- [Korean]

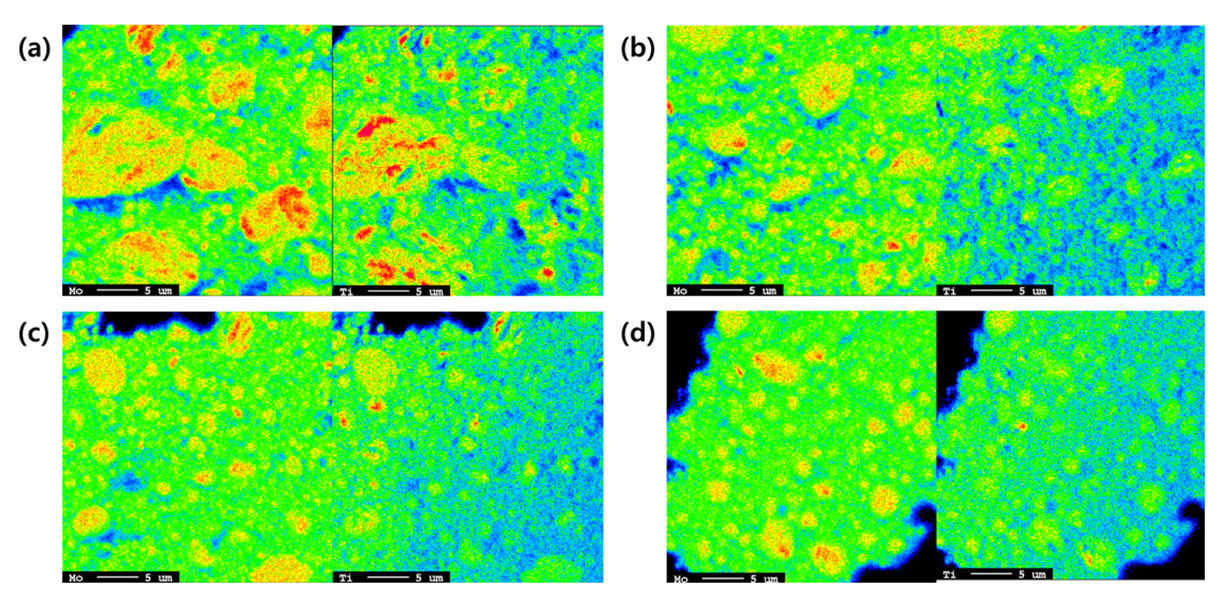

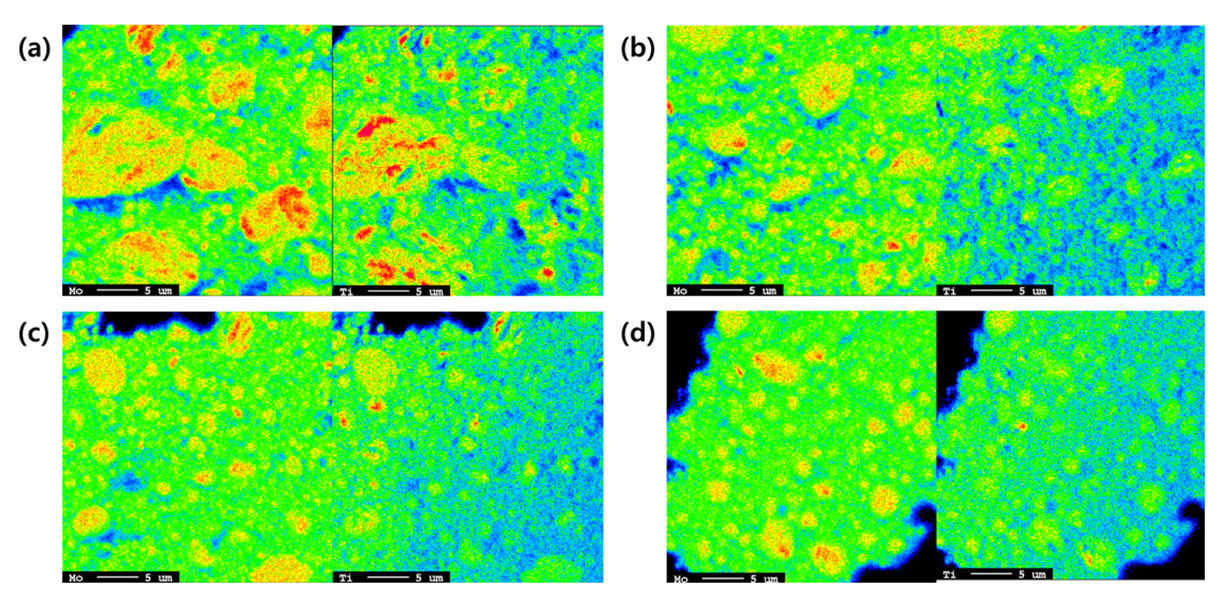

- Fabrication of Ti-Mo Core-shell Powder and Sintering Properties for Application as a Sputtering Target

-

Won Hee Lee, Chun Woong Park, Heeyeon Kim, Yuncheol Ha, Jongmin Byun, Young Do Kim

-

J Powder Mater. 2024;31(1):43-49. Published online February 28, 2024

-

DOI: https://doi.org/10.4150/KPMI.2024.31.1.43

-

-

PDF PDF

- [Korean]

- Alloy Design and Powder Manufacturing of Al-Cu-Si alloy for Low-Temperature Aluminum Brazing

-

Heeyeon Kim, Chun Woong Park, Won Hee Lee, Young Do Kim

-

J Powder Mater. 2023;30(4):339-345. Published online August 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.4.339

-

-

Abstract Abstract

PDF PDF

This study investigates the melting point and brazing properties of the aluminum (Al)-copper (Cu)-silicon (Si)-tin (Sn) alloy fabricated for low-temperature brazing based on the alloy design. Specifically, the Al-20Cu-10Si-Sn alloy is examined and confirmed to possess a melting point of approximately 520°C. Analysis of the melting point of the alloy based on composition reveals that the melting temperature tends to decrease with increasing Cu and Si content, along with a corresponding decrease as the Sn content rises. This study verifies that the Al-20Cu-10Si-5Sn alloy exhibits high liquidity and favorable mechanical properties for brazing through the joint gap filling test and Vickers hardness measurements. Additionally, a powder fabricated using the Al-20Cu-10Si-5Sn alloy demonstrates a melting point of around 515°C following melting point analysis. Consequently, it is deemed highly suitable for use as a low-temperature Al brazing material.

|