Search

- Page Path

- HOME > Search

- [English]

- Design of Conductive Inks Containing Carbon Black and Silver Nanowires for Patternable Screen-Printing on Fabrics

- Seokhwan Kim, Geumseong Lee, Jinwoo Park, Dahye Shin, Ki-Il Park, Kyoung Jin Jung, Yuho Min

- J Powder Mater. 2024;31(6):500-507. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00409

- 1,900 View

- 55 Download

- 1 Citations

-

Abstract

Abstract

PDF

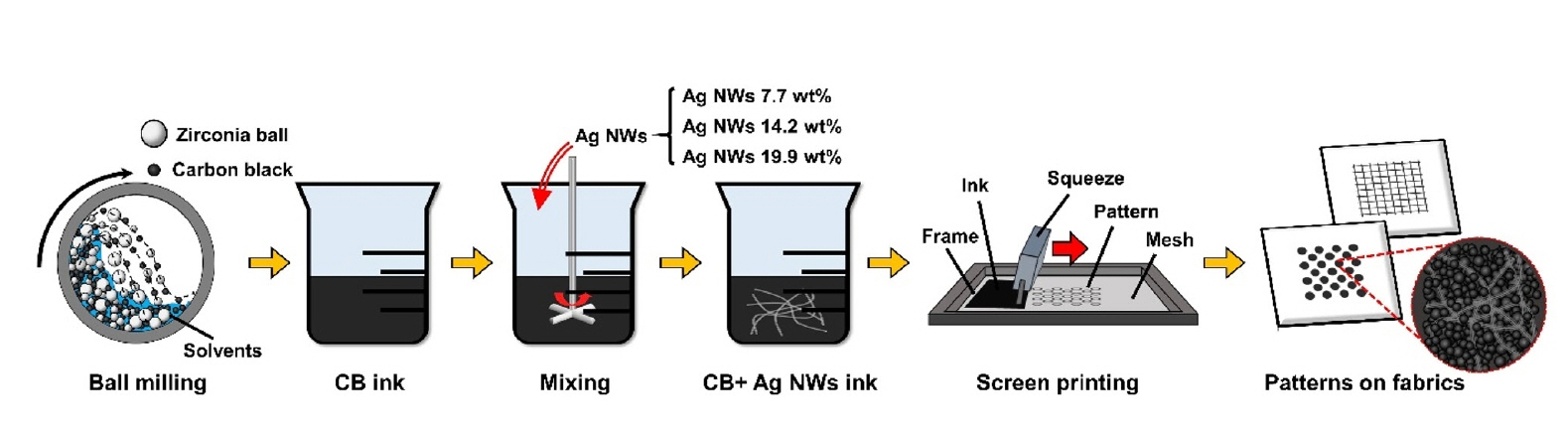

PDF - This study developed conductive inks composed of carbon black (CB) and silver nanowires (Ag NWs) for cost-effective screen-printing on fabrics. The Ag NW density within the CB matrix was precisely controlled, achieving tunable electrical conductivity with minimal Ag NW usage. The resulting inks were successfully patterned into shapes such as square grids and circles on textile surfaces, demonstrating excellent conductivity and fidelity. Adding 19.9 wt% Ag NWs reduced sheet resistance by ~92% compared to CB-only inks, highlighting the effectiveness and potential of this hybrid approach for cost-effective, high-performance textile-based electronics. The one-dimensional morphology of Ag NWs facilitated the formation of conductive percolation networks, creating efficient electron pathways within the CB matrix even at low loadings. This work advances the field of CB-based conductive inks and provides a scalable and practical method for producing functional, patterned electronic textiles.

-

Citations

Citations to this article as recorded by- Multifunctional Screen-Printed Conductive Inks: Design Principles, Performance Challenges, and Application Horizons

Nahid Islam, Manisha Das, Bashir Ahmed Johan, Syed Shaheen Shah, Atif Saeed Alzahrani, Md. Abdul Aziz

ACS Applied Electronic Materials.2025; 7(16): 7503. CrossRef

- Multifunctional Screen-Printed Conductive Inks: Design Principles, Performance Challenges, and Application Horizons

- [Korean]

- Fabrication of Nanowire by Electrospinning Process Using Nickel Oxide Particle Recovered from MLCC

- Haein Shin, Jongwon Bae, Minsu Kang, Kun-Jae Lee

- J Powder Mater. 2023;30(6):502-508. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.502

- 705 View

- 13 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF With the increasing demand for electronic products, the amount of multilayer ceramic capacitor (MLCC) waste has also increased. Recycling technology has recently gained attention because it can simultaneously address raw material supply and waste disposal issues. However, research on recovering valuable metals from MLCCs and converting the recovered metals into high-value-added materials remains insufficient. Herein, we describe an electrospinning (E-spinning) process to recover nickel from MLCCs and modulate the morphology of the recovered nickel oxide particles. The nickel oxalate powder was recovered using organic acid leaching and precipitation. Nickel oxide nanoparticles were prepared via heat treatment and ultrasonic milling. A mixture of nickel oxide particles and polyvinylpyrrolidone (PVP) was used as the E-spinning solution. A PVP/NiO nanowire composite was fabricated via Espinning, and a nickel oxide nanowire with a network structure was manufactured through calcination. The nanowire diameters and morphologies are discussed based on the nickel oxide content in the E-spinning solution.

-

Citations

Citations to this article as recorded by- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

Eunbi Park, Jongwon Bae, Sera Kang, Minsu Kang, Suseong Lee, Kun-Jae Lee

Journal of Powder Materials.2025; 32(5): 375. CrossRef

- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

- [Korean]

- Synthesis of TiO2 Nanowires by Thermal Oxidation of Titanium Alloy Powder

- Yoo-Young Kim, Kwon-Koo Cho

- J Korean Powder Metall Inst. 2018;25(1):48-53. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.48

- 726 View

- 2 Download

-

Abstract

Abstract

PDF

PDF One-dimensional rutile TiO2 is an important inorganic compound with applicability in sensors, solar cells, and Li-based batteries. However, conventional synthesis methods for TiO2 nanowires are complicated and entail risks of environmental contamination. In this work, we report the growth of TiO2 nanowires on a Ti alloy powder (Ti-6wt%Al-4wt%V, Ti64) using simple thermal oxidation under a limited supply of O2. The optimum condition for TiO2 nanowire synthesis is studied for variables including temperature, time, and pressure. TiO2 nanowires of ~5 μm in length and 100 nm in thickness are richly synthesized under the optimum condition with single-crystalline rutile phases. The formation of TiO2 nanowires is greatly influenced by synthesis temperature and pressure. The synthesized TiO2 nanowires are characterized using field-emission scanning electron microscopy (FE-SEM), X-ray diffraction (XRD), and high-resolution transmission electron microscopy (HR-TEM).

- [Korean]

- Synthesis and Characterization of Nickel Nanowires by an Anodic Aluminum Oxide Template-Based Electrodeposition

- Hyo-Ryoung Lim, Yong-Ho Choa, Young-In Lee

- J Korean Powder Metall Inst. 2015;22(3):216-220. Published online June 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.3.216

- 728 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Vertically oriented nickel nanowire arrays with a different diameter and length are synthesized in porous anodic aluminium oxide templates by an electrodeposition method. The pore diameters of the templates are adjusted by controlling the anodization conditions and then they are utilized as templates to grow nickel nanowire arrays. The nickel nanowires have the average diameters of approximately 25 and 260 nm and the crystal structure, morphology and microstructure of the nanowires are systematically investigated using XRD, FE-SEM and TEM analysis. The nickel nanowire arrays show a magnetic anisotropy with the easy axis parallel to the nanowires and the coercivity and remanence enhance with decreasing a wire diameter and increasing a wire length.

TOP

KPMI

KPMI

First

First Prev

Prev