- [Korean]

- Effect of Sintering Conditions on the Microstructure of an FeCrMnNiCo High-Entropy Alloy

-

Seonghyun Park, Sang-Hwa Lee, Junho Lee, Seok-Jae Lee, Jae-Gil Jung

-

J Powder Mater. 2024;31(5):406-413. Published online October 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00185

-

-

1,299

View

-

40

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

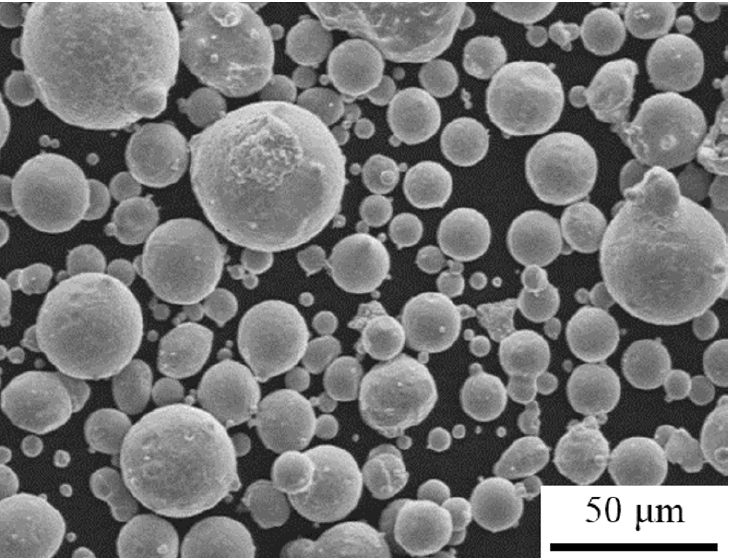

- We investigated the microstructure of an FeCrMnNiCo alloy fabricated by spark plasma sintering under different sintering temperatures (1000–1100°C) and times (1–600 s). All sintered alloys consisted of a single face-centered cubic phase. As the sintering time or temperature increased, the grains of the sintered alloys became partially coarse. The formation of Cr7C3 carbide occurred on the surface of the sintered alloys due to carbon diffusion from the graphite crucible. The depth of the layer containing Cr7C3 carbides increased to ~110 μm under severe sintering conditions (1100°C, 60 s). A molten zone was observed on the surface of the alloys sintered at higher temperatures (>1060°C) due to severe carbon diffusion that reduced the melting point of the alloy. The porosity of the sintered alloys decreased with increasing time at 1000°C, but increased at higher temperatures above 1060°C due to melting-induced porosity formation.

-

Citations

Citations to this article as recorded by  - Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Microstructure and mechanical properties of oxide-dispersion-strengthened CrMnFeCoNiC0.2O0.2 high-entropy alloy fabricated by mechanical alloying and spark plasma sintering

Sang-Hwa Lee, Seonghyun Park, Ka Ram Lim, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2025; 947: 149284. CrossRef

- [Korean]

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

-

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

-

J Powder Mater. 2023;30(6):470-477. Published online December 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.6.470

-

-

2,795

View

-

32

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

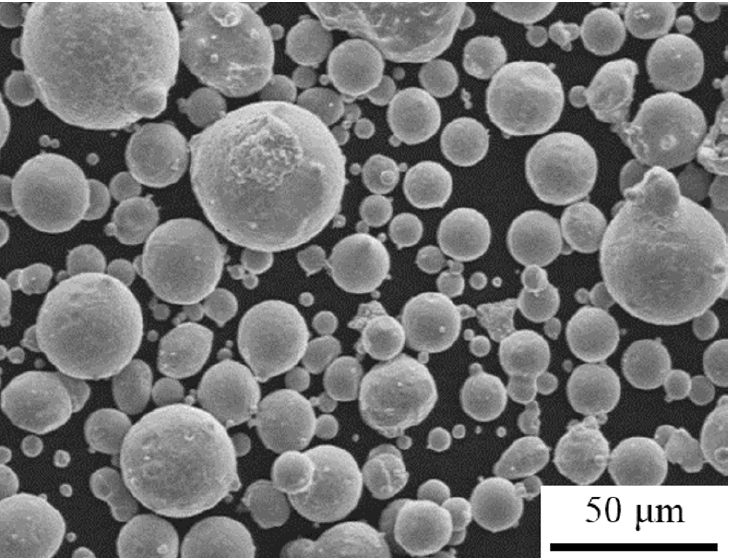

The effects of annealing on the microstructure and mechanical properties of Al–Zn–Mg–Cu–Si alloys fabricated by high-energy ball milling (HEBM) and spark plasma sintering (SPS) were investigated. The HEBM-free sintered alloy primarily contained Mg2Si, Q-AlCuMgSi, and Si phases. Meanwhile, the HEBM-sintered alloy contains Mg-free Si and θ-Al2Cu phases due to the formation of MgO, which causes Mg depletion in the Al matrix. Annealing without and with HEBM at 500°C causes partial dissolution and coarsening of the Q-AlCuMgSi and Mg2Si phases in the alloy and dissolution of the θ-Al2Cu phase in the alloy, respectively. In both alloys, a thermally stable α-AlFeSi phase was formed after long-term heat treatment. The grain size of the sintered alloys with and without HEBM increased from 0.5 to 1.0 μm and from 2.9 to 6.3 μm, respectively. The hardness of the sintered alloy increases after annealing for 1 h but decreases significantly after 24 h of annealing. Extending the annealing time to 168 h improved the hardness of the alloy without HEBM but had little effect on the alloy with HEBM. The relationship between the microstructural factors and the hardness of the sintered and annealed alloys is discussed. -

Citations

Citations to this article as recorded by  - Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Hanjung Kwon, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2024; 31: 205. CrossRef

|