1500RPM과 비교하여 플래시의 양이 증가하였다. 마찰압력이 증가하였을 때, 플래시의 양은 증가하며, 상대적으로 얇은 두께의 플래시가 발생함을 확인할 수 있다. 이는 회전속도와 마찰압력이 이종재료 마찰용접에 사용되는 소재(F-05-140 분말소결재, SCM440 주조재)가 연화 되기 충분한 에너지를 공급하지 못하였을 때, 용접 부위의 열 유동 및 소성 변형이 균일하게 발생하지 못하고[16], 불균일한 소성 유동을 유발함과 동시에 취약상이 발생할 수 있는 용접부를 플래시로 배출하지 못한 결과를 발생시킬 수 있다[17, 18].

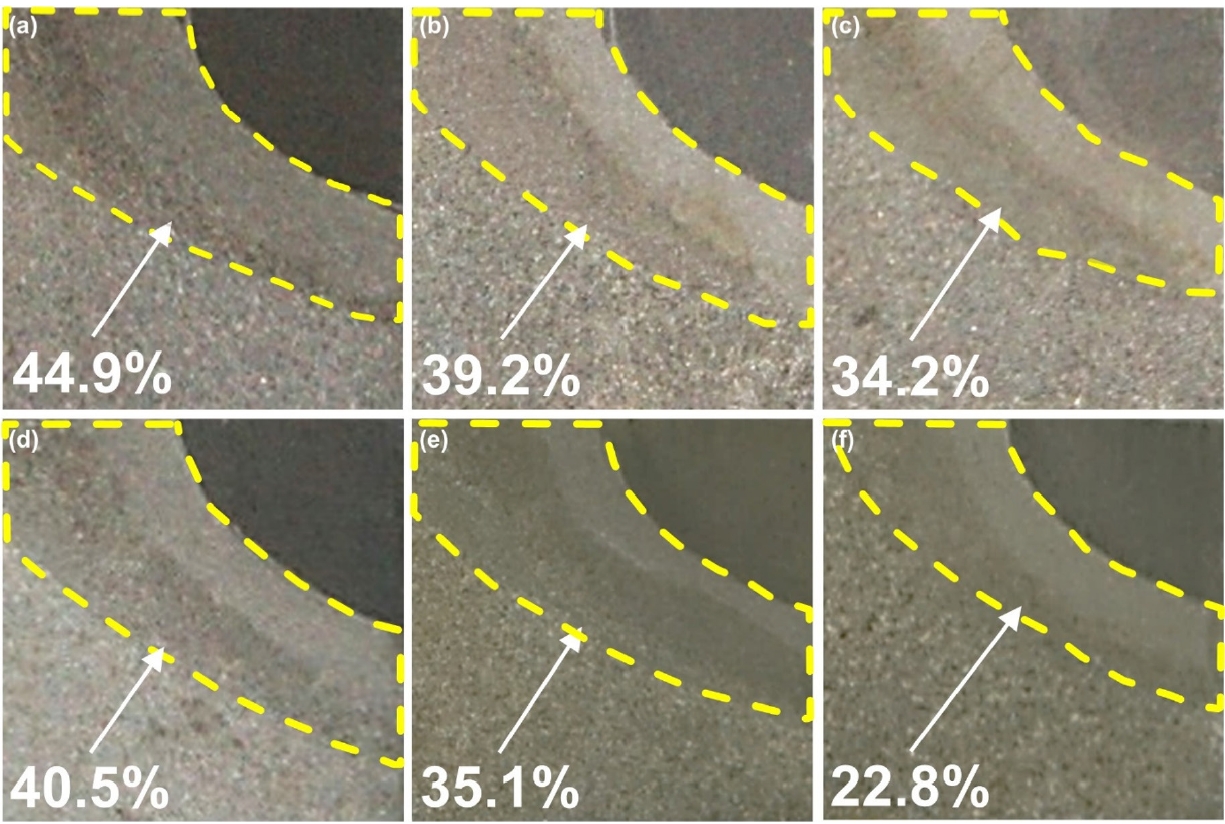

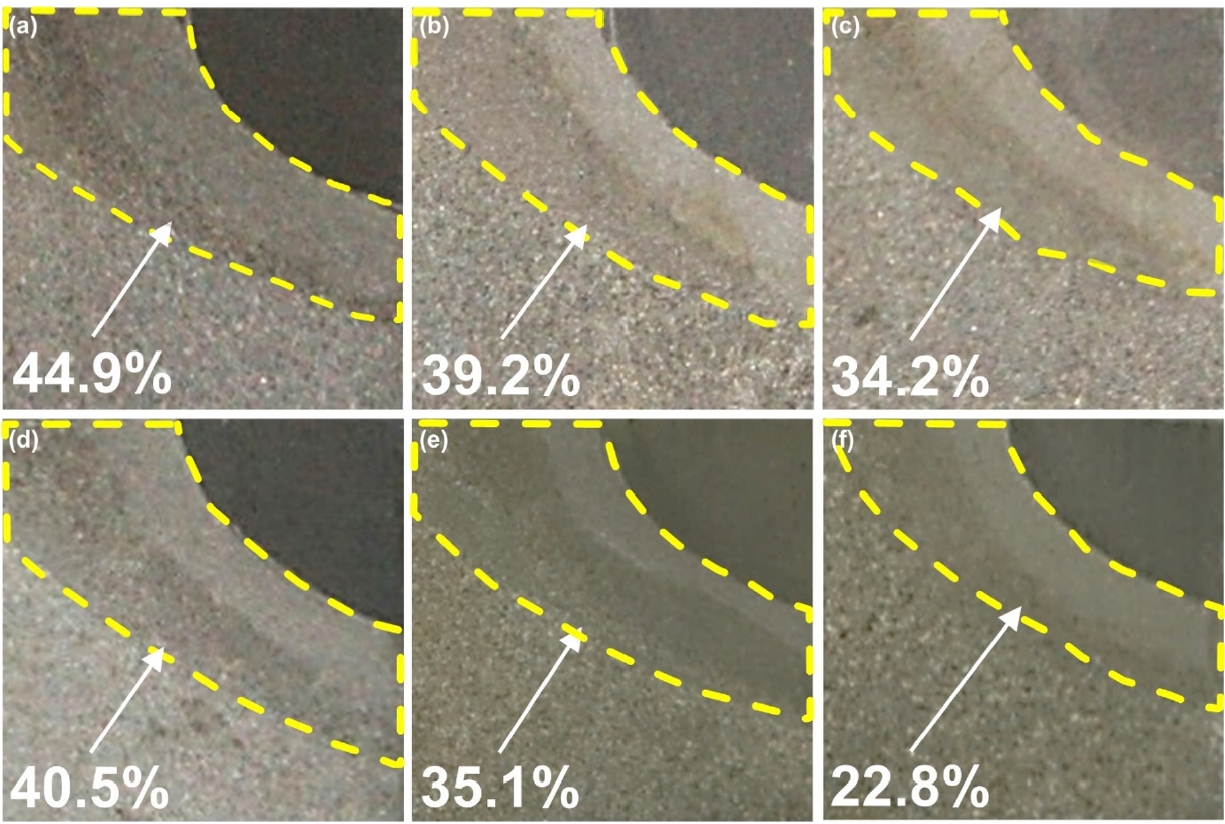

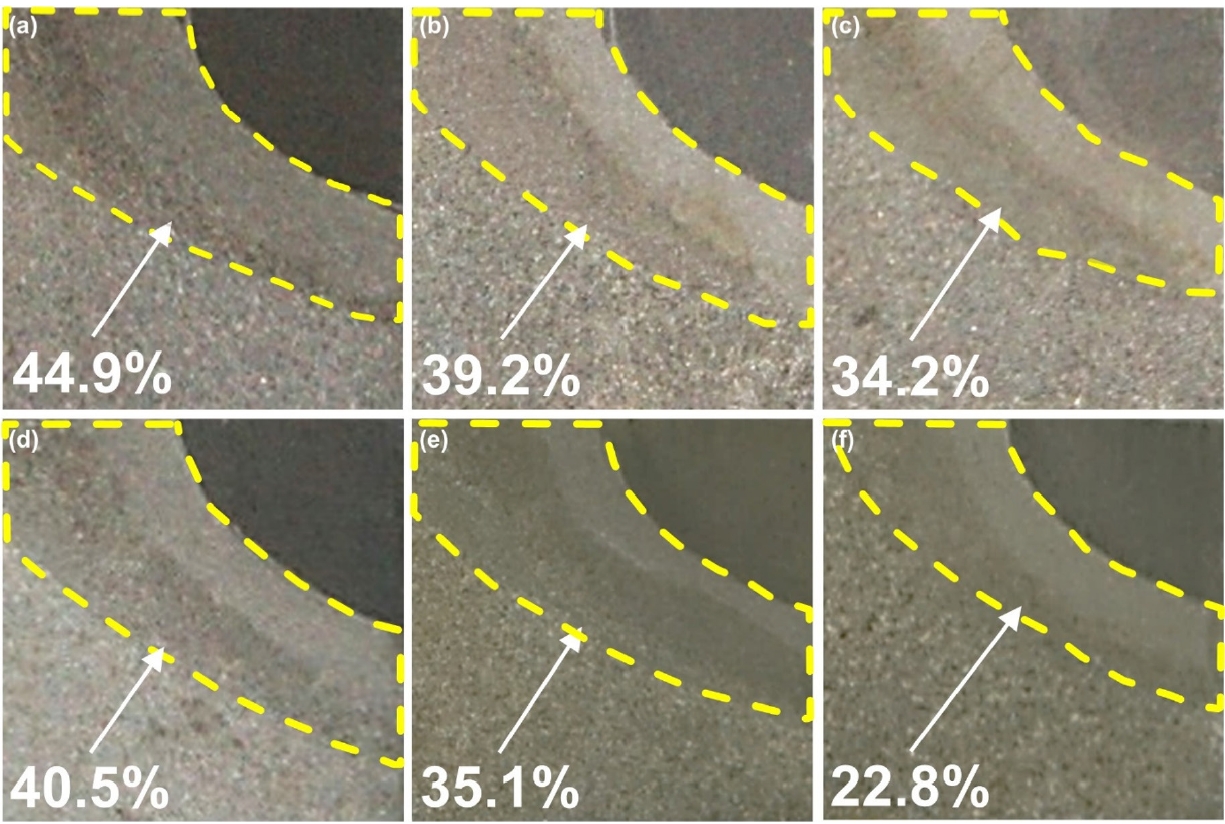

- 공정 조건에 따른 소성 유동은 이종재료 마찰용접에서 상대적으로 기계적 물성이 낮은 F-05-140 탄소강의 미세조직에 큰 영향을 미칠 것으로 판단되었으며[19], 이를 확인하기 위해 F-05-140 분말소결재 용접 부위의 용접부, 열영향부(Heat affected zone, HAZ), 모재(matrix)의 비율을 확인하고자 하였다. 고해상도 근접촬영용 광학 카메라를 이용하여 동일한 위치에서 F-05-140 모재, F-05-140 열영향부, 용접부, SCM440 열영향부를 촬영하였으며, F-05-140 열영향부의 상대적인 비율을 분석하였다(그림 3).

- 이종재료 마찰용접의 회전속도와 마찰압력이 증가할수록 F-05-140 분말소결재의 열영향부는 감소하는 결과를 확인하였으며, 측정한 결과는 1500RPM에서 200MPa - 44.9%, 300MPa - 39.2%, 400MPa - 34.2%로, 2000RPM에서 200MPa - 40.5%, 300MPa - 35.1%, 400MPa - 22.8%로 확인되었다(그림 2). 이는 그림 2의 플래시 배출양의 양상과 유사하며, 이종재료 마찰용접 시 용접부 뿐만 아니라 상대적으로 기계적 물성이 낮은 재료의 열영향부도 플래시로 배출될 수 있음을 의미한다[20]. 또한, 2000RPM에서 마찰압력이 증가할수록 플래시 배출량이 급격히 증가하였는데(40.5% → 22.8%), 이는 마찰용접에서 공정 조건을 통해 확보한 마찰에너지가 비선형적으로 용접 부위의 소성 유동을 증가시킨 결과로 판단된다[21, 22].

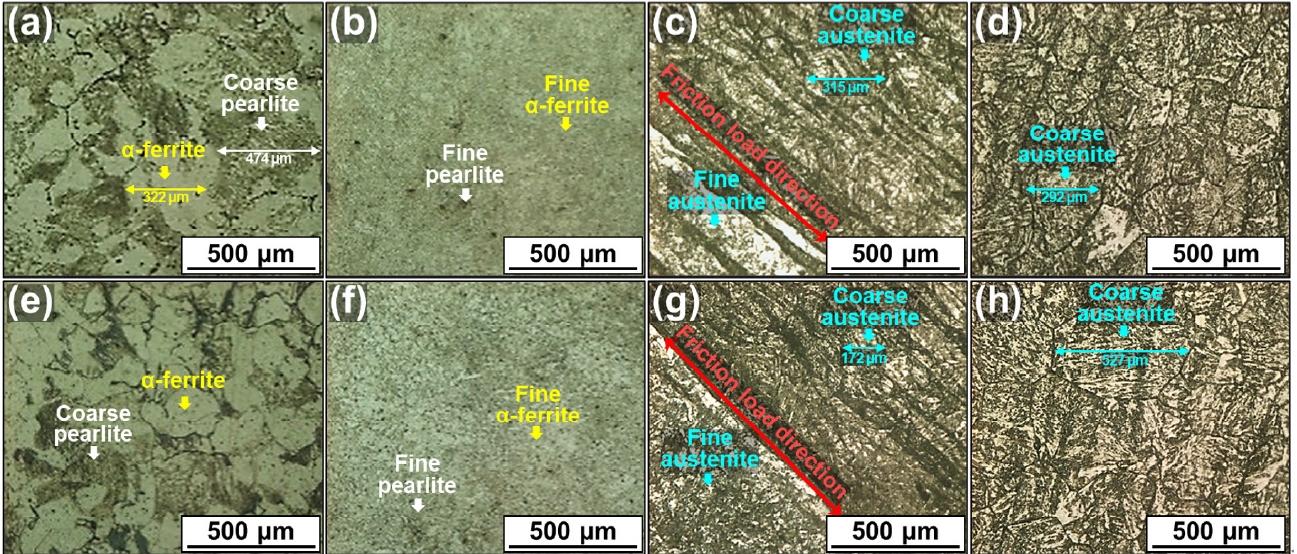

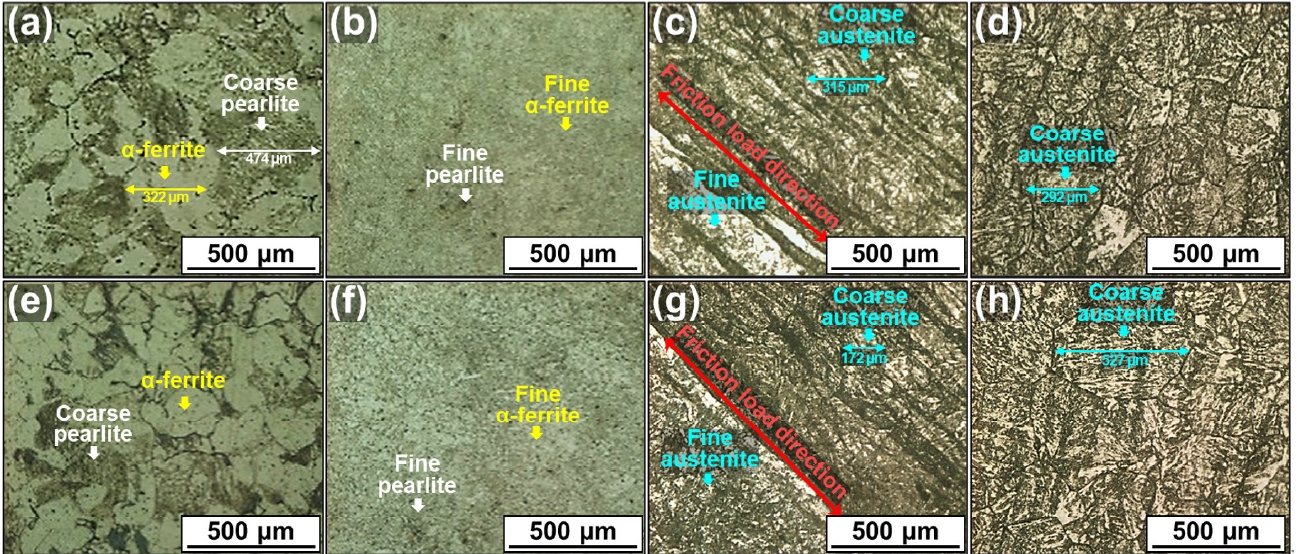

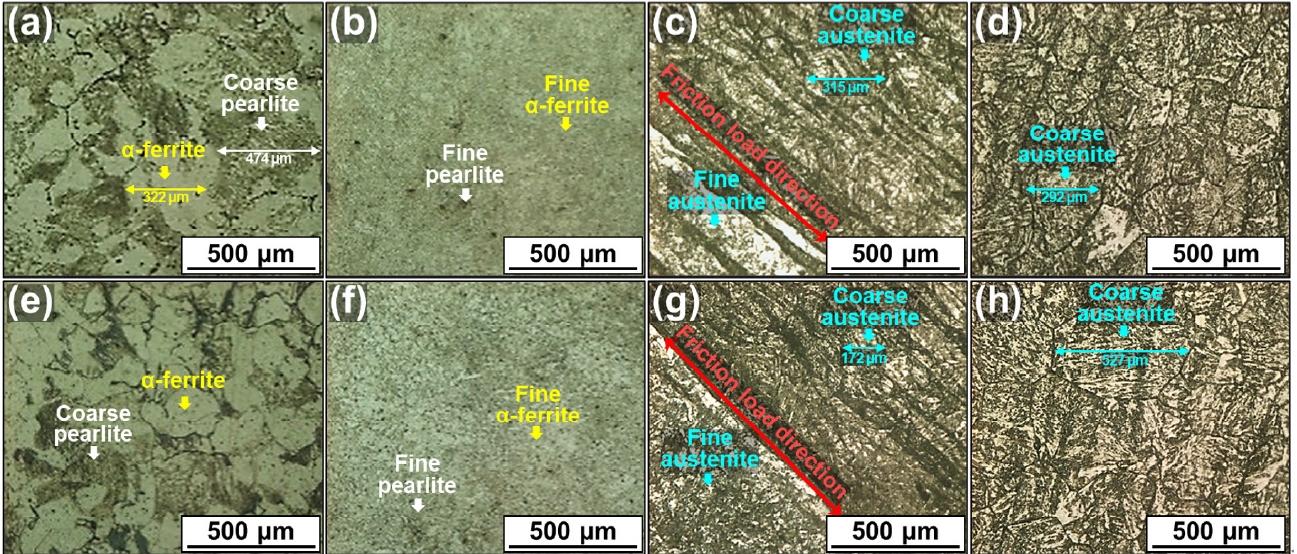

- 용접 부위의 미세조직 변화를 관찰하기 위해 1500RPM - 200MPa 조건과 2000RPM - 400 MPa에서 수행한 이종재료 마찰용접의 용접 부위에서 광학현미경 관찰을 수행하였으며, 그림 4는 F-05-140 분말소결재의 모재와 열영향부, SCM440 주조재의 모재와 열영향부 관찰 결과이다.

- F-05-140 탄소강 분말소결재의 모재에서는 아공석강(hypo-eutectoid steel)의 특징인 α-페라이트(α-ferrite) 및 시멘타이트(cementite)와 페라이트가 라멜라(lamellar) 구조를 가지는 펄라이트(pearlite)가 조대하게 관찰되었으며, α-페라이트와 펄라이트는 각 306μm와 361μm의 평균 결정립 크기를 나타냈다(그림 4(a, e)). 반면 F-05-140의 열영향부에서는 상대적으로 미세한 페라이트와 펄라이트가 관찰되었다(그림 4(b, f)). SCM440의 모재에서 약 400μm 크기의 오스테나이트(austenite) 상과 단류선이 관찰되었으며(그림 4(d, f)), 열영향부에서는 용접 부위에 가까울수록 미세한 오스테나이트가, 멀수록 조대한 오스테나이트가 관찰됨과 동시에 마찰 응력 방향이 회전 방향의 45%로 형성되었다(그림 4(c, g)). 열영향부는 모재부와 비교하여 결정립 크기가 급격히 감소하는 결과를 보이는데, 이는 마찰용접 중 가해진 마찰압력과 열에너지로 인해 소성 유동이 발생하고, 소성 유동으로 인해 전위(dislocation)가 급격히 성장하여 새로운 결정립계를 형성함으로써 결정립 미세화가 발생하며, 용융된 강이 하부 임계 냉각속도에 근접한 속도로 냉각될 때 상대적으로 부족한 확산속도에 의해 재결정화가 미세한 펄라이트 및 오스테나이트 내부에 베이나이트가 형성된 것으로 보인다[23-25]. Hall-Patch equation의 관점에서 결정립계가 감소하면, 소성 변형에서 상호 간섭할 수 있는 슬립(slip) 수가 증가하고, 슬립방향의 제한이 발생하여 기계적 물성이 향상될 것으로 예상된다[26]. 하지만, 이종재료 마찰용접은 1500RPM - 200MPa와 2000RPM - 400MPa 공정 조건에서 열영향부의 미세조직에 큰 차이를 보이지 않는데, 이는 열변형을 받은 용접 부위가 마찰용접의 소성 유동을 통해 플래시로 배출됨으로써, 유사한 영향을 받은 미세조직만 잔류한 결과로 판단된다[27, 28].

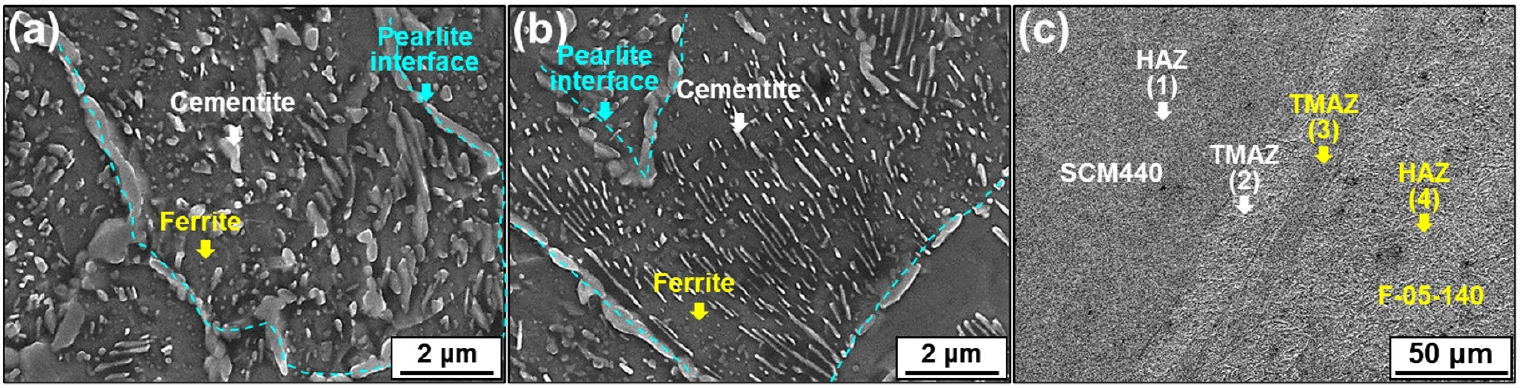

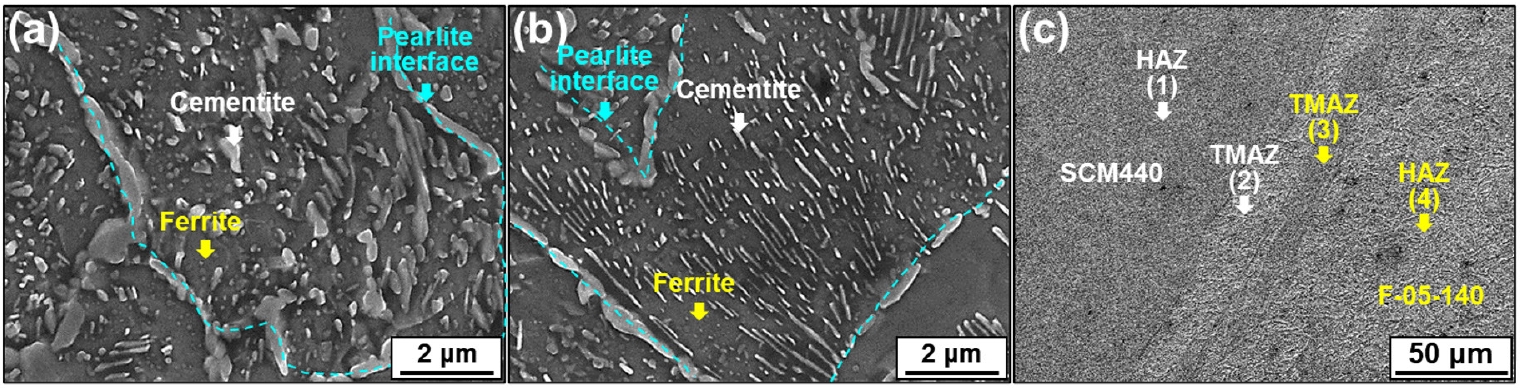

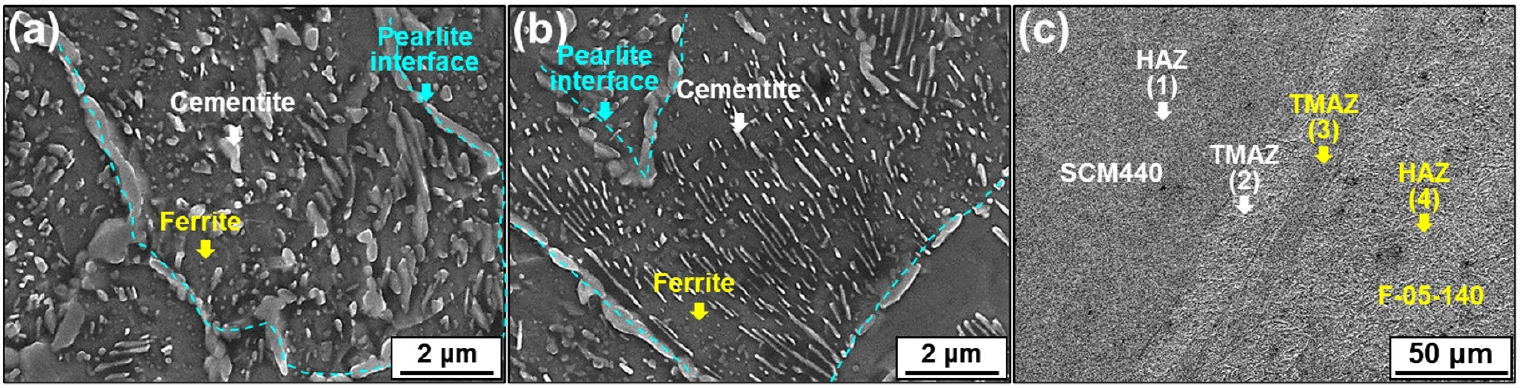

- 마찰 용접 조건에 따른 F-05-140 분말소결재 열-기계적영향부 미세조직을 관찰하기 위해 1500RPM - 200MPa 조건과 2000RPM - 400MPa에서 마찰 용접 후 전계방사형 주사전자현미경 관찰을 수행하였으며, 그림 5(a, b)에 나타내었다. 또한, 용접부에서 발생하는 물질 전이를 확인하기 위해 주사전자현미경 관찰을 수행하여 그림 5(c)에 나타내었으며, 각 미세조직의 성분분석을 위해 에너지 분산 분광법으로 분석하여 표 3에 정리하였다.

- 1500RPM - 200MPa 조건에서 수행된 마찰용접 후 F-05-140 탄소강 분말소결재의 열-기계적영향부는 약 10μm의 펄라이트 결정립계를 나타냈으며, 펄라이트 내부의 시멘타이트가 마찰열로 인해 페라이트와 분리되어 불규칙한 구형으로 관찰되었다(그림 5(a)). 상대적으로 높은 마찰열로 인해 다량의 열영향부가 플래시로 배출되는 2000RPM – 400MPa 조건에서 수행된 마찰용접 후 F-05-140 열-기계적영향부의 미세조직에서 펄라이트 결정립 크기는 10μm로 다른 마찰용접 조건의 열-기계적영향부 미세조직과 유사하였으나, 시멘타이트가 그림 5(b)와 같이 미세한 침상으로 관찰되었다. 이는 마찰용접 중 가해진 마찰압력과 열에너지로 인한 소성 유동이 전위를 급격히 성장시킴과 동시에 높은 마찰압력은 플래시 배출 속도를 증가시키며, 이로 인해 상대적으로 낮은 마찰압력과 열에너지를 가지는 마찰용접 조건에서는 가열-냉각 시간이 길어 시멘타이트가 구상화되지만, 높은 마찰압력 조건에서는 재결정화가 활발히 일어나 베이나이트와 유사한 미세조직을 나타내는 것으로 보인다[23-26]. 그림 5(c)는 2000RPM - 400MPa 조건으로 마찰용접한 F-05-140 분말소결재와 SCM440 주조재의 접합부 주사전자현미경 사진이며, SCM440 주조재는 흰색으로(열영향부(1), 열-기계적영향부(2)) F-05-140 분말소결재는 노란색으로(열-기계적영향부(3), 열영향부(4)) 표시하였다. 표 3에서 나타낸 에너지분산분광법 결과에서 각 소재의 열영향부는 모재와 유사한 조성을 나타내는 반면, 열-기계적영향부는 접합 상대 소재와 유사한 조성을 나타내었다. 이는 마찰용접 용융부가 마찰압력으로 인해 충분히 플래시로 배출된 결과로 판단되며[28], 마찰용접부의 물질 전이를 통해 우수한 접합부 기계적 물성을 나타낼 것으로 보인다[29].

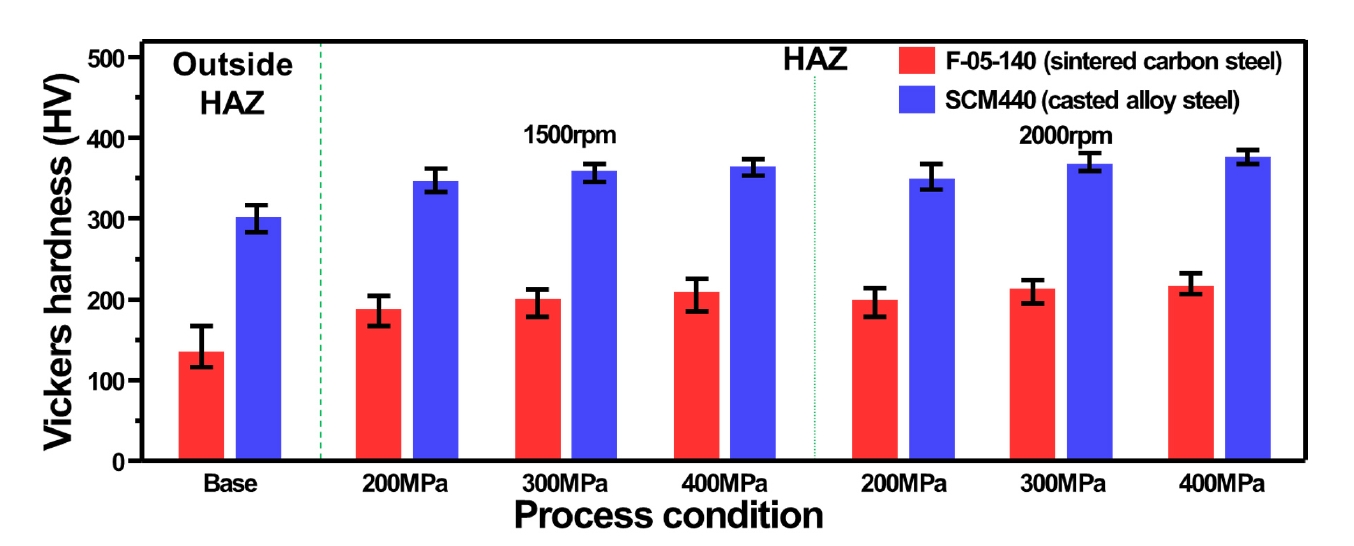

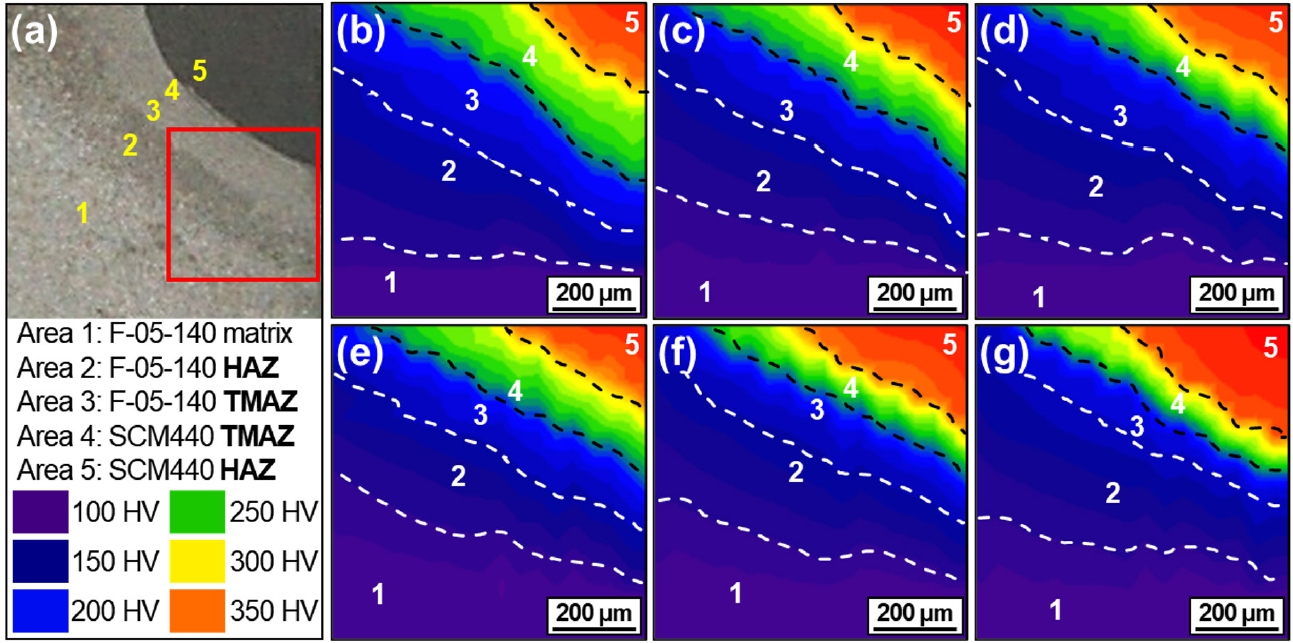

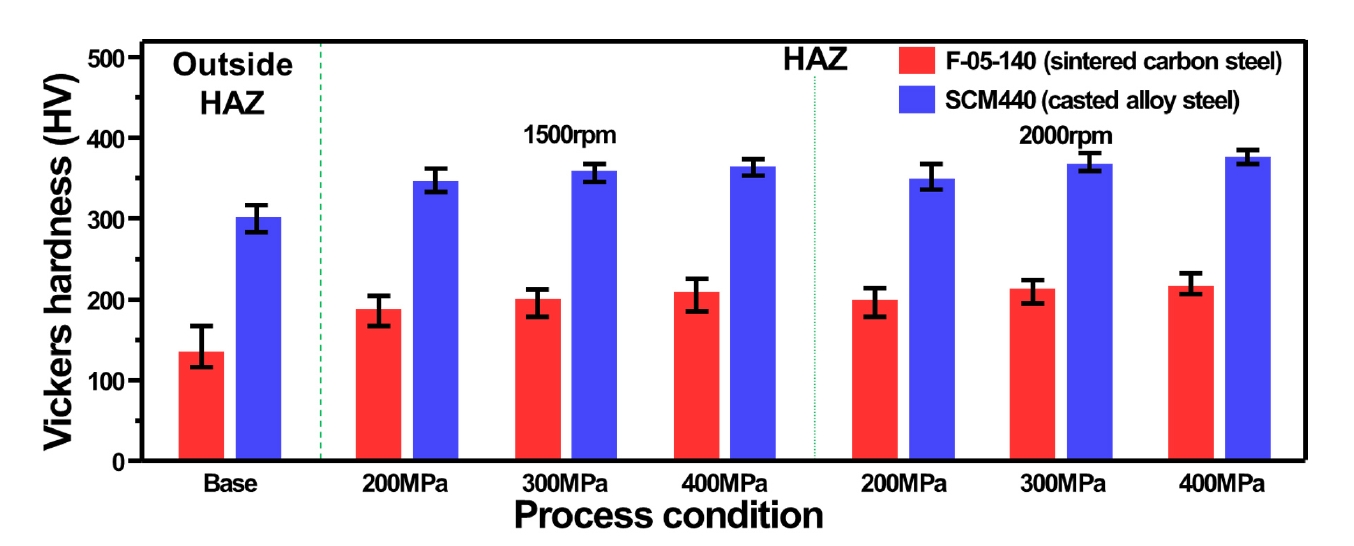

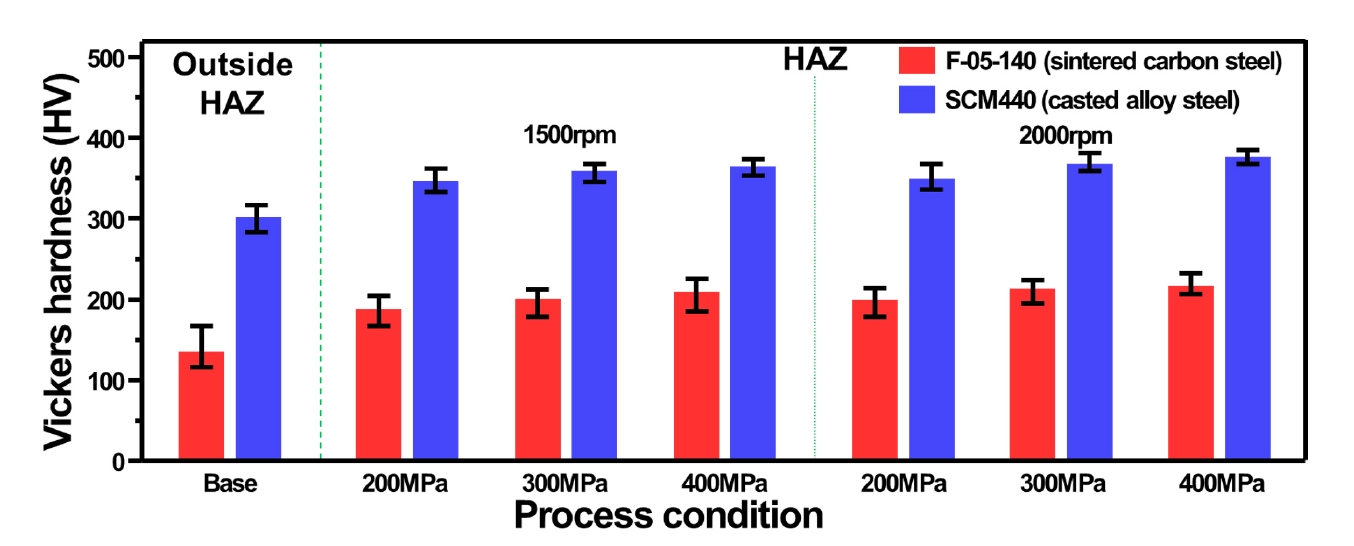

- 마찰용접 조건에 따른 용접부의 기계적 물성을 확인하기 위해, 모재와 각 공정 조건에 따른 열영향부의 경도를 측정하였으며, 마이크로 비커스 경도(Micro-Vickers Hardness) 측정 결과를 이를 그림 6에 정리하였다.

- 마찰용접에 영향을 받지 않는 F-05-140 탄소강 모재부는 모든 조건에서 137.12HV ±37.51의 경도 값을 나타내었으며, SCM440 합금강 모재부는 300.07HV ±16.27의 결과를 나타내었다. 이는 F-05-140 분말소결재와 SCM440 주조재의 경도와 유사한 결과이며, 상대적으로 편차가 큰 F-05-140 탄소강은 분말소결재의 특징인 낮은 상대 밀도로 인한 결과로 판단된다[29-31]. 마찰용접 후 F-05-140과 SCM440 열영향부의 경도는 1500RPM - 200MPa, 300MPa, 400MPa 마찰 용접 조건에서 각 189.12HV ±18.79 / 347.27HV ±14.59, 201.71HV ±15.72 / 359.11HV ±12.71, 209.27HV ±14.72 / 363.29HV ±9.73이며, 2000RPM - 200MPa, 300MPa, 400MPa 마찰 용접 후, 각 201.55HV ±16.57 / 349.12HV ±15.72, 217.37HV ±12.17 / 361.59HV ±10.07, 218.53HV ±11.39 / 370.43HV ±5.31로 측정되었다. 모재부와 비교하여 F-05-140 열영향부는 마찰용접 조건에 따라 40~60% 경도 값이 향상되었고, SCM440 열영향부는 마찰용접 조건에 따라 16~24% 경도가 향상되었으며, 회전속도와 비교하여 마찰압력이 향상될수록 큰 경도 상승폭을 나타내었다. F-05-140 탄소강은 분말소결재로, 마찰용접을 통해 기공이 치밀화 됨과 동시에 마찰에너지를 통한 결정립 미세화가 발생하고, SCM440 합금강의 첨가원소들이 확산되어 상대적으로 열영향부의 기계적 물성이 크게 향상되었으며, SCM440 합금강의 열영향부는 오스테나이트의 결정립미세화를 통한 기계적 물성 향상되어 20% 정도의 기계적 물성 향상을 나타낸 것으로 판단된다[20, 32]. 마찰압력 및 회전속도에 따라 열영향부의 경도는 큰 차이를 보이지 않으나, 편차가 감소하게 되는데, 마찰압력 및 회전속도가 증가함에 따라 취약한 용융부가 플래시로 배출되고, 균일한 미세조직을 잔류하는 결과로 볼 수 있다[32].

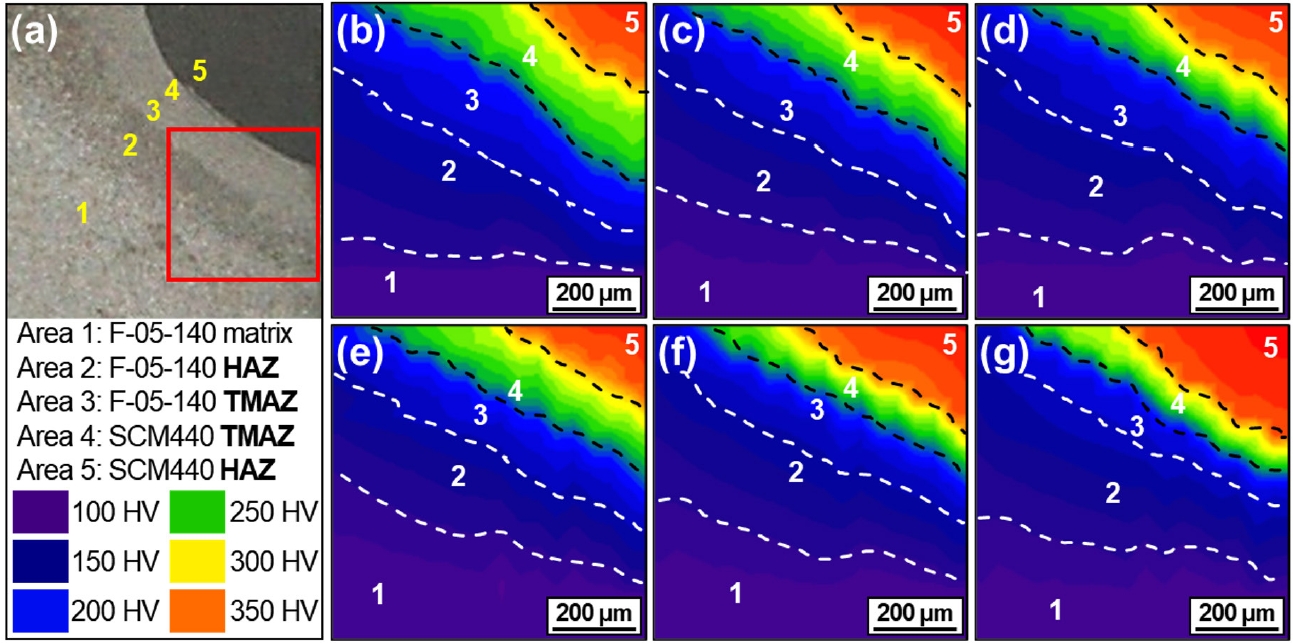

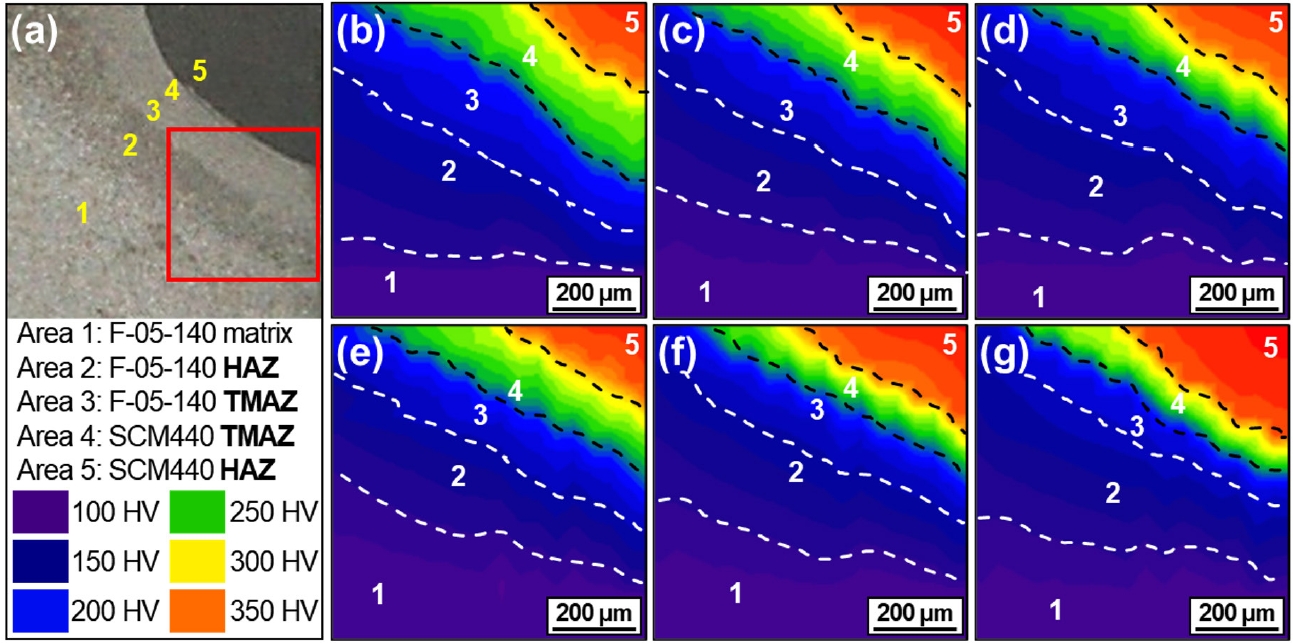

- 마찰용접 조건에 따른 F-05-140과 SCM440의 열영향부와 열-기계적영향부 변화를 확인하기 위해 경도 매핑을 수행하였으며, 결과는 그림 7과 같다.

- 경도 분포 및 미세조직 분석을 기반으로 마찰용접 후 F-05-140 탄소강 분말소결재의 모재부, 열영향부, 열-기계적영향부와 SCM440 합금강 주조재의 열-기계적영향부, 열영향부를 분석하였으며, 150HV이하 구간은 F-05-140 모재 (1), 150~200HV 구간은 F-05-140 열영향부 (2), 200~250HV 구간은 F-05-140 열-기계적영향부 (3), 250~350HV 구간은 SCM440 열-기계적영향부 (4), 350HV 이상은 SCM440 열영향부로, 미세조직 분석 결과와 일치하였다. 회전속도가 증가함에 따라 접합부의 열-기계적영향부는 감소하는 경향을 보였으며, 마찰압력이 증가함에 따라 열영향부 또한 감소하는 경향을 확인할 수 있다. 이는 마찰용접에서 회전속도와 마찰압력 모두 마찰에너지를 증가시킴으로써, 열-기계적영향부가 플래시로 배출되는 속도를 증가시키며, 결과적으로 마찰에너지가 증가할수록 마찰용접 후 열-기계적영향부의 부피는 감소한다[30, 33]. 반면, 열영향부는 마찰압력 증가로 발생되는 마찰에너지 증가가 열에너지를 향상시키며, 이로 인해 모재부로 보다 깊이 열영향부가 나타나는 현상으로 관찰된다[32-34]. 본 연구에서는 마찰용접부의 기계적 물성 개선을 목표로 하였으므로, 상대적으로 기계적 물성이 우수한 열영향부가 존재하고, 접합 특성을 향상할 수 있으나, 석출과 같은 취약 미세구조를 발생할 수 있는 열-기계적영향부가 최소화 될 수 있는 2000RPM - 400MPa 마찰용접 조건이 F-05-140 탄소강 분말소결재와 SCM440 합금강 주조재의 최적 공정 조건이라 판단된다.

3. Results and Discussion

- 본 연구는 이종재료 마찰용접의 공정 조건에 따른 접합부 물성을 향상하기 위해, 강도와 인성, 내마모성이 우수한 SCM440 합금강 주조재와, 진동 감쇠능과 피로물성이 우수하며, 기계가공이 용이한 F-05-140 탄소강 주조재의 마찰용접 후 미세조직 변화와 기계적 물성의 상관성을 규명하였으며, 다양한 형태의 접합부가 공존하는 소재의 이종재료 마찰용접의 용접부 물성을 향상하였다. 이종재료 간 마찰용접 수행 시, 마찰압력과 회전속도가 미세조직에 미치는 영향을 확인하여, 이를 기계적 물성과 연관지어 접합 특성을 연구하였다. 공정 조건에 제어된 이종재료 마찰용접에서 취약부로 작용하는 용융부를 플래시를 통해 제거하였으며, 열-기계적영향부를 잔류시킴으로써 접합 특성을 향상하였다. 결과적으로 마찰용접 후 열영향부와 열-기계적영향부는 500μm 이하의 두께를 가졌으며, 모재와 비교하여 F-05-140 탄소강 분말소결재 열영향부는 60%, SCM440 합금강 주조재 열영향부는 24% 향상되었으며, 이는 접합부의 취약 미세조직를 회피하였음에도 상용 소재와 비교하여 우수한 기계적 물성과 접합부 특성을 나타내는 것을 시사한다. 마찰용접은 우수한 금속 접합방법임에도 한계가 존재하였으나, 본 연구와 같이 이종 재료일 뿐 아니라 제조방법의 차이가 있음에도 우수한 접합부 기계적 물성을 보여줌으로써, 마찰용접의 적용 범위를 확장할 수 있는 연구로 판단된다.

4. Conclusion

-

Conflict of Interest

저자들은 이해상충관련 해당사항 없음을 선언합니다.

-

Author Information and Contribution

이지성: 과장; conceptualization, investigation, writing–original draft, 이한성: 박사후연구원; conceptualization, investigation, writing–original draft, 송은효: 학생; investigation, writing–original draft, 안병민: 교수; conceptualization, funding acquisition, supervision, writing–review & editing.

-

Acknowledgement

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2021R1A2C1005478).

Article information

| Elemental composition (wt. %) | Fe | C | Si | Mn | Cr | Mo |

|---|---|---|---|---|---|---|

| F-05-140 | Bal. | 0.59 | - | - | - | - |

| SCM440 | Bal. | 0.54 | 0.25 | 0.76 | 1.0 | 0.2 |

| Rotational speed (RPM) | Friction pressure (MPa) | Friction time (s) | Forging pressure (MPa) | Forging time (s) |

|---|---|---|---|---|

| 1500 | 200 | 4 | 700 | 2.5 |

| 2000 | 300 | |||

| 400 |

| Point |

Composition (wt. %) |

|||||||

|---|---|---|---|---|---|---|---|---|

| Fe | C | Si | Mn | Cr | Ni | Mo | Cu | |

| (1) | 93.26 | 3.82 | 0.31 | 0.82 | 1.13 | 0.21 | 0.26 | 0.19 |

| (2) | 94.06 | 5.31 | - | - | 0.12 | - | - | 0.51 |

| (3) | 93.75 | 4.27 | 0.19 | 0.64 | 1.03 | - | 0.12 | - |

| (4) | 93.09 | 6.19 | - | - | - | - | - | 0.72 |

- 1. G. B. Sathishkumar, P. Sethuraman, C. Chanakyan, S. Sundaraselvan, A. J. Arockiam, S. V. Alagarsamy, A. Elmariung, M. Meignanamoorthy, M. Ravichandran and S. Jayasathyakawin: Mater. Today Proc., 81 (2023) 208.Article

- 2. H. Ma, G. Qin, P. Geng, S. Wang and D. Zhang: J. Manuf. Process., 61 (2021) 349.Article

- 3. S-.H. An and Y-.K. Jeong: J. Powder Mater., 31 (2024) 37.ArticlePDF

- 4. H. Lee, M. Kim and B. Ahn: J. Powder Mater., 30 (2023) 332.Article

- 5. S. Sundaraselvan, N. Senthilkumar, T. Balamurugan, C. Kaviarasu, G. B. Sathishkumar and M. Rajesh: Mater. Today Proc., 74 (2023) 91.Article

- 6. N. Xu, Z. H. Qiu, B. K. Gu, Z. Y. Liu, S. Y. Zhu, Q. N. Song, D. Wang and J. Shen: J. Mater. Res. Technol., 30 (2024) 3594.Article

- 7. Z. Guo, T. Ma, X. Yang, W. Li, Q. Xu, Y. Li, J. Li and A. Vairis: Mater. Sci. Eng., A, 909 (2024) 146818.Article

- 8. Z. Guo, T. Ma, X. Yang, J. Tao, J. Li, W. Li and A. Vairis: Mater. Sci. Eng., A, 872 (2024) 144991.Article

- 9. J. Liu, B. Wu, Z. Wang, C. Li, G. Chen and Y. Miao: Mater. Des., 225 (2023) 111520.Article

- 10. K-.Y. Kim, M-.H. Oh and I-.C. Choi: J. Korean Soc. for Heat Treat., 34 (2021) 309.

- 11. B. Vinith, S. A. D. Dharshan, S. Aravind and B. K. Singh: Int. J. Inter. Des. Manuf., 17 (2023) 1443.ArticlePDF

- 12. A. Sharma, H. Lee and B. Ahn: J. Mater. Sci., 57 (2022) 17957.ArticlePDF

- 13. D. G. Hattingh, M. N. James, F. K. Schwim, R. Opperman, D. Bernard and I. Wedderburn: Int. J. Press. Vessels Pip., 210 (2024) 105263.Article

- 14. H. Wang, G. Qin, B. Fu, Y. Gao and C. Li: Mater. Des., 245 (2024) 113234.Article

- 15. H. Lee, A. Sharma and B. Ahn: J. Mater. Sci., 57 (2022) 18089.ArticlePDF

- 16. W. Zhao, Y. Zhu, X. Yi, M. Zhai, K. Zhao, F. Wang, A. Fu and H. He: Mater. Today Commun., 40 (2024) 109459.Article

- 17. H. Lee, A. Sharma and B. Ahn: J. Alloys Compd., 947 (2023) 169545.Article

- 18. K. Tonekura, T. Shinohara and K. Masaki: J. Manuf. Process., 68 (2021) 158.Article

- 19. W. Y. Li, S. X. Shi, F. F. Wang, T. J. Ma, J. L. Li, D. L. Gao and A. Vairis: Int. J. Therm. Sci., 67 (2013) 192.Article

- 20. A. Sharma, H. Lee and B. Ahn: Powder Metall., 64 (2021) 192.Article

- 21. C. Y. Jiang, L. H. Wu, F. C. Liu, P. Xue, B. L. Xiao, D. R. Ni and Z. Y. Ma: J. Mater. Res. Technol., 29 (2024) 3340.Article

- 22. D. Zhang, G. Qin, P. Geng and H. Ma: J. Manuf. Process., 64 (2021) 20.Article

- 23. S. Sangal and K. Mondal: Wear, 500-501 (2022) 204355.Article

- 24. L. K. Huang, F. Liu and M. X. Huang: J. Mater. Sci. Technol., 176 (2024) 211.Article

- 25. T. Zhang, Y. Wang, C. Zhang, L. Wang, H. Di and W. Xu: Int. J. Fatigue, 172 (2023) 107641.Article

- 26. I. Gutierrez: Mater. Sci. Eng., A, 571 (2013) 57.Article

- 27. J. Luo, Y. H. Ye, J. J. Xu, J. Y. Luo, S. M. Chen, X. C. Wang and K.W. Liu: Mater. Des., 30 (2009) 353.Article

- 28. W.-Y. Li, T. J. Ma, S. Q. Yang, Q. Z. Xu, Y. Zhang, J. L. Li and H. L. Liao: Mater. Lett., 62 (2008) 293.Article

- 29. S. Li, L. Shi, J. Chen, X. Yang, A. Hartmaier and C. Wu: Mater. Sci. Eng. A, 896 (2024) 146267.Article

- 30. D. Ambrosio, Y. Morisada, K. Ushioda and H. Fujii: J. Mater. Process. Technol., 320 (2023) 118116.Article

- 31. Y. Zhang, P. Zhao, Y. Tong, H. Dong, J. Zhou, F. Qin, Y. Bi and P. Li: Materials, 17 (2024) 1342.Article

- 32. F.C. Liu and T.W. Nelson: Mater. Sci. Eng. A, 710 (2018) 280.Article

- 33. S. Fukumoto, S. Tanaka, T. Ono, H. Tsubakino, T. Tomita, M. Aritoshi and K. Okita: Mater. Trans., 47 (2006) 1071.Article

- 34. Y. Lu, X. Zhang, H. Wang, C. Kan, F. Zhang, P. Dai and H. Wang: Mater. Charact., 189 (2022) 111959.Article

References

Figure & Data

References

Citations

Fig. 1.

Fig. 2.

Fig. 3.

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

| Elemental composition (wt. %) | Fe | C | Si | Mn | Cr | Mo |

|---|---|---|---|---|---|---|

| F-05-140 | Bal. | 0.59 | - | - | - | - |

| SCM440 | Bal. | 0.54 | 0.25 | 0.76 | 1.0 | 0.2 |

| Rotational speed (RPM) | Friction pressure (MPa) | Friction time (s) | Forging pressure (MPa) | Forging time (s) |

|---|---|---|---|---|

| 1500 | 200 | 4 | 700 | 2.5 |

| 2000 | 300 | |||

| 400 |

| Point | Composition (wt. %) |

|||||||

|---|---|---|---|---|---|---|---|---|

| Fe | C | Si | Mn | Cr | Ni | Mo | Cu | |

| (1) | 93.26 | 3.82 | 0.31 | 0.82 | 1.13 | 0.21 | 0.26 | 0.19 |

| (2) | 94.06 | 5.31 | - | - | 0.12 | - | - | 0.51 |

| (3) | 93.75 | 4.27 | 0.19 | 0.64 | 1.03 | - | 0.12 | - |

| (4) | 93.09 | 6.19 | - | - | - | - | - | 0.72 |

Table 1.

Table 2.

Table 3.

TOP

KPMI

KPMI

ePub Link

ePub Link Cite this Article

Cite this Article