Search

- Page Path

- HOME > Search

- [Korean]

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- Eunhyo Song, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00059

- 586 View

- 21 Download

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

- [English]

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 3,880 View

- 101 Download

- 1 Citations

-

Abstract

Abstract

PDF

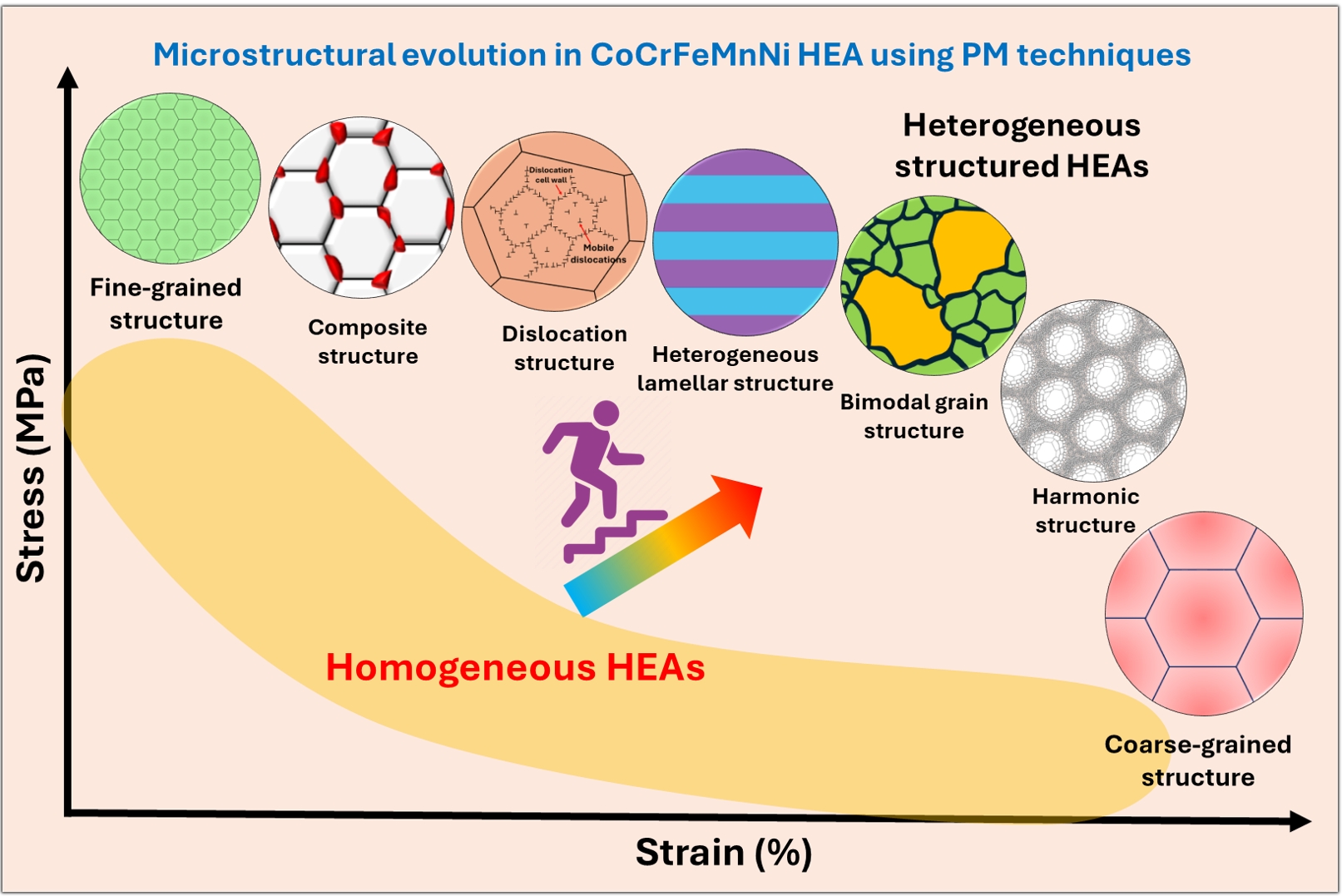

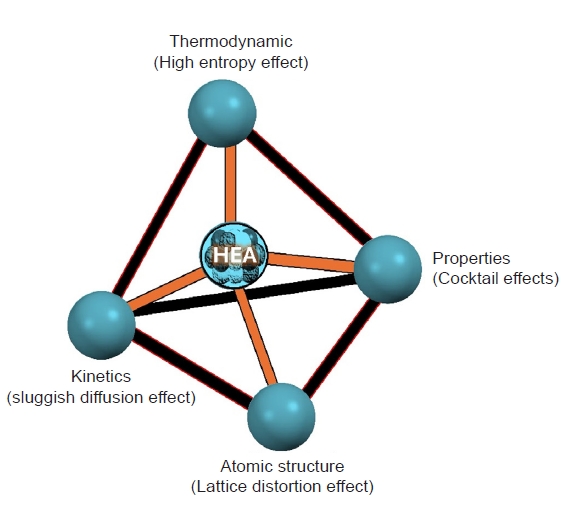

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- [English]

- Advances in Powder Metallurgy for High-Entropy Alloys

- Sheetal Kumar Dewangan, Cheenepalli Nagarjuna, Hansung Lee, K. Raja Rao, Man Mohan, Reliance Jain, Byungmin Ahn

- J Powder Mater. 2024;31(6):480-492. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00297

- 4,209 View

- 158 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) represent a revolutionary class of materials characterized by their multi-principal element compositions and exceptional mechanical properties. Powder metallurgy, a versatile and cost-effective manufacturing process, offers significant advantages for the development of HEAs, including precise control over their composition, microstructure, and mechanical properties. This review explores innovative approaches integrating powder metallurgy techniques in the synthesis and optimization of HEAs. Key advances in powder production, sintering methods, and additive manufacturing are examined, highlighting their roles in improving the performance, advancement, and applicability of HEAs. The review also discusses the mechanical properties, potential industrial applications, and future trends in the field, providing a comprehensive overview of the current state and future prospects of HEA development using powder metallurgy.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Latest Advancements and Mechanistic Insights into High-Entropy Alloys: Design, Properties and Applications

Anthoula Poulia, Alexander E. Karantzalis

Materials.2025; 18(24): 5616. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

- Jisung Lee, Hansung Lee, Eunhyo Song, Byungmin Ahn

- J Powder Mater. 2024;31(5):414-421. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00311

- 751 View

- 15 Download

-

Abstract

Abstract

PDF

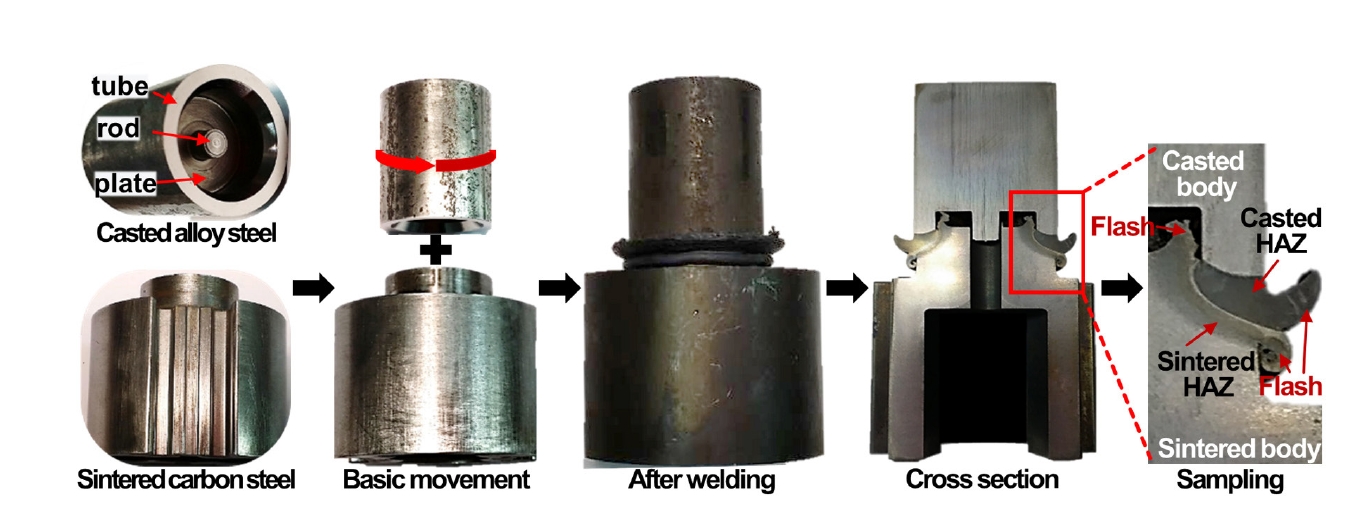

PDF - Friction welding, which uses heat and plastic flow to join metals, is expanding across industries due to its ability to weld heterogeneous alloys and simple process. However, process research is essential for materials with complex geometries, and limited research has been conducted on friction welding between cast and sintered metals. This study analyzed the mechanical properties and microstructural evolution of the joint by controlling the rotational speed and friction pressure, which affect the removal of the heat-affected zone in friction welding of casted SCM440 and sintered F-05-140. Hardness mapping and microstructure observations with material transition were performed to investigate the correlation between phase behavior and welding conditions. These results are anticipated to reduce costs and improve the mechanical properties of key mobility components.

- [Korean]

- Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

- Minsu Kim, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2023;30(6):478-483. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.478

- 1,065 View

- 15 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF High-entropy alloys (HEAs) are characterized by having five or more main elements and forming simple solids without forming intermetallic compounds, owing to the high entropy effect. HEAs with these characteristics are being researched as structural materials for extreme environments. Conventional refractory alloys have excellent hightemperature strength and stability; however, problems occur when they are used extensively in a high-temperature environment, leading to reduced fatigue properties due to oxidation or a limited service life. In contrast, refractory entropy alloys, which provide refractory properties to entropy alloys, can address these issues and improve the hightemperature stability of the alloy through phase control when designed based on existing refractory alloy elements. Refractory high-entropy alloys require sufficient milling time while in the process of mechanical alloying because of the brittleness of the added elements. Consequently, the high-energy milling process must be optimized because of the possibility of contamination of the alloyed powder during prolonged milling. In this study, we investigated the hightemperature oxidation behavior of refractory high-entropy alloys while optimizing the milling time.

-

Citations

Citations to this article as recorded by- Tailored high-temperature oxidation behavior and nanomechanical properties of Al0.75VCrZrNb lightweight refractory high-entropy alloys

Hansung Lee, Hwi Geun Yu, Reliance Jain, Man Mohan, Younggeon Lee, Sheetal Kumar Dewangan, Byungmin Ahn

International Journal of Refractory Metals and Hard Materials.2026; 135: 107507. CrossRef - Simultaneous enhancement of strength and ductility of Al matrix composites enabled by submicron-sized high-entropy alloy phases

Chahee Jung, Seungin Nam, Hansol Son, Juyeon Han, Jaewon Jeong, Hyokyung Sung, Hyoung Seop Kim, Seok Su Sohn, Hyunjoo Choi

Journal of Materials Research and Technology.2024; 33: 1470. CrossRef

- Tailored high-temperature oxidation behavior and nanomechanical properties of Al0.75VCrZrNb lightweight refractory high-entropy alloys

- [Korean]

- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

- Hansung Lee, Minsu Kim, Byungmin Ahn

- J Powder Mater. 2023;30(4):332-338. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.332

- 790 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Thermite welding is an exceptional process that does not require additional energy supplies, resulting in welded joints that exhibit mechanical properties and conductivity equivalent to those of the parent materials. The global adoption of thermite welding is growing across various industries. However, in Korea, limited research is being conducted on the core technology of thermite welding. Currently, domestic production of thermite powder in Korea involves recycling copper oxide (CuO). Unfortunately, controlling the particle size of waste CuO poses challenges, leading to the unwanted formation of pores and cracks during thermite welding. In this study, we investigate the influence of powder particle size on thermite welding in the production of Cu-thermite powder using waste CuO. We conduct the ball milling process for 0.5–24 h using recycled CuO. The evolution of the powder shape and size is analyzed using particle size analysis and scanning electron microscopy (SEM). Furthermore, we examine the thermal reaction characteristics through differential scanning calorimetry. Additionally, the microstructures of the welded samples are observed using optical microscopy and SEM to evaluate the impact of powder particle size on weldability. Lastly, hardness measurements are performed to assess the strengths of the welded materials.

-

Citations

Citations to this article as recorded by- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

Jisung Lee, Hansung Lee, Eunhyo Song, Byungmin Ahn

Journal of Powder Materials.2024; 31(5): 414. CrossRef

- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

- [Korean]

- Development of Novel Composite Powder Friction Modifier for Improving Wheel-rail Adhesion in High-speed Train

- Min Chul Oh, Byungmin Ahn

- J Korean Powder Metall Inst. 2018;25(6):501-506. Published online December 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.6.501

- 561 View

- 3 Download

-

Abstract

Abstract

PDF

PDF With the recent remarkable improvements in the average speeds of contemporary trains, a necessity has arisen for the development of new friction modifiers to improve adhesion characteristics at the wheel-rail interface. The friction modifier must be designed to reduce slippage or sliding of the trains’ wheels on the rails under conditions of rapid acceleration or braking without excessive rolling contact wear. In this study, a novel composite material consisting of metal, ceramic, and polymer is proposed as a friction modifier to improve adhesion between wheels and rails. A blend of Al-6Cu-0.5Mg metallic powder, Al2O3 ceramic powder, and Bakelite-based polymer in various weight-fractions is hot-pressed at 150°C to form a bulk composite material. Variation in the adhesion coefficient is evaluated using a high-speed wheel-rail friction tester, with and without application of the composite friction modifier, under both dry and wet conditions. The effect of varying the weighting fractions of metal and ceramic friction powders is detailed in the paper.

TOP

KPMI

KPMI

First

First Prev

Prev