Search

- Page Path

- HOME > Search

- [Korean]

- Hydrogen Reduction Behavior of NCM-based Lithium-ion Battery Cathode Materials

- So-Yeong Lee, So-Yeon Lee, Dae-Hyeon Lee, Ho-Sang Sohn

- J Powder Mater. 2024;31(2):163-168. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00017

- 1,671 View

- 43 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - As the demand for lithium-ion batteries for electric vehicles is increasing, it is important to recover valuable metals from waste lithium-ion batteries. In this study, the effects of gas flow rate and hydrogen partial pressure on hydrogen reduction of NCM-based lithium-ion battery cathode materials were investigated. As the gas flow rate and hydrogen partial pressure increased, the weight loss rate increased significantly from the beginning of the reaction due to the reduction of NiO and CoO by hydrogen. At 700 °C and hydrogen partial pressure above 0.5 atm, Ni and Li2O were produced by hydrogen reduction. From the reduction product and Li recovery rate, the hydrogen reduction of NCM-based cathode materials was significantly affected by hydrogen partial pressure. The Li compounds recovered from the solution after water leaching of the reduction products were LiOH, LiOH·H2O, and Li2CO3, with about 0.02 wt% Al as an impurity.

-

Citations

Citations to this article as recorded by- Reduction Roasting of Black Mass Recovered from NCM-based Spent Lithium-ion Batteries Using CH4 Gas

Sang-Yeop Lee, Jae-Ho Hwang, Ho-Sang Sohn

Resources Recycling.2025; 34(5): 93. CrossRef

- Reduction Roasting of Black Mass Recovered from NCM-based Spent Lithium-ion Batteries Using CH4 Gas

- [Korean]

- Research Trends of Cathode Materials for Lithium-Ion Batteries used in Electric Vehicles

- Dong-Yo Shin, Hyo-Jin Ahn

- J Korean Powder Metall Inst. 2019;26(1):58-69. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.58

- 1,031 View

- 7 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF High performance lithium-ion batteries (LIBs) have attracted considerable attention as essential energy sources for high-technology electrical devices such as electrical vehicles, unmanned drones, uninterruptible power supply, and artificial intelligence robots because of their high energy density (150-250 Wh/kg), long lifetime (> 500 cycles), low toxicity, and low memory effects. Of the high-performance LIB components, cathode materials have a significant effect on the capacity, lifetime, energy density, power density, and operating conditions of high-performance LIBs. This is because cathode materials have limitations with respect to a lower specific capacity and cycling stability as compared to anode materials. In addition, cathode materials present difficulties when used with LIBs in electric vehicles because of their poor rate performance. Therefore, this study summarizes the structural and electrochemical properties of cathode materials for LIBs used in electric vehicles. In addition, we consider unique strategies to improve their structural and electrochemical properties.

-

Citations

Citations to this article as recorded by- Estimation of Representative Mechanical Property of Porous Electrode for Secondary Batteries with Homogenization Method

Changmin Pyo, Jaewoong Kim

Journal of the Korean Society of Manufacturing Process Engineers.2022; 21(9): 85. CrossRef

- Estimation of Representative Mechanical Property of Porous Electrode for Secondary Batteries with Homogenization Method

- [Korean]

- Effect of Single and Dual Doping of Rare Earth Metal Ce and Nd Elements on Electrochemical Properties of LiNi0.83 Co0.11Mn0.06O2 Cathode Lithium-ion Battery Material

- Yoo-Young Kim, Jong-Keun Ha, Kwon-Koo Cho

- J Korean Powder Metall Inst. 2019;26(1):49-57. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.49

- 2,009 View

- 22 Download

- 2 Citations

-

Abstract

Abstract

PDF

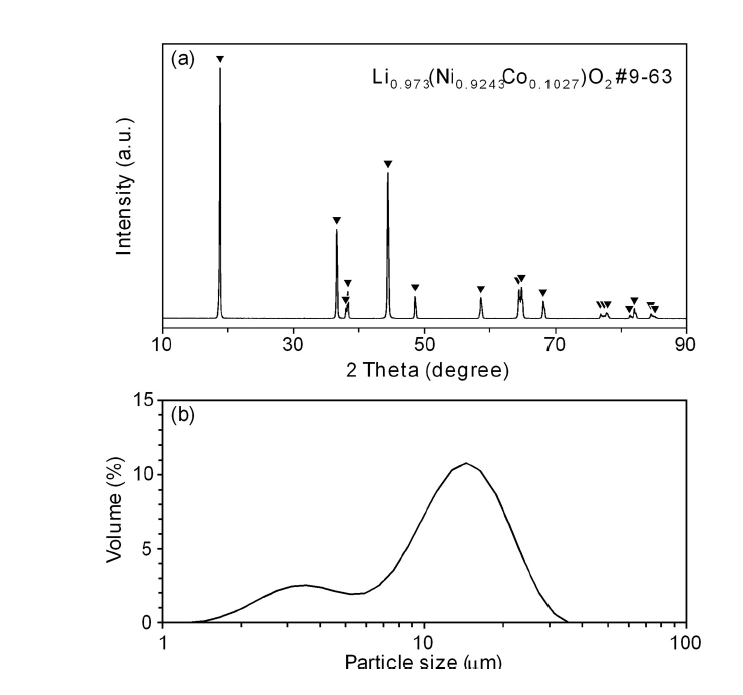

PDF Layered LiNi0.83Co0.11Mn0.06O2 cathode materials single- and dual-doped by the rare-earth elements Ce and Nd are successfully fabricated by using a coprecipitation-assisted solid-phase method. For comparison purposes, nondoping pristine LiNi0.83Co0.11Mn0.06O2 cathode material is also prepared using the same method. The crystal structure, morphology, and electrochemical performances are characterized using X-ray diffraction (XRD), scanning electron microscopy (SEM), energy dispersive spectrometer (EDS) mapping, and electrochemical techniques. The XRD data demonstrates that all prepared samples maintain a typical α-NaFeO2-layered structure with the

R-3m -

Citations

Citations to this article as recorded by- Numerical approach for lithium-ion battery performance considering various cathode active material composition for electric vehicles using 1D simulation

Heewon Choi, Nam-gyu Lim, Seong Jun Lee, Jungsoo Park

Journal of Mechanical Science and Technology.2021; 35(6): 2697. CrossRef - Synthesis of CeVO4-V2O5 nanowires by cation-exchange method for high-performance lithium-ion battery electrode

Xueliu Xu, Shiying Chang, Taofang Zeng, Yidan Luo, Dong Fang, Ming Xie, Jianhong Yi

Journal of Alloys and Compounds.2021; 887: 161237. CrossRef

- Numerical approach for lithium-ion battery performance considering various cathode active material composition for electric vehicles using 1D simulation

- [Korean]

- Effects of Precursor Co-Precipitation Temperature on the Properties of LiNi1/3Co1/3Mn1/3O2 Powders

- Woonghee Choi, Chan Hyoung Kang

- J Korean Powder Metall Inst. 2016;23(4):287-296. Published online August 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.4.287

- 1,906 View

- 36 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Ni1/3Co1/3Mn1/3(OH)2 powders have been synthesized in a continuously stirred tank reactor via a co-precipitation reaction between aqueous metal sulfates and NaOH using NH4OH as a chelating agent. The co-precipitation temperature is varied in the range of 30-80°C. Calcination of the prepared precursors with Li2CO3 for 8 h at 1000°C in air results in Li Ni1/3Co1/3Mn1/3O2 powders. Two kinds of obtained powders have been characterized by X-ray diffraction (XRD), scanning electron microscopy, particle size analyzer, and tap density measurements. The co-precipitation temperature does not differentiate the XRD patterns of precursors as well as their final powders. Precursor powders are spherical and dense, consisting of numerous acicular or flaky primary particles. The precursors obtained at 70 and 80°C possess bigger primary particles having more irregular shapes than those at lower temperatures. This is related to the lower tap density measured for the former. The final powders show a similar tendency in terms of primary particle shape and tap density. Electrochemical characterization shows that the initial charge/discharge capacities and cycle life of final powders from the precursors obtained at 70 and 80°C are inferior to those at 50°C. It is concluded that the optimum co-precipitation temperature is around 50°C.

-

Citations

Citations to this article as recorded by- A kinetic descriptor to optimize Co-precipitation of Nickel-rich cathode precursors for Lithium-ion batteries

Seon Hwa Lee, Ki Young Kwon, Byeong Kil Choi, Hyun Deog Yoo

Journal of Electroanalytical Chemistry.2022; 924: 116828. CrossRef

- A kinetic descriptor to optimize Co-precipitation of Nickel-rich cathode precursors for Lithium-ion batteries

- [Korean]

- Characteristics of Ni1/3Co1/3Mn1/3(OH)2 Powders Prepared by Co-Precipitation in Air and Nitrogen Atmospheres

- Woonghee Choi, Se-Ryen Park, Chan Hyoung Kang

- J Korean Powder Metall Inst. 2016;23(2):136-142. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.136

- 2,773 View

- 58 Download

- 6 Citations

-

Abstract

Abstract

PDF

PDF As precursors of cathode materials for lithium ion batteries, Ni1/3Co1/3Mn1/3(OH)2 powders are prepared in a continuously stirred tank reactor via a co-precipitation reaction between aqueous metal sulfates and NaOH in the presence of NH4OH in air or nitrogen ambient. Calcination of the precursors with Li2CO3 for 8 h at 1,000°C in air produces dense spherical cathode materials. The precursors and final powders are characterized by X-ray diffraction (XRD), scanning electron microscopy, particle size analysis, tap density measurement, and thermal gravimetric analysis. The precursor powders obtained in air or nitrogen ambient show XRD patterns identified as Ni1/3Co1/3Mn1/3(OH)2. Regardless of the atmosphere, the final powders exhibit the XRD patterns of LiNi1/3Co1/3Mn1/3O2 (NCM). The precursor powders obtained in air have larger particle size and lower tap density than those obtained in nitrogen ambient. NCM powders show similar tendencies in terms of particle size and tap density. Electrochemical characterization is performed after fabricating a coin cell using NCM as the cathode and Li metal as the anode. The NCM powders from the precursors obtained in air and those from the precursors obtained in nitrogen have similar initial charge/discharge capacities and cycle life. In conclusion, the powders co-precipitated in air can be utilized as precursor materials, replacing those synthesized in the presence of nitrogen injection, which is the usual industrial practice.

-

Citations

Citations to this article as recorded by- Thermodynamic modeling and parameters optimization for Ni0.8Co0.1Mn 0.1(OH)2 synthesis via transitional metal coprecipitation

Zanlang Tang, Chen Liu, Xincun Tang, Haonan Liu, Biao Qin

Materials Science and Engineering: B.2026; 326: 119205. CrossRef - Stabilization of High Nickel Cathode Materials with Core-Shell Structure via Co-precipitation Method

Minjeong Kim, Soonhyun Hong, Heongkwon Jeon, Jahun Koo, Heesang Lee, Gyuseok Choi, Chunjoong Kim

Korean Journal of Materials Research.2022; 32(4): 216. CrossRef - Spherical agglomeration of nickel-manganese-cobalt hydroxide in turbulent Batchelor vortex flow

Xiaotong Sun, Jinsoo Kim, Woo-Sik Kim

Chemical Engineering Journal.2021; 421: 129924. CrossRef - Design strategies for development of nickel-rich ternary lithium-ion battery

Kyu Hwan Choi, Xuyan Liu, Xiaohong Ding, Qiang Li

Ionics.2020; 26(3): 1063. CrossRef - Effect of Single and Dual Doping of Rare Earth Metal Ce and Nd Elements on Electrochemical Properties of LiNi0.83 Co0.11Mn0.06O2 Cathode Lithium-ion Battery Material

Yoo-Young Kim, Jong-Keun Ha, Kwon-Koo Cho

Journal of Korean Powder Metallurgy Institute.2019; 26(1): 49. CrossRef - Effects of Precursor Co-Precipitation Temperature on the Properties of LiNi1/3Co1/3Mn1/3O2 Powders

Woonghee Choi, Chan Hyoung Kang

Journal of Korean Powder Metallurgy Institute.2016; 23(4): 287. CrossRef

- Thermodynamic modeling and parameters optimization for Ni0.8Co0.1Mn 0.1(OH)2 synthesis via transitional metal coprecipitation

TOP

KPMI

KPMI

First

First Prev

Prev