Search

- Page Path

- HOME > Search

Research Article

- [Korean]

- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

- Kiho Song, Sang in Lee, Hyunseung Song, Changui Ahn

- J Powder Mater. 2024;31(6):513-520. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00304

- 961 View

- 24 Download

-

Abstract

Abstract

PDF

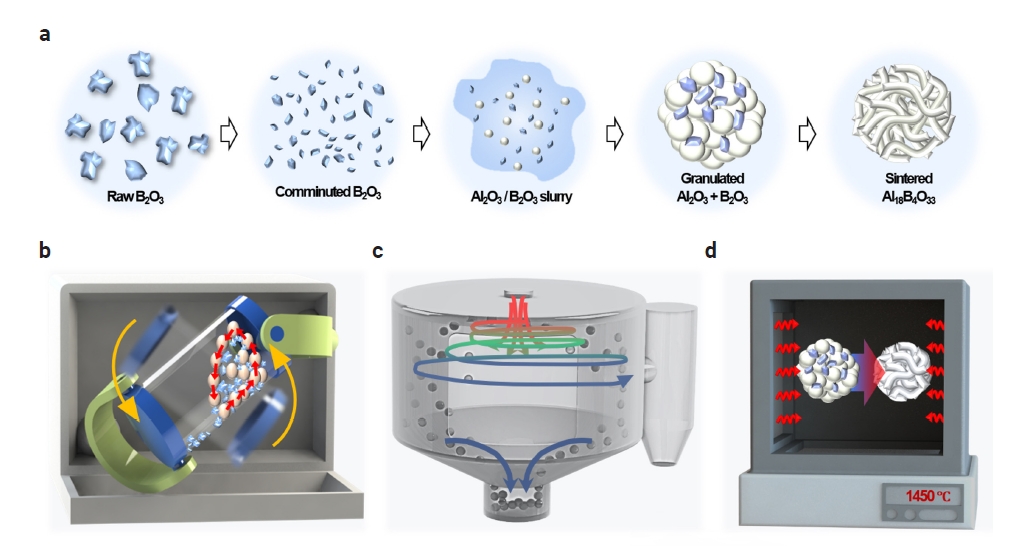

PDF - Ceramic materials have become essential due to their high durability, chemical stability, and excellent thermal stability in various advanced industries such as aerospace, automotive, and semiconductor. However, high-performance ceramic materials face limitations in commercialization due to the high cost of raw materials and complex manufacturing processes. Aluminum borate (Al₁₈B₄O₃₃) has emerged as a promising alternative due to its superior mechanical strength and thermal stability, despite its simple manufacturing process and low production cost. In this study, we propose a method for producing Al₁₈B₄O₃₃ spherical powder with increased uniformity and high flowability by controlling the particle size of B₂O₃. The content ratio of the manufactured Al18B4O33 spherical powder was Al2O3: B2O3 = 87:13, and it exhibited a 17% reduction in the Hausner ratio (1.04) and a 29% decrease in the angle of repose (23.9°) compared to pre-milling conditions, demonstrating excellent flowability.

TOP

KPMI

KPMI

First

First Prev

Prev