Search

- Page Path

- HOME > Search

- [English]

- Recovery of Barium, Nickel, and Titanium Powders from Waste MLCC

- Haein Shin, Kun-Jae Lee

- J Powder Mater. 2024;31(5):374-381. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00192

- 2,264 View

- 57 Download

-

Abstract

Abstract

PDF

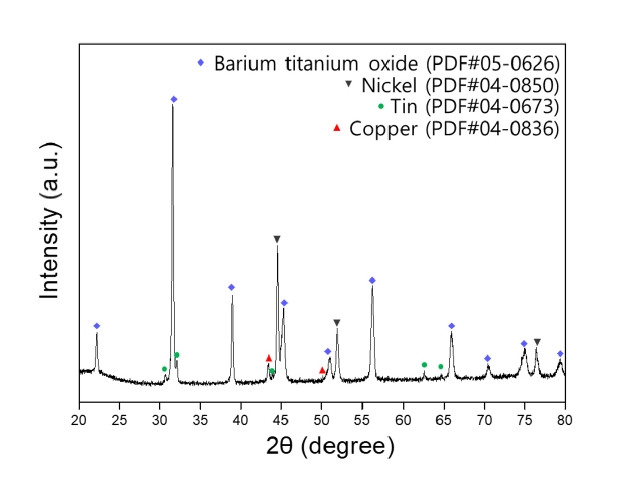

PDF - The development of the electronics industry has led to an increased demand for the manufacture of MLCC (Multilayer Ceramic Capacitors), which in turn is expected to result in a rise in MLCC waste. The MLCC contains various metals, notably barium, titanium, and nickel, whose disposal is anticipated to increase correspondingly. Recently, recycling technologies for electronic waste have garnered attention as they address waste management and raw material supply challenges. This paper investigates the recovery of barium, nickel, and titanium from the MLCC by a hydrometallurgical process. Using citric acid, which is an organic acid, the metal inside the MLCC was leached. Additionally, metal materials were recovered through precipitation and complexing processes. As a result, barium and titanium were recovered from the leachate of the waste MLCC, and 93% of the nickel-based powder was recovered. Furthermore, the optimal recovery process conditions for recycling these metal elements were investigated.

- [Korean]

- Characterization of Classification of Synthesized Ni Nanopowders by Pulsed Wire Evaporation Method

- Joong-Hark Park, Geon-Hong Kim, Dong-Jin Lee, Soon-Jik Hong

- J Korean Powder Metall Inst. 2017;24(5):389-394. Published online October 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.5.389

- 641 View

- 4 Download

-

Abstract

Abstract

PDF

PDF Ni wires with a diameter and length of 0.4 and 100 mm, respectively, and a purity of 99.9% are electrically exploded at 25 cycles per minute. The Ni nanopowders are successfully synthesized by a pulsed wire evaporation (PWE) method, in which Ar gas is used as the ambient gas. The characterization of the nanopowders is carried out using X-ray diffraction (XRD) and a high-resolution transmission electronmicroscope (HRTEM). The Ni nanopowders are classified for a multilayer ceramic condenser (MLCC) application using a type two Air-Centrifugal classifier (model: CNI, MP-250). The characterization of the classified Ni nanopowders are carried out using a scanning electron microscope (SEM) and particle size analysis (PSA) to observe the distribution and minimum classification point (minimum cutting point) of the nanopowders.

TOP

KPMI

KPMI

First

First Prev

Prev