Search

- Page Path

- HOME > Search

Research Article

- [Korean]

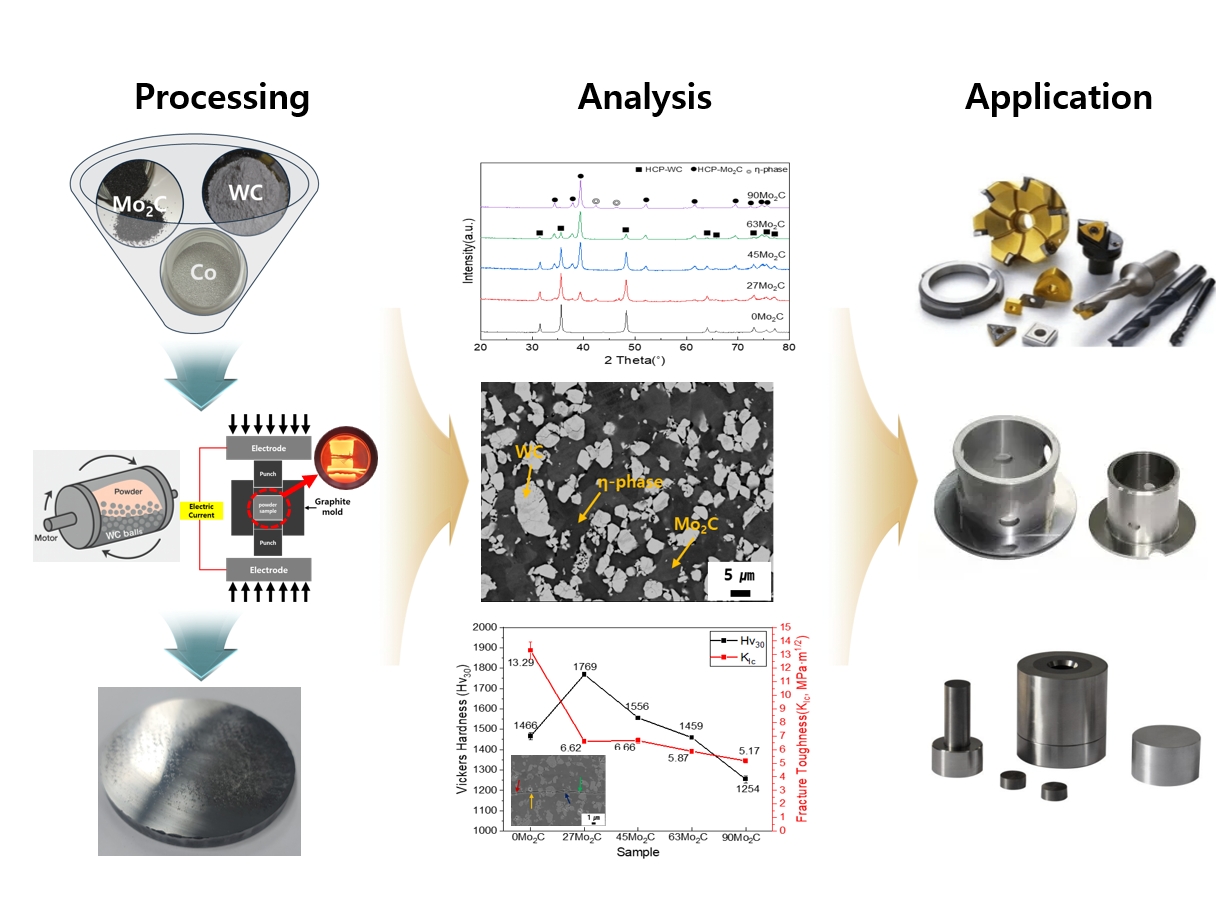

- Optimization of Mechanical Properties in WC–Mo₂C–Co Cemented Carbides via Dual Hard-Phase Based Heterogeneous Microstructure Design

- Jinwoo Seok, Jong Tae Kim, Juree Jung, SongYi Kim, Bin Lee, Junhee Han, Leeseung Kang

- J Powder Mater. 2025;32(5):428-436. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00297

- 460 View

- 14 Download

-

Abstract

Abstract

PDF

PDF - WC–Mo₂C–Co cemented carbides were fabricated to investigate the effects of Mo₂C addition on microstructure and mechanical properties. Dual hard-phase design using WC and Mo₂C was employed to optimize the balance between hardness and toughness. Spark plasma sintering (SPS) was conducted at various temperatures after ball milling, and 1300 °C for 5 min was identified as the optimized sintering condition, achieving complete densification and phase stability. The addition of Mo₂C refined the microstructure by suppressing abnormal WC grain growth through preferential dissolution of Mo₂C into the Co binder. Hardness increased up to 1769 Hv30 due to grain refinement and solid-solution strengthening, while promoted η-phase formation and reduced fracture toughness.The 27Mo₂C composition exhibited the most balanced combination of hardness and toughness. These results demonstrate that controlled Mo₂C addition enables dual hard-phase strengthening and microstructure optimization in WC–Mo₂C–Co carbides for advanced cutting and forming applications.

TOP

KPMI

KPMI

First

First Prev

Prev