Search

- Page Path

- HOME > Search

- [English]

- Characterization of the Manufacturing Process and Mechanical Properties of CoCrFeMnNi High-Entropy Alloys via Metal Injection Molding and Hot Isostatic Pressing

- Eun Seong Kim, Jae Man Park, Do Won Lee, Hyojeong Ha, Jungho Choe, Jaemin Wang, Seong Jin Park, Byeong-Joo Lee, Hyoung Seop Kim

- J Powder Mater. 2024;31(3):243-254. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00059

- 2,075 View

- 56 Download

-

Abstract

Abstract

PDF

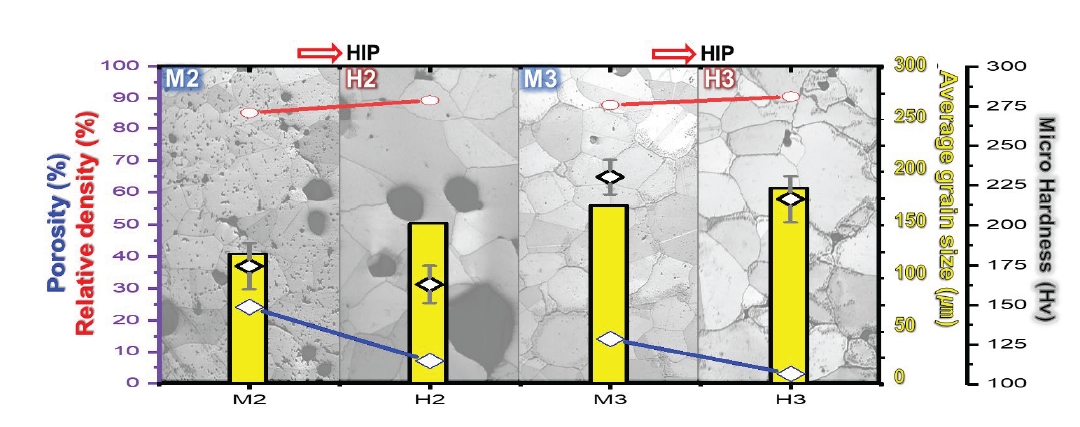

PDF - High-entropy alloys (HEAs) have been reported to have better properties than conventional materials; however, they are more expensive due to the high cost of their main components. Therefore, research is needed to reduce manufacturing costs. In this study, CoCrFeMnNi HEAs were prepared using metal injection molding (MIM), which is a powder metallurgy process that involves less material waste than machining process. Although the MIM-processed samples were in the face-centered cubic (FCC) phase, porosity remained after sintering at 1200°C, 1250°C, and 1275°C. In this study, the hot isostatic pressing (HIP) process, which considers both temperature (1150°C) and pressure (150 MPa), was adopted to improve the quality of the MIM samples. Although the hardness of the HIP-treated samples decreased slightly and the Mn composition was significantly reduced, the process effectively eliminated many pores that remained after the 1275°C MIM process. The HIP process can improve the quality of the alloy.

- [Korean]

- Microstructure and Mechanical Property of Ti-Mn-Cu Alloys with Magnetic Pulsed Compaction

- Ye Jun Yun, Chun Woong Park, Won June Choi, Jongmin Byun

- J Korean Powder Metall Inst. 2021;28(1):20-24. Published online February 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.1.20

- 796 View

- 6 Download

-

Abstract

Abstract

PDF

PDF Ti-based alloys are widely used in biomaterials owing to their excellent biocompatibility. In this study, Ti- Mn-Cu alloys are prepared by high-energy ball milling, magnetic pulsed compaction, and pressureless sintering. The microstructure and microhardness of the Ti-Mn-Cu alloys with variation of the Cu addition and compaction pressure are analyzed. The correlation between the composition, compaction pressure, and density is investigated by measuring the green density and sintered density for samples with different compositions, subjected to various compaction pressures. For all compositions, it is confirmed that the green density increases proportionally as the compaction pressure increases, but the sintered density decreases owing to gas formation from the pyrolysis of TiH2 powders and reduction of oxides on the surface of the starting powders during the sintering process. In addition, an increase in the amount of Cu addition changes the volume fractions of the α-Ti and β-Ti phases, and the microstructure of the alloys with different compositions also changes. It is demonstrated that these changes in the phase volume fraction and microstructure are closely related to the mechanical properties of the Ti-Mn-Cu alloys.

- [Korean]

- Planar Shock Wave Compaction of Oxidized Copper Nano Powders using High Speed Collision and Its Mechanical Properties

- Dong-Hyun Ahn, Wooyeol Kim, Lee Ju Park, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2014;21(1):39-43. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.39

- 857 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Bulk nanostructured copper was fabricated by a shock compaction method using the planar shock wave generated by a single gas gun system. Nano sized powders, average diameter of 100 nm, were compacted into the capsule and target die, which were designed to eliminate the effect of undesired shock wave, and then impacted with an aluminum alloy target at 400 m/s. Microstructure and mechanical properties of the shock compact specimen were analyzed using an optical microscope (OM), scanning electron microscope (SEM), and micro indentation. Hardness results showed low values (approximately 45~80 Hv) similar or slightly higher than those of conventional coarse grained commercial purity copper. This result indicates the poor quality of bonding between particles. Images from OM and SEM also confirmed that no strong bonding was achieved between them due to the insufficient energy and surface oxygen layer of the powders.

-

Citations

Citations to this article as recorded by- Compressibility of hierarchic-architectured agglomerates of hydrogen-reduced copper nanopowders

Dong-Hyun Ahn, Wooyeol Kim, Eun Yoo Yoon, Hyoung Seop Kim

Journal of Materials Science.2016; 51(1): 82. CrossRef - Analysis of the Change in Microstructures of Nano Copper Powders During the Hydrogen Reduction using X-ray Diffraction Patterns and Transmission Electron Microscope, and the Mechanical Property of Compacted Powders

Dong-Hyun Ahn, Dong Jun Lee, Wooyeol Kim, Lee Ju Park, Hyoung Seop Kim

Journal of Korean Powder Metallurgy Institute.2014; 21(3): 207. CrossRef

- Compressibility of hierarchic-architectured agglomerates of hydrogen-reduced copper nanopowders

TOP

KPMI

KPMI

First

First Prev

Prev