Search

- Page Path

- HOME > Search

- [Korean]

- Preparation of Porous W-Cu by Freeze Casting of Tert-butyl Alcohol Slurry Mixed with WO3-CuO Powder

- Youngmin Kim, Ji Young Kim, Minju Son, Wonyong Kwon, Eui Seon Lee, Sung-Tag Oh

- J Powder Mater. 2025;32(6):466-471. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00437

- 683 View

- 7 Download

-

Abstract

Abstract

PDF

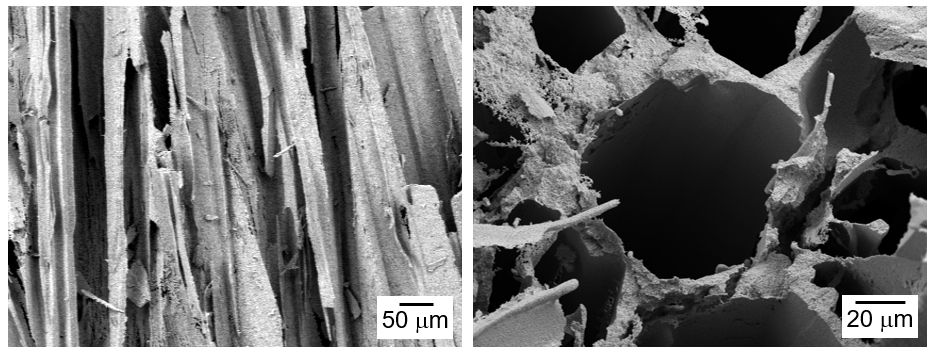

PDF - The influence of process conditions on the microstructure of porous W-Cu, fabricated by freeze casting using tert-butyl alcohol as the freezing agent, was investigated. The slurries containing 10 vol% of WO3-CuO powder were prepared by milling with a small amount of citric acid and polyethylene glycol as dispersants. The slurries with dispersion stability were frozen in a mold with the lower part cooled to -25°C, followed by sublimation in a vacuum to remove the freezing agent. The sintered W-1 vol% Cu in a hydrogen atmosphere exhibited aligned pores with the size of 50 μm, which were generated by sublimation of directionally solidified tert-butyl alcohol crystals. In the cross-section of the specimen, hexagonal pores corresponding to the crystal structure of tert-butyl alcohol was observed. Microstructure analysis of the struts revealed that Cu was distributed non-uniformly due to the mutual insolubility and low wettability of the W-Cu system.

- [Korean]

- Characteristics of WO3-CuO Powder Mixture Prepared by High-Energy Ball Milling in a Bead Mill for the Synthesis of W-Cu Nanocomposite Powder

- Hae-Ryong Park, Sung-Soo Ryu

- J Korean Powder Metall Inst. 2017;24(5):406-413. Published online October 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.5.406

- 1,032 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF A Nanosized WO3 and CuO powder mixture is prepared using novel high-energy ball milling in a bead mill to obtain a W-Cu nanocomposite powder, and the effect of milling time on the structural characteristics of WO3-CuO powder mixtures is investigated. The results show that the ball-milled WO3-CuO powder mixture reaches at steady state after 10 h milling, characterized by the uniform and narrow particle size distribution with primary crystalline sizes below 50 nm, a specific surface area of 37 m2/g, and powder mean particle size (D50) of 0.57 μm. The WO3-CuO powder mixtures milled for 10 h are heat-treated at different temperatures in H2 atmosphere to produce W-Cu powder. The XRD results shows that both the WO3 and CuO phases can be reduced to W and Cu phases at temperatures over 700°C. The reduced W-Cu nanocomposite powder exhibits excellent sinterability, and the ultrafine W-Cu composite can be obtained by the Cu liquid phase sintering process.

-

Citations

Citations to this article as recorded by- Morphological Characteristics of W/Cu Composite Nanoparticles with Complex Phase Structure Synthesized via Reactive Radio Frequency (RF) Thermal Plasma

Chulwoong Han, Song-Yi Kim, Soobin Kim, Ji-Woon Lee

Metals.2024; 14(9): 1070. CrossRef

- Morphological Characteristics of W/Cu Composite Nanoparticles with Complex Phase Structure Synthesized via Reactive Radio Frequency (RF) Thermal Plasma

TOP

KPMI

KPMI

First

First Prev

Prev