- [English]

- Hot-Cracking Behaviors in (CoNi)85Mo15 Medium-Entropy Alloys Manufactured via Powder Bed Fusion

-

Seungjin Nam, Heechan Jung, Haeum Park, Chahee Jung, Jeong Min Park, Hyoung Seop Kim, Seok Su Sohn

-

J Powder Mater. 2024;31(6):537-545. Published online December 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00262

-

-

1,412

View

-

27

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

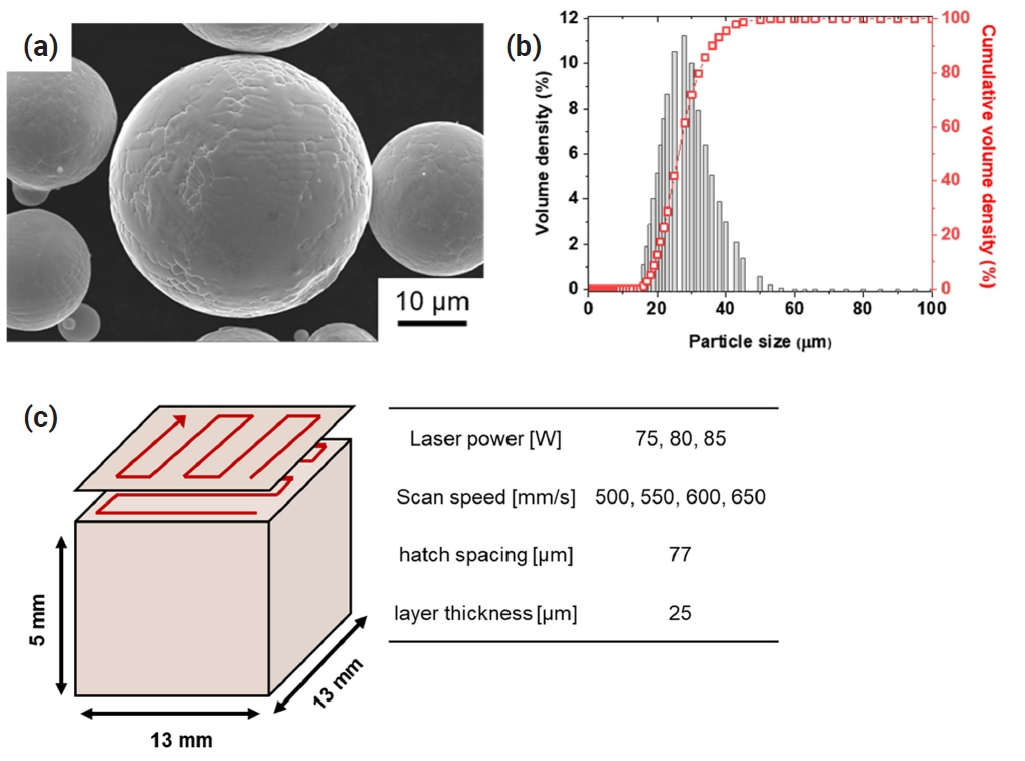

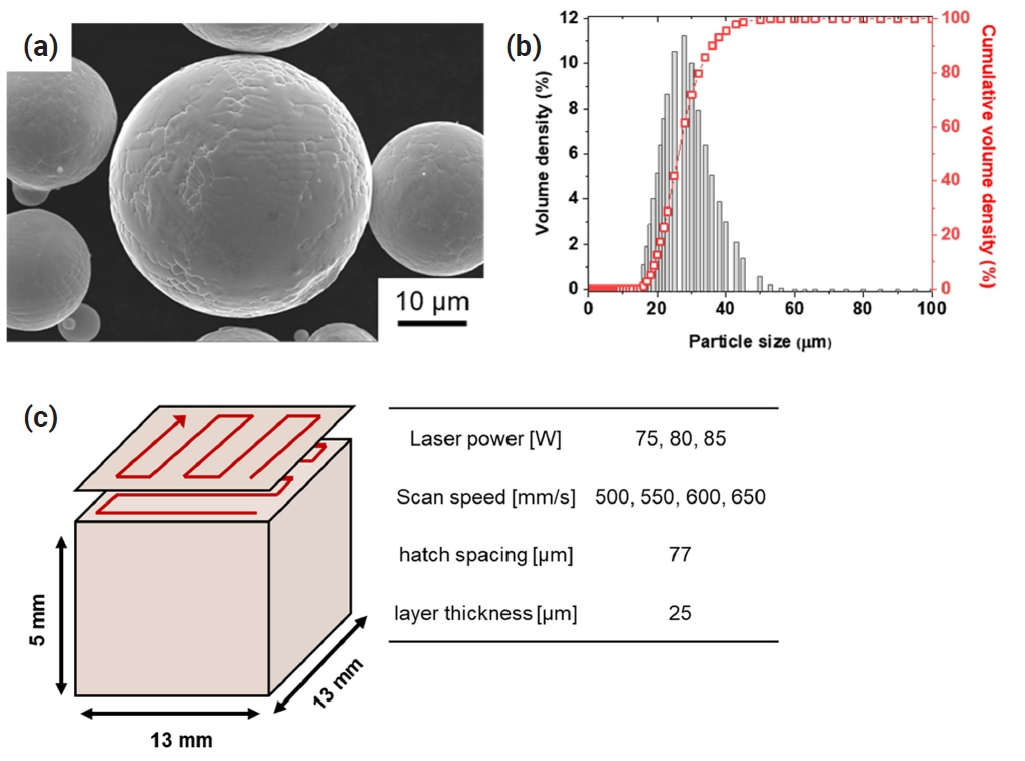

- Additive manufacturing makes it possible to improve the mechanical properties of alloys through segregation engineering of specific alloying elements into the dislocation cell structure. In this study, we investigated the mechanical and microstructural characteristics of CoNi-based medium-entropy alloys (MEAs), including the refractory alloying element Mo with a large atomic radius, manufactured via laser-powder bed fusion (L-PBF). In an analysis of the printability depending on the processing parameters, we achieved a high compressive yield strength up to 653 MPa in L-PBF for (CoNi)85Mo15 MEAs. However, severe residual stress remained at high-angle grain boundaries, and a brittle µ phase was precipitated at Mo-segregated dislocation cells. These resulted in hot-cracking behaviors in (CoNi)85Mo15 MEAs during L-PBF. These findings highlight the need for further research to adjust the Mo content and processing techniques to mitigate cracking behaviors in L-PBF-manufactured (CoNi)85Mo15 MEAs.

-

Citations

Citations to this article as recorded by  - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

|