Search

- Page Path

- HOME > Search

- [Korean]

- TiO2 Thin Film Coating on an Nb-Si–Based Superalloy via Atomic Layer Deposition

- Ji Young Park, Su Min Eun, Jongmin Byun, Byung Joon Choi

- J Powder Mater. 2024;31(3):255-262. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00052

- 2,040 View

- 51 Download

-

Abstract

Abstract

PDF

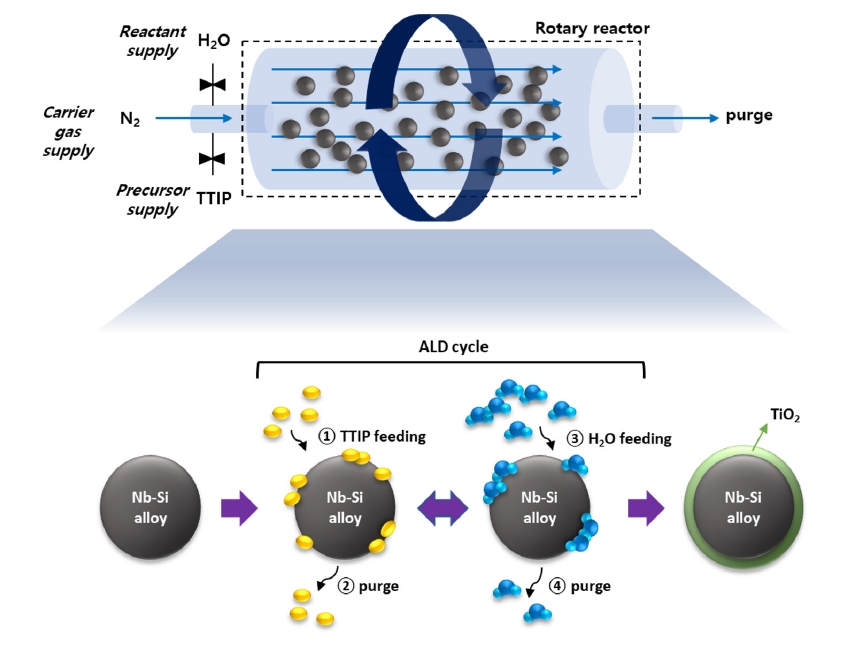

PDF - Nano-oxide dispersion–strengthened (ODS) superalloys have attracted attention because of their outstanding mechanical reinforcement mechanism. Dispersed oxides increase the material’s strength by preventing grain growth and recrystallization, as well as increasing creep resistance. In this research, atomic layer deposition (ALD) was applied to synthesize an ODS alloy. It is useful to coat conformal thin films even on complex matrix shapes, such as nanorods or powders. We coated an Nb-Si–based superalloy with TiO2 thin film by using rotary-reactor type thermal ALD. TiO2 was grown by controlling the deposition recipe, reactor temperature, N2 flow rate, and rotor speed. We could confirm the formation of uniform TiO2 film on the surface of the superalloy. This process was successfully applied to the synthesis of an ODS alloy, which could be a new field of ALD applications.

- [Korean]

- Evaluation of Microstructures and Mechanical Properties of Ni-Y2O3 Sintered Alloys Based on the Powder Preparation Methods

- Gun-Woo Jung, Ji-Ho Cha, Min-Seo Jang, Minsuk Oh, Jeshin Park

- J Powder Mater. 2023;30(6):484-492. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.484

- 1,091 View

- 15 Download

-

Abstract

Abstract

PDF

PDF In this study, Ni-Y2O3 powder was prepared by alloying recomposition oxidation sintering (AROS), solution combustion synthesis (SCS), and conventional mechanical alloying (MA). The microstructure and mechanical properties of the alloys were investigated by spark plasma sintering (SPS). Among the Ni-Y2O3 powders synthesized by the three methods, the AROS powder had approximately 5 nm of Y2O3 crystals uniformly distributed within the Ni particles, whereas the SCS powder contained a mixture of Ni and Y2O3 nanoparticles, and the MA powder formed small Y2O3 crystals on the surface of large Ni particles by milling the mixture of Ni and Y2O3. The average grain size of Y2O3 in the sintered alloys was approximately 15 nm, with the AROS sinter having the smallest, followed by the SCS sinter at 18 nm, and the MA sinter at 22 nm. The yield strength (YS) of the SCS- and MA-sintered alloys were 1511 and 1688 MPa, respectively, which are lower than the YS value of 1697 MPa for the AROS-sintered alloys. The AROS alloy exhibited improved strength compared to the alloys fabricated by SCS and conventional MA methods, primarily because of the increased strengthening from the finer Y2O3 particles and Ni grains.

- [Korean]

- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

- Young-Kyun Kim, Jong-Kwan Park, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2018;25(1):36-42. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.36

- 821 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In order to expand the application of oxide dispersion-strengthened (ODS) steel, a composite material is manufactured by adding mechanically alloyed ODS steel powder to conventional steel and investigated in terms of microstructure and wear properties. For comparison, a commercial automobile part material is also tested. Initial microstructural observations confirm that the composite material with added ODS steel contains i) a pearlitic Fe matrix area and ii) an area with Cr-based carbides and ODS steel particles in the form of a Fe-Fe3C structure. In the commercial material, various hard Co-, Fe-Mo-, and Cr-based particles are present in a pearlitic Fe matrix. Wear testing using the VSR engine simulation wear test confirms that the seatface widths of the composite material with added ODS steel and the commercial material are increased by 24% and 47%, respectively, with wear depths of 0.05 mm and 0.1 mm, respectively. The ODS steel-added composite material shows better wear resistance. Post-wear-testing surface and cross-sectional observations show that particles in the commercial material easily fall off, while the ODS steel-added material has an even, smooth wear surface.

-

Citations

Citations to this article as recorded by- First principles determination of formation of a Cr shell on the interface between Y–Ti–O nanoparticles and a ferritic steel matrix

Ki-Ha Hong, Jae Bok Seol, Jeoung Han Kim

Applied Surface Science.2019; 481: 69. CrossRef - Thermal Properties and Microstructural Changes of Fe-Co System Valve Seat Alloy by High Densification Process

In-Shup Ahn, Dong-Kyu Park, Kwang-Bok Ahn, Seoung-Mok Shin

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 112. CrossRef

- First principles determination of formation of a Cr shell on the interface between Y–Ti–O nanoparticles and a ferritic steel matrix

- [Korean]

- High Temperature Oxidation Behavior of Fe-14Cr Ferritic Oxide Dispersion Strengthened Steels Manufactured by Mechanical Alloying Process

- Young-Kyun Kim, Jong-Kwan Park, Hwi-Jun Kim, Man-Sik Kong, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2017;24(2):133-140. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.133

- 679 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the oxidation properties of Fe-14Cr ferritic oxide-dispersion-strengthened (ODS) steel at various high temperatures (900, 1000, and 1100°C for 24 h). The initial microstructure shows that no clear structural change occurs even under high-temperature heat treatment, and the average measured grain size is 0.4 and 1.1 μm for the as-fabricated and heat-treated specimens, respectively. Y–Ti–O nanoclusters 10–50 nm in size are observed. High-temperature oxidation results show that the weight increases by 0.27 and 0.29 mg/cm2 for the asfabricated and heat-treated (900°C) specimens, and by 0.47 and 0.50 mg/cm2 for the as-fabricated and heat-treated (1000°C) specimens, respectively. Further, after 24 h oxidation tests, the weight increases by 56.50 and 100.60 mg/cm2 for the as-fabricated and heat-treated (1100°C) specimens, respectively; the latter increase is approximately 100 times higher than that at 1000°C. Observation of the surface after the oxidation test shows that Cr2O3 is the main oxide on a specimen tested at 1000°C, whereas Fe2O3 and Fe3O4 phases also form on a specimen tested at 1100°C, where the weight increases rapidly. The high-temperature oxidation behavior of Fe-14Cr ODS steel is confirmed to be dominated by changes in the Cr2O3 layer and generation of Fe-based oxides through evaporation.

-

Citations

Citations to this article as recorded by- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

Young-Kyun Kim, Jong-Kwan Park, Kee-Ahn Lee

journal of Korean Powder Metallurgy Institute.2018; 25(1): 36. CrossRef

- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

TOP

KPMI

KPMI

First

First Prev

Prev