Search

- Page Path

- HOME > Search

- [Korean]

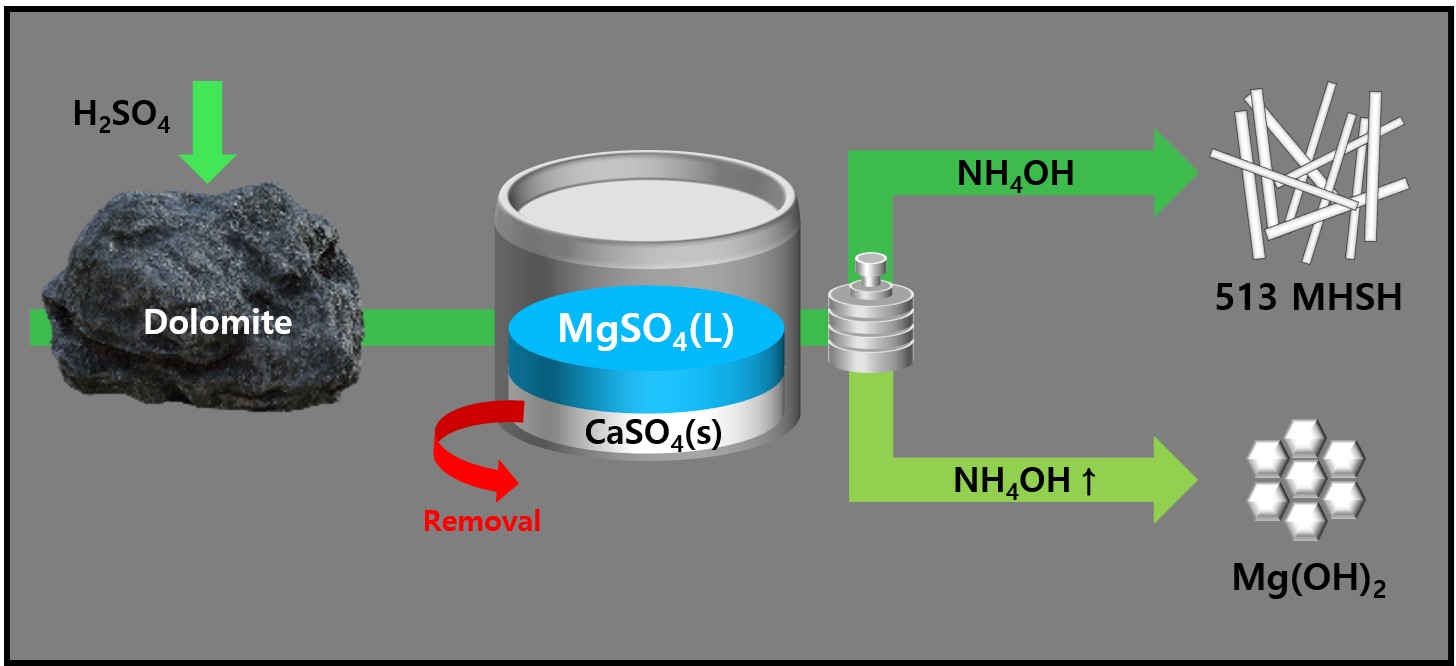

- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

- Jiyeon Kim, HyunSeung Shim, Seong-Ju Hwang, YooJin Kim

- J Powder Mater. 2025;32(5):399-405. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00227

- 433 View

- 8 Download

-

Abstract

Abstract

PDF

PDF - 513 magnesium hydroxide sulfate hydrate (MHSH) and Mg(OH)₂ were synthesized by controlling the pH and concentration using a domestic resource, dolomite (CaMg(CO3)2), as the raw material. The MgSO₄ was extracted by treating dolomite with sulfuric acid under various conditions. Hexagonal plate-shaped Mg(OH)₂ and needle-like 513 MHSH were synthesized under the hydrothermal condition. The morphology of the synthesized materials was controlled by adjusting the pH (SO42-/OH- ratio) and hydrothermal reaction time. As the pH of the solution increased, the formation of plate-like structures became dominant, whereas lower pH values (higher SO42- concentration) led to needle-like forms. The results of the 513 MHSH, which was synthesized using reagents and sea bittern, are consistent with the synthesis conditions, and we observed changes in the length and aspect ratio of the needle-shaped structure in response to adjusting the hydrothermal reaction time.

- [Korean]

- Effect of Acid Leaching Conditions on the Properties of Cr Powder Produced by Self-propagating High-temperature Synthesis

- YongKwan Lee, YeongWoo Cho, ShinYoung Choi, SungGue Heo, Ju Won, KyoungTae Park, MiHye Lee, JaeJin Sim

- J Powder Mater. 2023;30(3):233-241. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.233

- 762 View

- 3 Download

-

Abstract

Abstract

PDF

PDF In this study, we evaluated the effects of acid leaching on the properties of Cr powder synthesized using self-propagating high-temperature synthesis (SHS). Cr powder was synthesized from a mixture of Cr2O3 and magnesium (Mg) powders using the SHS Process, and the byproducts after the reaction were removed using acid leaching. The properties of the recovered Cr powder were analyzed via X-ray diffraction (XRD), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), particle size analysis (PSA), and oxygen content analysis. The results show that perfect selective leaching of Cr is challenging because of various factors such as incomplete reaction, reaction kinetics, the presence of impurities, and incompatibility between the acid and metal mixture. Therefore, this study provides essential information on the properties under acidic conditions during the production of high-quality Cr powder using a self-propagating high-temperature synthesis method.

- [Korean]

- Effect of H2SO4 and Reaction Time on Synthesis of 5Mg(OH)2∙MgSO4∙3H2O Whiskers using Hydrothermal Reaction

- Areum Choi, Nuri Oh, YooJin Kim

- J Korean Powder Metall Inst. 2020;27(5):401-405. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.401

- 1,047 View

- 2 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Magnesium hydroxide sulfate hydrate (MHSH) whiskers were synthesized via a hydrothermal reaction by using MgO as the reactant as well as the acid solution. The effects of the H2SO4 amount and reaction time at the same temperature were studied. In general, MHSH whiskers were prepared using MgSO4 in aqueous ammonia. In this work, to reduce the formation of impurities and increase the purity of MHSH, we employed a synthesis technique that did not require the addition of a basic solution. Furthermore, the pH value, which was controlled by the H2SO4 amount, acted as an important factor for the formation of high-purity MHSH. MgO was used as the raw material because it easily reacts in water and forms Mg+ and MgOH+ ions that bind with SO4 2- ions to produce MHSH. Their morphologies and structures were determined using X-ray diffraction (XRD) and scanning electron microscopy (SEM).

-

Citations

Citations to this article as recorded by- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

Jiyeon Kim, HyunSeung Shim, Seong-Ju Hwang, YooJin Kim

Journal of Powder Materials.2025; 32(5): 399. CrossRef - Study of SiO2 coating and carboxylic surface-modification on Mg-based inorganic fiber by one-step reflux reaction

Minsol Park, Areum Choi, Seiki Kim, Wooyoung Shim, YooJin Kim

Journal of the Korean Ceramic Society.2022; 59(6): 869. CrossRef - Effect of sulfate ion on synthesis of 5 Mg(OH)2·MgSO4·3H2O whiskers using non-hydrothermal method with acid catalyst

Areum Choi, Nuri Oh, YooJin Kim

Journal of the Korean Ceramic Society.2022; 59(2): 224. CrossRef

- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

- [Korean]

- Fabrication of Metallic Tantalum Powder by Magnesium-gas Reduction of Tantalum Oxide

- Dong-Won Lee

- J Korean Powder Metall Inst. 2018;25(5):390-394. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.390

- 839 View

- 14 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Metallic tantalum powder is manufactured by reducing tantalum oxide (Ta2O5) with magnesium gas at 1,073–1,223 K in a reactor under argon gas. The high thermodynamic stability of magnesium oxide makes the reduction reaction from tantalum oxide into tantalum powder possible. The microstructure after the reduction reaction has the form of a mixture of tantalum and magnesium oxide, and the latter could be entirely eliminated by dissolving in weak hydrochloric acid. The powder size in SEM microstructure for the tantalum powder increases after acid leaching in the range of 50–300 nm, and its internal crystallite sizes are observed to be 11.5 to 24.7 nm with increasing reduction temperatures. Moreover, the optimized reduction temperature is found to be 1,173 K as the minimum oxygen concentration is approximately 1.3 wt.%.

-

Citations

Citations to this article as recorded by- A review of tantalum resources and its production

Xue WEI, Long-gong XIA, Zhi-hong LIU, Le-ru ZHANG, Qi-hou LI

Transactions of Nonferrous Metals Society of China.2023; 33(10): 3132. CrossRef - Valuable metal recovery from waste tantalum capacitors via cryogenic crushing-alkaline calcination-leaching process

Longgong Xia, Xue Wei, Hongjun Wang, Fengchun Ye, Zhihong Liu

Journal of Materials Research and Technology.2022; 16: 1637. CrossRef

- A review of tantalum resources and its production

- [Korean]

- Study on Hardness and Corrosion Resistance of Magnesium by Anodizing and Sealing Treatment With Nano-diamond Powder

- Soo Young Kang, Dae Won Lee

- J Korean Powder Metall Inst. 2014;21(4):260-265. Published online August 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.4.260

- 1,062 View

- 7 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF In this study, in order to increase surface ability of hardness and corrosion of magnesium alloy, anodizing and sealing with nano-diamond powder was conducted. A porous oxide layer on the magnesium alloy was successfully made at 85°C through anodizing. It was found to be significantly more difficult to make a porous oxide layer in the magnesium alloy compared to an aluminum alloy. The oxide layer made below 73°C by anodizing had no porous layer. The electrolyte used in this study is DOW 17 solution. The surface morphology of the magnesium oxide layer was investigated by a scanning electron microscope. The pores made by anodizing were sealed by water and aqueous nanodiamond powder respectively. The hardness and corrosion resistance of the magnesium alloy was increased by the anodizing and sealing treatment with nano-diamond powder.

-

Citations

Citations to this article as recorded by- The effect of different turbulent flow on failure behavior in secondary loop of the pressurized water reactor

Y. Hu, L. Zhao, Y.H. Lu, T. Shoji

Nuclear Engineering and Design.2020; 368: 110812. CrossRef - Effect of heat treatment on corrosion resistance and adhesion property in Zn-Mg-Zn multi-layer coated steel prepared by PVD process

Jong Min Byun, Su-Ryong Bang, Hyun Woo Kim, Tae-Yeob Kim, Suk-Jun Hong, Young Do Kim

Surface and Coatings Technology.2017; 309: 1010. CrossRef - Convergent Study of Aluminum Anodizing Method on the Thermal Fatigue

Soo Young Kang

Journal of the Korea Convergence Society.2016; 7(5): 169. CrossRef - Convergent Study of Texture on the Mechanical Properties of Electrodeposits

Soo Young Kang

Journal of the Korea Convergence Society.2016; 7(6): 193. CrossRef

- The effect of different turbulent flow on failure behavior in secondary loop of the pressurized water reactor

TOP

KPMI

KPMI

First

First Prev

Prev