- [Korean]

- Comparison of the Properties of Rare-Earth Zirconate Thermal Barrier Coatings for Hydrogen-Fueled Gas Turbines

-

Gun-Woong Lee, Min-Soo Nam, Min-Ji Kim, HyunSuk Jung, Seongwon Kim

-

J Powder Mater. 2025;32(6):472-480. Published online December 31, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00423

-

-

Abstract Abstract

PDF PDF

- Thermal barrier coatings (TBCs) for hydrogen-fueled gas turbines withstand higher combustion temperatures and increased steam concentrations compared to conventional natural-gas systems. These harsh operating conditions significantly accelerate the thermal degradation of widely used YSZ coatings, emphasizing the need for alternative top-coat materials with improved phase stability and reduced thermal conductivity. In this study, rare-earth zirconate ceramics, Gd2Zr2O7 (GdZO), Tm2Zr2O7 (TmZO), and a mixed composition (Gd0.5Tm0.5)2Zr2O7 (Gd/TmZO), are synthesized and investigated as potential next-generation TBC candidates. Each material was comparatively examined with a focus on crystal structure, thermophysical properties, and thermal conductivity. Furthermore, high-temperature steam exposure experiments were performed to simulate hydrogen combustion environments. Microstructural analyses, high-temperature degradation behavior, and phase stability evaluations were carried out to obtain fundamental experimental data. This study provides essential baseline information for the design and development of high-performance TBC materials suitable for the hydrogen-fueled gas turbine systems.

- [Korean]

- Fabrication and High-Temperature Performance Evaluation of Light-Weight Insulation Materials and Coatings for Reusable Thermal Protection Systems

-

Min-Soo Nam, Jong-Il Kim, Jaesung Shin, Hyeonjun Kim, Bum-Seok Oh, Seongwon Kim

-

J Powder Mater. 2024;31(6):521-529. Published online December 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00318

-

-

1,546

View

-

54

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

- Light-weight ceramic insulation materials and high-emissivity coatings were fabricated for reusable thermal protection systems (TPS). Alumina-silica fibers and boric acid were used to fabricate the insulation, which was heat treated at 1250 °C. High-emissivity coating of borosilicate glass modified with TaSi2, MoSi2, and SiB6 was applied via dip-and-spray coating methods and heat-treated at 1100°C. Testing in a high-velocity oxygen fuel environment at temperatures over 1100 °C for 120 seconds showed that the rigid structures withstood the flame robustly. The coating effectively infiltrated into the fibers, confirmed by scanning electron microscopy, energy-dispersive X-ray spectroscopy, and X-ray diffraction analyses. Although some oxidation of TaSi2 occurred, thereby increasing the Ta2O5 and SiO2 phases, no significant phase changes or performance degradation were observed. These results demonstrate the potential of these materials for reusable TPS applications in extreme thermal environments.

-

Citations

Citations to this article as recorded by  - Durability Assessment of Tile-Type Reusable Thermal Protection Materials

Minjeong Kim, Seong Man Choi

Materials.2026; 19(2): 303. CrossRef

- [Korean]

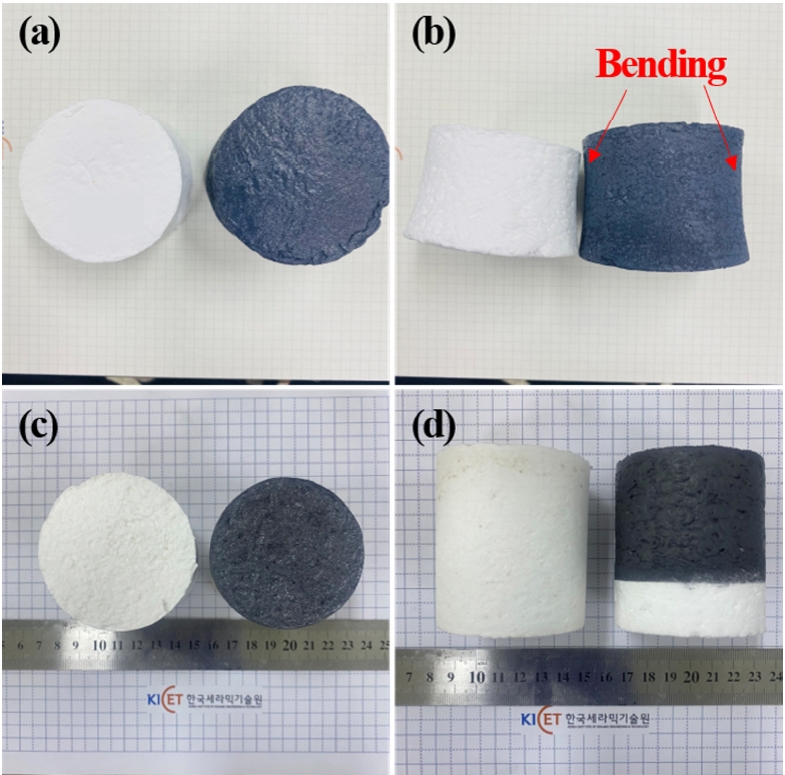

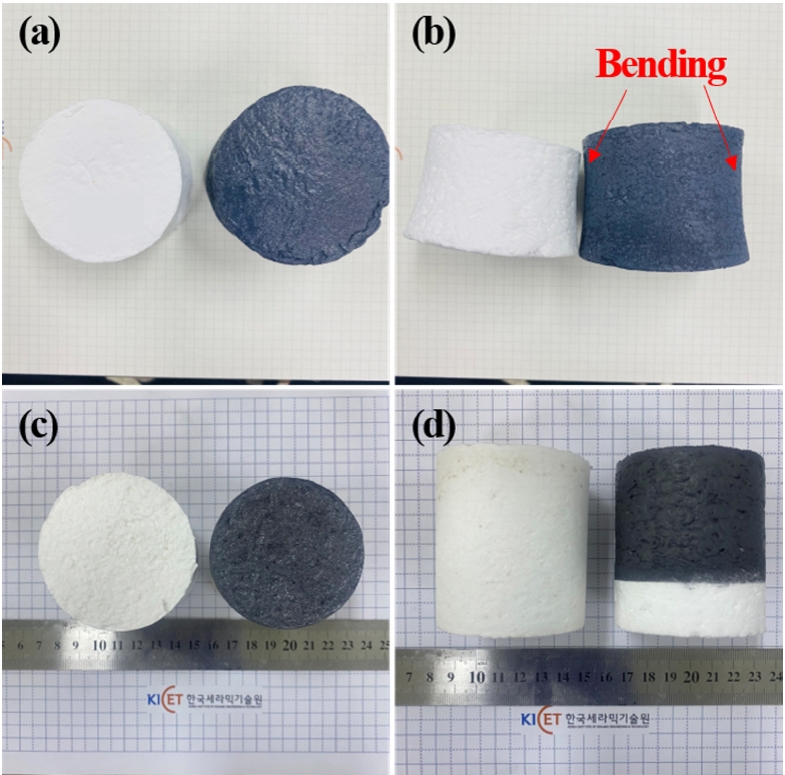

- Fabrication of Light-weight Ceramic Insulation Materials by Using Oxide Ceramic Fibers for Reusable Thermal Protection Systems

-

Seongwon Kim, Min-Soo Nam, Yoon-Suk Oh, Sahn Nahm, Jaesung Shin, Hyeonjun Kim, Bum-Seok Oh

-

J Powder Mater. 2022;29(6):477-484. Published online December 1, 2022

-

DOI: https://doi.org/10.4150/KPMI.2022.29.6.477

-

-

1,545

View

-

28

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

Thermal protection systems (TPS) are a group of materials that are indispensable for protecting spacecraft from the aerodynamic heating occurring during entry into an atmosphere. Among candidate materials for TPS, ceramic insulation materials are usually considered for reusable TPS. In this study, ceramic insulation materials, such as alumina enhanced thermal barrier (AETB), are fabricated via typical ceramic processing from ceramic fiber and additives. Mixtures of silica and alumina fibers are used as raw materials, with the addition of B4C to bind fibers together. Reaction-cured glass is also added on top of AETB to induce water-proof functionality or high emissivity. Some issues, such as the elimination of clumps in the AETB, and processing difficulties in the production of reusable surface insulation are reported as well. -

Citations

Citations to this article as recorded by  - Fabrication and High-Temperature Performance Evaluation of Light-Weight Insulation Materials and Coatings for Reusable Thermal Protection Systems

Min-Soo Nam, Jong-Il Kim, Jaesung Shin, Hyeonjun Kim, Bum-Seok Oh, Seongwon Kim

Journal of Powder Materials.2024; 31(6): 521. CrossRef

- [Korean]

- Comparison of Properties with Different Sintering Process of 3Y-TZP/WC Composites

-

Min-Soo Nam, Jae-Hyung Choi, Sahn Nahm, Seongwon Kim

-

J Powder Mater. 2022;29(5):424-431. Published online October 1, 2022

-

DOI: https://doi.org/10.4150/KPMI.2022.29.5.424

-

-

889

View

-

3

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

3Y-TZP ceramics obtained by doping 3 mol.% of Y2O3 to ZrO2 to stabilize the phase transition are widely used in the engineering ceramic industry due to their excellent mechanical properties such as high strength, fracture toughness, and wear resistance. An additional increase in mechanical properties is possible by manufacturing a composite in which a high-hardness material such as oxide or carbide is added to the 3Y-TZP matrix. In this study, composite powder was prepared by dispersing a designated percentage of WC in the 3Y-TZP matrix, and the results were compared after manufacturing the composite using the different processes of spark plasma sintering and HP. The difference between the densification behavior and porosity with the process mechanism was investigated. The correlation between the process conditions and phase formation was examined based on the crystalline phase formation behavior. Changes to the microstructure according to the process conditions were compared using field-emission scanning electron microscopy. The toughness-strengthening mechanism of the composite with densification and phase formation was also investigated. -

Citations

Citations to this article as recorded by  - Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

journal of Korean Powder Metallurgy Institute.2023; 30(5): 409. CrossRef

|