- [Korean]

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

-

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

-

J Powder Mater. 2025;32(3):244-253. Published online June 30, 2025

-

DOI: https://doi.org/10.4150/jpm.2025.00087

-

-

Abstract Abstract

PDF PDF

- Ti-6Al-4V alloy is widely utilized in aerospace and medical sectors due to its high specific strength, corrosion resistance, and biocompatibility. However, its low machinability makes it difficult to manufacture complex-shaped products. Advancements in additive manufacturing have focused on producing high-performance, complex components using the laser powder bed fusion (LPBF) process, which is a specialized technique for customized geometries. The LPBF process exposes materials to extreme thermal conditions and rapid cooling rates, leading to residual stresses within the parts. These stresses are intensified by variations in the thermal history across regions of the component. These variations result in differences in microstructure and mechanical properties, causing distortion. Although support structure design has been researched to minimize residual stress, few studies have conducted quantitative analyses of stress variations due to different support designs. This study investigated changes in the residual stress and mechanical properties of Ti-6Al-4V alloy fabricated using LPBF, focusing on support structure design.

- [English]

- Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

-

Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

-

J Powder Mater. 2024;31(2):137-145. Published online April 30, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00038

-

-

4,745

View

-

119

Download

-

6

Citations

-

Abstract Abstract

PDF PDF

- In order to predict the process window of laser powder bed fusion (LPBF) for printing metallic components, the calculation of volumetric energy density (VED) has been widely calculated for controlling process parameters. However, because it is assumed that the process parameters contribute equally to heat input, the VED still has limitation for predicting the process window of LPBF-processed materials. In this study, an explainable machine learning (xML) approach was adopted to predict and understand the contribution of each process parameter to defect evolution in Ti alloys in the LPBF process. Various ML models were trained, and the Shapley additive explanation method was adopted to quantify the importance of each process parameter. This study can offer effective guidelines for fine-tuning process parameters to fabricate high-quality products using LPBF.

-

Citations

Citations to this article as recorded by  - Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

Jaemin Wang, Seungyeon Lee, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park, Dierk Raabe

Acta Materialia.2026; 304: 121751. CrossRef - From physics to intelligence: a review of AI-driven modeling strategies in laser direct energy deposition additive manufacturing

Seyedeh Fatemeh Nabavi, Saeid Nahavandi, Hamid Garmestani

Optics & Laser Technology.2026; 199: 114946. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Automated segmentation and analysis of microscopy images of laser powder bed fusion melt tracks

Aagam Shah, Reimar Weissbach, David A. Griggs, A. John Hart, Elif Ertekin, Sameh Tawfick

Journal of Manufacturing Processes.2025; 154: 61. CrossRef - Coefficient of Thermal Expansion of AlSi10Mg, 316L Stainless Steel and Ti6Al4V Alloys Made with Laser Powder Bed Fusion

Selami Emanet, Edem Honu, Kekeli Agbewornu, Evelyn Quansah, Congyuan Zeng, Patrick Mensah

Materials.2025; 18(19): 4468. CrossRef - Adaptive slicing for increased productivity of metal laser powder bed fusion

Lars Vanmunster, Louca R. Goossens, Laurent Sergeant, Brecht Van Hooreweder, Bey Vrancken

Additive Manufacturing.2025; 112: 105000. CrossRef

- [English]

- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

-

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

-

J Powder Mater. 2024;31(1):8-15. Published online February 28, 2024

-

DOI: https://doi.org/10.4150/KPMI.2024.31.1.8

-

-

4,535

View

-

139

Download

-

5

Citations

-

Abstract Abstract

PDF PDF

The emergence of ferrous-medium entropy alloys (FeMEAs) with excellent tensile properties represents a potential direction for designing alloys based on metastable engineering. In this study, an FeMEA is successfully fabricated using laser powder bed fusion (LPBF), a metal additive manufacturing technology. Tensile tests are conducted on the LPBF-processed FeMEA at room temperature and cryogenic temperatures (77 K). At 77 K, the LPBF-processed FeMEA exhibits high yield strength and excellent ultimate tensile strength through active deformation-induced martensitic transformation. Furthermore, due to the low stability of the face-centered cubic (FCC) phase of the LPBF-processed FeMEA based on nano-scale solute heterogeneity, stress-induced martensitic transformation occurs, accompanied by the appearance of a yield point phenomenon during cryogenic tensile deformation. This study elucidates the origin of the yield point phenomenon and deformation behavior of the FeMEA at 77 K. -

Citations

Citations to this article as recorded by  - Stronger weld than base metal in face-centered cubic alloy through multi-scale heterogeneity

Yoona Lee, Sangwon Park, Dongwon Shin, Marcia Myung Hye Ahn, Wei Xiong, Nokeun Park, Hyoung Seop Kim, Je In Lee, Wookjin Lee, Yoon Suk Choi, Jeong Min Park, Namhyun Kang

Materials Research Letters.2026; : 1. CrossRef - Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

Journal of Powder Materials.2025; 32(2): 130. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Cryogenic tensile behavior of carbon-doped CoCrFeMnNi high-entropy alloys additively manufactured by laser powder bed fusion

Haeum Park, Hyeonseok Kwon, Kyung Tae Kim, Ji-Hun Yu, Jungho Choe, Hyokyung Sung, Hyoung Seop Kim, Jung Gi Kim, Jeong Min Park

Additive Manufacturing.2024; 86: 104223. CrossRef - Recent progress in high-entropy alloys for laser powder bed fusion: Design, processing, microstructure, and performance

Asker Jarlöv, Zhiguang Zhu, Weiming Ji, Shubo Gao, Zhiheng Hu, Priyanka Vivegananthan, Yujia Tian, Devesh Raju Kripalani, Haiyang Fan, Hang Li Seet, Changjun Han, Liming Tan, Feng Liu, Mui Ling Sharon Nai, Kun Zhou

Materials Science and Engineering: R: Reports.2024; 161: 100834. CrossRef

- [Korean]

- Effect of Bulk Shape on Mechanical Properties of Ti-6Al-4V Alloy Manufactured by Laser Powder Bed Fusion

-

Haeum Park, Yeon Woo Kim, Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Jung Gi Kim, Jeong Min Park

-

J Powder Mater. 2023;30(2):140-145. Published online April 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.2.140

-

-

2,499

View

-

33

Download

-

6

Citations

-

Abstract Abstract

PDF PDF

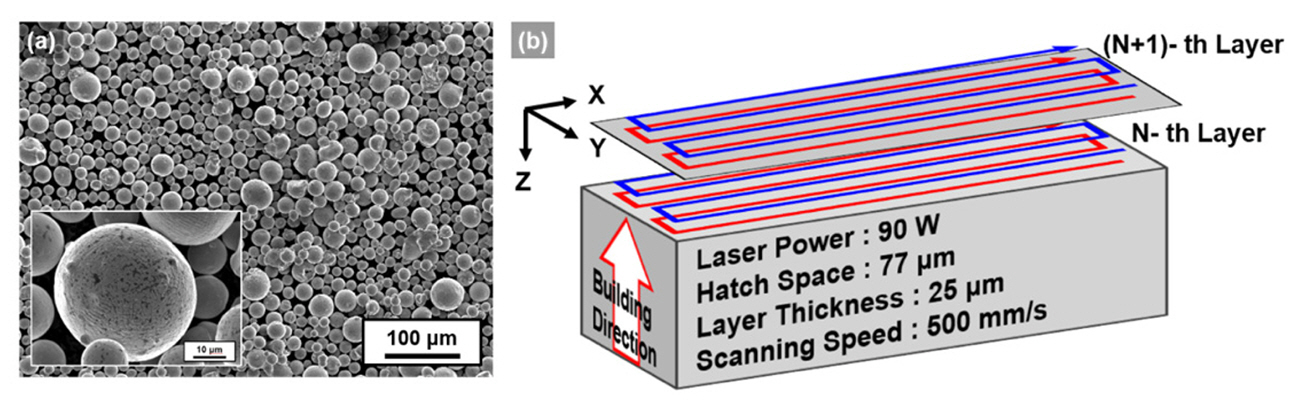

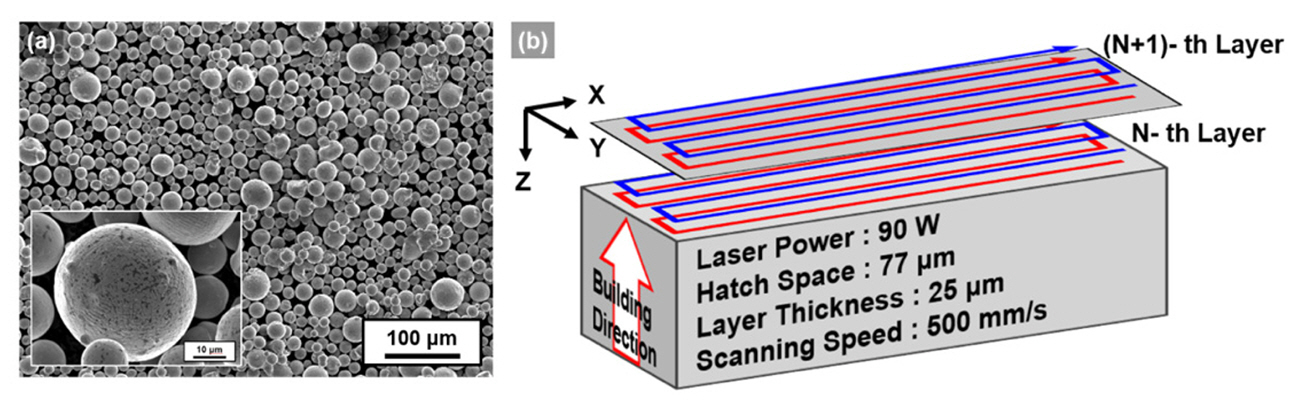

Although the Ti–6Al–4V alloy has been used in the aircraft industry owing to its excellent mechanical properties and low density, the low formability of the alloy hinders broadening its applications. Recently, laser-powder bed fusion (L-PBF) has become a novel process for overcoming the limitations of the alloy (i.e., low formability), owing to the high degree of design freedom for the geometry of products having outstanding performance used in hightech applications. In this study, to investigate the effect of bulk shape on the microstructure and mechanical properties of L-PBFed Ti-6Al-4V alloys, two types of samples are fabricated using L-PBF: thick and thin samples. The thick sample exhibits lower strength and higher ductility than the thin sample owing to the larger grain size and lower residual dislocation density of the thick sample because of the heat input during the L-PBF process. -

Citations

Citations to this article as recorded by  - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef - Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

journal of Korean Powder Metallurgy Institute.2024; 31(1): 1. CrossRef - Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

journal of Korean Powder Metallurgy Institute.2024; 31(2): 137. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef - High-speed manufacturing-driven strength-ductility improvement of H13 tool steel fabricated by selective laser melting

Yeon Woo Kim, Haeum Park, Young Seong Eom, Dong Gill Ahn, Kyung Tae Kim, Ji-hun Yu, Yoon Suk Choi, Jeong Min Park

Powder Metallurgy.2023; 66(5): 582. CrossRef

|