- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

-

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

-

J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00150

-

-

Abstract Abstract

PDF PDF

- The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [Korean]

- Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

-

Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

-

J Powder Mater. 2024;31(4):302-307. Published online August 30, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00157

-

-

1,559

View

-

35

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

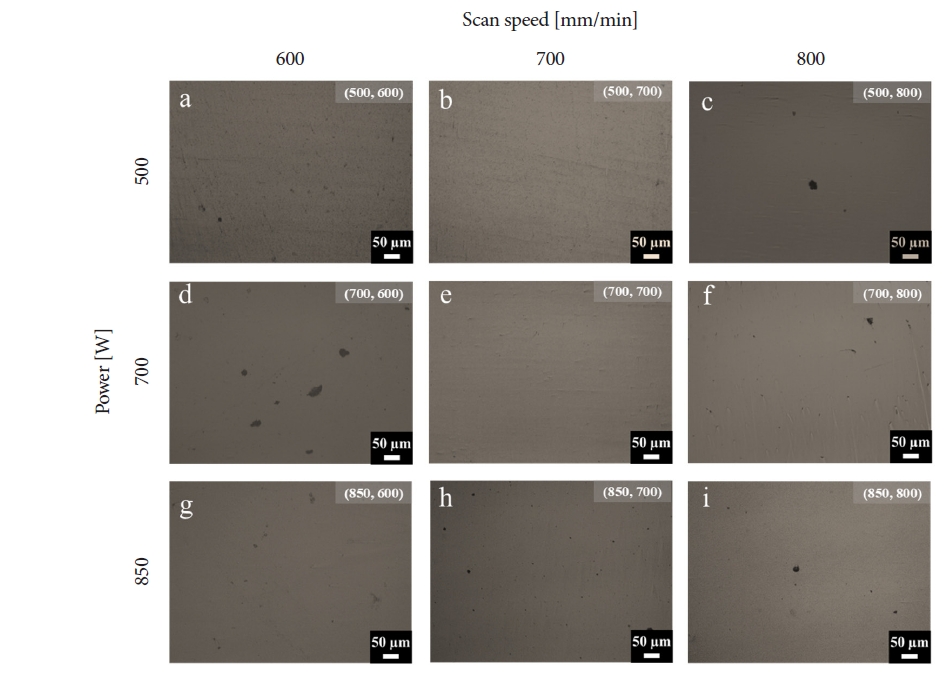

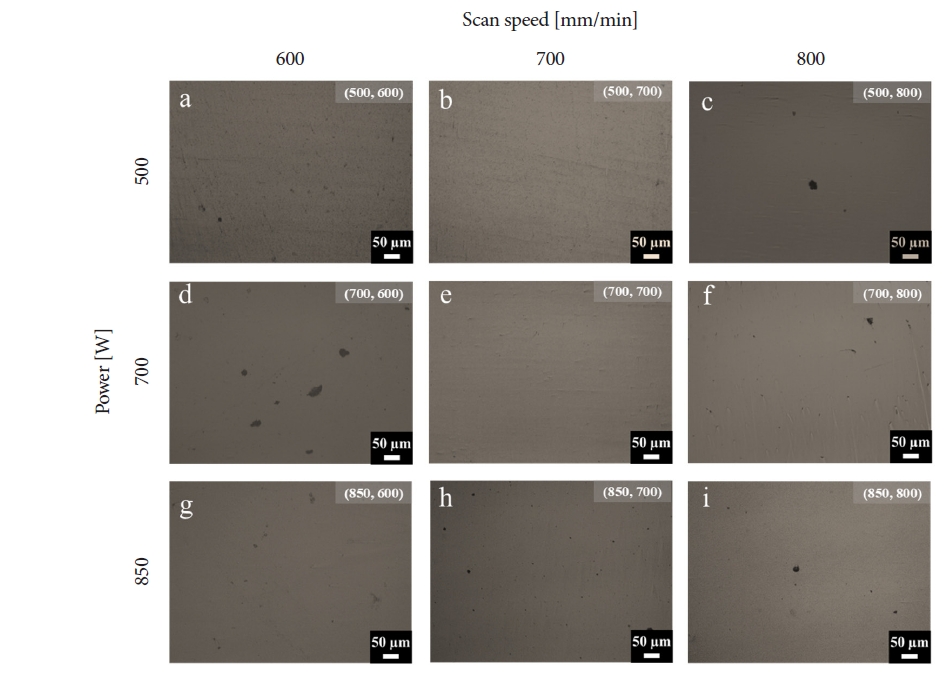

- This study explored the process-structure-property (PSP) relationships in Ti-6Al-4V alloys fabricated through direct energy deposition (DED) additive manufacturing. A systematic investigation was conducted to clarify how process variables—specifically, manipulating the cooling rate and energy input by adjusting the laser power and scan speed during the DED process—influenced the phase fractions, pore structures, and the resultant mechanical properties of the samples under various processing conditions. Significant links were found between the controlled process parameters and the structural and mechanical characteristics of the produced alloys. The findings of this research provide foundational knowledge that will drive the development of more effective and precise control strategies in additive manufacturing, thereby improving the performance and reliability of produced materials. This, in turn, promises to make significant contributions to both the advancement of additive manufacturing technologies and their applications in critical sectors.

-

Citations

Citations to this article as recorded by  - Microstructural and tribological performance of Ti6Al4V alloy modified by laser surface texturing

Bryan Ivan Quintanar-Abarca, Dulce Viridiana Melo-Máximo, Lizbeth Melo-Máximo, Esmeralda Uribe-Lam, Erika García-López

Journal of Materials Science.2026; 61(2): 1309. CrossRef - Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef

- [English]

- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

-

Seoyeon Jeon, Hyunjoo Choi

-

J Powder Mater. 2024;31(3):213-219. Published online June 27, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00150

-

-

2,682

View

-

74

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

- Additive Manufacturing (AM) is a process that fabricates products by manufacturing materials according to a three-dimensional model. It has recently gained attention due to its environmental advantages, including reduced energy consumption and high material utilization rates. However, controlling defects such as melting issues and residual stress, which can occur during metal additive manufacturing, poses a challenge. The trial-and-error verification of these defects is both time-consuming and costly.

Consequently, efforts have been made to develop phenomenological models that understand the influence of process variables on defects, and mechanical/electrical/thermal properties of geometrically complex products. This paper introduces modeling techniques that can simulate the powder additive manufacturing process. The focus is on representative metal additive manufacturing processes such as Powder Bed Fusion (PBF), Direct Energy Deposition (DED), and Binder Jetting (BJ) method.

To calculate thermal-stress history and the resulting deformations, modeling techniques based on Finite Element Method (FEM) are generally utilized. For simulating the movements and packing behavior of powders during powder classification, modeling techniques based on Discrete Element Method (DEM) are employed. Additionally, to simulate sintering and microstructural changes, techniques such as Monte Carlo (MC), Molecular Dynamics (MD), and Phase Field Modeling (PFM) are predominantly used.

-

Citations

Citations to this article as recorded by  - Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- [Korean]

- Combinatorial Experiment for Al-6061 and Al-12Si alloy Based on Directed Energy Deposition (DED) Process

-

Seoyeon Jeon, Suwon Park, Yongwook Song, Jiwon Park, Hyunyoung Park, Boram Lee, Hyunjoo Choi

-

J Powder Mater. 2023;30(6):463-469. Published online December 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.6.463

-

-

2,055

View

-

45

Download

-

4

Citations

-

Abstract Abstract

PDF PDF

Aluminum alloys, known for their high strength-to-weight ratios and impressive electrical and thermal conductivities, are extensively used in numerous engineering sectors, such as aerospace, automotive, and construction. Recently, significant efforts have been made to develop novel aluminum alloys specifically tailored for additive manufacturing. These new alloys aim to provide an optimal balance between mechanical properties and thermal/ electrical conductivities. In this study, nine combinatorial samples with various alloy compositions were fabricated using direct energy deposition (DED) additive manufacturing by adjusting the feeding speeds of Al6061 alloy and Al-12Si alloy powders. The effects of the alloying elements on the microstructure, electrical conductivity, and hardness were investigated. Generally, as the Si and Cu contents decreased, electrical conductivity increased and hardness decreased, exhibiting trade-off characteristics. However, electrical conductivity and hardness showed an optimal combination when the Si content was adjusted to below 4.5 wt%, which can sufficiently suppress the grain boundary segregation of the α- Si precipitates, and the Cu content was controlled to induce the formation of Al2Cu precipitates. -

Citations

Citations to this article as recorded by  - Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef - Trends in Materials Modeling and Computation for Metal Additive Manufacturing

Seoyeon Jeon, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2024; 31(3): 213. CrossRef - The Challenges and Advances in Recycling/Re-Using Powder for Metal 3D Printing: A Comprehensive Review

Alex Lanzutti, Elia Marin

Metals.2024; 14(8): 886. CrossRef - Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

Journal of Powder Materials.2024; 31(4): 302. CrossRef

|