Search

- Page Path

- HOME > Search

- [Korean]

- Laser-Induced Porous Graphene Electrodes for Flexible Heater

- Min Gi An, Jaehak Lee, Jung Hwan Park

- J Powder Mater. 2025;32(6):492-500. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00332

- 491 View

- 1 Download

-

Abstract

Abstract

PDF

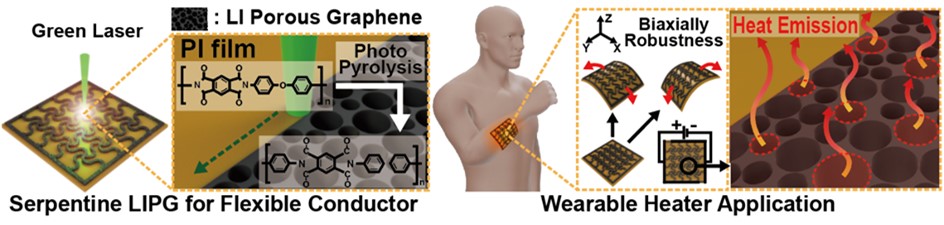

PDF - A flexible heater with high thermal efficiency and mechanical durability was developed by fabricating laser-induced porous graphene (LIPG) electrodes on polyimide films using a 532 nm green laser. Laser power, scan speed, and line distance were precisely optimized based on photothermal simulations to generate uniform porous graphene structures with large surface area and excellent heat dissipation characteristics. Raman, X-ray diffraction, and X-ray photoelectron spectroscopy analyses confirmed that the optimized LIPG exhibited highly graphitized features with low oxygen defects. Scanning electron microscope analysis revealed that porous morphologies formed only within a specific laser scan speed range, whereas excessive or insufficient irradiation resulted in collapsed or absent porosity. The serpentine-patterned LIPG heater maintained stable electrical resistance under repeated multidirectional bending, demonstrating excellent flexibility and mechanical stability. The heater also achieved rapid and uniform heating up to 80 °C within seconds, maintaining consistent temperature distribution even on curved surfaces.

- [Korean]

- Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

- Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

- J Powder Mater. 2025;32(2):104-112. Published online March 4, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00458

- 852 View

- 31 Download

-

Abstract

Abstract

PDF

PDF - A hybrid energy harvester that consisted of thermoelectric (TE) composite film and electrospun piezoelectric (PE) polymeric membranes was constructed. TE composites were fabricated by dispersing inorganic TE powders inside polyvinylidene fluoride elastomer using a drop-casting technique. The polyvinylidene fluoride-trifluoroethylene, which was chosen due to its excellent chemical resistance, mechanical stability, and biocompatibility, was electrospun onto an aluminum foil to fabricate the ultra-flexible PE membranes. To create a hybrid energy harvester that can simultaneously convert heat and mechanical energy resources into electricity, the TE composite films attached to the PE membrane were encapsulated with protective polydimethylsiloxane. The fabricated energy harvester converted the outputs with a maximum voltage of 4 V (PE performance) and current signals of 0.2 μA (TE performance) under periodical heat input and mechanical bending in hybrid modes. This study demonstrates the potential of the hybrid energy harvester for powering flexible and wearable electronics, offering a sustainable and reliable power source.

- [English]

- Recent Advances in Thermoelectric Materials and Devices: Improving Power Generation Performance

- Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Kwi-Il Park

- J Powder Mater. 2025;32(1):1-15. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00395

- 8,946 View

- 194 Download

- 3 Citations

-

Abstract

Abstract

PDF

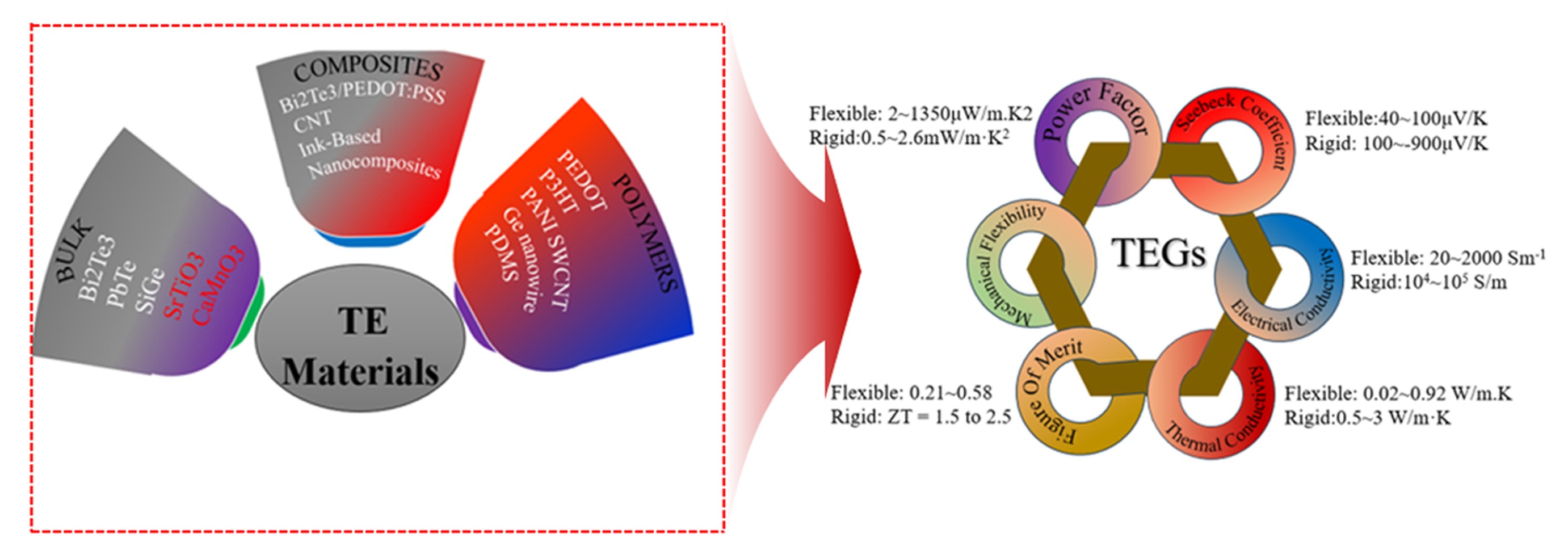

PDF - Thermoelectric materials have been the focus of extensive research interest in recent years due to their potential in clean power generation from waste heat. Their conversion efficiency is primarily reflected by the dimensionless figure of merit, with higher values indicating better performance. There is a pressing need to discover materials that increase output power and improve performance, from the material level to device fabrication. This review provides a comprehensive analysis of recent advancements, such as Bi2Te3-based nanostructures that reduce thermal conductivity while maintaining electrical conductivity, GeTe-based high entropy alloys that utilize multiple elements for improved thermoelectric properties, porous metal-organic frameworks offering tunable structures, and organic/hybrid films that present low-cost, flexible solutions. Innovations in thermoelectric generator designs, such as asymmetrical geometries, segmented modules, and flexible devices, have further contributed to increased efficiency and output power. Together, these developments are paving the way for more effective thermoelectric technologies in sustainable energy generation.

-

Citations

Citations to this article as recorded by- Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

Muhammad Sohaib Tahir, Xue Dong, Muhammad Mansoor Khan

Results in Engineering.2025; 27: 106344. CrossRef - Summary of Publications in the Special Issue: Advances in Corrosion Resistant Coatings

Yong X. Gan

Coatings.2025; 15(11): 1350. CrossRef - Standard Reference Thermoelectric Modules Based on Metallic Combinations and Geometric Design

EunA Koo, Hanhwi Jang, SuDong Park, Sang Hyun Park, Sae-byul Kang

Applied Sciences.2025; 15(18): 10273. CrossRef

- Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

- [Korean]

- Development of Highly Transparent and Thermo-Shielding Flexible Film via Colloidal ITO Nanocrystals

- Hyoin Bae, Hyeyeon Jung, Juna Lee, Dahye Shin, Sungyeon Heo

- J Powder Mater. 2024;31(6):508-512. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00423

- 850 View

- 16 Download

-

Abstract

Abstract

PDF

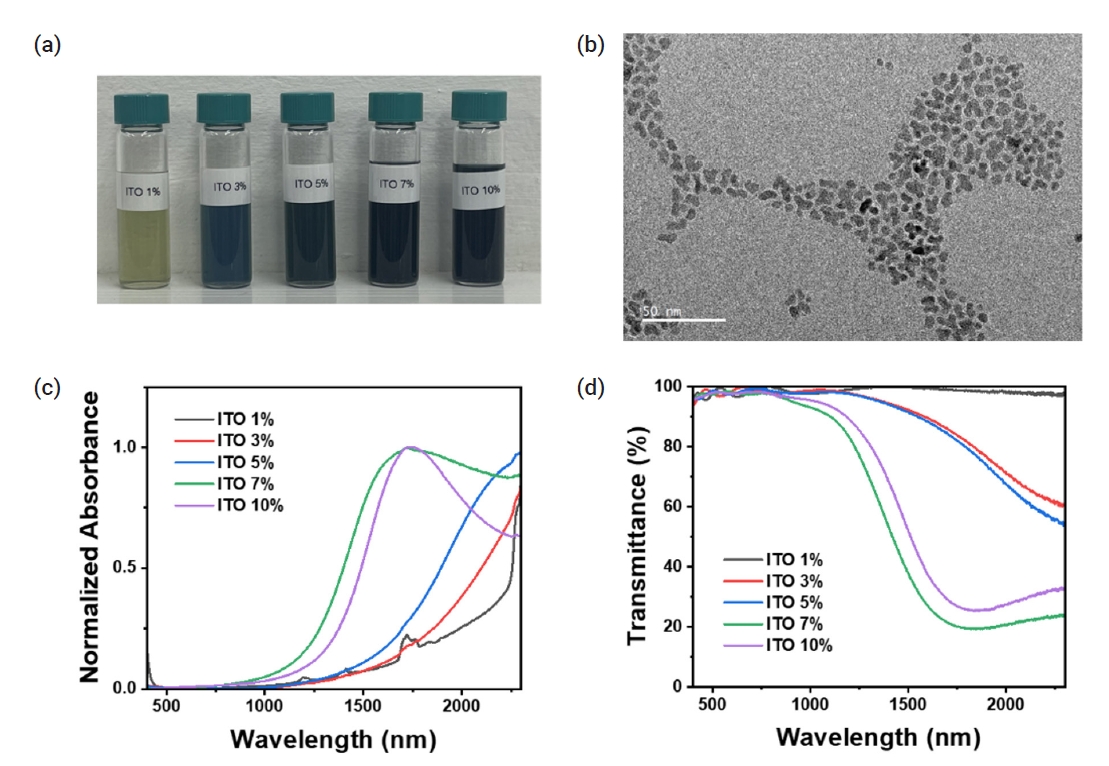

PDF - Infrared radiation accounts for approximately 50% of the solar spectrum. Specifically, the near-infrared (NIR) spectrum, ranging from 760 nm to 2500 nm, is primarily responsible for solar heat gain, increasing indoor temperatures and reducing heating and cooling efficiency. To address this issue, we developed a highly transparent thermo-shielding flexible film that maintains a high transmittance of the visible region (T = 80%) while reducing the transmittance of the NIR region (T ≈ 0%). NIR-absorbing indium tin oxide (ITO) nanocrystals were coated onto polyethylene terephthalate (PET) films, and both films were sandwiched to improve the NIR absorption properties and protect the nanocrystal film layer. The fabricated films were applied to a model house and decreased the indoor temperature by approximately 8°C. Our study demonstrates that energy consumption can be reduced by ITO nanocrystal-coated flexible films, with potential implications for the smart window and mobility markets.

- [Korean]

- Development of Composite-film-based Flexible Energy Harvester using Lead-free BCTZ Piezoelectric Nanomaterials

- Gwang Hyeon Kim, Hyeon Jun Park, Bitna Bae, Haksu Jang, Cheol Min Kim, Donghun Lee, Kwi-Il Park

- J Powder Mater. 2024;31(1):16-22. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.16

- 1,506 View

- 31 Download

- 8 Citations

-

Abstract

Abstract

PDF

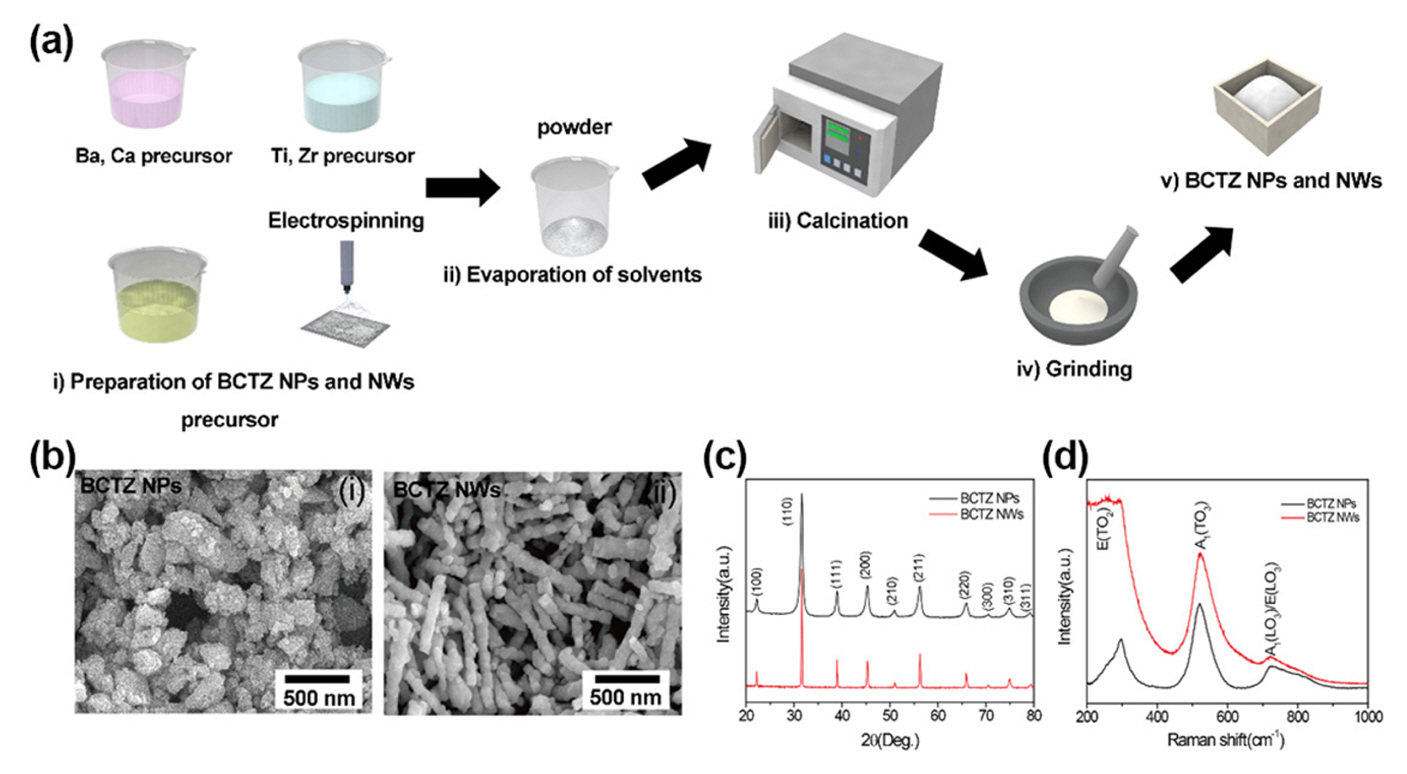

PDF - Composite-based piezoelectric devices are extensively studied to develop sustainable power supply and selfpowered devices owing to their excellent mechanical durability and output performance. In this study, we design a leadfree piezoelectric nanocomposite utilizing (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 (BCTZ) nanomaterials for realizing highly flexible energy harvesters. To improve the output performance of the devices, we incorporate porous BCTZ nanowires (NWs) into the nanoparticle (NP)-based piezoelectric nanocomposite. BCTZ NPs and NWs are synthesized through the solidstate reaction and sol-gel-based electrospinning, respectively; subsequently, they are dispersed inside a polyimide matrix. The output performance of the energy harvesters is measured using an optimized measurement system during repetitive mechanical deformation by varying the composition of the NPs and NWs. A nanocomposite-based energy harvester with 4:1 weight ratio generates the maximum open-circuit voltage and short-circuit current of 0.83 V and 0.28 A, respectively. In this study, self-powered devices are constructed with enhanced output performance by using piezoelectric energy harvesting for application in flexible and wearable devices.

-

Citations

Citations to this article as recorded by- Long‐Lasting, Steady and Enhanced Energy Harvesting by Inserting a Conductive Layer into the Piezoelectric Polymer

HakSu Jang, Gwang Hyeon Kim, Dong Won Jeon, Hyeon Jun Park, BitNa Bae, Nagamalleswara Rao Alluri, Cheol Min Kim, Changyeon Baek, Min‐Ku Lee, Sung Beom Cho, Gyoung‐Ja Lee, Kwi‐Il Park

Advanced Functional Materials.2025;[Epub] CrossRef - Flexible hybrid thermoelectric films made of bismuth telluride-PEDOT:PSS composites enabled by freezing-thawing process and simple chemical treatment

Cheol Min Kim, Seoha Kim, Nagamalleswara Rao Alluri, Bitna Bae, Momanyi Amos Okirigiti, Gwang Hyun Kim, Hyeon Jun Park, Haksu Jang, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Materials Today Chemistry.2025; 44: 102532. CrossRef - Dual-controlled piezoelectric composite film with enhanced crystallinity and defect-free via solvent vapor treatment

HakSu Jang, Hyeon Jun Park, Gwang Hyeon Kim, Cheol Min Kim, Nagamalleswara Rao Alluri, BitNa Bae, HyoMin Jeon, DongHun Lee, Kwi-Il Park

Nano Energy.2025; 136: 110705. CrossRef - Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

Journal of Powder Materials.2025; 32(1): 16. CrossRef - Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

Journal of Powder Materials.2025; 32(2): 104. CrossRef - Flexible Thermoelectric Energy Harvester with Stacked Structure of Thermoelectric Composite Films Made of PVDF and Bi2Te3-Based Particles

Da Eun Shin, Nagamalleswara Rao Alluri, Kwi-Il Park

ACS Applied Energy Materials.2024; 7(19): 8288. CrossRef - Enhanced energy harvesting of fibrous composite membranes via plasma-piezopolymer interaction

Hyeon Jun Park, Bitna Bae, HakSu Jang, Dong Yeol Hyeon, Dong Hun Lee, Gwang Hyun Kim, Cheol Min Kim, Nagamalleswara Rao Alluri, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Nano Energy.2024; 131: 110299. CrossRef - CoFe2O4-BaTiO3 core-shell-embedded flexible polymer composite as an efficient magnetoelectric energy harvester

Bitna Bae, Nagamalleswara Rao Alluri, Cheol Min Kim, Jungho Ryu, Gwang Hyeon Kim, Hyeon Jun Park, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Geon-Tae Hwang, Kwi-Il Park

Materials Today Physics.2024; 48: 101567. CrossRef

- Long‐Lasting, Steady and Enhanced Energy Harvesting by Inserting a Conductive Layer into the Piezoelectric Polymer

- [Korean]

- Mechanical Properties of Bulk Graphite using Artificial Graphite Scrap as a Function of Particle Size

- Sang Hye Lee, Sang Min Lee, Won Pyo Jang, Jae Seung Roh

- J Korean Powder Metall Inst. 2021;28(1):13-19. Published online February 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.1.13

- 1,787 View

- 17 Download

- 7 Citations

-

Abstract

Abstract

PDF

PDF Bulk graphite is manufactured using graphite scrap as the filler and phenolic resin as the binder. Graphite scrap, which is the by-product of processing the final graphite product, is pulverized and sieved by particle size. The relationship between the density and porosity is analyzed by measuring the mechanical properties of bulk graphite. The filler materials are sieved into mean particle sizes of 10.62, 23.38, 54.09, 84.29, and 126.64 μm. The bulk graphite density using the filler powder with a particle size of 54.09 μm is 1.38 g/cm3, which is the highest value in this study. The compressive strength tends to increase as the bulk graphite density increases. The highest compressive strength of 43.14 MPa is achieved with the 54.09 μm powder. The highest flexural strength of 23.08 MPa is achieved using the 10.62 μm powder, having the smallest average particle size. The compressive strength is affected by the density of bulk graphite, and the flexural strength is affected by the filler particle size of bulk graphite.

-

Citations

Citations to this article as recorded by- Effect of Microstructural Change under Pressure during Isostatic Pressing on Mechanical and Electrical Properties of Isotropic Carbon Blocks

Tae-Sub Byun, Sang-Hye Lee, Suk-Hwan Kim, Jae-Seung Roh

Materials.2024; 17(2): 387. CrossRef - Feasibility assessment of manufacturing carbonized blocks from rice husk charcoal

Young-Min Hwang, Jae-Seung Roh, Gibeop Nam

Biomass Conversion and Biorefinery.2024; 14(20): 26409. CrossRef - Improving the packing and mechanical properties of graphite blocks by controlling filler particle-size distribution

Hye in Hwang, Ji Hong Kim, Ji Sun Im

Advanced Composite Materials.2024; 33(5): 762. CrossRef - Effect of Impregnation and Graphitization on EDM Performance of Graphite Blocks Using Recycled Graphite Scrap

Sang-Hye Lee, Dong-Pyo Jeon, Hyun-Yong Lee, Dong-Gu Lee, Jae-Seung Roh

Processes.2023; 11(12): 3368. CrossRef - Ultrafine Graphite Scrap and Carbon Blocks Prepared by High-Solid-Loading Bead Milling and Conventional Ball Milling: A Comparative Assessment

Chonradee Amnatsin, Waroot Kanlayakan, Siraprapa Lhosupasirirat, Nattarut Verojpipath, Boonsueb Pragobjinda, Tanakorn Osotchan, Chakrit Sirisinha, Toemsak Srikhirin

ACS Omega.2023; 8(50): 47919. CrossRef - The Effect of the Heating Rate during Carbonization on the Porosity, Strength, and Electrical Resistivity of Graphite Blocks Using Phenolic Resin as a Binder

Sang-Hye Lee, Jae-Hyun Kim, Woo-Seok Kim, Jae-Seung Roh

Materials.2022; 15(9): 3259. CrossRef - Rheological Behaviour of Hard-Metal Carbide Powder Suspensions at High Shear Rates

B. Hausnerová, P. Sáha, J. Kubát, T. Kitano, J. Becker

Journal of Polymer Engineering.2000;[Epub] CrossRef

- Effect of Microstructural Change under Pressure during Isostatic Pressing on Mechanical and Electrical Properties of Isotropic Carbon Blocks

- [Korean]

- Flexible Cu-In-Se Quantum Dot-Sensitized Solar Cells Based on Nanotube Electrodes

- Jae-Yup Kim

- J Korean Powder Metall Inst. 2019;26(1):45-48. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.45

- 455 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Quantum dots (QDs) are an attractive material for application in solar energy conversion devices because of their unique properties including facile band-gap tuning, a high-absorption coefficient, low-cost processing, and the potential multiple exciton generation effect. Recently, highly efficient quantum dot-sensitized solar cells (QDSCs) have been developed based on CdSe, PbS, CdS, and Cu-In-Se QDs. However, for the commercialization and wide application of these QDSCs, replacing the conventional rigid glass substrates with flexible substrates is required. Here, we demonstrate flexible CISe QDSCs based on vertically aligned TiO2 nanotube (NT) electrodes. The highly uniform TiO2 NT electrodes are prepared by two-step anodic oxidation. Using these flexible photoanodes and semi-transparent Pt counter electrodes, we fabricate the QDSCs and examine their photovoltaic properties. In particular, photovoltaic performances are optimized by controlling the nanostructure of TiO2 NT electrodes.

- [Korean]

- Recent Progress in Flexible Energy Harvesting Devices based on Piezoelectric Nanomaterials

- Kwi-Il Park

- J Korean Powder Metall Inst. 2018;25(3):263-272. Published online June 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.3.263

- 1,089 View

- 4 Download

- 6 Citations

-

Abstract

Abstract

PDF

PDF Recent developments in the field of energy harvesting technology that convert ambient energy resources into electricity enable the use of self-powered energy systems in wearable and portable electronic devices without the need for additional external power sources. In particular, piezoelectric-effect-based flexible energy harvesters have drawn much attention because they can guarantee power generation from ubiquitous mechanical and vibrational movements. In response to demand for sustainable, permanent, and remote use of real-life personal electronics, many research groups have investigated flexible piezoelectric energy harvesters (f-PEHs) that employ nanoscaled piezoelectric materials such as nanowires, nanoparticles, nanofibers, and nanotubes. In those attempts, they have proven the feasibility of energy harvesting from tiny periodic mechanical deformations and energy utilization of f-PEH in commercial electronic devices. This review paper provides a brief overview of f-PEH devices based on piezoelectric nanomaterials and summarizes the development history, output performance, and applications.

-

Citations

Citations to this article as recorded by- A Self-Powered Cationic Microfiber-Based Triboelectric Air Filter for High-Speed Particulate Matter Removal and Smart Monitoring

Tae-hyung Kim, Jin-Kyeom Kim

Journal of Powder Materials.2025; 32(6): 481. CrossRef - Development and Characterization of Hafnium-Doped BaTiO3 Nanoparticle-Based Flexible Piezoelectric Devices

HakSu Jang, Hyeon Jun Park, Gwang Hyeon Kim, Gyoung-Ja Lee, Jae-Hoon Ji, Donghun Lee, Young Hwa Jung, Min-Ku Lee, Changyeon Baek, Kwi-Il Park

JOURNAL OF SENSOR SCIENCE AND TECHNOLOGY.2024; 33(1): 34. CrossRef - Enhanced Piezoelectric Performance of Composite Fibers Based on Lead-Free BCTZ Ceramics and P(VDF-TrFE) Piezopolymer for Self-Powered Wearable Sensors

Sung Cheol Park, Chaeyoung Nam, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

ACS Sustainable Chemistry & Engineering.2022; 10(43): 14370. CrossRef - A Comparison Study of Output Performance of Organic-Inorganic Piezoelectric Nanocomposite Made of Piezoelectric/Non-piezoelectric Polymers and BaTiO3 Nanoparticles

Dong Yeol Hyeon, Kwi-Il Park

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 119. CrossRef - Piezoelectric Flexible Energy Harvester Based on BaTiO3 Thin Film Enabled by Exfoliating the Mica Substrate

Dong Yeol Hyeon, Kwi-Il Park

Energy Technology.2019;[Epub] CrossRef - Piezoelectric Energy Harvesting from Two-Dimensional Boron Nitride Nanoflakes

Gyoung-Ja Lee, Min-Ku Lee, Jin-Ju Park, Dong Yeol Hyeon, Chang Kyu Jeong, Kwi-Il Park

ACS Applied Materials & Interfaces.2019; 11(41): 37920. CrossRef

- A Self-Powered Cationic Microfiber-Based Triboelectric Air Filter for High-Speed Particulate Matter Removal and Smart Monitoring

TOP

KPMI

KPMI

First

First Prev

Prev