Search

- Page Path

- HOME > Search

- [Korean]

- Comparison of the Properties of Rare-Earth Zirconate Thermal Barrier Coatings for Hydrogen-Fueled Gas Turbines

- Gun-Woong Lee, Min-Soo Nam, Min-Ji Kim, HyunSuk Jung, Seongwon Kim

- J Powder Mater. 2025;32(6):472-480. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00423

- 768 View

- 13 Download

-

Abstract

Abstract

PDF

PDF - Thermal barrier coatings (TBCs) for hydrogen-fueled gas turbines withstand higher combustion temperatures and increased steam concentrations compared to conventional natural-gas systems. These harsh operating conditions significantly accelerate the thermal degradation of widely used YSZ coatings, emphasizing the need for alternative top-coat materials with improved phase stability and reduced thermal conductivity. In this study, rare-earth zirconate ceramics, Gd2Zr2O7 (GdZO), Tm2Zr2O7 (TmZO), and a mixed composition (Gd0.5Tm0.5)2Zr2O7 (Gd/TmZO), are synthesized and investigated as potential next-generation TBC candidates. Each material was comparatively examined with a focus on crystal structure, thermophysical properties, and thermal conductivity. Furthermore, high-temperature steam exposure experiments were performed to simulate hydrogen combustion environments. Microstructural analyses, high-temperature degradation behavior, and phase stability evaluations were carried out to obtain fundamental experimental data. This study provides essential baseline information for the design and development of high-performance TBC materials suitable for the hydrogen-fueled gas turbine systems.

- [English]

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

- J Powder Mater. 2025;32(3):179-190. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00094

- 4,764 View

- 179 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Area-selective atomic layer deposition (AS-ALD) is a bottom-up process that selectively deposits thin films onto specific areas of a wafer surface. The surface reactions of AS-ALD are controlled by blocking the adsorption of precursors using inhibitors such as self-assembled monolayers (SAMs) or small molecule inhibitors. To increase selectivity during the AS-ALD process, the design of both the inhibitor and the precursor is crucial. Both inhibitors and precursors vary in reactivity and size, and surface reactions are blocked through interactions between precursor molecules and surface functional groups. However, challenges in the conventional SAM-based AS-ALD method include thermal instability and potential damage to substrates during the removal of residual SAMs after the process. To address these issues, recent studies have proposed alternative inhibitors and process design strategies.

-

Citations

Citations to this article as recorded by- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

Hojeong Yoon, Saima Sadiq, Junhyeok Park, Kyungwon Kwak, Minhaeng Cho

The Journal of Physical Chemistry Letters.2026; 17(4): 1119. CrossRef

- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

- [English]

- Bandgap Tuning and Quenching Effects of In(Zn)P@ZnSe@ZnS Quantum Dots

- Sang Yeon Lee, Su Hyun Park, Gyungsu Byun, Chang-Yeoul Kim

- J Powder Mater. 2024;31(3):226-235. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00003

- 3,050 View

- 44 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - InP quantum dot (QDs) have attracted researchers’ interest due to their applicability in quantum dot light-emitting displays (QLED) or biomarkers for detecting cancers or viruses. The surface or interface control of InP QD core/shell has substantially increased quantum efficiency, with a quantum yield of 100% reached by introducing HF to inhibit oxide generation. In this study, we focused on the control of bandgap energy of quantum dots by changing the Zn/(In+Zn) ratio in the In(Zn)P core. Zinc incorporation can change the photoluminescent light colors of green, yellow, orange, and red. Diluting a solution of as-synthesized QDs by more than 100 times did not show any quenching effects by the Förster resonance energy transfer phenomenon between neighboring QDs.

-

Citations

Citations to this article as recorded by- Enhancing luminescence of QD thin films, polymer composite films, and LED devices by nanostructures

Hongcheng Yang, Junjie Hao, Mingyu Sun, Yujie Song, Kai Wang, Yujie Song, Xiao Wei Sun, Wenda Zhang

The Innovation.2026; 7(2): 101121. CrossRef

- Enhancing luminescence of QD thin films, polymer composite films, and LED devices by nanostructures

- [Korean]

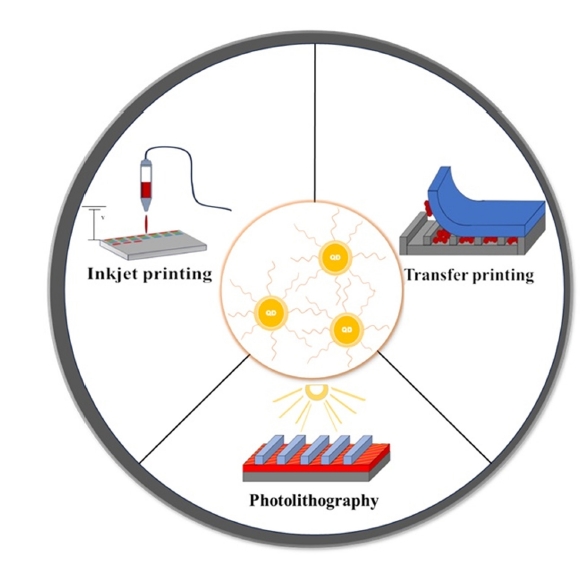

- Recent Developments in Quantum Dot Patterning Technology for Quantum Dot Display

- Yeong Jun Jin, Kyung Jun Jung, Jaehan Jung

- J Powder Mater. 2024;31(2):169-179. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00073

- 7,044 View

- 156 Download

-

Abstract

Abstract

PDF

PDF - Colloidal quantum dot (QDs) have emerged as a crucial building block for LEDs due to their size-tunable emission wavelength, narrow spectral line width, and high quantum efficiency. Tremendous efforts have been dedicated to improving the performance of quantum dot light-emitting diodes (QLEDs) in the past decade, primarily focusing on optimization of device architectures and synthetic procedures for high quality QDs. However, despite these efforts, the commercialization of QLEDs has yet to be realized due to the absence of suitable large-scale patterning technologies for high-resolution devices., This review will focus on the development trends associated with transfer printing, photolithography, and inkjet printing, and aims to provide a brief overview of the fabricated QLED devices. The advancement of various quantum dot patterning methods will lead to the development of not only QLED devices but also solar cells, quantum communication, and quantum computers.

- [English]

- Eco-Friendly Powder and Particles-Based Triboelectric Energy Harvesters

- Rayyan Ali Shaukat, Jihun Choi, Chang Kyu Jeong

- J Powder Mater. 2023;30(6):528-535. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.528

- 2,052 View

- 38 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF Since their initial development in 2012, triboelectric nanogenerators (TENGs) have gained popularity worldwide as a desired option for harnessing energy. The urgent demand for TENGs is attributed to their novel structural design, low cost, and use of large-scale materials. The output performance of a TENG depends on the surface charge density of the friction layers. Several recycled and biowaste materials have been explored as friction layers to enhance the output performance of TENGs. Natural and oceanic biomaterials have also been investigated as alternatives for improving the performance of TENG devices. Moreover, structural innovations have been made in TENGs to develop highly efficient devices. This review summarizes the recent developments in recycling and biowaste materials for TENG devices. The potential of natural and oceanic biowaste materials is also discussed. Finally, future outlooks for the structural developments in TENG devices are presented.

-

Citations

Citations to this article as recorded by- Triboelectric Nanogenerators for Future Space Missions

Rayyan Ali Shaukat, Muhammad Muqeet Rehman, Maryam Khan, Rui Chang, Carlo Saverio Iorio, Yarjan Abdul Samad, Yijun Shi

Nano-Micro Letters.2026;[Epub] CrossRef - Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System

Saba Ejaz, Imran Shah, Shahid Aziz, Gul Hassan, Ahmed Shuja, Muhammad Asif Khan, Dong-Won Jung

Micromachines.2025; 16(2): 230. CrossRef - Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

Journal of Powder Materials.2025; 32(1): 16. CrossRef - Sustainable Triboelectric Nanogenerator from Abalone Shell Powder for Self-Powered Humidity Sensing

Yunsook Yang, Farhan Akhtar, Shahzad Iqbal, Muhammad Muqeet Rehman, Woo Young Kim

Sensors.2025; 25(24): 7584. CrossRef - Research Trends in Magneto-Mechano-Electric (MME) Energy Harvesting Devices

So Ie Jeong, Geon-Tae Hwang

Journal of Powder Materials.2025; 32(6): 529. CrossRef

- Triboelectric Nanogenerators for Future Space Missions

- [Korean]

- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

- Hansung Lee, Minsu Kim, Byungmin Ahn

- J Powder Mater. 2023;30(4):332-338. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.332

- 922 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Thermite welding is an exceptional process that does not require additional energy supplies, resulting in welded joints that exhibit mechanical properties and conductivity equivalent to those of the parent materials. The global adoption of thermite welding is growing across various industries. However, in Korea, limited research is being conducted on the core technology of thermite welding. Currently, domestic production of thermite powder in Korea involves recycling copper oxide (CuO). Unfortunately, controlling the particle size of waste CuO poses challenges, leading to the unwanted formation of pores and cracks during thermite welding. In this study, we investigate the influence of powder particle size on thermite welding in the production of Cu-thermite powder using waste CuO. We conduct the ball milling process for 0.5–24 h using recycled CuO. The evolution of the powder shape and size is analyzed using particle size analysis and scanning electron microscopy (SEM). Furthermore, we examine the thermal reaction characteristics through differential scanning calorimetry. Additionally, the microstructures of the welded samples are observed using optical microscopy and SEM to evaluate the impact of powder particle size on weldability. Lastly, hardness measurements are performed to assess the strengths of the welded materials.

-

Citations

Citations to this article as recorded by- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

Jisung Lee, Hansung Lee, Eunhyo Song, Byungmin Ahn

Journal of Powder Materials.2024; 31(5): 414. CrossRef

- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

- [Korean]

- Recent Studies on Area Selective Atomic Layer Deposition of Elemental Metals

- Min Gyoo Cho, Jae Hee Go, Byung Joon Choi

- J Powder Mater. 2023;30(2):156-168. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.156

- 3,110 View

- 81 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The semiconductor industry faces physical limitations due to its top-down manufacturing processes. High cost of EUV equipment, time loss during tens or hundreds of photolithography steps, overlay, etch process errors, and contamination issues owing to photolithography still exist and may become more serious with the miniaturization of semiconductor devices. Therefore, a bottom-up approach is required to overcome these issues. The key technology that enables bottom-up semiconductor manufacturing is area-selective atomic layer deposition (ASALD). Here, various ASALD processes for elemental metals, such as Co, Cu, Ir, Ni, Pt, and Ru, are reviewed. Surface treatments using chemical species, such as self-assembled monolayers and small-molecule inhibitors, to control the hydrophilicity of the surface have been introduced. Finally, we discuss the future applications of metal ASALD processes.

-

Citations

Citations to this article as recorded by- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

Chan Hyeon Yang, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 509. CrossRef - Selective Atomic Layer Deposition of Co Thin Films Using Co(EtCp)2 Precursor

Sujeong Kim, Yong Tae Kim, Jaeyeong Heo

Korean Journal of Materials Research.2024; 34(3): 163. CrossRef

- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

- [Korean]

- Recent Developments in Synthesis of Colloidal Quantum Dots

- Jae-Yong Jung, Jong-Pal Hong, Young-Kuk Kim

- J Korean Powder Metall Inst. 2018;25(4):346-354. Published online August 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.4.346

- 1,936 View

- 13 Download

-

Abstract

Abstract

PDF

PDF Over the last decade, the study of the synthesis of semiconductor colloidal quantum dots has progressed at a tremendous rate. Colloidal quantum dots, which possess unique spectral-luminescent characteristics, are of great interest in the development of novel materials and devices, which are promising for use in various fields. Several studies have been carried out on hot injection synthesis methods. However, these methods have been found to be unsuitable for large-capacity synthesis. Therefore, this review paper introduces synthesis methods other than the hot injection synthesis method, to synthesize quantum dots with excellent optical properties, through continuous synthesis and large capacity synthesis. In addition, examples of the application of synthesized colloid quantum dots in displays, solar cells, and bio industries are provided.

- [Korean]

- Control of Nano-Scaled Surface Microstructure of Al Sample for Improving Heat Release Ability

- In-Chul Yeo, In-Cheol Kang

- J Korean Powder Metall Inst. 2015;22(1):21-26. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.21

- 722 View

- 2 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, the control of microstructure for increasing surface roughness of Al with an electro-chemical reaction and a post treatment is systematically investigated. The Al specimen is electro-chemically treated in an electrolyte. In condition of the post treatment at 100°C for 10 min, a change of the surface microstructure occur at 50V (5 min), and a oxidized layer is at 400V, to which lead a decreasing surface roughness. The minimum temperature of the post treatment for a change of microstructure is 80°C. Moreover, in the condition of 300V (5 min), the electro-chemical reaction is followed by the post treatment at 100°C, the critical enduring time for the change of microstructure is 3 min. The longer post treatment time leads to the rougher surface. The treated Al specimen demonstrate better heat release ability owing to the higher surface roughness than the non-treated Al.

-

Citations

Citations to this article as recorded by- Measurement of the Thermal Conductivity of a Polycrystalline Diamond Thin Film via Light Source Thermal Analysis

Hojun Kim, Daeyoon Kim, Nagyeong Lee, Yurim Lee, Kwangbae Kim, Ohsung Song

Korean Journal of Materials Research.2021; 31(12): 665. CrossRef - Effect of Tin Addition on the Melting Temperatures and Mechanical Properties of Al-Si-Cu Brazing Filler Metals

Min Sang Kim, Chun Woong Park, Jong Min Byun, Young Do Kim

Korean Journal of Materials Research.2016; 26(7): 376. CrossRef

- Measurement of the Thermal Conductivity of a Polycrystalline Diamond Thin Film via Light Source Thermal Analysis

- [Korean]

- Microstructure and Mechanical Properties of CNT/Al Composite Fabricated by a Powder-in-Sheath Rolling Method utilizing Copper Tube as a Sheath

- Seong-Hee Lee

- J Korean Powder Metall Inst. 2014;21(5):343-348. Published online October 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.5.343

- 683 View

- 0 Download

-

Abstract

Abstract

PDF

PDF A powder-in-sheath rolling (PSR) process utilizing a copper alloy tube was applied to a fabrication of a multi-walled carbon nanotube (CNT) reinforced aluminum matrix composite. A copper tube with an outer diameter of 30 mm and a wall thickness of 2 mm was used as a sheath material. A mixture of pure aluminum powders and CNTs with the volume contents of 1, 3, 5 vol% was filled in the tube by tap filling and then processed to 93.3% height reduction by a rolling mill. The relative density of the CNT/Al composite fabricated by the PSR decreased slightly with increasing of CNTs content, but showed high value more than 98%. The average hardness of the 5%CNT/Al composite increased more than 3 times, compared to that of unreinforced pure Al powder compaction. The hardness of the CNT/Al composites was some higher than that of the composites fabricated by PSR using SUS304 tube. Therefore, it is concluded that the type of tube affects largely on the mechanical properties of the CNT/Al composites in the PSR process.

- [Korean]

- Preparation of Cathode Materials for Lithium Rechargeable Batteries using Transition Metals Recycled from Li(Ni1-x-yCoxMny)O2 Secondary Battery Scraps

- Jae-won Lee, Dae Weon Kim, Seong Tae Jang

- J Korean Powder Metall Inst. 2014;21(2):131-136. Published online April 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.2.131

- 617 View

- 3 Download

-

Abstract

Abstract

PDF

PDF Cathode materials and their precursors are prepared with transition metal solutions recycled from the the waste lithium-ion batteries containing NCM (nickel-cobalt-manganese) cathodes by a H2 and C-reduction process. The recycled transition metal sulfate solutions are used in a co-precipitation process in a CSTR reactor to obtain the transition metal hydroxide. The NCM cathode materials (Ni:Mn:Co=5:3:2) are prepared from the transition metal hydroxide by calcining with lithium carbonate. X-ray diffraction and scanning electron microscopy analyses show that the cathode material has a layered structure and particle size of about 10 μm. The cathode materials also exhibited a capacity of about 160 mAh/g with a retention rate of 93~96% after 100 cycles.

- [Korean]

- Fabrication and Evaluation of Carbon Nanotube Reinforced Al Matrix Composite by a Powder-in-sheath Rolling Method

- Seong-Hee Lee, Dongmin Hong

- J Korean Powder Metall Inst. 2014;21(1):50-54. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.50

- 922 View

- 1 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF A powder-in-sheath rolling method was applied to a fabrication of a carbon nano tube (CNT) reinforced aluminum composite. A STS304 tube with an outer diameter of 34 mm and a wall thickness of 2 mm was used as a sheath material. A mixture of pure aluminum powders and CNTs with the volume contents of 1, 3, 5 vol was filled in the tube by tap filling and then processed to 73.5% height reduction by a rolling mill. The relative density of the CNT/ Al composite fabricated by the powder-in-sheath rolling decreased slightly with increasing of CNTs content, but exhibited high value more than 98. The grain size of the aluminum matrix was largely decreased with addition of CNTs; it decreased from 24 μm to 0.9 μm by the addition of only 1 volCNT. The average hardness of the composites increased by approximately 3 times with the addition of CNTs, comparing to that of unreinforced pure aluminum. It is concluded that the powder-in-sheath rolling method is an effective process for fabrication of CNT reinforced Al matrix composites.

-

Citations

Citations to this article as recorded by- Torsion Property of the Structure Bonded Aluminum Foam Due to Impact

G.W. Hwang, J.U. Cho

Archives of Metallurgy and Materials.2017; 62(2): 1353. CrossRef - A Fatigue Fracture Study on TDCB Aluminum Foam Specimen of Type Mode III Bonded with Adhesive

J.H. Lee, J.U. Cho

Archives of Metallurgy and Materials.2017; 62(2): 1359. CrossRef - Experimental Study On Fracture Property Of Double Cantilever Beam Specimen With Aluminum Foam

Y.C. Kim, H.K. Choi, J.U. Cho

Archives of Metallurgy and Materials.2015; 60(2): 1151. CrossRef - Experimental Study On Fracture Property Of Tapered Double Cantilever Beam Specimen With Aluminum Foam

Y.C. Kim, S.S. Kim, J.U. Cho

Archives of Metallurgy and Materials.2015; 60(2): 1459. CrossRef - Microstructure and Mechanical Properties of CNT/Al Composite Fabricated by a Powder-in-Sheath Rolling Method utilizing Copper Tube as a Sheath

Seong-Hee Lee

Journal of Korean Powder Metallurgy Institute.2014; 21(5): 343. CrossRef

- Torsion Property of the Structure Bonded Aluminum Foam Due to Impact

TOP

KPMI

KPMI

First

First Prev

Prev