- [English]

- Finite Element and Discrete Element Analyses of Anisotropic Powder Compaction for Axial Flux Motor Cores

-

Jeong Ah Lee, Do Won Lee, , Hyojeong Ha, Ki Hyuk Kwon, Eon Byeong Park, Taeyoung Kim, Hyoung Seop Kim

-

J Powder Mater. 2025;32(6):451-458. Published online December 31, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00409

-

-

Abstract Abstract

PDF PDF

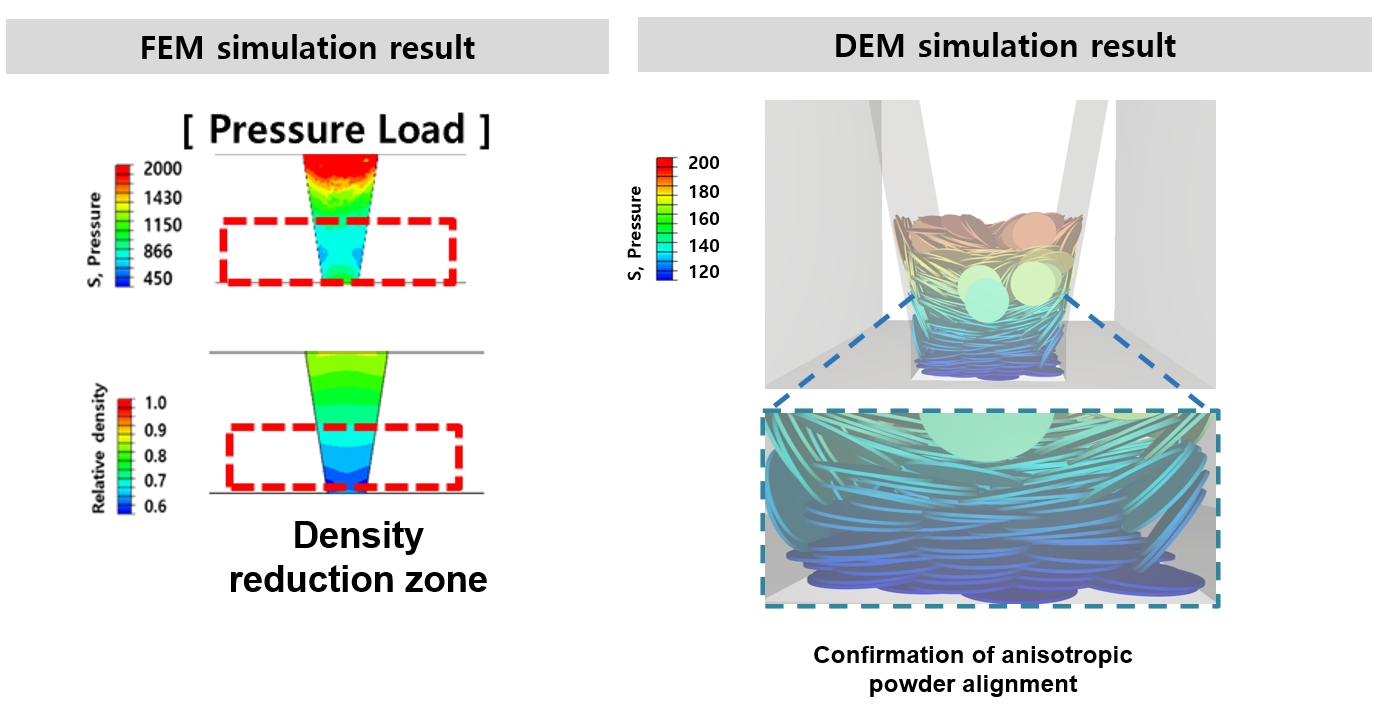

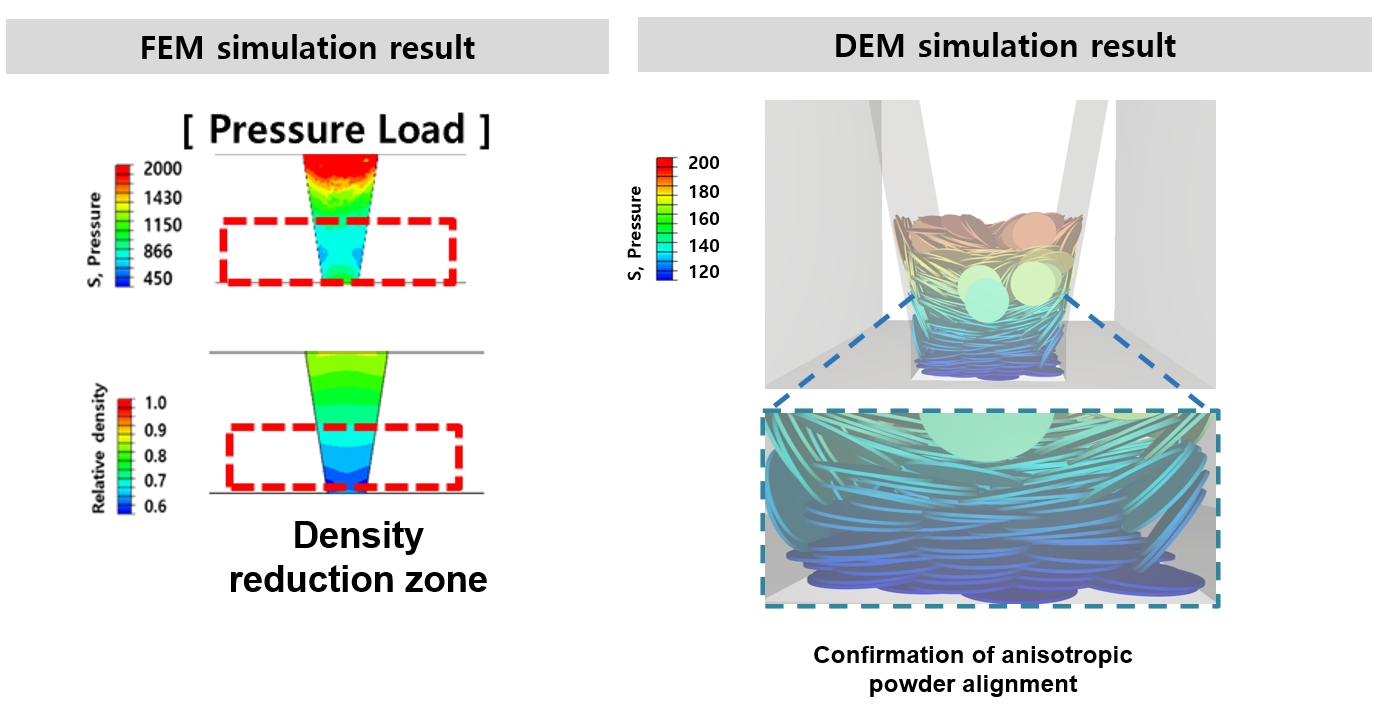

- This study investigates the compaction behavior of anisotropic, plate-like powders used in axial flux motor cores through a combined FEM–DEM approach. A porous continuum FEM model captures stress and density evolution during die pressing, revealing strong gradients along the compaction direction, with higher stress and densification near the upper punch and reduced compaction in the lower region. Guided by these results, DEM simulations examine particle packing, orientation, and contact pressure in representative zones. The DEM analysis shows that higher local pressure promotes denser packing and in-plane particle alignment near the upper punch, while the lower region exhibits more random orientations and lower contact forces. As a result, the multi-scale FEM–DEM framework clarifies how anisotropic particle behavior governs local densification and offers practical guidance for die design and process optimization to achieve more uniform density and controlled magnetic-property-relevant particle alignment in axial flux motor cores.

- [Korean]

- Prediction of Crack Density in additive manufactured AA7075 Alloy Reinforced with ZrH2 inoculant via Response Surface Method

-

Jeong Ah Lee, Jungho Choe, Hyoung Seop Kim

-

J Powder Mater. 2023;30(3):203-209. Published online June 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.3.203

-

-

2,133

View

-

9

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

Aluminum alloy-based additive manufacturing (AM) has emerged as a popular manufacturing process for the fabrication of complex parts in the automotive and aerospace industries. The addition of an inoculant to aluminum alloy powder has been demonstrated to effectively reduce cracking by promoting the formation of equiaxed grains. However, the optimization of the AM process parameters remains challenging owing to their variability. In this study, the response surface methodology (RSM) was used to predict the crack density of AM-processed Al alloy samples. RSM was performed by setting the process parameters and equiaxed grain ratio, which influence crack propagation, as independent variables and designating crack density as a response variable. The RSM-based quadratic polynomial models for crack-density prediction were found to be highly accurate. The relationship among the process parameters, crack density, and equiaxed grain fraction was also investigated using RSM. The findings of this study highlight the efficacy of RSM as a reliable approach for optimizing the properties of AM-processed parts with limited experimental data. These results can contribute to the development of robust AM processing strategies for the fabrication of highquality Al alloy components for various applications. -

Citations

Citations to this article as recorded by  - Synergistic strengthening of crack-free Al–Zn–Mg–Cu alloys with hierarchical microstructures achieved via laser powder bed fusion

Jungho Choe, Kyung Tae Kim, Jeong Min Park, Hyomoon Joo, Sang Guk Jeong, Eun Seong Kim, Soung Yeoul Ahn, Gang Hee Gu, Hyoung Seop Kim

Materials Research Letters.2024; 12(8): 598. CrossRef

|