- [English]

- Effect of Calcium Addition on the High-Temperature Recovery of Nd and Dy from Nd-Fe-B Scrap Using Mg-Based Extractants

-

Hyoseop Kim

-

J Powder Mater. 2024;31(6):493-499. Published online December 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00283

-

-

Abstract Abstract

PDF PDF

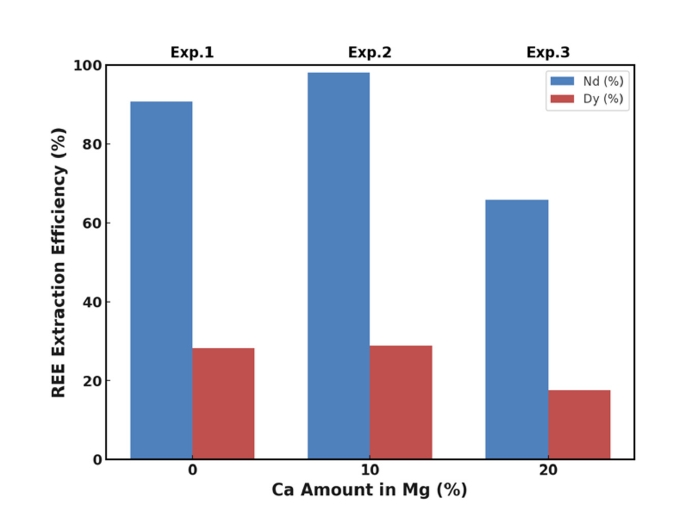

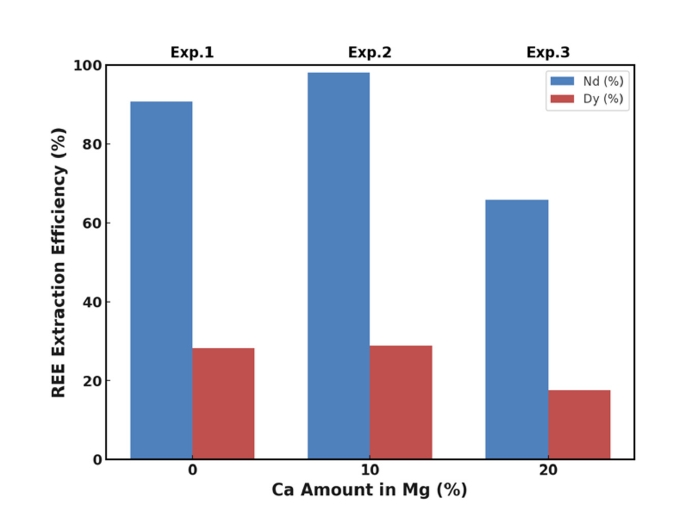

- This study investigated whether calcium (Ca) addition improved the recovery of neodymium (Nd) and dysprosium (Dy) from Nd-Fe-B magnet scrap using magnesium (Mg)-based liquid metal extraction (LME). Traditional LME processes are limited to temperatures up to 850 °C due to oxidation issues, reducing the efficiency of rare earth element (REE) recovery, especially for Dy. By adding 10 wt.% Ca to Mg and increasing the processing temperature to 1,000 °C, we achieved nearly 100% Nd and approximately 38% Dy recovery, compared to 91% and 28%, respectively, with pure Mg at 850 °C. However, excessive Ca addition (20 wt.%) decreased the recovery efficiency due to the formation of stable intermetallic compounds. These results highlight the critical role of Ca in optimizing REE recycling from Nd-Fe-B magnet scrap.

- [Korean]

- Preparation and Refinement Behavior of (Hf-Ti-Ta-Zr-Nb)C High-Entropy Carbide Powders by Ultra High Energy Ball Milling Process

-

Junwoo Song, Junhee Han, Song-Yi Kim, Jinwoo Seok, Hyoseop Kim

-

J Powder Mater. 2022;29(1):34-40. Published online February 1, 2022

-

DOI: https://doi.org/10.4150/KPMI.2022.29.1.34

-

-

1,369

View

-

3

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

Recently, high-entropy carbides have attracted considerable attention owing to their excellent physical and chemical properties such as high hardness, fracture toughness, and conductivity. However, as an emerging class of novel materials, the synthesis methods, performance, and applications of high-entropy carbides have ample scope for further development. In this study, equiatomic (Hf-Ti-Ta-Zr-Nb)C high-entropy carbide powders have been prepared by an ultrahigh- energy ball-milling (UHEBM) process with different milling times (1, 5, 15, 30, and 60 min). Further, their refinement behavior and high-entropy synthesis potential have been investigated. With an increase in the milling time, the particle size rapidly reduces (under sub-micrometer size) and homogeneous mixing of the prepared powder is observed. The distortions in the crystal lattice, which occur as a result of the refinement process and the multicomponent effect, are found to improve the sintering, thereby notably enhancing the formation of a single-phase solid solution (high-entropy). Herein, we present a procedure for the bulk synthesis of highly pure, dense, and uniform FCC single-phase (Fm3m crystal structure) (Hf-Ti-Ta-Zr-Nb)C high-entropy carbide using a milling time of 60 min and a sintering temperature of 1,600°C. -

Citations

Citations to this article as recorded by  - Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

Hansung Lee, Minsu Kim, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(4): 332. CrossRef

|