- [Korean]

- High-Hardness Cemented Carbide With Nickel-Tungsten Alloy Binder

-

Hanjung Kwon

-

J Powder Mater. 2024;31(4):318-323. Published online August 30, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00227

-

-

Abstract Abstract

PDF PDF

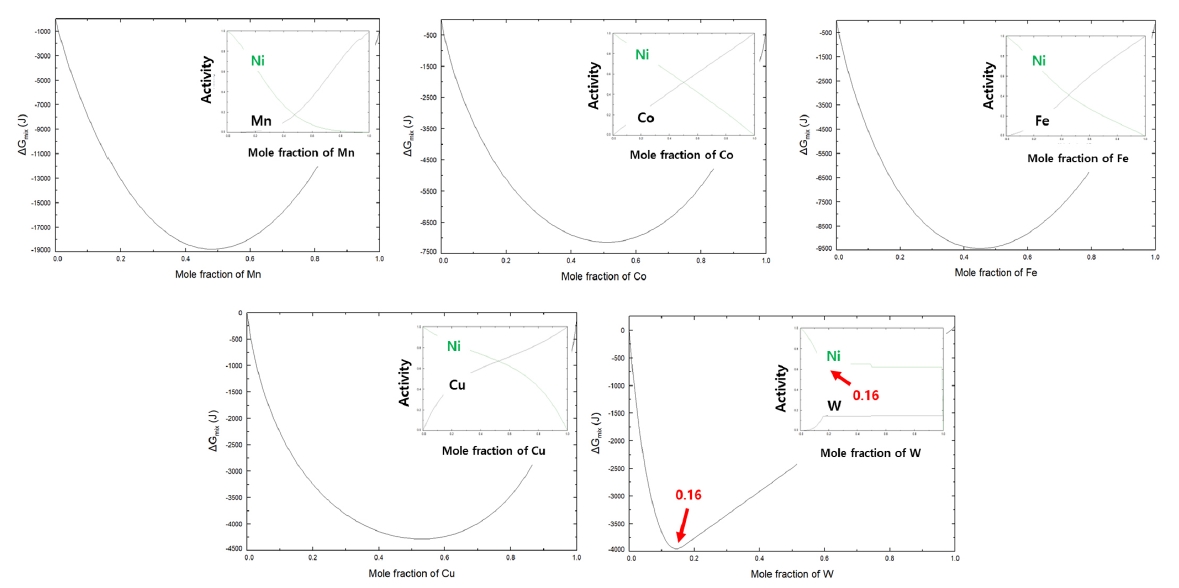

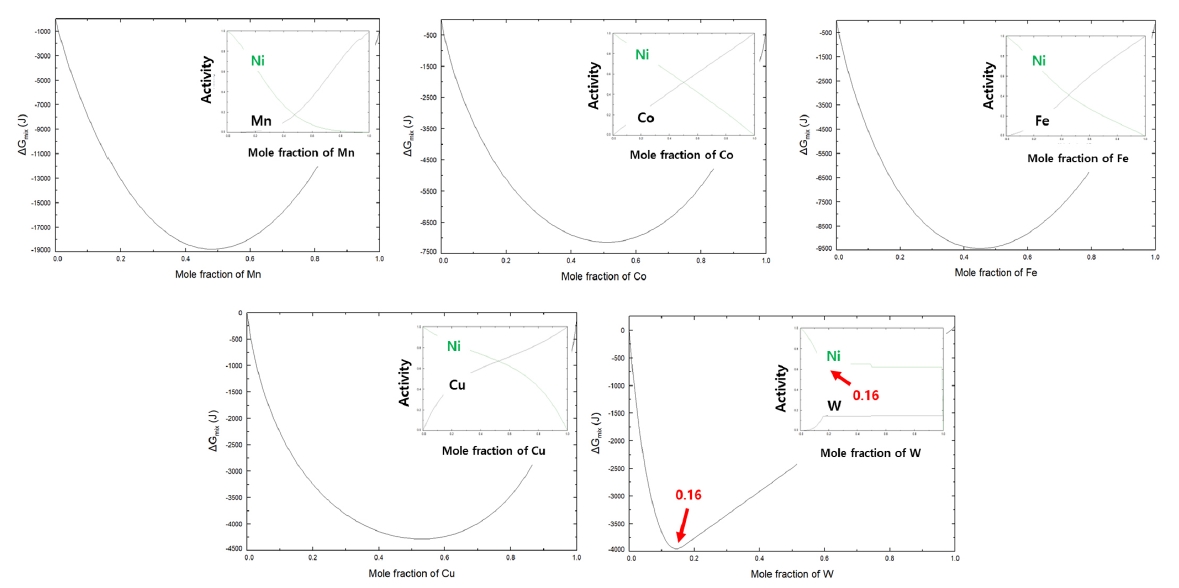

- Cemented carbide for cutting tools, which is composed of carbide as a hard phase and metallic component as a metallic phase, mainly uses cobalt as the metallic phase due to the excellent mechanical properties of cobalt. However, as the demand for machining difficult-to-machine materials such as titanium and carbon fiber-reinforced plastics has recently increased, the development of high-hardness cemented carbide is necessary and the replacement of cobalt metal with a high-hardness alloy is required. In this study, we would like to introduce high-hardness cemented carbide fabricated using nickel-tungsten alloy as the metallic phase. First, nickel-tungsten alloy powder of the composition for formation of intermetallic compound confirmed through thermodynamic calculations was synthesized, and cemented carbide was prepared through the sintering process of tungsten carbide and the synthesized alloy powder. Through evaluating the mechanical properties of high-hardness cemented carbide with the nickel-tungsten alloy binder, the possibility of producing high-hardness cemented carbide by using the alloys with high-hardness was confirmed.

- [Korean]

- Evaluation of Oxygen Reduction and Surface Chemical State of Ti-48Al-2Cr-2Nb Powder by Ca Vapor

-

Taeheon Kim, Hanjung Kwon, Jae-Won Lim

-

J Korean Powder Metall Inst. 2021;28(1):31-37. Published online February 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.1.31

-

-

1,115

View

-

4

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

This study explores reducing the oxygen content of a commercial Ti-48Al-2Cr-2Nb powder to less than 400 ppm by deoxidation in the solid state (DOSS) using Ca vapor, and investigates the effect of Ca vapor on the surface chemical state. As the deoxidation temperature increases, the oxygen concentration of the Ti-48Al-2Cr-2Nb powder decreases, achieving a low value of 745 ppm at 1100°C. When the deoxidation time is increased to 2 h, the oxygen concentration decreases to 320pp m at 1100°C, and the oxygen reduction rate is approximately 78% compared to that of the raw material. The deoxidized Ti-48Al-2Cr-2nb powder maintains a spherical shape, but the surface shape changes slightly owing to the reaction of Ca and Al. The oxidation state of Ti and Al on the surface of the Ti-48Al-2Cr-2Nb powder corresponds to a mixture of TiO2 and Al2O3. As a result, the peaks of metallic Ti and Ti suboxide intensify as TiO2 and Al2O3 in the surface oxide layer are reduced by Ca vapor deposition -

Citations

Citations to this article as recorded by  - Production of spherical TiAl alloy powder by copper-assisted spheroidization

Jin Qian, Bo Yin, Dashun Dong, Geng Wei, Ming Shi, Shaolong Tang

Journal of Materials Research and Technology.2023; 25: 1860. CrossRef - Ca-Mg Multiple Deoxidation of Ti-50Al-2Cr-2Nb Intermetallic Compound Powder for Additive Manufacturing

Seongjae Cho, Taeheon Kim, Jae-Won Lim

ECS Journal of Solid State Science and Technology.2022; 11(4): 045008. CrossRef

|