Search

- Page Path

- HOME > Search

- [English]

- Fabrication and Pore Characteristics of Metal Powder Filters with a Cross-Sealed Honeycomb Shape Using Material Extrusion Additive Manufacturing

- Minji Kim, Min-Jeong Lee, Su-Jin Yun, Poong-Yeon Kim, Hyeon Ju Kim, Juyong Kim, Jung Woo Lee, Jung-Yeul Yun

- J Powder Mater. 2025;32(4):299-308. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00234

- 957 View

- 26 Download

-

Abstract

Abstract

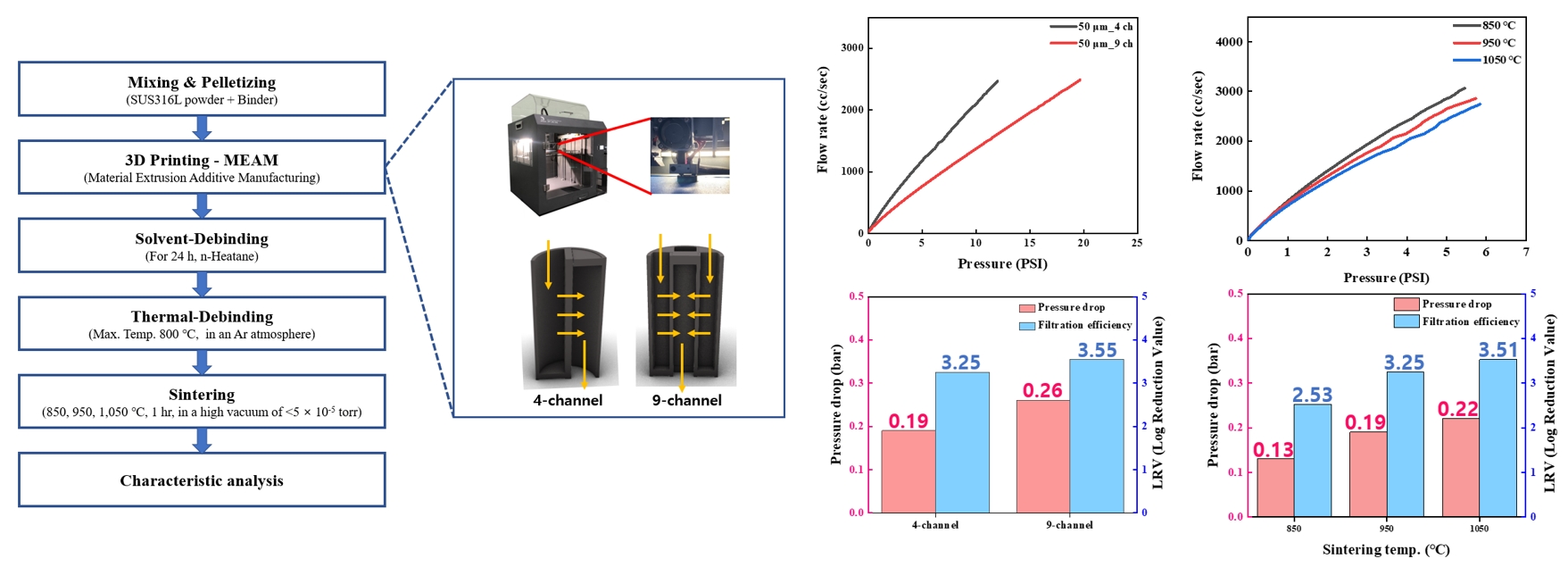

PDF

PDF - The development of high-performance metal filters is essential for maintaining ultra-clean environments in semiconductor manufacturing. In this study, cross-sealed honeycomb filters were fabricated using STS316L powder via material extrusion additive manufacturing (MEAM) for semiconductor gas filtration. The effects of filter geometry (4 or 9 channels) and sintering temperature (850°C, 950°C, or 1,050°C) on performance were examined. First, 4-channel and 9-channel filters sintered at the same temperature (950°C) exhibited similar porosities of 50.08% and 50.57%, but the 9-channel filter showed a higher pressure-drop (0.26 bar) and better filtration-efficiency (3.55 LRV) than the 4-channel filter (0.19 bar and 3.25 LRV, respectively). Second, for filters with the same geometry (4-channel) increasing the sintering temperature reduced porosity from 64.52% to 40.33%, while the pressure-drop increased from 0.13 bar to 0.22 bar and filtration-efficiency improved from 2.53 LRV to 3.51 LRV. These findings demonstrate that filter geometry and sintering temperature are key factors governing the trade-off between air permeability, pressure-drop, and filtration efficiency. This work provides insights and data for optimizing MEAM-based high-performance metal powder filter design.

- [English]

- Multi-step Metals Additive Manufacturing Technologies

- Ji-Won Oh, Jinsu Park, Hanshin Choi

- J Korean Powder Metall Inst. 2020;27(3):256-267. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.256

- 1,625 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Metal additive manufacturing (AM) technologies are classified into two groups according to the consolidation mechanisms and densification degrees of the as-built parts. Densified parts are obtained via a single-step process such as powder bed fusion, directed energy deposition, and sheet lamination AM technologies. Conversely, green bodies are consolidated with the aid of binder phases in multi-step processes such as binder jetting and material extrusion AM. Green-body part shapes are sustained by binder phases, which are removed for the debinding process. Chemical and/or thermal debinding processes are usually devised to enhance debinding kinetics. The pathways to final densification of the green parts are sintering and/or molten metal infiltration. With respect to innovation types, the multistep metal AM process allows conventional powder metallurgy manufacturing to be innovated continuously. Eliminating cost/time-consuming molds, enlarged 3D design freedom, and wide material selectivity create opportunities for the industrial adoption of multi-step AM technologies. In addition, knowledge of powders and powder metallurgy fuel advances of multi-step AM technologies. In the present study, multi-step AM technologies are briefly introduced from the viewpoint of the entire manufacturing lifecycle.

-

Citations

Citations to this article as recorded by- Potential and challenges for Powder Bed Fusion – Laser Beam (PBF-LB) in industrial ceramic additive manufacturing

Christian Berger, Gabriela Schimo-Aichhorn, Stefan Gronau, Franziska Saft, Sarah Seiringer, Uwe Scheithauer

Open Ceramics.2024; 18: 100614. CrossRef - Fabrication of Cu-Infiltrated Journal Bearing by Binder Jetting Additive Manufacturing

Jin Man Jang

Crystals.2024; 14(11): 912. CrossRef - SiC-Si composite part fabrication via SiC powder binder jetting additive manufacturing and molten-Si infiltration

Ji-Won Oh, Jinsu Park, Sahn Nahm, Hanshin Choi

International Journal of Refractory Metals and Hard Materials.2021; 101: 105686. CrossRef

- Potential and challenges for Powder Bed Fusion – Laser Beam (PBF-LB) in industrial ceramic additive manufacturing

TOP

KPMI

KPMI

First

First Prev

Prev