Articles

- Page Path

- HOME > J Powder Mater > Volume 32(4); 2025 > Article

-

Research Article

- Fabrication and Pore Characteristics of Metal Powder Filters with a Cross-Sealed Honeycomb Shape Using Material Extrusion Additive Manufacturing

-

Minji Kim1,2

, Min-Jeong Lee1,2

, Min-Jeong Lee1,2 , Su-Jin Yun1

, Su-Jin Yun1 , Poong-Yeon Kim1

, Poong-Yeon Kim1 , Hyeon Ju Kim1

, Hyeon Ju Kim1 , Juyong Kim3

, Juyong Kim3 , Jung Woo Lee2,*

, Jung Woo Lee2,* , Jung-Yeul Yun1,*

, Jung-Yeul Yun1,*

-

Journal of Powder Materials 2025;32(4):299-308.

DOI: https://doi.org/10.4150/jpm.2025.00234

Published online: August 29, 2025

1Nanomaterials Research Center, Korea Institute of Materials Science KIMS, Changwon 51508, Republic of Korea

2Department of Materials Science and Engineering, Pusan National University, Busan 46241, Republic of Korea

33DP R&D Center, REPROTECH, Suwon 16229, Republic of Korea

-

*Corresponding author: Jung-Yeul Yun E-mail: yjy1706@kims.re.kr

*Corresponding author: Jung Woo Lee E-mail: jungwoolee@pusan.ac.kr

© The Korean Powder Metallurgy & Materials Institute

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 930 Views

- 25 Download

Abstract

- The development of high-performance metal filters is essential for maintaining ultra-clean environments in semiconductor manufacturing. In this study, cross-sealed honeycomb filters were fabricated using STS316L powder via material extrusion additive manufacturing (MEAM) for semiconductor gas filtration. The effects of filter geometry (4 or 9 channels) and sintering temperature (850°C, 950°C, or 1,050°C) on performance were examined. First, 4-channel and 9-channel filters sintered at the same temperature (950°C) exhibited similar porosities of 50.08% and 50.57%, but the 9-channel filter showed a higher pressure-drop (0.26 bar) and better filtration-efficiency (3.55 LRV) than the 4-channel filter (0.19 bar and 3.25 LRV, respectively). Second, for filters with the same geometry (4-channel) increasing the sintering temperature reduced porosity from 64.52% to 40.33%, while the pressure-drop increased from 0.13 bar to 0.22 bar and filtration-efficiency improved from 2.53 LRV to 3.51 LRV. These findings demonstrate that filter geometry and sintering temperature are key factors governing the trade-off between air permeability, pressure-drop, and filtration efficiency. This work provides insights and data for optimizing MEAM-based high-performance metal powder filter design.

- This study investigates SUS316L-based cross-sealed honeycomb metal filters fabricated via Material Extrusion Additive Manufacturing (MEAM). By analyzing geometry (4- vs. 9-channel) and sintering temperature, we reveal trade-offs between porosity, air permeability, pressure drop, and filtration efficiency, providing guidelines for optimizing high-performance filters.

Graphical abstract

- Porous metals are solid materials containing numerous internal pores, and they have been extensively studied and applied in various industries due to their unique properties such as enhanced surface area for adsorption and catalytic activity, lightweight characteristics, and energy absorption [1-4]. In particular, maintaining an ultra-clean environment is crucial in semiconductor manufacturing processes, and high-performance metal filters are required to effectively remove fine particles and contaminants present in process gases [5-7]. Most commercial filters have simple disk or cylindrical geometries, which limits their ability to simultaneously improve filtration efficiency by capturing impurity particles and reduce the pressure drop, which refers to the difference in gas pressure before and after the filter [8, 9].

- With recent advances in additive manufacturing (AM) technology, the demand for metal filters with complex internal architectures and optimized performance has been increasing [10-12]. Among various 3D printing-based filter fabrication methods, such as Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Material Extrusion Additive Manufacturing (MEAM), PBF and DED typically rely on laser-based equipment, which involves high capital and operating costs and imposes restrictions on usable materials [13-15]. In contrast, MEAM does not require lasers, which results in lower initial investment costs and enables the use of a wide range of feedstock materials. Additionally, the absence of mold fabrication enhances cost efficiency, makes it suitable for prototyping, and provides greater design flexibility for easily creating complex and precise structures [16-20]. Compared with the simple tube- or disk-shaped filters commonly available on the market, the complex internal channel geometry of the filters developed in this study is expected to enhance filtration efficiency by diversifying airflow paths and increasing the contact area with particles. These design advantages can be particularly beneficial in industrial fields such as semiconductor processing, where high-purity and high-efficiency filtration are required [21, 22].

- In this study, the fabrication and pore characteristics of STS316L-based metal powder filters with a cross-sealed honeycomb shape using the MEAM process were systematically investigated, focusing on filter geometry and the evolution of pore structure with varying sintering temperatures. Two filter designs with identical outer dimensions (20 mm in diameter and 25 mm in height) but different internal flow channel numbers (4-channel and 9-channel) were produced to analyze the effects of structural complexity on porosity, air permeability, gas pressure drop, and filtration efficiency. Furthermore, three sintering temperatures (850, 950, and 1,050°C) were employed to examine microstructural changes and the corresponding reduction in porosity, followed by quantitative evaluation of variations in air permeability and filtration performance. Through this approach, this study aims to elucidate the combined effects of geometry and sintering conditions, which are two key variables influencing the performance of metal filters, and to provide fundamental data for establishing optimized design strategies for the development of high-performance metal filters.

1. Introduction

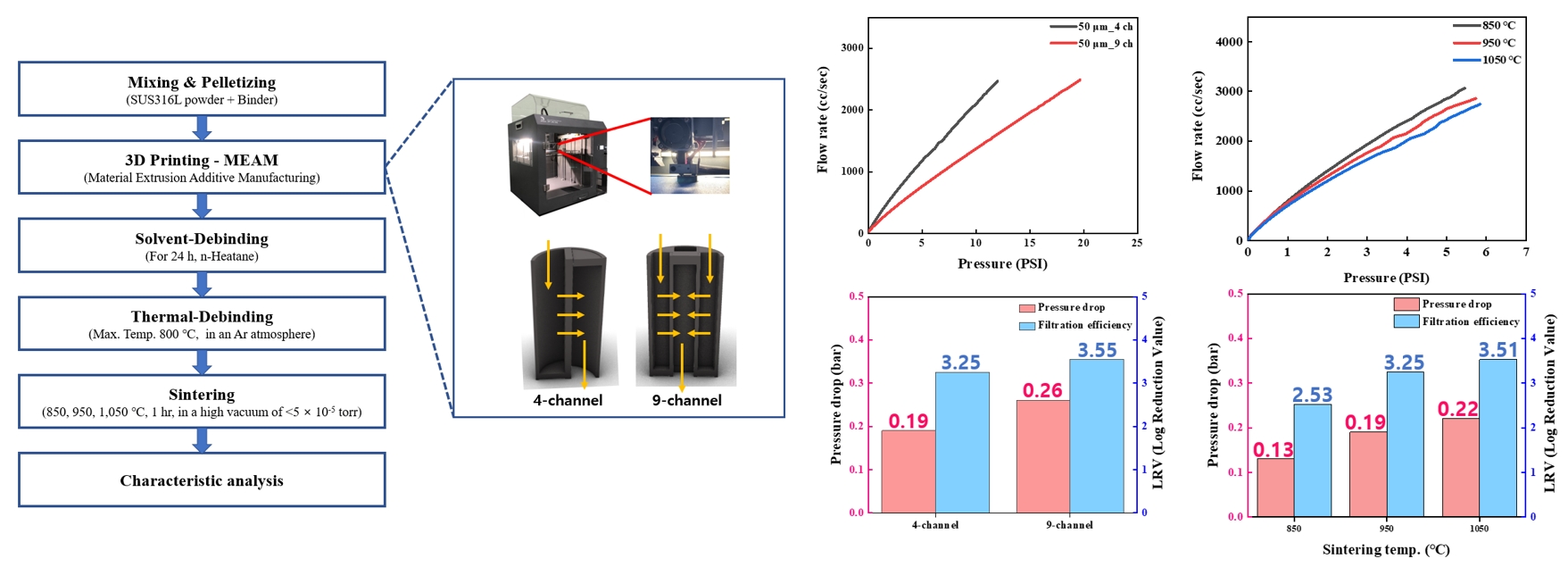

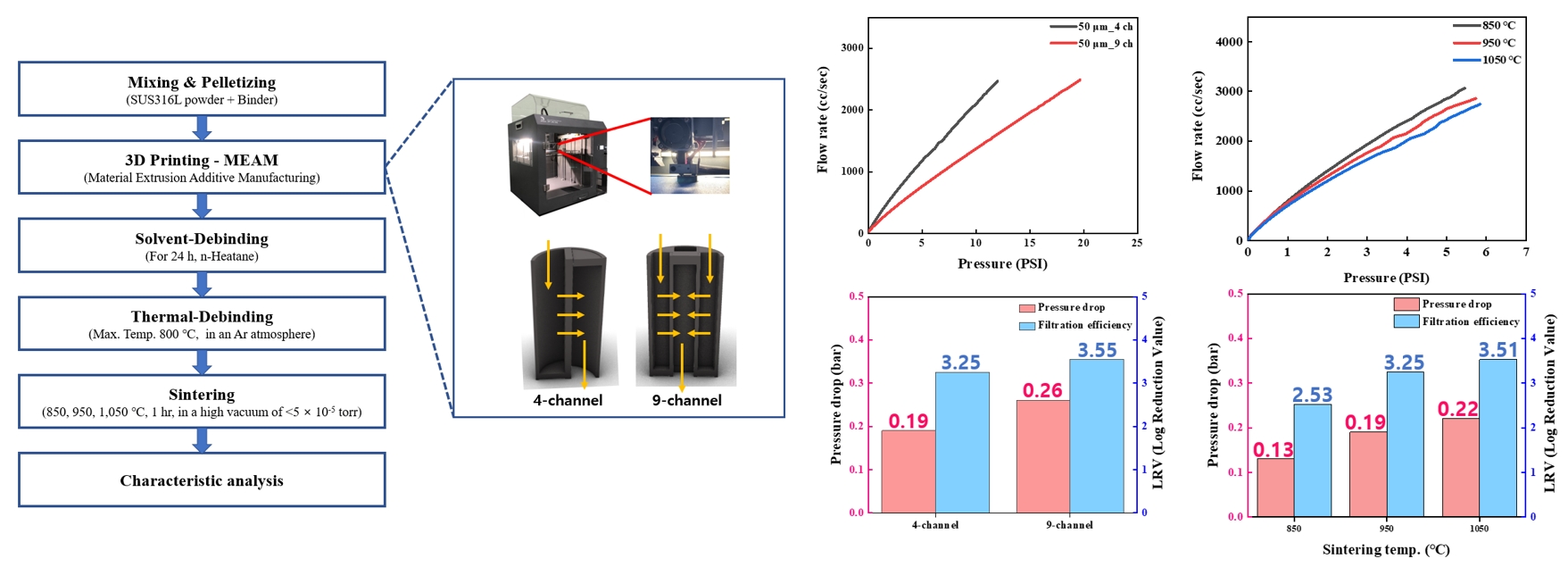

- The manufacturing process of the honeycomb filters produced in this study is illustrated in Fig. 1. The process involves mixing the STS316L metal powder with the binder, pelletizing the mixture, and then shaping it using the Material Extrusion Additive Manufacturing (MEAM) process. This is followed by solvent debinding and thermal debinding to remove the binder, and finally sintering to produce the final filters, which were then subjected to characterization.

- The chemical composition of the STS316L metal powder (Daido, Japan) and the M1 binder (Atect, Japan) used in this study are presented in Table 1 and Table 2, respectively. The STS316L powder and M1 binder were mixed in a weight ratio of 86.34 wt.% to 13.66 wt.% to prepare the feedstock. The prepared feedstock was used to fabricate two honeycomb filter structures with different internal flow path complexities: a 4-channel design and a 9-channel design. Fig. 2 shows the modeling images of these filters, where Fig. 2(a) and (b) depict the overall geometry and cross-section of the 4-channel filter, and Fig. 2(c) and (d) show those of the 9-channel filter. The internal channels were designed with cross-shielded sections at the top and bottom to force the fluid to pass through the internal walls. Both filters were designed with the same external dimensions (20 mm in diameter and 25 mm in height), but the total wall volume and mass were increased in the 9-channel design due to the greater number of internal channels.

- MEAM-based additive manufacturing was performed using an RPT_CME300 (REPROTECH, Korea) system under the following conditions: nozzle diameter of 0.4 mm, nozzle temperature of 175°C, bed temperature of 65°C, layer height of 125 μm, and printing speed of 35 mm/s. The green parts were immersed in n-heptane for 24 h to perform solvent debinding, removing the low-molecular-weight binder components SA (stearic acid) and PW (paraffin wax), followed by thermal debinding in an argon (Ar) atmosphere, where the temperature was ramped to 800°C at a rate of 1°C/min and held for 1 h to remove the high-molecular-weight binders EVA and PE. Subsequently, the debound specimens were sintered under high vacuum (5 × 10⁻5 torr) at 850, 950, and 1,050°C for 1 h to evaluate the effects of sintering temperature on the pore structure.

- Sintering temperature was set as one of the key process variables to analyze its effect on the pore structure and filtration performance of metal filters. The powder used was STS316L stainless steel, which has a melting point of approximately 1,400°C. Therefore, sintering was conducted below the melting point, selecting a temperature range where neck formation between particles and pore retention are balanced. Generally, the sintering process is divided into initial, intermediate, and final stages, with the intermediate stage being most suitable for filter fabrication, as it ensures sufficient neck growth to secure mechanical strength while maintaining an adequate level of penetrating pores. In contrast, in the final stage, excessive densification eliminates pores, reducing permeability and impairing the filter’s functionality. Based on this theoretical background and previous studies, we selected the range of 850–1,050°C corresponding to the intermediate sintering stage. [23, 24]

- The particle morphology of the STS316L powder was examined using field emission scanning electron microscopy (FE-SEM, SU-70, Hitachi, Japan) in order to characterize surface features. The particle size distribution was measured using a laser diffraction particle size analyzer (PSA, LS13 320, Beckman Coulter). The microstructure of the sintered filters was examined using scanning electron microscopy (SEM, JSM-IT300, JEOL, Japan). The porosity was quantified based on SEM cross-sectional images using the ImageJ software. Air permeability was evaluated using a Gas Permeameter (GP-101A, Porous Materials Inc., USA) by measuring the flow rate versus gas pressure curves, and the gas pressure drop (ΔP) and filtration efficiency (Log Reduction Value, LRV) were quantitatively assessed following the international standard test method SEMI F38, which evaluates the particle removal efficiency of gas filters.

2. Experimental Section

- The STS316L powder used in this study served as the key raw material for fabricating filters via the MEAM process. The particle morphology and size distribution of the powder significantly affect not only printability, forming density, and sintering behavior, but also the final porosity and air permeability. Fig. 3(a) shows an FE-SEM (SU-70, Hitachi, Japan) image of the powder surface, which exhibits an overall irregular morphology. This is attributed to rapid and irregular solidification mechanisms inherent to the water atomization process. Fig. 3(b) presents the particle size distribution, measured using a laser diffraction particle size analyzer (PSA, LS13 320, Beckman Coulter), which shows a normal distribution with a single peak in the 10–100 µm range. The median particle size (D50) was approximately 50 µm. These characteristics confirm the suitability of the powder for stable material flow during MEAM processing and for controlled pore structure development during sintering.

- The metal powder filters fabricated via the MEAM process were designed with two types of internal flow channel structures: 4-channel and 9-channel. Their external appearance and cross-sectional images are shown in Fig. 4. Fig. 4(a) presents the overall morphology and top/bottom views of the 4-channel filter sintered at 950°C, while Fig. 4(c) shows those of the 9-channel filter under the same conditions. As observed in the top and bottom views, both filters adopt a cross-shield configuration, in which the upper and lower sections are alternately blocked. Fig. 4(b) and (d) illustrate the internal wall structures (indicated by red dashed lines) of the 4-channel and 9-channel filters, respectively. Compared with the 4-channel design, the 9-channel filter provides more finely divided flow paths, which increase fluid dispersion and particle contact probability. In addition, the cross-shield design guides the fluid to enter through the upper opening, pass through the internal walls, and exit from the lower opening.

- Although both filters were designed with identical outer dimensions (20 mm in diameter and 25 mm in height), differences in the number of channels and the total volume of internal walls resulted in variations in mass. The 4-channel filter weighed approximately 13.9 g, while the 9-channel filter weighed 17.1 g, which can be attributed to the increased fraction of metallic walls in the latter. Cross-sectional analysis of the internal walls, as shown in Fig. 4(b) and (d), revealed that the 4-channel filter had an internal wall cross-sectional area of 0.74 cm² and a wall volume of 1.85 cm³, whereas the 9-channel filter had values of 1.26 cm² and 3.16 cm³, respectively. This increased internal wall structure enlarges the effective filtration area for particle capture but simultaneously raises flow resistance, which can impact air permeability.

- Fig. 5 presents the microstructures and porosity of specimens sintered at 950°C. The porosity data were obtained by performing three measurements each at the center and edge regions of every specimen, resulting in a total of six measurements per specimen, which were then averaged and expressed with standard deviations. Differences between measurement locations were negligible. In the microstructural images, the STS316L particles appear as bright regions, whereas the pores are observed as dark regions. Fig. 5(a) and (b) show the microstructures of the 4-channel and 9-channel filters, respectively, where no significant differences were observed between the two geometries. This indicates that comparable microstructural uniformity was achieved under identical MEAM and sintering conditions. Fig. 5(c) displays the porosity results, revealing values of 50.42% (standard deviation 0.80) for the 4-channel filter and 50.53% (standard deviation 0.93) for the 9-channel filter, suggesting that the number of internal channels had no meaningful influence on microstructural uniformity or porosity.

- Fig. 6 shows the microstructures and porosity of 4-channel type filters sintered at different temperatures (850, 950, and 1,050°C). The microstructures in Fig. 6(a)–(c) reveal progressive densification with increasing temperature, as the STS316L regions become coarser while the pore regions diminish. According to the porosity results shown in Fig. 6(d), quantitative image analysis of the metallic and pore areas indicated a gradual decrease in porosity from 63.68% at 850°C to 50.42% at 950°C, and further to 39.38% at 1,050°C. The corresponding standard deviations were 0.73, 0.80, and 0.96, all below 1, confirming the reliability of the measurements. In particular, specimens sintered at 1,050°C exhibited a pronounced reduction in pore size and number, along with the formation of a continuous metallic network, indicating the development of a high-density structure.

- Air permeability represents the relationship between gas flow rate and applied gas pressure across the filter, where a steeper slope in the flow rate–pressure curve indicates superior permeability. As shown in Fig. 7(a), the 4-channel filter exhibited higher flow rates than the 9-channel filter, demonstrating better air permeability. Air permeability represents the relationship between the gas flow rate and the applied pressure across the filter, where a steeper slope in the flow rate–pressure curve indicates superior permeability. As shown in Fig. 8(a) and (b), the 4-channel filter exhibited higher flow rates than the 9-channel filter, thereby demonstrating superior air permeability.

- Gas pressure drop (ΔP) is another critical parameter for evaluating filter performance and is defined by the equation ΔP = Pupstream – Pdownstream. This represents the difference between the pressure of the gas introduced at the filter inlet (Pupstream) and the pressure measured at the outlet after passing through the filter (Pdownstream). A higher pressure drop indicates greater energy loss within the filter, reflecting increased resistance to gas flow.

- Filtration efficiency, another key performance metric, quantifies the ability of the filter to remove particles from the gas stream. In this study, filtration efficiency was expressed as the Log Reduction Value (LRV), which is calculated by counting the number of particles in the gas before and after filtration and then applying a logarithmic transformation. A higher LRV indicates a greater degree of particle removal, and thus, superior filtration performance.

- Experimental results showed that the 9-channel filter exhibited a higher pressure drop compared to the 4-channel filter due to its larger internal wall area and volume, which increased flow resistance. However, this structural characteristic also provided a greater effective surface area for particle capture, thereby improving filtration efficiency. Consequently, the 9-channel filter achieved a filtration efficiency of 3.55 LRV, surpassing the 3.25 LRV of the 4-channel filter. In summary, the 9-channel filter presents a trade-off: while the increased flow resistance results in higher pressure drop, it simultaneously provides enhanced filtration efficiency. This highlights the coexistence of advantages and limitations depending on the intended design objectives.

- The effect of sintering temperature is shown in Fig. 8(a) and (b). The results were obtained from tests conducted using the 4-channel filter, with the channel configuration fixed to isolate the effect of sintering temperature. As sintering temperature increased, air permeability decreased while gas pressure drop increased. Filtration efficiency improved from 2.53 LRV at 850°C to 3.25 LRV at 950°C, and to 3.51 LRV at 1,050°C. This behavior results from pore shrinkage and densification due to enhanced neck growth among particles, which reduces porosity but enhances particle interception.

- In summary, differences in air permeability, gas pressure drop, and filtration efficiency are governed by internal channel complexity and wall structure. The 9-channel filter achieved higher filtration efficiency but exhibited lower permeability and higher pressure drop, reflecting a trade-off relationship. Similarly, higher sintering temperatures reduce porosity and permeability but improve filtration performance. These findings highlight the importance of simultaneously optimizing filter geometry and sintering conditions for balanced performance.

3. Results and Discussion

- In semiconductor manufacturing processes, removing fine particles and contaminants that may cause wafer defects is critical for maintaining an ultra-clean environment. In this study, honeycomb-type metal filters with identical outer dimensions (20 mm in diameter and 25 mm in height) were fabricated using the Material Extrusion Additive Manufacturing (MEAM) process, and the effects of internal channel numbers (4-channel and 9-channel) on pore characteristics and filtration performance were systematically investigated. From a component designer’s perspective, the optimal number of channels may vary depending on the intended application. If air flow is the primary concern, the 4-channel configuration is more advantageous, whereas if filtration efficiency is the priority, the 9-channel configuration is more suitable.

- The results showed that the porosity values of the 4-channel and 9-channel filters were 50.57% and 50.08%, respectively, with negligible differences. However, significant variations were observed in air permeability, gas pressure drop, and filtration efficiency. The 4-channel filter, with its simpler internal geometry and smaller wall area (0.74 cm²) and volume (1.85 cm³), exhibited lower flow resistance and superior air permeability. Conversely, the 9-channel filter, having a larger wall area (1.26 cm²), demonstrated higher filtration efficiency (3.55 LRV) but reduced air permeability and increased pressure drop (0.26 bar).

- The sintering temperature was also a critical factor: as it increased, the microstructure became denser, and porosity decreased from 64.52% at 850°C to 40.33% at 1,050°C. This densification led to reduced air permeability and increased gas pressure drop (0.13 bar to 0.22 bar), while filtration efficiency improved from 2.53 to 3.51 LRV due to enhanced particle capture by finer pore structures.

- These findings confirm that internal geometry and sintering temperature are two key design parameters that jointly affect the trade-off between permeability, pressure loss, and filtration efficiency. The results underscore the need for an optimized design strategy that balances filtration performance and energy consumption. This study provides valuable insights and quantitative effects of geometry and heat treatment conditions on filter performance, offering valuable data for the development of advanced metal filters and structural optimization for high-purity industrial applications, including semiconductor manufacturing.

4. Conclusion

-

Funding

This work is supported by the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (no.00431424).

-

Conflict of Interest

The authors have no conflicts of interest to declare.

-

Data Availability Statement

The data that support the findings of this study are not publicly available due to confidentiality greements but are available from the corresponding author on reasonable request.

-

Author Information and Contribution

Minji Kim: M.S. candidate; conceptualization, writing–original Draft

Min-Jeong Lee: Ph.D. candidate; investigation (experimental assistance)

Su-Jin Yun: Researcher; investigation (experimental assistance)

Poong-Yeon Kim: Researcher; investigation (experimental assistance)

Hyeon Ju Kim: Researcher; investigation (experimental assistance)

Juyong Kim: Researcher; investigation (experimental assistance)

Jung Woo Lee: Professor, corresponding author; supervision, writing – review & editing

Jung-Yeul Yun: Ph.D., corresponding author; funding acquisition, supervision, writing – Review & editing

-

Acknowledgments

None.

Article information

| Component | C | Si | Mn | Ni | Cr | Cu | Mo | V | Other |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.02 | 0.8 | 0.2 | 12 | 17 | - | 2.5 | - | - |

| Component | PW | EVA | PE | SA |

|---|---|---|---|---|

| wt.% | 57 | 20 | 20 | 3 |

- 1. S. Rashidi, J. A. Exfahani and A. Rashidi: Renewable and Sustainable Energy Rev., 73 (2023) 1198.Article

- 2. B. Zhu, M. Duke, L. F. Dumee, E. Des Ligneris, L. Kong and S. Gray: Membranes., 8 (2018) 83.Article

- 3. G. Korotcenkov and B. K. Cho: Crit. Rev. Solid State Mater. Sci., 35 (2010) 1-37.

- 4. H. Föll, J. Carstensen and S. Frey: J. Nanomater., 2006 (2006) 091635.Article

- 5. Y. Lee, H. S. Kim and J. H. Lee: J. Semiconductor Tech. Sci., 22 (2022) 145.Article

- 6. R. L. Smith and P. K. Chatterjee: J. Vac. Sci. Technol., A, 14 (1996) 1761.

- 7. Semiconductor Solutions Catalog, Mott Corporation (Published June 2025).

- 8. J. Park, H. J. Ryu and H. K. Seok: J. Powder Mater., 21 (2014) 160.

- 9. J. Banhart and J. Baumeister: MRS Online Proceedings Library (OPL)., 521 (1998) 121.Article

- 10. W. E. Frazier: J. Mater. Eng. Perform., 23 (2014) 1917.ArticlePDF

- 11. T. DebRoy, H. Wei, J. S. Zuback, T. Mukherjee, J. W. Elmer, J. O. Milewski and W. Zhang: Prog. Mater Sci., 92 (2018) 112.Article

- 12. D. Herzog, V. Seyda, E. Wycisk and C. Emmelmann: Acta Mater., 117 (2016) 371.Article

- 13. M. Vaezi, H. Seitz and S. Yang: Int. J. Adv. Manuf. Technol., 67 (2013) 1721.ArticlePDF

- 14. L. E. Murr, S. M. Gaytan, D. A. Ramirez, E. Martinez, J. Hernandez, K. N. Amato and R. B. Wicker: J. Mater. Sci. Technol., 28 (2012) 1.Article

- 15. A. G. Demir and B. Previtali: CIRP Annals., 68 (2019) 793.

- 16. A. I. Nurhudan, S. Supriadi, Y. Whulanza and A. S. Saragih: J. Manuf. Processes., 66 (2021) 228.Article

- 17. J. Gonzalez-Gutierrez, S. Cano, S. Schuschnigg, C. Kukla, J. Sapkota and C. Holzer: Mater., 11 (2018) 840.Article

- 18. P. Sevilla: J. Alloys Compd., 439 (2007) 67.Article

- 19. M. J. Lee, Y. J. Yi, H. J. Kim, M. H. Park, B. K. Kim and J. Y. Yun: Arch. Metall. Mater., 64 (2019) 547.

- 20. M. J. Lee, Y. J. Yi, H. J Kim, M. H. Park, B. K. Kim and J. Y. Yun: J. Powder Mater., 25 (2018) 415.Article

- 21. P. Liu and G. F. Chen: Porous Materials., Elsevier (2014), 10.

- 22. C. Osburn, H. Berger, R. Donovan and G. Jones: J. Environ. Sci., 31 (1988) 45.ArticlePDF

- 23. M. N. Rahaman: Ceramic Processing and Sintering., CRC Press (2017), 497.

- 24. R. M. German: Sintering Theory and Practice., Wiley (1996), 135.

References

Figure & Data

References

Citations

Fig. 1.

Fig. 2.

Fig. 3.

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Graphical abstract

| Component | C | Si | Mn | Ni | Cr | Cu | Mo | V | Other |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.02 | 0.8 | 0.2 | 12 | 17 | - | 2.5 | - | - |

| Component | PW | EVA | PE | SA |

|---|---|---|---|---|

| wt.% | 57 | 20 | 20 | 3 |

PW, paraffin wax; EVA, ethylene-vinyl acetate; PE, polyethylene; SA, stearic acid.

Table 1.

Table 2.

TOP

KPMI

KPMI

ePub Link

ePub Link Cite this Article

Cite this Article