Search

- Page Path

- HOME > Search

- [English]

- Laser Processing of an Al0.1CoCrFeNi High Entropy Alloy + Cu Composite Powders via Laser Powder Bed Fusion

- Kwangtae Son, Ji-Woon Lee, Soon-Jik Hong, Somayeh Pasebani

- J Powder Mater. 2025;32(4):277-287. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00101

- 1,115 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - This study examined process–structure relationships in laser powder bed fusion of Al₀.₁CoCrFeNi + Cu composites, focusing on densification, elemental distribution, and solidification cracking. Mechanically mixed Al₀.₁CoCrFeNi and Cu powders were processed across a range of laser powers (100–250 W) and scan speeds (200–800 mm/s). Increased volumetric energy density (VED) improved densification, with a plateau near 200 J/mm³ yielding ~96% relative density; however, this value was still below application-grade thresholds. At low VED, insufficient thermal input and short melt pool residence times promoted Cu segregation, while higher VED facilitated improved elemental mixing. Elemental mapping showed partial co-segregation of Ni with Cu at low energies. Solidification cracks were observed across all processing conditions. In high VED regimes, cracking exhibited a minimal correlation with segregation behavior and was primarily attributed to steep thermal gradients, solidification shrinkage, and residual stress accumulation. In contrast, at low VED, pronounced Cu segregation appeared to exacerbate cracking through localized thermal and mechanical mismatch.

- [English]

- Hot-Cracking Behaviors in (CoNi)85Mo15 Medium-Entropy Alloys Manufactured via Powder Bed Fusion

- Seungjin Nam, Heechan Jung, Haeum Park, Chahee Jung, Jeong Min Park, Hyoung Seop Kim, Seok Su Sohn

- J Powder Mater. 2024;31(6):537-545. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00262

- 1,413 View

- 27 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Additive manufacturing makes it possible to improve the mechanical properties of alloys through segregation engineering of specific alloying elements into the dislocation cell structure. In this study, we investigated the mechanical and microstructural characteristics of CoNi-based medium-entropy alloys (MEAs), including the refractory alloying element Mo with a large atomic radius, manufactured via laser-powder bed fusion (L-PBF). In an analysis of the printability depending on the processing parameters, we achieved a high compressive yield strength up to 653 MPa in L-PBF for (CoNi)85Mo15 MEAs. However, severe residual stress remained at high-angle grain boundaries, and a brittle µ phase was precipitated at Mo-segregated dislocation cells. These resulted in hot-cracking behaviors in (CoNi)85Mo15 MEAs during L-PBF. These findings highlight the need for further research to adjust the Mo content and processing techniques to mitigate cracking behaviors in L-PBF-manufactured (CoNi)85Mo15 MEAs.

-

Citations

Citations to this article as recorded by- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- [Korean]

- Prediction of Crack Density in additive manufactured AA7075 Alloy Reinforced with ZrH2 inoculant via Response Surface Method

- Jeong Ah Lee, Jungho Choe, Hyoung Seop Kim

- J Powder Mater. 2023;30(3):203-209. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.203

- 2,130 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

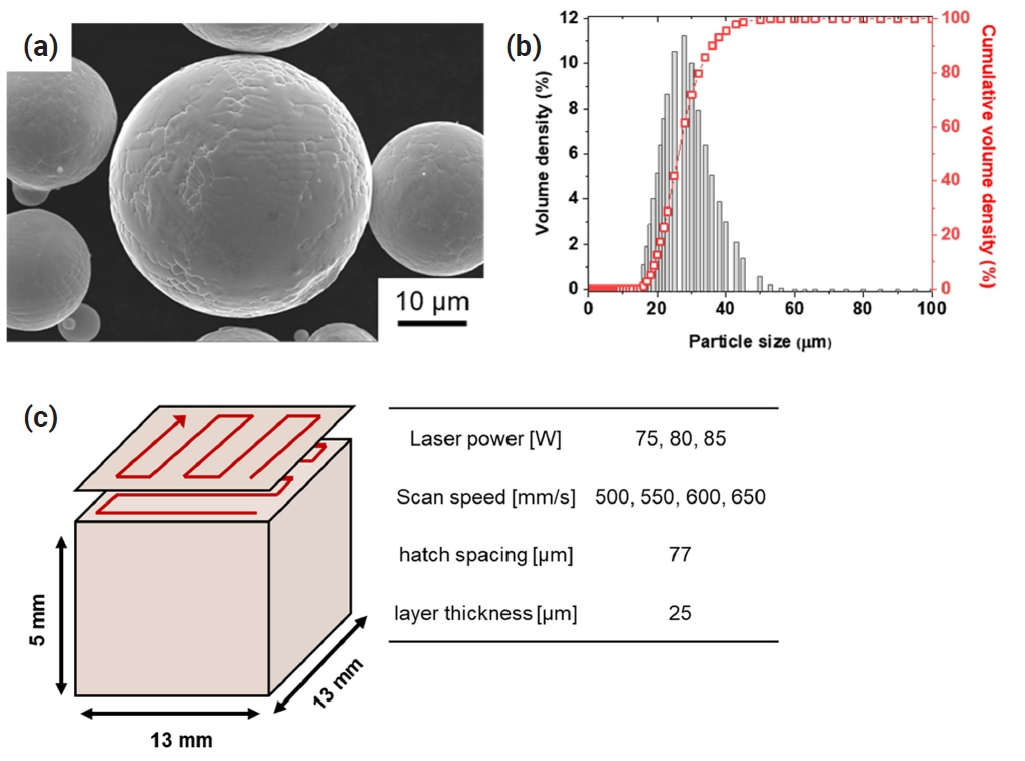

PDF Aluminum alloy-based additive manufacturing (AM) has emerged as a popular manufacturing process for the fabrication of complex parts in the automotive and aerospace industries. The addition of an inoculant to aluminum alloy powder has been demonstrated to effectively reduce cracking by promoting the formation of equiaxed grains. However, the optimization of the AM process parameters remains challenging owing to their variability. In this study, the response surface methodology (RSM) was used to predict the crack density of AM-processed Al alloy samples. RSM was performed by setting the process parameters and equiaxed grain ratio, which influence crack propagation, as independent variables and designating crack density as a response variable. The RSM-based quadratic polynomial models for crack-density prediction were found to be highly accurate. The relationship among the process parameters, crack density, and equiaxed grain fraction was also investigated using RSM. The findings of this study highlight the efficacy of RSM as a reliable approach for optimizing the properties of AM-processed parts with limited experimental data. These results can contribute to the development of robust AM processing strategies for the fabrication of highquality Al alloy components for various applications.

-

Citations

Citations to this article as recorded by- Synergistic strengthening of crack-free Al–Zn–Mg–Cu alloys with hierarchical microstructures achieved via laser powder bed fusion

Jungho Choe, Kyung Tae Kim, Jeong Min Park, Hyomoon Joo, Sang Guk Jeong, Eun Seong Kim, Soung Yeoul Ahn, Gang Hee Gu, Hyoung Seop Kim

Materials Research Letters.2024; 12(8): 598. CrossRef

- Synergistic strengthening of crack-free Al–Zn–Mg–Cu alloys with hierarchical microstructures achieved via laser powder bed fusion

TOP

KPMI

KPMI

First

First Prev

Prev