- [Korean]

- Effect of Anisotropy on the Wear Behavior of Age-Treated Maraging Steel Manufactured by LPBF

-

Seung On Lim, Se-Eun Shin

-

J Powder Mater. 2024;31(4):308-317. Published online August 5, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00171

-

-

2,123

View

-

38

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

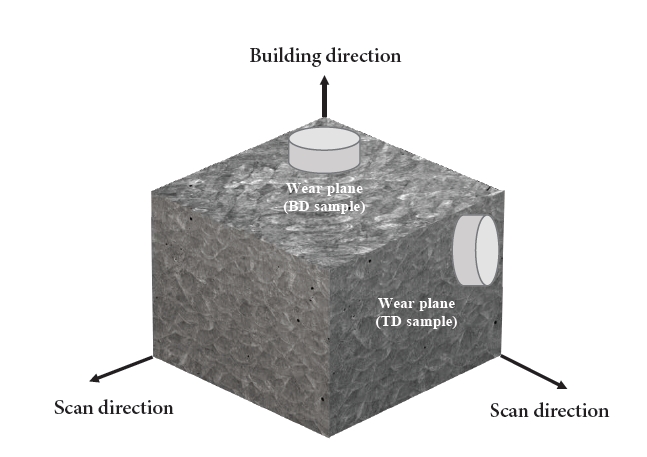

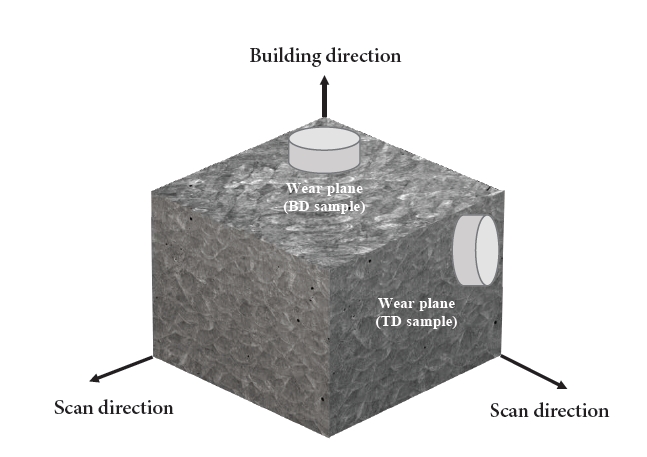

- Maraging steel has excellent mechanical properties resulting from the formation of precipitates within the matrix through aging treatment. Maraging steel fabricated by the laser powder bed fusion (LPBF) process is suitable for applications including precise components and optimized design. The anisotropic characteristic, which depends on the stacking direction, affects the mechanical properties. This study aimed to analyze the influence of anisotropy on the wear behavior of maraging steel after aging treatment. The features of additive manufacturing tended to disappear after heat treatment. However, some residual cellular and dendrite structures were observed. In the wear tests, a high wear rate was observed on the building direction plane for all counter materials. This is believed to be because the oxides formed on the wear track positively affected the wear characteristics; meanwhile, the bead shape in the stacking direction surface was vulnerable to wear, leading to significant wear.

-

Citations

Citations to this article as recorded by  - Unveiling age-hardening mechanisms: first-principles carbide insights and enhanced thermomechanical fatigue in niobium-bearing austenitic stainless steels

Godwin Kwame Ahiale, Jin Woong Park, Raj Narayan Hajra, Yong-Jun Oh, Won Doo Choi, Tae-Wook Na, Gi Yong Kim, Hyun-Ju Choi, Jeoung Han Kim

Materials Science and Engineering: A.2026; 949: 149397. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- [Korean]

- Microstructures and Mechanical Properties of Al-B4C Composites Fabricated by DED Process

-

Yu-Jeong An, Ju-Yeon Han, Hyunjoo Choi, Se-Eun Shin

-

J Powder Mater. 2023;30(3):262-267. Published online June 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.3.262

-

-

1,066

View

-

8

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

Boron carbide (B4C) is highly significant in the production of lightweight protective materials when added to aluminum owing to its exceptional mechanical properties. In this study, a method for fabricating Al-B4C composites using high-energy ball milling and directed energy deposition (DED) is presented. Al-4 wt.% B4C composites were fabricated under 21 different laser conditions to analyze the microstructure and mechanical properties at different values of laser power and scan speeds. The composites fabricated at a laser power of 600 W and the same scan speed exhibited the highest hardness and generated the fewest pores. In contrast, the composites fabricated at a laser power of 1000 W exhibited the lowest hardness and generated a significant number of large pores. This can be explained by the influence of the microstructure on the energy density at different values of laser power. -

Citations

Citations to this article as recorded by  - Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef

- [Korean]

- Microstructures and Mechanical Properties of Ti-20Mo-0.5EB Composites

-

Suhyun Bae, Wonki Jeong, Se-Eun Shin

-

J Korean Powder Metall Inst. 2021;28(5):403-409. Published online October 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.5.403

-

-

Abstract Abstract

PDF PDF

In this study, Ti-Mo-EB composites are prepared by ball milling and spark plasma sintering (SPS) to obtain a low elastic modulus and high strength and to evaluate the microstructure and mechanical properties as a function of the process conditions. As the milling time and sintering temperature increased, Mo, as a β-Ti stabilizing element, diffused, and the microstructure of β-Ti increased. In addition, the size of the observed phase was small, so the modulus and hardness of α-Ti and β-Ti were measured using nanoindentation equipment. In both phases, as the milling time and sintering temperature increased, the modulus of elasticity decreased, and the hardness increased. After 12 h of milling, the specimen sintered at 1000°C showed the lowest values of modulus of elasticity of 117.52 and 101.46 GPa for α-Ti and β-Ti, respectively, confirming that the values are lower compared to the that in previously reported studies.

|