Search

- Page Path

- HOME > Search

- [Korean]

- Enhancement of the Electrochemical Performance of SiOx Anodes by Al2O3 Coating via Powder Atomic Layer Deposition

- Donggeon Shin, Yoonsoo Han

- J Powder Mater. 2025;32(6):501-508. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00416

- 665 View

- 6 Download

-

Abstract

Abstract

PDF

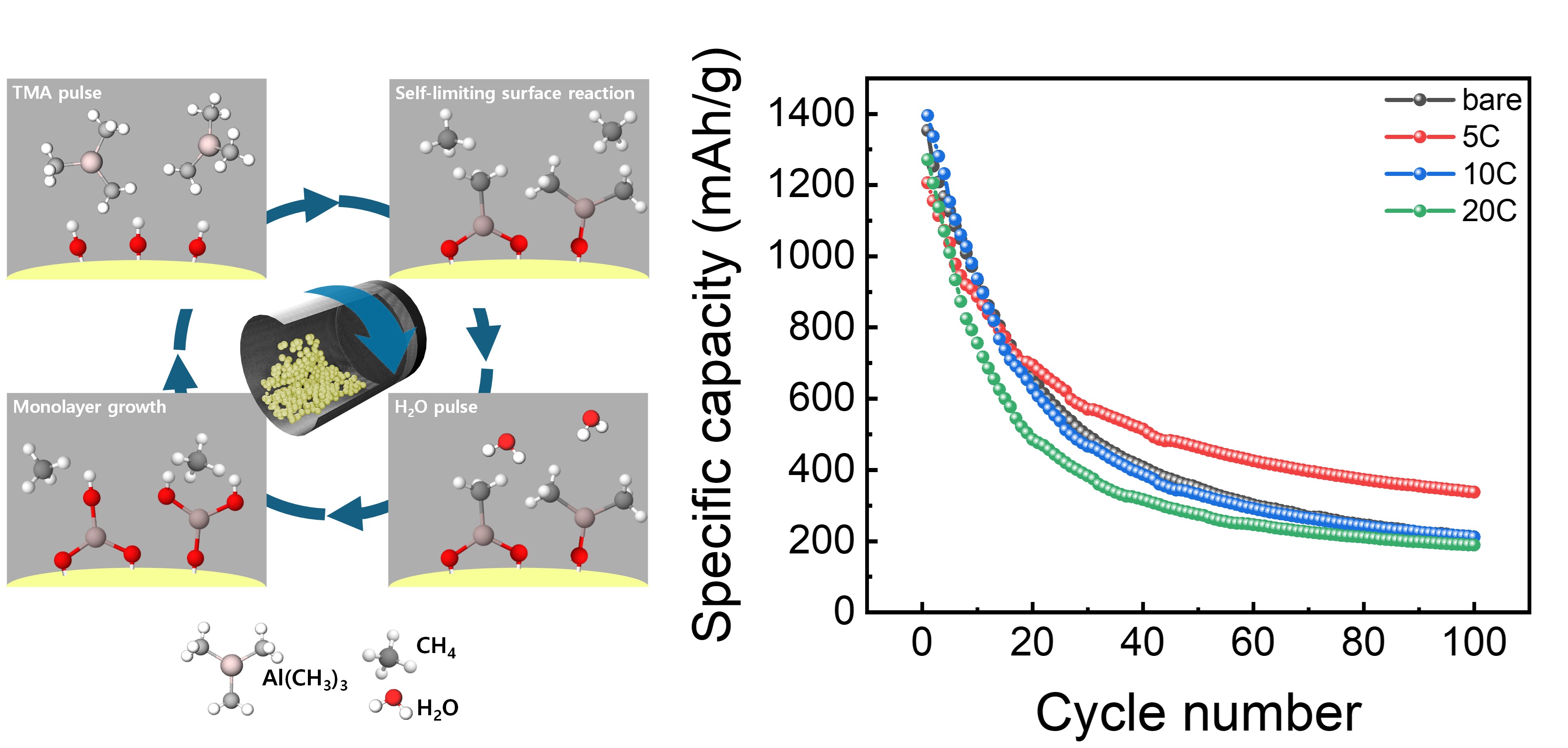

PDF - Silicon based anode materials offer high theoretical capacity but suffer from severe volume expansion and unstable interfacial properties during repeated lithiation and delithiation, resulting in rapid performance degradation. In this study, a thin aluminum oxide coating layer was deposited on Si/SiOx Carbon anode materials using a powder atomic layer deposition (PALD) process to address these limitations. EDS mapping and XRD analyses confirmed the uniform formation of an amorphous aluminum oxide coating with increasing thickness as the deposition cycles increased. Electrochemical evaluation showed that the electrode coated with 5 PALD cycles exhibited approximately 78% higher capacity retention after 100 cycles at 1 A g-1 and a higher initial Coulombic efficiency compared to the bare electrode. The coated electrode also delivered approximately 22% higher capacity at a high current density of 5 A g-1, indicating enhanced rate capability. Cyclic voltammetry analysis revealed increased surface controlled reaction contributions and improved reaction kinetics. These results demonstrate that PALD derived aluminum oxide coatings effectively stabilize the electrode electrolyte interface and enhance the electrochemical performance of silicon based anodes, highlighting their potential for next generation high capacity lithium ion batteries. generation high capacity lithium ion battery anode materials.

- [English]

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

- J Powder Mater. 2025;32(3):179-190. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00094

- 4,697 View

- 174 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Area-selective atomic layer deposition (AS-ALD) is a bottom-up process that selectively deposits thin films onto specific areas of a wafer surface. The surface reactions of AS-ALD are controlled by blocking the adsorption of precursors using inhibitors such as self-assembled monolayers (SAMs) or small molecule inhibitors. To increase selectivity during the AS-ALD process, the design of both the inhibitor and the precursor is crucial. Both inhibitors and precursors vary in reactivity and size, and surface reactions are blocked through interactions between precursor molecules and surface functional groups. However, challenges in the conventional SAM-based AS-ALD method include thermal instability and potential damage to substrates during the removal of residual SAMs after the process. To address these issues, recent studies have proposed alternative inhibitors and process design strategies.

-

Citations

Citations to this article as recorded by- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

Hojeong Yoon, Saima Sadiq, Junhyeok Park, Kyungwon Kwak, Minhaeng Cho

The Journal of Physical Chemistry Letters.2026; 17(4): 1119. CrossRef

- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

- [Korean]

- TiO2 Thin Film Coating on an Nb-Si–Based Superalloy via Atomic Layer Deposition

- Ji Young Park, Su Min Eun, Jongmin Byun, Byung Joon Choi

- J Powder Mater. 2024;31(3):255-262. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00052

- 2,040 View

- 51 Download

-

Abstract

Abstract

PDF

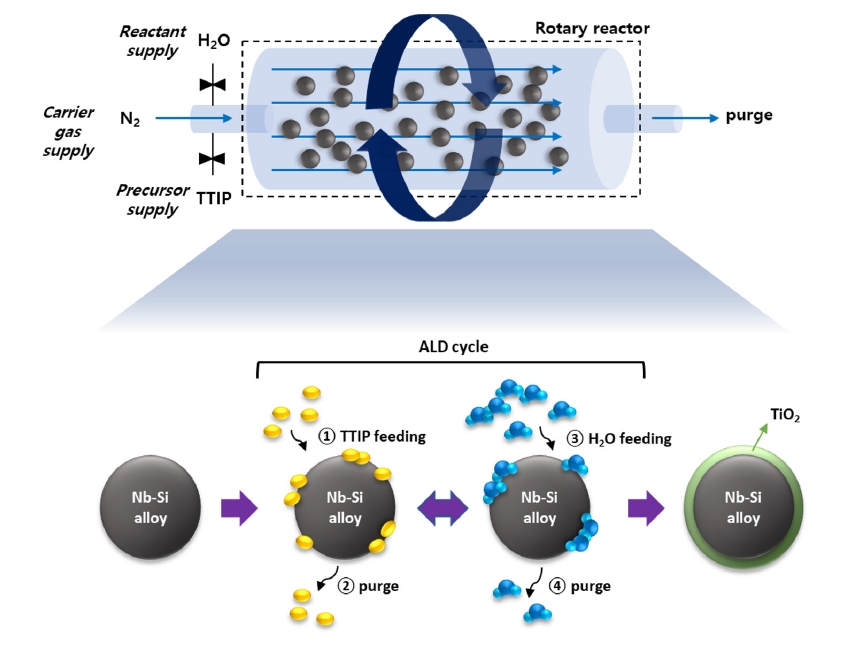

PDF - Nano-oxide dispersion–strengthened (ODS) superalloys have attracted attention because of their outstanding mechanical reinforcement mechanism. Dispersed oxides increase the material’s strength by preventing grain growth and recrystallization, as well as increasing creep resistance. In this research, atomic layer deposition (ALD) was applied to synthesize an ODS alloy. It is useful to coat conformal thin films even on complex matrix shapes, such as nanorods or powders. We coated an Nb-Si–based superalloy with TiO2 thin film by using rotary-reactor type thermal ALD. TiO2 was grown by controlling the deposition recipe, reactor temperature, N2 flow rate, and rotor speed. We could confirm the formation of uniform TiO2 film on the surface of the superalloy. This process was successfully applied to the synthesis of an ODS alloy, which could be a new field of ALD applications.

- [Korean]

- Recent Studies on Area Selective Atomic Layer Deposition of Elemental Metals

- Min Gyoo Cho, Jae Hee Go, Byung Joon Choi

- J Powder Mater. 2023;30(2):156-168. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.156

- 3,083 View

- 81 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The semiconductor industry faces physical limitations due to its top-down manufacturing processes. High cost of EUV equipment, time loss during tens or hundreds of photolithography steps, overlay, etch process errors, and contamination issues owing to photolithography still exist and may become more serious with the miniaturization of semiconductor devices. Therefore, a bottom-up approach is required to overcome these issues. The key technology that enables bottom-up semiconductor manufacturing is area-selective atomic layer deposition (ASALD). Here, various ASALD processes for elemental metals, such as Co, Cu, Ir, Ni, Pt, and Ru, are reviewed. Surface treatments using chemical species, such as self-assembled monolayers and small-molecule inhibitors, to control the hydrophilicity of the surface have been introduced. Finally, we discuss the future applications of metal ASALD processes.

-

Citations

Citations to this article as recorded by- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

Chan Hyeon Yang, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 509. CrossRef - Selective Atomic Layer Deposition of Co Thin Films Using Co(EtCp)2 Precursor

Sujeong Kim, Yong Tae Kim, Jaeyeong Heo

Korean Journal of Materials Research.2024; 34(3): 163. CrossRef

- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

- [Korean]

- Thermoelectric Performance Enhancement of Sintered Bi-Te Pellets by Rotary-type Atomic Layer Deposition

- Myeong Jun Jung, Ji Young Park, Su Min Eun, Byung Joon Choi

- J Powder Mater. 2023;30(2):130-139. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.130

- 1,460 View

- 13 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF Thermoelectric materials and devices are energy-harvesting devices that can effectively recycle waste heat into electricity. Thermoelectric power generation is widely used in factories, engines, and even in human bodies as they continuously generate heat. However, thermoelectric elements exhibit poor performance and low energy efficiency; research is being conducted to find new materials or improve the thermoelectric performance of existing materials, that is, by ensuring a high figure-of-merit (zT) value. For increasing zT, higher σ (electrical conductivity) and S (Seebeck coefficient) and a lower к (thermal conductivity) are required. Here, interface engineering by atomic layer deposition (ALD) is used to increase zT of n-type BiTeSe (BTS) thermoelectric powders. ALD of the BTS powders is performed in a rotary-type ALD reactor, and 40 to 100 ALD cycles of ZnO thin films are conducted at 100°C. The physical and chemical properties and thermoelectric performance of the ALD-coated BTS powders and pellets are characterized. It is revealed that electrical conductivity and thermal conductivity are decoupled, and thus, zT of ALD-coated BTS pellets is increased by more than 60% compared to that of the uncoated BTS pellets. This result can be utilized in a novel method for improving the thermoelectric efficiency in materials processing.

-

Citations

Citations to this article as recorded by- Highly deformable and hierarchical 3D composite sponge for versatile thermoelectric energy conversion

Jong Min Park, Changyeon Baek, Min-Ku Lee, Nagamalleswara Rao Alluri, Gyoung-Ja Lee, Kyung Tae Kim, Kwi-Il Park

Applied Surface Science.2025; 692: 162730. CrossRef - Thermal Confinement and Filtering Effect of SnSe by Insertion of Atomic-Layer-Deposited ZnO Interfacial Layer

Myeong Jun Jung, Su Min Eun, Hogyoung Kim, Seong Keun Kim, Jongmin Byun, Byung Joon Choi

Korean Journal of Chemical Engineering.2025; 42(14): 3545. CrossRef - Investigation of the Thermal-to-Electrical Properties of Transition Metal-Sb Alloys Synthesized for Thermoelectric Applications

Jong Min Park, Seungki Jo, Sooho Jung, Jinhee Bae, Linh Ba Vu, Kwi-Il Park, Kyung Tae Kim

journal of Korean Powder Metallurgy Institute.2024; 31(3): 236. CrossRef - Enhancing Electrical Properties of N-type Bismuth Telluride Alloys through Graphene Oxide Incorporation in Extrusion 3D Printing

Jinhee Bae, Seungki Jo, Kyung Tae Kim

journal of Korean Powder Metallurgy Institute.2023; 30(4): 318. CrossRef

- Highly deformable and hierarchical 3D composite sponge for versatile thermoelectric energy conversion

- [Korean]

- Recent progress on Performance Improvements of Thermoelectric Materials using Atomic Layer Deposition

- Seunghyeok Lee, Tae Joo Park, Seong Keun Kim

- J Powder Mater. 2022;29(1):56-62. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.56

- 1,621 View

- 30 Download

-

Abstract

Abstract

PDF

PDF Atomic layer deposition (ALD) is a promising technology for the uniform deposition of thin films. ALD is based on a self-limiting mechanism, which can effectively deposit thin films on the surfaces of powders of various sizes. Numerous studies are underway to improve the performance of thermoelectric materials by forming core-shell structures in which various materials are deposited on the powder surface using ALD. Thermoelectric materials are especially relevant as clean energy storage materials due to their ability to interconvert between thermal and electrical energy by the Seebeck and Peltier effects. Herein, we introduce a surface and interface modification strategy based on ALD to control the performance of thermoelectric materials. We also discuss the properties of the interface between various deposition materials and thermoelectric materials.

- [Korean]

- Rotation Speed Dependence of ZnO Coating Layer on SnSe powders by Rotary Atomic Layer Deposition Reactor

- Myeong Jun Jung, Ye Jun Yun, Jongmin Byun, Byung Joon Choi

- J Korean Powder Metall Inst. 2021;28(3):239-245. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.239

- 627 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The SnSe single crystal shows an outstanding figure of merit (

ZT ) of 2.6 at 973 K; thus, it is considered to be a promising thermoelectric material. However, the mass production of SnSe single crystals is difficult, and their mechanical properties are poor. Alternatively, we can use polycrystalline SnSe powder, which has better mechanical properties. In this study, surface modification by atomic layer deposition (ALD) is chosen to increase theZT value of SnSe polycrystalline powder. SnSe powder is ground by a ball mill. An ALD coating process using a rotary-type reactor is adopted. ZnO thin films are grown by 100 ALD cycles using diethylzinc and H2O as precursors at 100°C. ALD is performed at rotation speeds of 30, 40, 50, and 60 rpm to examine the effects of rotation speed on the thin film characteristics. The physical and chemical properties of ALD-coated SnSe powders are characterized by scanning and tunneling electron microscopy combined with energy-dispersive spectroscopy. The results reveal that a smooth oxygenrich ZnO layer is grown on SnSe at a rotation speed of 30 rpm. This result can be applied for the uniform coating of a ZnO layer on various powder materials.-

Citations

Citations to this article as recorded by- Thermal Confinement and Filtering Effect of SnSe by Insertion of Atomic-Layer-Deposited ZnO Interfacial Layer

Myeong Jun Jung, Su Min Eun, Hogyoung Kim, Seong Keun Kim, Jongmin Byun, Byung Joon Choi

Korean Journal of Chemical Engineering.2025; 42(14): 3545. CrossRef

- Thermal Confinement and Filtering Effect of SnSe by Insertion of Atomic-Layer-Deposited ZnO Interfacial Layer

- [Korean]

- Recent Research Progress on the Atomic Layer Deposition of Noble Metal Catalysts for Polymer Electrolyte Membrane Fuel Cell

- Jeong Hwan Han

- J Korean Powder Metall Inst. 2020;27(1):63-71. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.63

- 604 View

- 4 Download

-

Abstract

Abstract

PDF

PDF It is necessary to fabricate uniformly dispersed nanoscale catalyst materials with high activity and long-term stability for polymer electrolyte membrane fuel cells with excellent electrochemical characteristics of the oxygen reduction reaction and hydrogen oxidation reaction. Platinum is known as the best noble metal catalyst for polymer electrolyte membrane fuel cells because of its excellent catalytic activity. However, given that Pt is expensive, considerable efforts have been made to reduce the amount of Pt loading for both anode and cathode catalysts. Meanwhile, the atomic layer deposition (ALD) method shows excellent uniformity and precise particle size controllability over the three-dimensional structure. The research progress on noble metal ALD, such as Pt, Ru, Pd, and various metal alloys, is presented in this review. ALD technology enables the development of polymer electrolyte membrane fuel cells with excellent reactivity and durability.

- [Korean]

- Atomic Layer Deposition for Powder Coating

- Seok Choi, Jeong Hwan Han, Byung Joon Choi

- J Korean Powder Metall Inst. 2019;26(3):243-250. Published online June 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.3.243

- 2,041 View

- 45 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Atomic layer deposition (ALD) is widely used as a tool for the formation of near-atomically flat and uniform thin films in the semiconductor and display industries because of its excellent uniformity. Nowadays, ALD is being extensively used in diverse fields, such as energy and biology. By controlling the reactivity of the surface, either homogeneous or inhomogeneous coating on the shell of nanostructured powder can be accomplished by the ALD process. However, the ALD process on the powder largely depends on the displacement of powder in the reactor. Therefore, the technology for the fluidization of the powder is very important to redistribute its position during the ALD process. Herein, an overview of the three types of ALD reactors to agitate or fluidize the powder to improve the conformality of coating is presented. The principle of fluidization its advantages, examples, and limitations are addressed.

-

Citations

Citations to this article as recorded by- High-performance of ZnO/TiO2 heterostructured thin-film photocatalyst fabricated via atomic layer deposition

Ji Young Park, Jeong Hwan Han, Byung Joon Choi

Journal of Vacuum Science & Technology A.2024;[Epub] CrossRef - TiO2 Thin Film Coating on an Nb-Si–Based Superalloy via Atomic Layer Deposition

Ji Young Park, Su Min Eun, Jongmin Byun, Byung Joon Choi

journal of Korean Powder Metallurgy Institute.2024; 31(3): 255. CrossRef - Atomic layer deposition of ZnO layers on Bi2Te3 powders: Comparison of gas fluidization and rotary reactors

Myeong Jun Jung, Myeongjun Ji, Jeong Hwan Han, Young-In Lee, Sung-Tag Oh, Min Hwan Lee, Byung Joon Choi

Ceramics International.2022; 48(24): 36773. CrossRef

- High-performance of ZnO/TiO2 heterostructured thin-film photocatalyst fabricated via atomic layer deposition

- [Korean]

- Recent Developments in H2 Production Photoelectrochemical Electrode Materials by Atomic Layer Deposition

- Jeong Hwan Han

- J Korean Powder Metall Inst. 2018;25(1):60-68. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.60

- 808 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The design and fabrication of photoelectrochemical (PEC) electrodes for efficient water splitting is important for developing a sustainable hydrogen evolution system. Among various development approaches for PEC electrodes, the chemical vapor deposition method of atomic layer deposition (ALD), based on self-limiting surface reactions, has attracted attention because it allows precise thickness and composition control as well as conformal coating on various substrates. In this study, recent research progress in improving PEC performance using ALD coating methods is discussed, including 3D and heterojunction-structured PEC electrodes, ALD coatings of noble metals, and the use of sulfide materials as co-catalysts. The enhanced long-term stability of PEC cells by ALD-deposited protecting layers is also reviewed. ALD provides multiple routes to develop improved hydrogen evolution PEC cells.

-

Citations

Citations to this article as recorded by- Improved Interface and Electrical Properties by Inserting an Ultrathin SiO2 Buffer Layer in the Al2O3/Si Heterojunction

Doyeon Kim, Jae‐Young Choi, Sang Wook Ryu, Woo‐Byoung Kim

Advanced Functional Materials.2019;[Epub] CrossRef

- Improved Interface and Electrical Properties by Inserting an Ultrathin SiO2 Buffer Layer in the Al2O3/Si Heterojunction

- [Korean]

- Formation of Uniform SnO2 Coating Layer on Carbon Nanofiber by Pretreatment in Atomic Layer Deposition

- Dong Ha Kim, Doh-Hyung Riu, Byung Joon Choi

- J Korean Powder Metall Inst. 2018;25(1):43-47. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.43

- 816 View

- 2 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Carbon nanofibers (CNF) are widely used as active agents for electrodes in Li-ion secondary battery cells, supercapacitors, and fuel cells. Nanoscale coatings on CNF electrodes can increase the output and lifespan of battery devices. Atomic layer deposition (ALD) can control the coating thickness at the nanoscale regardless of the shape, suitable for coating CNFs. However, because the CNF surface comprises stable C–C bonds, initiating homogeneous nuclear formation is difficult because of the lack of initial nucleation sites. This study introduces uniform nucleation site formation on CNF surfaces to promote a uniform SnO2 layer. We pretreat the CNF surface by introducing H2O or Al2O3 (trimethylaluminum + H2O) before the SnO2 ALD process to form active sites on the CNF surface. Transmission electron microscopy and energy-dispersive spectroscopy both identify the SnO2 layer morphology on the CNF. The Al2O3-pretreated sample shows a uniform SnO2 layer, while island-type SnOx layers grow sparsely on the H2Opretreated or untreated CNF.

-

Citations

Citations to this article as recorded by- Atomic layer deposition of ZnO layers on Bi2Te3 powders: Comparison of gas fluidization and rotary reactors

Myeong Jun Jung, Myeongjun Ji, Jeong Hwan Han, Young-In Lee, Sung-Tag Oh, Min Hwan Lee, Byung Joon Choi

Ceramics International.2022; 48(24): 36773. CrossRef - Effects of SnO2 layer coated on carbon nanofiber for the methanol oxidation reaction

Dong Ha Kim, Dong-Yo Shin, Young-Geun Lee, Geon-Hyoung An, Jeong Hwan Han, Hyo-Jin Ahn, Byung Joon Choi

Ceramics International.2018; 44(16): 19554. CrossRef

- Atomic layer deposition of ZnO layers on Bi2Te3 powders: Comparison of gas fluidization and rotary reactors

- [Korean]

- Recent Progress on the Application of Atomic Layer Deposition for Lithium Ion Batteries

- Dong Ha Kim, Byung Joon Choi

- J Korean Powder Metall Inst. 2016;23(2):170-176. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.170

- 3,075 View

- 31 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Lithium-ion batteries (LIBs) are rapidly improving in capacity and life cycle characteristics to meet the requirements of a wide range of applications, such as portable electronics, electric vehicles, and micro- or nanoelectromechanical systems. Recently, atomic layer deposition (ALD), one of the vapor deposition methods, has been explored to expand the capability of LIBs by producing near-atomically flat and uniform coatings on the shell of nanostructured electrodes and membranes for conventional LIBs. In this paper, we introduce various ALD coatings on the anode, cathode, and separator materials to protect them and improve their electrochemical and thermomechanical stability. In addition, we discuss the effects of ALD coatings on the three-dimensional structuring and conduction layer through activation of electrochemical reactions and facilitation of fluent charge collection.

-

Citations

Citations to this article as recorded by- Atomic Layer Deposition for Powder Coating

Seok Choi, Jeong Hwan Han, Byung Joon Choi

Journal of Korean Powder Metallurgy Institute.2019; 26(3): 243. CrossRef - Formation of Uniform SnO2 Coating Layer on Carbon Nanofiber by Pretreatment in Atomic Layer Deposition

Dong Ha Kim, Doh-Hyung Riu, Byung Joon Choi

journal of Korean Powder Metallurgy Institute.2018; 25(1): 43. CrossRef

- Atomic Layer Deposition for Powder Coating

TOP

KPMI

KPMI

First

First Prev

Prev