Search

- Page Path

- HOME > Search

- [English]

- Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

- Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

- J Powder Mater. 2024;31(5):365-373. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00213

- 926 View

- 38 Download

- 2 Citations

-

Abstract

Abstract

PDF

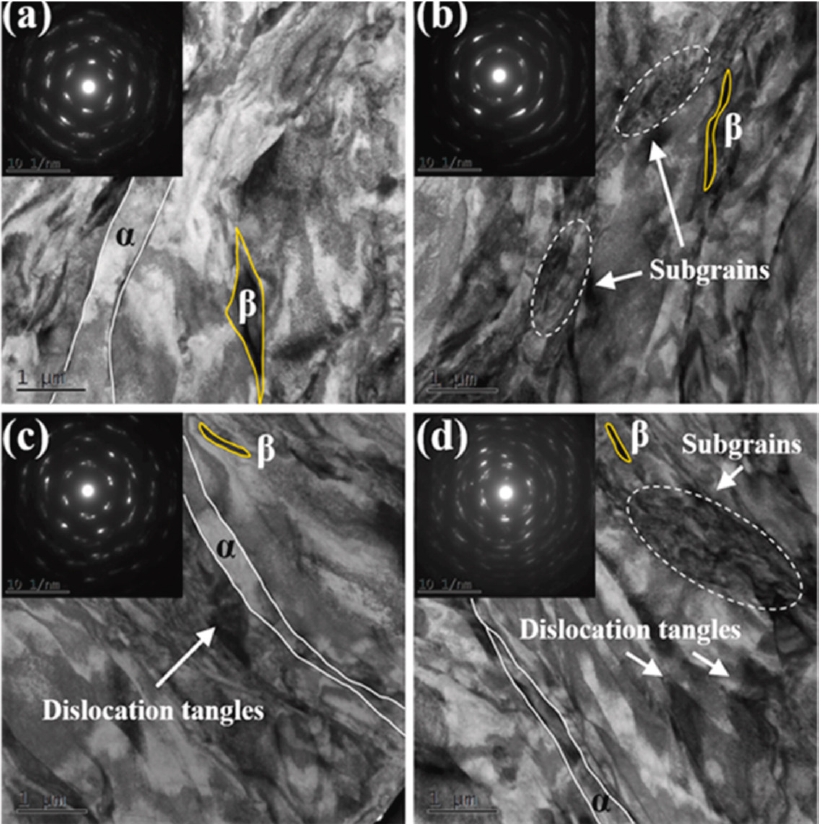

PDF - This review examines the microstructural and mechanical properties of a Ti-6Al-4V alloy produced by wrought processing and powder metallurgy (PM), specifically laser powder bed fusion (LPBF) and hot isostatic pressing. Wrought methods, such as forging and rolling, create equiaxed alpha (α) and beta (β) grain structures with balanced properties, which are ideal for fatigue resistance. In contrast, PM methods, particularly LPBF, often yield a martensitic α′ structure with high microhardness, enabling complex geometries but requiring post-processing to improve its properties and reduce stress. The study evaluated the effects of processing parameters on grain size, phase distribution, and material characteristics, guiding the choice of fabrication techniques for optimizing Ti-6Al-4V performance in aerospace, biomedical, and automotive applications. The analysis emphasizes tailored processing to meet advanced engineering demands.

-

Citations

Citations to this article as recorded by- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

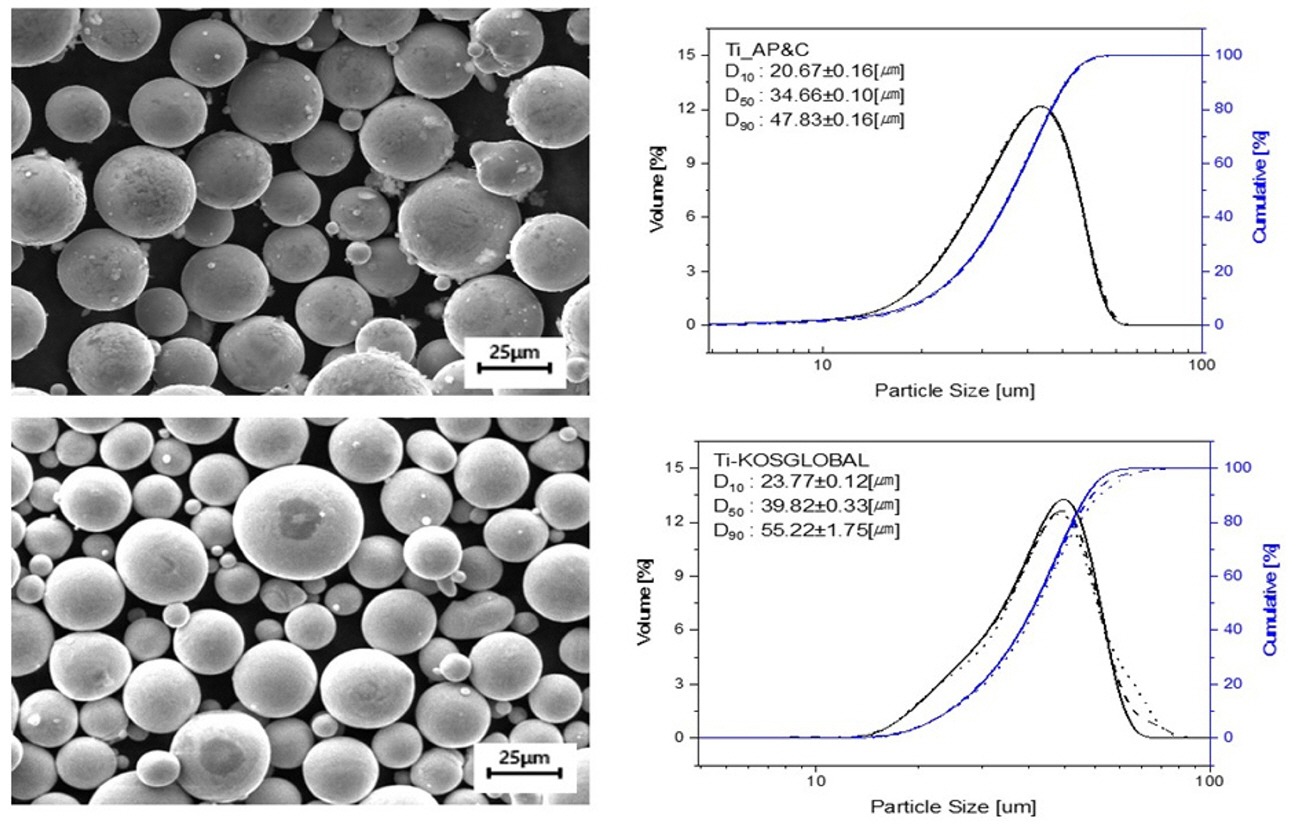

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef

- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

- [English]

- Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

- Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

- J Powder Mater. 2024;31(1):1-7. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.1

- 3,276 View

- 111 Download

- 6 Citations

-

Abstract

Abstract

PDF

PDF This study explores the profound impact of varying oxygen content on microstructural and mechanical properties in specimens HO and LO. The higher oxygen concentration in specimen HO is found to significantly influence alpha lath sizes, resulting in a size of 0.5-1 μm, contrasting with the 1-1.5 μm size observed in specimen LO. Pore fraction, governed by oxygen concentration, is high in specimen HO, registering a value of 0.11%, whereas specimen LO exhibits a lower pore fraction (0.02%). Varied pore types in each specimen further underscore the role of oxygen concentration in shaping microstructural morphology. Despite these microstructural variations, the average hardness remains consistent at ~370 HV. This study emphasizes the pivotal role of oxygen content in influencing microstructural features, contributing to a comprehensive understanding of the intricate interplay between elemental composition and material properties.

-

Citations

Citations to this article as recorded by- Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

Hadiseh Esmaeilpoor, Mahdi Aghaahmadi, Hyun Jong Yoo, Chan Woong Park, Tae Jin Jang, Seok Su Sohn, Jeoung Han Kim

Journal of Materials Science & Technology.2025; 213: 223. CrossRef - High-integrity diffusion bonding of laser powder bed fused, forged, and rolled Ti–6Al–4V alloys

Seoyeon Jeon, Hyunjong Ha, Dong Jun Lee, Hyeonil Park, Yong Nam Kwon, Hyunjoo Choi, Hyokyung Sung

Journal of Materials Research and Technology.2025; 35: 2108. CrossRef - Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

Journal of Powder Materials.2024; 31(5): 365. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

TOP

kpmi

kpmi

First

First Prev

Prev