Search

- Page Path

- HOME > Search

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- 728 View

- 46 Download

-

Abstract

Abstract

PDF

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [Korean]

- Study on the Elemental Diffusion Distance of a Pure Nickel Layer Additively Manufactured on 316H Stainless Steel

- UiJun Ko, Won Chan Lee, Gi Seung Shin, Ji-Hyun Yoon, Jeoung Han Kim

- J Powder Mater. 2024;31(3):220-225. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00164

- 1,527 View

- 52 Download

- 4 Citations

-

Abstract

Abstract

PDF

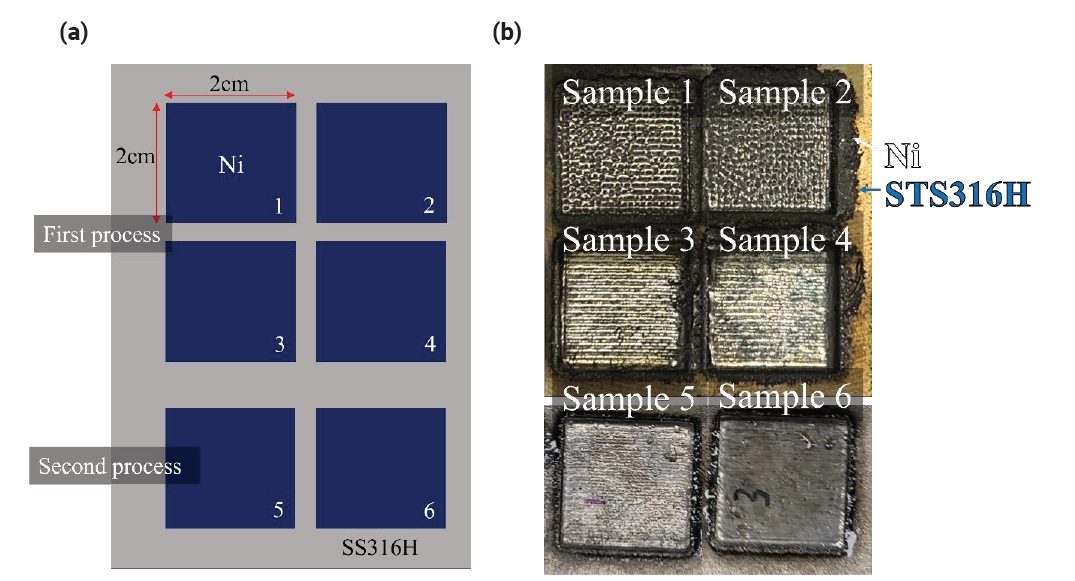

PDF - Molten salt reactors represent a promising advancement in nuclear technology due to their potential for enhanced safety, higher efficiency, and reduced nuclear waste. However, the development of structural materials that can survive under severe corrosion environments is crucial. In the present work, pure Ni was deposited on the surface of 316H stainless steel using a directed energy deposition (DED) process. This study aimed to fabricate pure Ni alloy layers on an STS316H alloy substrate. It was observed that low laser power during the deposition of pure Ni on the STS316H substrate could induce stacking defects such as surface irregularities and internal voids, which were confirmed through photographic and SEM analyses. Additionally, the diffusion of Fe and Cr elements from the STS316H substrate into the Ni layers was observed to decrease with increasing Ni deposition height. Analysis of the composition of Cr and Fe components within the Ni deposition structures allows for the prediction of properties such as the corrosion resistance of Ni.

-

Citations

Citations to this article as recorded by- Microstructural analysis and characterization of nickel deposition on 316H stainless steel via gas tungsten arc welding and powder laser cladding

Won Chan Lee, Jin Woong Park, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 342. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef - Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef - Evaluation of Mechanical Properties of Pure Ni Coatings on a Type 316H Stainless Steel Substrate via High-Velocity Oxy-fuel and Directed Energy Deposition Processes

Won Chan Lee, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

Journal of Powder Materials.2025; 32(4): 309. CrossRef

- Microstructural analysis and characterization of nickel deposition on 316H stainless steel via gas tungsten arc welding and powder laser cladding

- [Korean]

- Effect of Hot Isostatic Pressing on the Stellite 6 Alloy prepared by Directed Energy Deposition

- Joowon Suh, Jae Hyeon Koh, Young-Bum Chun, Young Do Kim, Jinsung Jang, Suk Hoon Kang, Heung Nam Han

- J Powder Mater. 2024;31(2):152-162. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00066

- 1,571 View

- 38 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - The directed energy deposited (DED) alloys show higher hardness values than the welded alloys due to the finer microstructure following the high cooling rate. However, defects such as microcracks, pores, and the residual stress are remained within the DED alloy. These defects deteriorate the wear behavior so post-processing such as heat treatment and hot isostatic pressing (HIP) are applied to DED alloys to reduce the defects. HIP was chosen in this study because the high pressure and temperature uniformly reduced the defects. The HIP is processed at 1150oC under 100 MPa for 4 hours. After HIP, microcracks are disappeared and porosity is reduced by 86.9%. Carbides are spherodized due to the interdiffusion of Cr and C between the dendrite and interdendrite region. After HIP, the nanohardness (GPa) of carbides increased from 11.1 to 12, and the Co matrix decreased from 8.8 to 7.9. Vickers hardness (HV) decreased by 18.9 % after HIP. The dislocation density (10-2/m2) decreased from 7.34 to 0.34 and the residual stress (MPa) changed from tensile 79 to a compressive -246 by HIP. This study indicates that HIP is effective in reducing defects, and the HIP DED Stellite 6 exhibits a higher HV than welded Stellite 6.

-

Citations

Citations to this article as recorded by- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

YongKwan Lee, Hyun-chul Kim, Myungsuk Kim, Soong Ju Oh, Kyoungtae Park, JaeJin Sim

Journal of Powder Materials.2025; 32(4): 330. CrossRef

- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

- [Korean]

- Microstructures and Mechanical Properties of Al-B4C Composites Fabricated by DED Process

- Yu-Jeong An, Ju-Yeon Han, Hyunjoo Choi, Se-Eun Shin

- J Powder Mater. 2023;30(3):262-267. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.262

- 981 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Boron carbide (B4C) is highly significant in the production of lightweight protective materials when added to aluminum owing to its exceptional mechanical properties. In this study, a method for fabricating Al-B4C composites using high-energy ball milling and directed energy deposition (DED) is presented. Al-4 wt.% B4C composites were fabricated under 21 different laser conditions to analyze the microstructure and mechanical properties at different values of laser power and scan speeds. The composites fabricated at a laser power of 600 W and the same scan speed exhibited the highest hardness and generated the fewest pores. In contrast, the composites fabricated at a laser power of 1000 W exhibited the lowest hardness and generated a significant number of large pores. This can be explained by the influence of the microstructure on the energy density at different values of laser power.

-

Citations

Citations to this article as recorded by- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- [Korean]

- Additive Manufacturing Optimization of Directed Energy Deposition-Processed Ti-6Al-4V Alloy using Energy Density and Powder Deposition Density

- Yukyeong Lee, Eun Sung Kim, Se-Ho Chun, Jae Bok Seol, Hyokyung Sung, Jung Seok Oh, Hyoung Seop Kim, Taekyung Lee, Tae-Hyun Nam, Jung Gi Kim

- J Korean Powder Metall Inst. 2021;28(6):491-496. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.491

- 989 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The process optimization of directed energy deposition (DED) has become imperative in the manufacture of reliable products. However, an energy-density-based approach without a sufficient powder feed rate hinders the attainment of an appropriate processing window for DED-processed materials. Optimizing the processing of DEDprocessed Ti-6Al- 4V alloys using energy per unit area (Eeff) and powder deposition density (PDDeff) as parameters helps overcome this problem in the present work. The experimental results show a lack of fusion, complete melting, and overmelting regions, which can be differentiated using energy per unit mass as a measure. Moreover, the optimized processing window (Eeff = 44~47 J/mm2 and PDDeff = 0.002~0.0025 g/mm2) is located within the complete melting region. This result shows that the Eeff and PDDeff-based processing optimization methodology is effective for estimating the properties of DED-processed materials.

-

Citations

Citations to this article as recorded by- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef

- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

- [Korean]

- Joint Properties of Inconel 718 Additive Manufactured on Ti-6Al-4V by FGM method

- Chan Woong Park, Jin Woong Park, Ki Chae Jung, Se-Hwan Lee, Sung-Hoon Kim, Jeoung Han Kim

- J Korean Powder Metall Inst. 2021;28(5):417-422. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.417

- 561 View

- 5 Download

-

Abstract

Abstract

PDF

PDF In the present work, Inconel 718 alloy is additively manufactured on the Ti-6Al-4V alloy, and a functionally graded material is built between Inconel 718 and Ti-6Al-4V alloys. The vanadium interlayer is applied to prevent the formation of detrimental intermetallic compounds between Ti-6Al-4V and Inconel 718 by direct joining. The additive manufacturing of Inconel 718 alloy is performed by changing the laser power and scan speed. The microstructures of the joint interface are characterized by scanning electron microscopy, energy-dispersive X-ray spectroscopy, and micro X-ray diffraction. Additive manufacturing is successfully performed by changing the energy input. The micro Vickers hardness of the additive manufactured Inconel 718 dramatically increased owing to the presence of the Cr-oxide phase, which is formed by the difference in energy input.

- [Korean]

- Investigation on Interfacial Microstructures of Stainless Steel/Inconel Bonded by Directed Energy Deposition of alloy Powders

- Yeong Seong Eom, Kyung Tae Kim, Soo-Ho Jung, Jihun Yu, Dong Yeol Yang, Jungho Choe, Chul Yong Sim, Seung Jun An

- J Korean Powder Metall Inst. 2020;27(3):219-225. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.219

- 1,616 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The directed energy deposition (DED) process of metal 3D printing technologies has been treated as an effective method for welding, repairing, and even 3-dimensional building of machinery parts. In this study, stainless steel 316L (STS316L) and Inconel 625 (IN625) alloy powders are additively manufactured using the DED process, and the microstructure of the fabricated STS316L/IN625 sample is investigated. In particular, there are no secondary phases in the interface between STS316L and the IN625 alloy. The EDS and Vickers hardness results clearly show compositionally and mechanically transient layers a few tens of micrometers in thickness. Interestingly, several cracks are only observed in the STS 316L rather than in the IN625 alloy near the interface. In addition, small-sized voids 200–400 nm in diameter that look like trapped pores are present in both materials. The cracks present near the interface are formed by tensile stress in STS316L caused by the difference in the CTE (coefficient of thermal expansion) between the two materials during the DED process. These results can provide fundamental information for the fabrication of machinery parts that require joining of two materials, such as valves.

-

Citations

Citations to this article as recorded by- Microstructures and mechanical properties of 316LSi/IN625 FGMs manufactured by CMT-WAAM

Jiang Aimin, Ahmad Baharuddin Abdullah, Shahir Mohd Yusuf

Advances in Mechanical Engineering.2025;[Epub] CrossRef

- Microstructures and mechanical properties of 316LSi/IN625 FGMs manufactured by CMT-WAAM

TOP

KPMI

KPMI

First

First Prev

Prev