Search

- Page Path

- HOME > Search

- [English]

- Effect of the Cross-rolling Process on the Microstructures and Mechanical Properties of 9Cr-1W ODS Steel

- Bu-An Kim, Sanghoon Noh

- J Powder Mater. 2025;32(1):37-42. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00332

- 329 View

- 13 Download

-

Abstract

Abstract

PDF

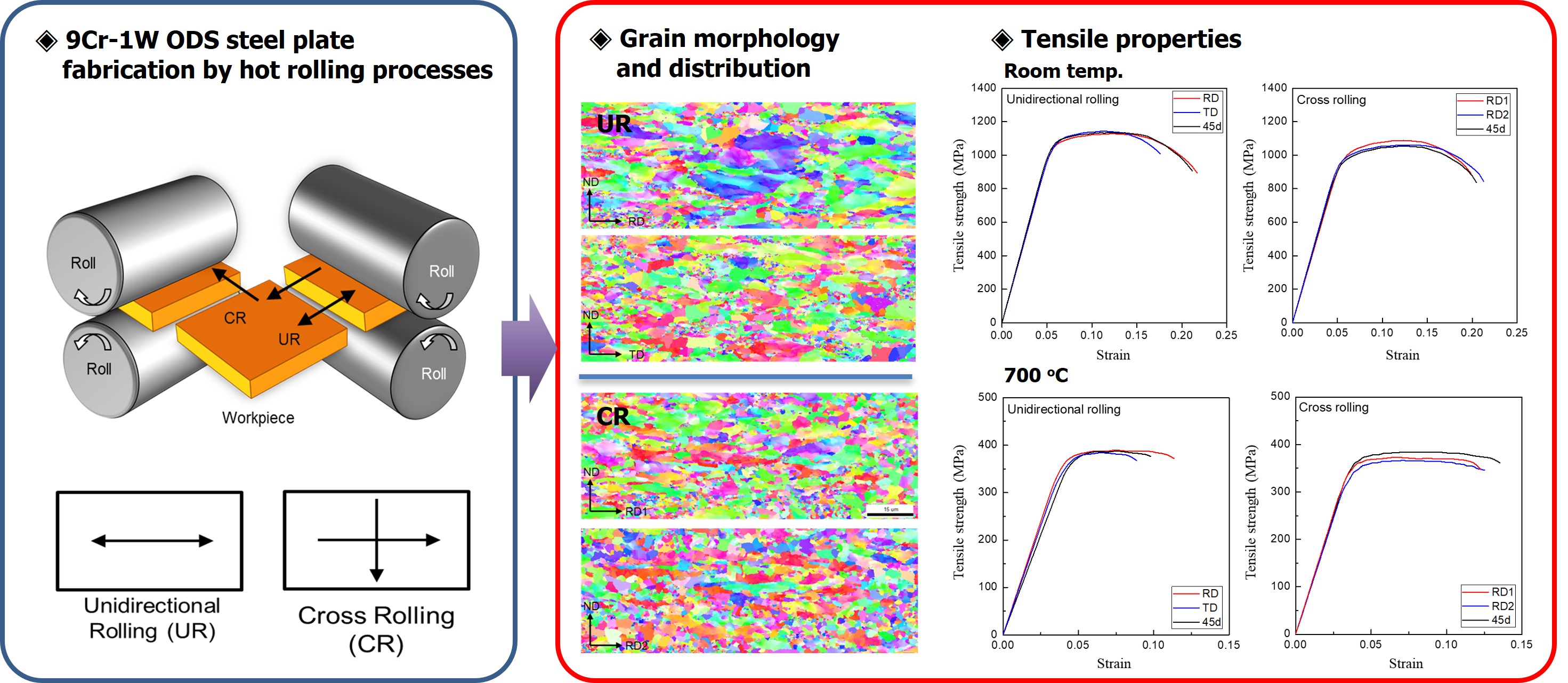

PDF - This study employed a cross-rolling process to fabricate oxide dispersion strengthened (ODS) steel plates and investigated their microstructures and mechanical properties. The 9Cr-1W ODS ferritic steel was fabricated using mechanical alloying and hot isostatic pressing. The hot cross-rolling process produced thick ODS ferritic steel plates with a well-extended rectangular shape. The working direction greatly affected the grain structure and crystal texture of the ODS ferritic steel. Cross-rolled plates showed fine micro-grains with random crystal orientation, while unidirectionally rolled plates exhibited a strong orientation with larger, elongated grains. Transmission electron microscopy revealed a uniform distribution of nano-oxide particles in both rolling methods, with no major differences. Tensile tests of the ODS ferritic steel plates showed that the unidirectional rolled plates had anisotropic elongation, while cross-rolled plates exhibited isotropic behavior with uniform elongation. Cross-rolling produced finer, more uniform grains, reducing anisotropy and improving mechanical properties, making it ideal for manufacturing wide ODS steel components.

- [Korean]

- Evolution on Microstructures and Tensile Properties of 10Cr-1Mo ODS Steel with Different Lengths of Mechanical Alloying Process Times

- Sanghoon Noh, Tae Kyu Kim

- J Korean Powder Metall Inst. 2021;28(5):375-380. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.375

- 375 View

- 3 Download

-

Abstract

Abstract

PDF

PDF In this study, we investigate the effect of the duration of mechanical alloying on the microstructures and mechanical properties of ODS ferritic/martensitic steel. The Fe(bal.)-10Cr-1Mo pre-alloyed powder and Y2O3 powder are mechanically alloyed for the different mechanical alloying duration (0 to 40 h) and then constantly fabricated using a uniaxial hot pressing process. Upon increasing the mechanical alloying time, the average powder diameter and crystallite size increased dramatically. In the initial stages within 5 h of mechanical alloying, inhomogeneous grain morphology is observed along with coarsened carbide and oxide distributions; thus, precipitate phases are temporarily observed between the two powders because of insufficient collision energy to get fragmented. After 40 h of the MA process, however, fine martensitic grains and uniformly distributed oxide particles are observed. This led to a favorable tensile strength and elongation at room temperature and 650°C.

- [Korean]

- Effect of Cobalt Contents on the Microstructure and Charpy Impact Properties of Ferritic/martensitic Oxide Dispersion Strengthened Steel

- Daehyun Kwon, Sanghoon Noh, Jung Gu Lee

- J Korean Powder Metall Inst. 2020;27(4):311-317. Published online August 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.4.311

- 415 View

- 3 Download

-

Abstract

Abstract

PDF

PDF In this study, the effects of Co content on the microstructure and Charpy impact properties of Fe-Cr-W ferritic/martensitic oxide dispersion strengthened (F/M ODS) steels are investigated. F/M ODS steels with 0–5 wt% Co are fabricated by mechanical alloying, followed by hot isostatic pressing, hot-rolling, and normalizing/tempering heat treatment. All the steels commonly exhibit two-phase microstructures consisting of ferrite and tempered martensite. The volume fraction of ferrite increases with the increase in the Co content, since the Co element considerably lowers the hardenability of the F/M ODS steel. Despite the lowest volume fraction of tempered martensite, the F/M ODS steel with 5 wt% Co shows the highest micro-Vickers hardness, owing to the solid solution-hardening effect of the alloyed Co. The high hardness of the steel improves the resistance to fracture initiation, thereby resulting in the enhanced fracture initiation energy in a Charpy impact test at – 40°C. Furthermore, the addition of Co suppresses the formation of coarse oxide inclusions in the F/M ODS steel, while simultaneously providing a high resistance to fracture propagation. Owing to these combined effects of Co, the Charpy impact energy of the F/M ODS steel increases gradually with the increase in the Co content.

- [Korean]

- A Precipitation Behavior of Nano-Oxide Particles in Mechanically Alloyed Fe-5Y2O3 Powders

- Ga Eon Kim, Sanghoon Noh, Ji Eun Choi, Young Do Kim, Tae Kyu Kim

- J Korean Powder Metall Inst. 2015;22(1):46-51. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.46

- 417 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF A precipitation behavior of nano-oxide particle in Fe-5Y2O3 alloy powders is studied. The mechanically alloyed Fe-5Y2O3 powders are pressed at 750°C for 1h, 850°C for 1h and 1150°C for 1h, respectively. The results of Xray diffraction pattern analysis indicate that the Y2O3 diffraction peak disappear after mechanically alloying process, but Y2O3 and YFe2O4 complex oxide precipitates peak are observed in the powders pressed at 1150°C. The differential scanning calorimetry study results reveal that the formation of precipitates occur at around 1054°C. Based on the transmission electron microscopy analysis result, the oxide particles with a composition of Y-Fe-O are found in the Fe-5Y2O3 alloy powders pressed at 1150°C. It is thus conclude that the mechanically alloyed Fe-5Y2O3 powders have no precipitates and the oxide particles in the powders are formed by a high temperature heat-treatment.

-

Citations

Citations to this article as recorded by- Mechanical properties of Mo-Si-B alloys fabricated by using core-shell powder with dispersion of yttria nanoparticles

Jong Min Byun, Su-Ryong Bang, Won June Choi, Min Sang Kim, Goo Won Noh, Young Do Kim

Metals and Materials International.2017; 23(1): 170. CrossRef

- Mechanical properties of Mo-Si-B alloys fabricated by using core-shell powder with dispersion of yttria nanoparticles

TOP

kpmi

kpmi

First

First Prev

Prev