Search

- Page Path

- HOME > Search

- [English]

- Epsilon Iron Oxide (ε-Fe2O3) as an Electromagnetic Functional Material: Properties, Synthesis, and Applications

- Ji Hyeong Jeong, Hwan Hee Kim, Jung-Goo Lee, Youn-Kyoung Baek

- J Powder Mater. 2024;31(6):465-479. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00290

- 3,461 View

- 90 Download

- 3 Citations

-

Abstract

Abstract

PDF

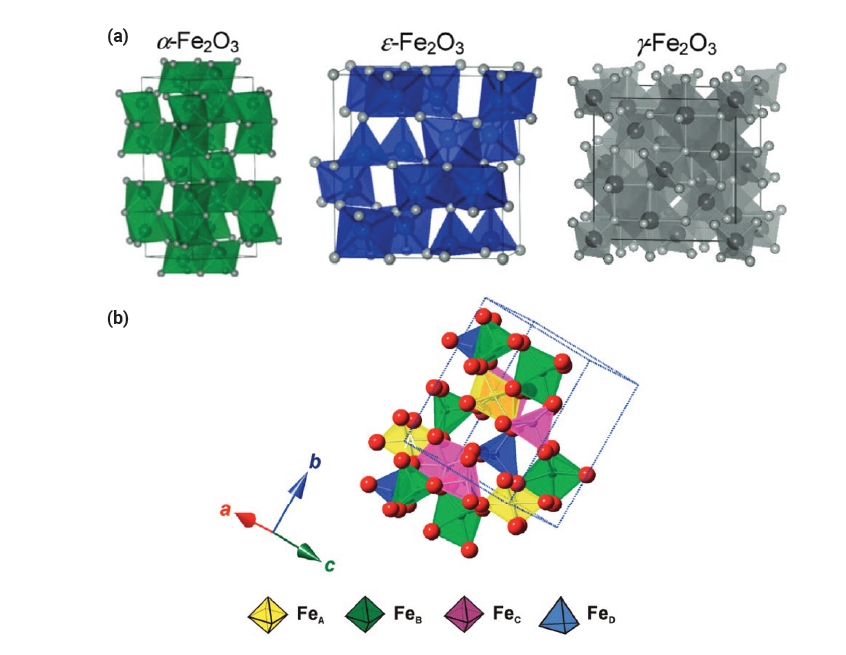

PDF - Iron oxide (ε-Fe₂O₃) is emerging as a promising electromagnetic material due to its unique magnetic and electronic properties. This review focuses on the intrinsic properties of ε-Fe₂O₃, particularly its high coercivity, comparable to that of rare-earth magnets, which is attributed to its significant magnetic anisotropy. These properties render it highly suitable for applications in millimeter wave absorption and high-density magnetic storage media. Furthermore, its semiconducting behavior offers potential applications in photocatalytic hydrogen production. The review also explores various synthesis methods for fabricating ε-Fe₂O₃ as nanoparticles or thin films, emphasizing the optimization of purity and stability. By exploring and harnessing the properties of ε-Fe₂O₃, this study aims to contribute to the advancement of next-generation electromagnetic materials with potential applications in 6G wireless telecommunications, spintronics, high-density data storage, and energy technologies.

-

Citations

Citations to this article as recorded by- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

Babak Enami Alamdari, Yu Tang, Danilo Erricolo, Lesley H. Sneed

Journal of Nondestructive Evaluation.2026;[Epub] CrossRef - Chemical Pressure Induced Strain Control of Magnetic Anisotropy in the Simple Perovskite ϵ-Fe2O3

Subir Roy, Gurleen K. Uppal, Alberto Acosta, Rachel Nickel, Charles A. Roberts, Johan van Lierop

Nano Letters.2026; 26(1): 34. CrossRef - Superparamagnetism of Baked Clays Containing Polymorphs of Iron Oxides: Experimental Study and Theoretical Modeling

Petr Kharitonskii, Andrei Krasilin, Nadezhda Belskaya, Svetlana Yanson, Nikita Bobrov, Andrey Ralin, Kamil Gareev, Nikita Zolotov, Dmitry Zaytsev, Elena Sergienko

Magnetochemistry.2025; 11(12): 103. CrossRef

- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

- [Korean]

- Research trend in Fabrication of Metastable-phase Iron Nitrides for Hard Magnetic Applications

- Kyung Min Kim, Jung-Goo Lee, Kyung Tae Kim, Youn-Kyoung Baek

- J Korean Powder Metall Inst. 2019;26(2):146-155. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.146

- 1,710 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Rare earth magnets are the strongest type of permanent magnets and are integral to the high tech industry, particularly in clean energies, such as electric vehicle motors and wind turbine generators. However, the cost of rare earth materials and the imbalance in supply and demand still remain big problems to solve for permanent magnet related industries. Thus, a magnet with abundant elements and moderate magnetic performance is required to replace rare-earth magnets. Recently, a”-Fe16N2 has attracted considerable attention as a promising candidate for next-generation non-rare-earth permanent magnets due to its gigantic magnetization (3.23 T). Also, metastable a”-Fe16N2 exhibits high tetragonality (c/a = 1.1) by interstitial introduction of N atoms, leading to a high magnetocrystalline anisotropy constant (K1 = 1.0MJ/m3). In addition, Fe has a large amount of reserves on the Earth compared to other magnetic materials, leading to low cost of raw materials and manufacturing for industrial production. In this paper, we review the synthetic methods of metastable a”-Fe16N2 with film, powder and bulk form and discuss the approaches to enhance magnetocrystalline anisotropy of a”-Fe16N2. Future research prospects are also offered with patent trends observed thus far.

-

Citations

Citations to this article as recorded by- Failure Cases according to Photocuring-Based Alumina 3D Printing

So-Young Ko, Shin-Il Go, Kyoung-Jun Jang, Sang-Jin Lee

Korean Journal of Materials Research.2024; 34(10): 457. CrossRef

- Failure Cases according to Photocuring-Based Alumina 3D Printing

- [Korean]

- Synthesis of KIT-1 Mesoporous Silicates Showing Two Different Macrosporous Strucrtues; Inverse-opal or Hollow Structures

- Youn-Kyoung Baek, Jung-Goo Lee, Young Kuk Kim

- J Korean Powder Metall Inst. 2016;23(3):189-194. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.3.189

- 596 View

- 1 Download

-

Abstract

Abstract

PDF

PDF We report a facile method for preparing KIT-1 mesoporous silicates with two different macroporous structures by dual templating. As a template for macropores, polystyrene (PS) beads are assembled into uniform three dimensional arrays by ice templating, i.e., by growing ice crystals during the freezing process of the particle suspension. Then, the polymeric templates are directly introduced into the precursor-gel solution with cationic surfactants for templating the mesopores, which is followed by hydrothermal crystallization and calcination. Later, by burning out the PS beads and the surfactants, KIT-1 mesoporous silicates with macropores are produced in a powder form. The macroporous structures of the silicates can be controlled by changing the amount of EDTANa4 salt under the same templating conditions using the PS beads and inverse-opal or hollow structures can be obtained. This strategy to prepare mesoporous powders with controllable macrostructures is potentially useful for various applications especially those dealing with bulky molecules such as, catalysis, separation, drug carriers and environmental adsorbents.

- [Korean]

- Synthesis of Silica-Core Gold-Satellite Nanoparticles and Their Surface-enhanced Raman Scattering Based Sensing Application

- Hyun Ji Choi, Young-Kuk Kim, Seok-Young Yoon, Youn-Kyoung Baek

- J Korean Powder Metall Inst. 2014;21(6):441-446. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.441

- 1,485 View

- 3 Download

-

Abstract

Abstract

PDF

PDF In this study, we synthesize silica-core gold-satellite nanoparticles (SGNPs) for the surface-enhanced Raman scattering (SERS) based sensing applications. They consist of gold satellite nanoparticles (AuNPs) fixed on the silica core nanoparticles, which sizes of AuNPs can be tunned by varying the amount of reactants (growth solution and reducing agent). Their surface plasmon resonance (SPR) properties were characterized by using UV-vis spectroscopy, showing that the growth of AuNPs on silica cores leads to the light absorption in the longer wavelength region. Furthermore, the size increase of AuNPs exhibited the dramatic change in SERS activity due to the formation of hot spots. The optimized SGNPs showing enhancement factor~3.8×106 exhibited a detection limit of rhodamine 6G (R6G) as low as 10−8 M. These findings suggest the importance of size control of SGNPs and their SPR properties to develop highly efficient SERS sensors.

- [Korean]

- Synthesis of Highly Dispersible Metal Nanoparticles in P3HT:PCBM Layers and Their Effects on the Performance of Polymer Solar Cells

- Min-Ji Kim, Gyu-Chae Choi, Young-Kuk Kim, Yang-Do Kim, Youn-Kyoung Baek

- J Korean Powder Metall Inst. 2014;21(3):179-184. Published online June 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.3.179

- 475 View

- 0 Download

-

Abstract

Abstract

PDF

PDF In this study, we prepare polymer solar cells incorporating organic ligand-modified Ag nanoparticles (OAgNPs) highly dispersed in the P3HT:PCBM layer. Ag nanoparticles decorated with water-dispersible ligands (WAgNPs) were also utilized as a control sample. The existence of the ligands on the Ag surface was confirmed by FTIR spectra. Metal nanoparticles with different surface chemistries exhibited different dispersion tendencies. O-AgNPs were highly dispersed even at high concentrations, whereas W-AgNPs exhibited significant aggregation in the polymer layer. Both dispersion and blending concentration of the Ag nanoparticles in P3HT:PCBM matrix had critical effects on the device performance as well as light absorption. The significant changes in short-circuit current density (JSC) of the solar cells seemed to be related to the change in the polymer morphology according to the concentration of AgNPs introduced. These findings suggested the importance of uniform dispersion of plasmonic metal nanoparticles and their blending concentration conditions in order to boost the solar cell performance.

- [Korean]

- Research Trend of Ceramic Filter for Water Treatment

- In-Hyuck Song, Jang-Hoon Ha, Byungseo Bae, Young-Jo Park, Jae-Woong Ko, Youn-Kyoung Baek, Young-Kuk Kim, Jung-Goo Lee, Yoo-Dong Hahn

- J Korean Powder Metall Inst. 2014;21(1):62-71. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.62

- 2,585 View

- 22 Download

- 4 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Reactive ceramic pellets incorporated iron for removing As(III), As(V), and Cr(VI) from aqueous solutions

Sunwon Rha, Yun Sik Gong, Ho Young Jo

Desalination and Water Treatment.2019; 158: 174. CrossRef - Application of Physical and Chemical Enhanced Backwashing to Reduce Membrane Fouling in the Water Treatment Process Using Ceramic Membranes

Seogyeong Park, Joon-Seok Kang, Jeong Jun Lee, Thi-Kim-Quyen Vo, Han-Seung Kim

Membranes.2018; 8(4): 110. CrossRef - Effects of particle size and forming pressure on pore properties of Fe-Cr-Al porous metal by pressureless sintering

Bon-Uk Koo, Yujeong Yi, Minjeong Lee, Byoung-Kee Kim

Metals and Materials International.2017; 23(2): 336. CrossRef - Characterization and Microstructure of an Extruded Flat-Tubular-Type Alumina Filter

Byung-Seo Bae, Jang-Hoon Ha, In-Hyuck Song

Journal of the Korean Ceramic Society.2014; 51(5): 406. CrossRef

- Reactive ceramic pellets incorporated iron for removing As(III), As(V), and Cr(VI) from aqueous solutions

- [Korean]

- Size Control of Nd-Fe-B Precursor Particles Prepared by Spray Drying and Its Effect on the Magnetic Properties of Nd-Fe-B Alloy Powders after Reduction-Diffusion

- Youn-Kyoung Baek, Young-Taek Seo, Jung-Goo Lee, Dong Su Kim, Dong Sik Bae, Chul-Jin Choi

- J Korean Powder Metall Inst. 2013;20(5):359-365.

- DOI: https://doi.org/10.4150/KPMI.2013.20.5.359

- 683 View

- 6 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - In this study, we fabricated Nd_2Fe_14B hard magnetic powders with various sizes via spray drying combined with reduction-diffusion process. Spray drying is widely used to produce nearly spherical particles that are relatively homogeneous. Thus, the precursor particles were prepared by spray drying using the aqueous solution containing Nd salts, Fe salts and boric acid with the target stoichiometric composition of Nd_2Fe_14B. The mean particle sizes of the spray-dried powders are in the range from one to seven micrometer, which are adjusted by controlling the concentrations of precursor solutions. After debinding the as-prepared precursor particles, ball milling was also conducted to control the particle sizes of Nd-Fe-B oxide powders. The resulting particles with different sizes were subjected to subsequent treatments including hydrogen reduction, Ca reduction and washing for CaO removal. The size effect of Nd-Fe-B oxide particles on the formation of Nd_2Fe_14B phase and magnetic properties was investigated.

-

Citations

Citations to this article as recorded by- Research trend in Fabrication of Metastable-phase Iron Nitrides for Hard Magnetic Applications

Kyung Min Kim, Jung-Goo Lee, Kyung Tae Kim, Youn-Kyoung Baek

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 146. CrossRef - Synthesize of Nd2Fe14B Powders from 1-D Nd2Fe14B Wires using Electrospinning Process

Nu Si A Eom, Su Noh, Muhammad Aneeq Haq, Bum Sung Kim

Journal of Korean Powder Metallurgy Institute.2019; 26(6): 477. CrossRef

- Research trend in Fabrication of Metastable-phase Iron Nitrides for Hard Magnetic Applications

- [Korean]

- The Effect of Mn Addition on Nitrogenation Behavior and Magnetic Properties of Sm-Fe Alloy Powder Produced by Reduction-diffusion Method

- Young-Taek Seo, Youn-Kyoung Baek, Jung-Goo Lee, Chul-Jin Choi

- J Korean Powder Metall Inst. 2013;20(1):13-18.

- DOI: https://doi.org/10.4150/KPMI.2013.20.1.013

- 686 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In the present study, we systematically investigated the effect of Mn addition on nitrogenation behavior and magnetic properties of Sm-Fe powders produced by reduction-diffusion process. Alloy powders with only Sm_2(Fe,Mn)_17 single phase were successfully produced by the reduction-diffusion process. The coercivity of Sm_2(Fe,Mn)_17 powder rapidly increased during nitrogenation and reached the maximum of 637 Oe after 16 hours. After further nitrogenation, it decreased. In contrast, the coercivity of Sm_2Fe_17 powder gradually increased during nitrogenation for 24 hours. The coercivity of Sm_2(Fe,Mn)_17 powder was higher than that of Sm_2Fe_17 powder at the same condition of nitrogenation. It was considered that the Mn addition facilitates the nitrogenation of Sm_2Fe_17 powder and enhances the coercivity.

-

Citations

Citations to this article as recorded by- Effect of Nb content on Sm2Fe17−xNbx and its nitrides prepared by reduction-diffusion method

Guizhi Yao, Haiming Tian, Cong Zhang, Huan Shi, Shifan Zeng, Sheng Gao, Shuangjiu Feng, Kai Zhu, Xucai Kan, Xiansong Liu

Journal of Materials Science: Materials in Electronics.2024;[Epub] CrossRef

- Effect of Nb content on Sm2Fe17−xNbx and its nitrides prepared by reduction-diffusion method

- [Korean]

- Trend in Research and Development Related to Lean Heavy Rare-earth Permanent Magnets for Next-generation Motors

- Jung-Goo Lee, Youn-Kyoung Baek, Ji-Hun Yu, Chul-Jin Choi

- J Korean Powder Metall Inst. 2012;19(2):151-159.

- DOI: https://doi.org/10.4150/KPMI.2012.19.2.151

- 711 View

- 1 Download

- 3 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Study on the Demagnetization and Classification of NdFeB Magnets According to Different Heat Treatment Temperatures

Byeong Jun Kim, Ik Keun Park, Young Sung Kim

Journal of the Korean Society of Manufacturing Technology Engineers.2021; 30(2): 119. CrossRef - Low Cost Design Study of Brushless DC Motor for Electric Water Pump Application

Tae-Uk Jung

Journal of Electrical Engineering and Technology.2014; 9(3): 942. CrossRef - Optimized Design of Rotor Considering Cost-Reduction of Small BLDC Motor for the Water Pump

Hoe-Cheon Kim, Tae-Uk Jung

The Transactions of The Korean Institute of Electrical Engineers.2013; 62(4): 495. CrossRef

- Study on the Demagnetization and Classification of NdFeB Magnets According to Different Heat Treatment Temperatures

TOP

KPMI

KPMI

First

First Prev

Prev