Search

- Page Path

- HOME > Search

- [English]

- Enhanced Compressive Strength of Fired Iron Ore Pellets: Effects of Blending Fine and Coarse Particle Concentrates

- Ngo Quoc Dung, Tran Xuan Hai, Nguyen Minh Thuyet, Nguyen Quang Tung, Arvind Barsiwal, Nguyen Hoang Viet

- J Powder Mater. 2025;32(4):315-329. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00129

- 1,811 View

- 70 Download

-

Abstract

Abstract

PDF

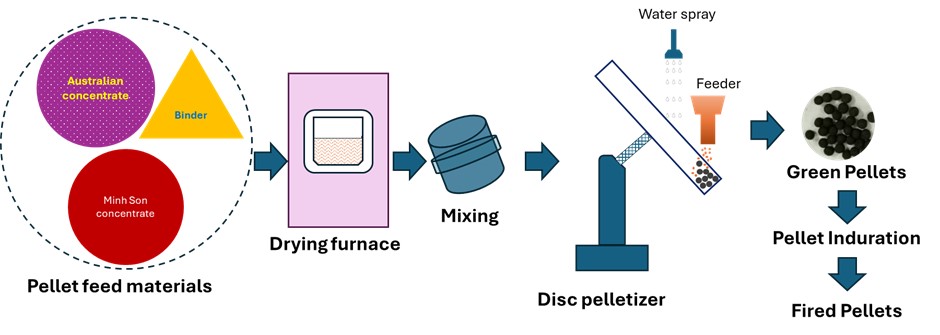

PDF - This study investigated the effects of oxidative firing parameters and raw material characteristics on the pelletization of Australian and Minh Son (Vietnam) iron ore concentrates. The influence of firing temperature (1050°C–1150°C) and holding time (15–120 min) on pellet compressive strength was examined, focusing on microstructural changes during consolidation. Green pellets were prepared using controlled particle size distributions and bentonite as a binder. Scanning electron microscopy and energy-dispersive X-ray spectroscopy analyses revealed that grain boundary diffusion, liquid phase formation, and densification significantly improved mechanical strength. X-ray diffraction confirmed the complete oxidation of magnetite to hematite at elevated temperatures, a critical transformation for metallurgical performance. Optimal firing conditions for both single and blended ore compositions yielded compressive strengths above 250 kgf/pellet, satisfying the requirements for blast furnace applications. These results provide valuable guidance for improving pellet production, promoting the efficient utilization of diverse ore types, and enhancing the overall performance of ironmaking operations.

- [English]

- Epsilon Iron Oxide (ε-Fe2O3) as an Electromagnetic Functional Material: Properties, Synthesis, and Applications

- Ji Hyeong Jeong, Hwan Hee Kim, Jung-Goo Lee, Youn-Kyoung Baek

- J Powder Mater. 2024;31(6):465-479. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00290

- 3,457 View

- 90 Download

- 3 Citations

-

Abstract

Abstract

PDF

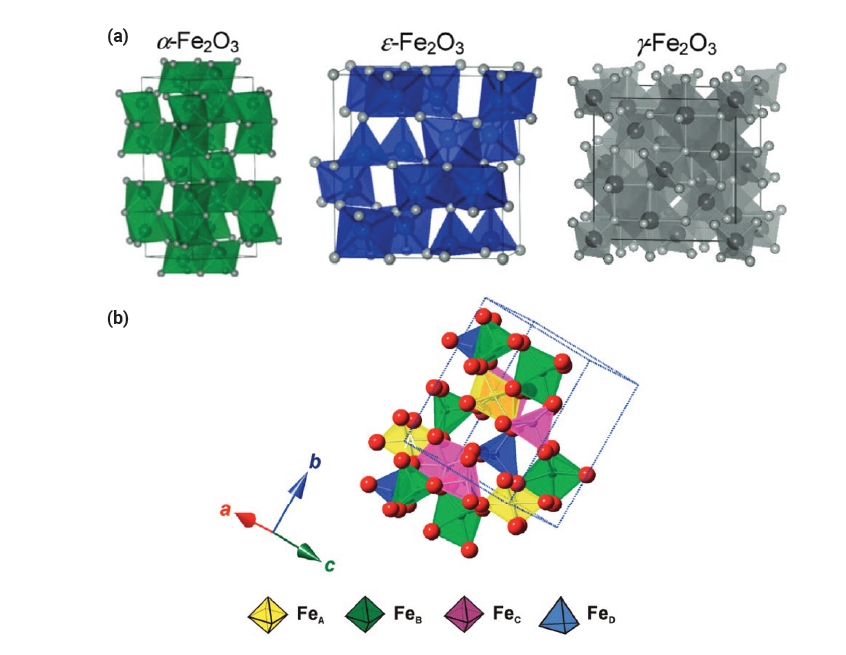

PDF - Iron oxide (ε-Fe₂O₃) is emerging as a promising electromagnetic material due to its unique magnetic and electronic properties. This review focuses on the intrinsic properties of ε-Fe₂O₃, particularly its high coercivity, comparable to that of rare-earth magnets, which is attributed to its significant magnetic anisotropy. These properties render it highly suitable for applications in millimeter wave absorption and high-density magnetic storage media. Furthermore, its semiconducting behavior offers potential applications in photocatalytic hydrogen production. The review also explores various synthesis methods for fabricating ε-Fe₂O₃ as nanoparticles or thin films, emphasizing the optimization of purity and stability. By exploring and harnessing the properties of ε-Fe₂O₃, this study aims to contribute to the advancement of next-generation electromagnetic materials with potential applications in 6G wireless telecommunications, spintronics, high-density data storage, and energy technologies.

-

Citations

Citations to this article as recorded by- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

Babak Enami Alamdari, Yu Tang, Danilo Erricolo, Lesley H. Sneed

Journal of Nondestructive Evaluation.2026;[Epub] CrossRef - Chemical Pressure Induced Strain Control of Magnetic Anisotropy in the Simple Perovskite ϵ-Fe2O3

Subir Roy, Gurleen K. Uppal, Alberto Acosta, Rachel Nickel, Charles A. Roberts, Johan van Lierop

Nano Letters.2026; 26(1): 34. CrossRef - Superparamagnetism of Baked Clays Containing Polymorphs of Iron Oxides: Experimental Study and Theoretical Modeling

Petr Kharitonskii, Andrei Krasilin, Nadezhda Belskaya, Svetlana Yanson, Nikita Bobrov, Andrey Ralin, Kamil Gareev, Nikita Zolotov, Dmitry Zaytsev, Elena Sergienko

Magnetochemistry.2025; 11(12): 103. CrossRef

- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

- [Korean]

- Size Control of Iron Oxide (Fe3O4) Nanoclusters according to Reaction Factors and Consequent Change in Their Magnetic Attraction

- Sanghoon Lee, Arim Byun, Jin-sil Choi

- J Powder Mater. 2023;30(4):297-304. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.297

- 1,041 View

- 13 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Iron oxide (Fe2O3) nanoclusters exhibit significant potential in the biomedical and pharmaceutical fields due to their strong magnetic properties, stability in solutions, and compatibility with living systems. They excel in magnetic separation processes, displaying high responsiveness to external magnetic fields. In contrast to conventional Fe2O3 nanoparticles that can aggregate in aqueous solutions due to their ferrimagnetic properties, these nanoclusters, composed of multiple nanoparticles, maintain their magnetic traits even when scaled to hundreds of nanometers. In this study, we develop a simple method using solvothermal synthesis to precisely control the size of nanoclusters. By adjusting precursor materials and reducing agents, we successfully control the particle sizes within the range of 90 to 420 nm. Our study not only enhances the understanding of nanocluster creation but also offers ways to improve their properties for applications such as magnetic separation. This is supported by our experimental results highlighting their size-dependent magnetic response in water. This study has the potential to advance both the knowledge and practical utilization of Fe2O3 nanoclusters in various applications.

-

Citations

Citations to this article as recorded by- Enzymatic properties of iron oxide nanoclusters and their application as a colorimetric glucose detection probe

Dahyun Bae, Minhee Kim, Jin-sil Choi

RSC Advances.2025; 15(6): 4573. CrossRef

- Enzymatic properties of iron oxide nanoclusters and their application as a colorimetric glucose detection probe

- [Korean]

- Controlling the Heat Generation Capability of Iron Oxide-Base Nanoparticles

- Jin-sil Choi

- J Korean Powder Metall Inst. 2021;28(6):518-526. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.518

- 684 View

- 5 Download

-

Abstract

Abstract

PDF

PDF This review summarizes the recent progress in iron-oxide-based heat generators. Cancer treatment using magnetic nanoparticles as a heat generator, termed magnetic fluid hyperthermia, is a promising noninvasive approach that has gained significant interest. Most previous studies on improving the hyperthermia effect have focused on the construction of dopant-containing iron oxides. However, their applications in a clinical application can be limited due to extra dopants, and pure iron oxide is the only inorganic material approved by the Food and Drug Administration (FDA). Several factors that influence the heat generation capability of iron-oxide-based nanoparticles are summarized by reviewing recent studies on hyperthermia agents. Thus, our paper will provide the guideline for developing pure iron oxide-based heat generators with high heat dissipation capabilities.

- [English]

- Fabrication and Characterization of Immiscible Fe-Cu Alloys using Electrical Explosion of Wire in Liquid

- Chu Dac Phuc, Nguyen Minh Thuyet, Jin-Chun Kim

- J Korean Powder Metall Inst. 2020;27(6):449-457. Published online December 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.6.449

- 1,567 View

- 12 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF Iron and copper are practically immiscible in the equilibrium state, even though their atomic radii are similar. As non-equilibrium solid solutions, the metastable Fe-Cu alloys can be synthesized using special methods, such as rapid quenching, vapor deposition, sputtering, ion-beam mixing, and mechanical alloying. The complexity of these methods (multiple steps, low productivity, high cost, and non-eco-friendliness) is a hinderance for their industrial applications. Electrical explosion of wire (EEW) is a well-known and effective method for the synthesis of metallic and alloy nanoparticles, and fabrication using the EEW is a simple and economic process. Therefore, it can be potentially employed to circumvent this problem. In this work, we propose the synthesis of Fe-Cu nanoparticles using EEW in a suitable solution. The powder shape, size distribution, and alloying state are analyzed and discussed according to the conditions of the EEW.

-

Citations

Citations to this article as recorded by- Scaling up plasma-derived metallic nanoalloys: A comprehensive review of production bottlenecks, manufacturing readiness, and AI-driven pathways to viability

Hugues Nkomba Museba, BongJu Lee

Journal of Alloys and Compounds.2026; 1054: 185926. CrossRef - Identification of the reconstruction induced high-entropy spinel oxide nanosheets for boosting alkaline water oxygen evolution

Xuexue Wang, Runqing Lu, Shanhe Gong, Shaokang Yang, Wenbo Wang, Zhongti Sun, Xiaozhen Zhang, Jun Liu, Xiaomeng Lv

Chemical Engineering Journal.2025; 503: 158488. CrossRef - Trends in bimetallic nanomaterials and methods for the removal of p-nitrophenol and its derivatives from wastewater

M. S. Qatan, F. Arshad, M. Miskam, G. A. Naikoo

International Journal of Environmental Science and Technology.2024; 21(5): 5247. CrossRef - Control of cluster coalescence during formation of bimetallic nanoparticles and nanoalloys obtained via electric explosion of two wires

K.V. Suliz, A.Yu. Kolosov, V.S. Myasnichenko, N.I. Nepsha, N.Yu. Sdobnyakov, A.V. Pervikov

Advanced Powder Technology.2022; 33(3): 103518. CrossRef

- Scaling up plasma-derived metallic nanoalloys: A comprehensive review of production bottlenecks, manufacturing readiness, and AI-driven pathways to viability

- [Korean]

- Recent Trends and Application Status of the Metal Matrix Composites (MMCs)

- Hyo-Seop Kim

- J Korean Powder Metall Inst. 2020;27(2):164-173. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.164

- 1,390 View

- 38 Download

-

Abstract

Abstract

PDF

PDF Metal matrix composites (MMCs), which are a combination of two or more constituents with different physical or chemical properties, are today receiving great attention in various areas, as they have high specific strength, corrosion resistance, fatigue strength, and good tribological properties. This paper presents a research review on the combination of matrix and reinforced materials, fabrication processes, and application status of metal matrix composites. In this paper, we aim to discuss and review the importance of metal composite materials as advanced materials that can be used in various applications such as transportation, defense, sports, and extreme environments. In addition, the applicability and technology development trends in new process technology fields such as additive manufacturing of metal composites will be described.

- [Korean]

- Magnetic Properties of Micron Sized Fe3O4 Crystals Synthesized by Hydrothermal Methods

- Ki-Bum Lee, Chunghee Nam

- J Korean Powder Metall Inst. 2019;26(6):481-486. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.481

- 1,148 View

- 8 Download

-

Abstract

Abstract

PDF

PDF Iron oxides currently attract considerable attention due to their potential applications in the fields of lithiumion batteries, bio-medical sensors, and hyperthermia therapy materials. Magnetite (Fe3O4) is a particularly interesting research target due to its low cost, good biocompatibility, outstanding stability in physiological conditions. Hydrothermal synthesis is one of several liquid-phase synthesis methods with water or an aqueous solution under high pressure and high temperature. This paper reports the growth of magnetic Fe3O4 particles from iron powder (spherical, <10 μm) through an alkaline hydrothermal process under the following conditions: (1) Different KOH molar concentrations and (2) different synthesis time for each KOH molar concentrations. The optimal condition for the synthesis of Fe3O4 using Fe powders is hydrothermal oxidation with 6.25 M KOH for 48 h, resulting in 89.2 emu/g of saturation magnetization at room temperature. The structure and morphologies of the synthesized particles are characterized by X-ray diffraction (XRD, 2θ = 20°–80°) with Cu-kα radiation and field emission scanning electron microscopy (FE-SEM), respectively. The magnetic properties of magnetite samples are investigated using a vibrating sample magnetometer (VSM). The role of KOH in the formation of magnetite octahedron is observed.

- [Korean]

- Research trend in Fabrication of Metastable-phase Iron Nitrides for Hard Magnetic Applications

- Kyung Min Kim, Jung-Goo Lee, Kyung Tae Kim, Youn-Kyoung Baek

- J Korean Powder Metall Inst. 2019;26(2):146-155. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.146

- 1,707 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Rare earth magnets are the strongest type of permanent magnets and are integral to the high tech industry, particularly in clean energies, such as electric vehicle motors and wind turbine generators. However, the cost of rare earth materials and the imbalance in supply and demand still remain big problems to solve for permanent magnet related industries. Thus, a magnet with abundant elements and moderate magnetic performance is required to replace rare-earth magnets. Recently, a”-Fe16N2 has attracted considerable attention as a promising candidate for next-generation non-rare-earth permanent magnets due to its gigantic magnetization (3.23 T). Also, metastable a”-Fe16N2 exhibits high tetragonality (c/a = 1.1) by interstitial introduction of N atoms, leading to a high magnetocrystalline anisotropy constant (K1 = 1.0MJ/m3). In addition, Fe has a large amount of reserves on the Earth compared to other magnetic materials, leading to low cost of raw materials and manufacturing for industrial production. In this paper, we review the synthetic methods of metastable a”-Fe16N2 with film, powder and bulk form and discuss the approaches to enhance magnetocrystalline anisotropy of a”-Fe16N2. Future research prospects are also offered with patent trends observed thus far.

-

Citations

Citations to this article as recorded by- Failure Cases according to Photocuring-Based Alumina 3D Printing

So-Young Ko, Shin-Il Go, Kyoung-Jun Jang, Sang-Jin Lee

Korean Journal of Materials Research.2024; 34(10): 457. CrossRef

- Failure Cases according to Photocuring-Based Alumina 3D Printing

- [English]

- Microwave Absorbance of Polymer Composites Containing SiC Fibers Coated with Ni-Fe Thin Films

- Tian Liu, Sung-Soo Kim, Woo-cheal Choi, Byungil Yoon

- J Korean Powder Metall Inst. 2018;25(5):375-378. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.375

- 1,094 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Conductive and dielectric SiC are fabricated using electroless plating of Ni–Fe films on SiC chopped fibers to obtain lightweight and high-strength microwave absorbers. The electroless plating of Ni–Fe films is achieved using a two-step process of surface sensitizing and metal plating. The complex permeability and permittivity are measured for the composite specimens with the metalized SiC chopped fibers dispersed in a silicone rubber matrix. The original noncoated SiC fibers exhibit considerable dielectric losses. The complex permeability spectrum does not change significantly with the Ni–Fe coating. Moreover, dielectric constant is sensitively increased with Ni–Fe coating, owing to the increase of the space charge polarization. The improvements in absorption capability (lower reflection loss and small matching thickness) are evident with Ni–Fe coating on SiC fibers. For the composite SiC fibers coated with Ni–Fe thin films, a -35 dB reflection loss is predicted at 7.6 GHz with a matching thickness of 4 mm.

-

Citations

Citations to this article as recorded by- Magnetic sputtering of FeNi/C bilayer film on SiC fibers for effective microwave absorption in the low-frequency region

Tong Guo, Ben Huang, Changgeng Li, Yumin Lou, Xiu-Zhi Tang, Xiaozhong Huang, Jianling Yue

Ceramics International.2021; 47(4): 5221. CrossRef

- Magnetic sputtering of FeNi/C bilayer film on SiC fibers for effective microwave absorption in the low-frequency region

- [English]

- Microstructural Characterization of Gas Atomized Copper-Iron Alloys with Composition and Powder Size

- Sardar Farhat Abbas, Taek-Soo Kim

- J Korean Powder Metall Inst. 2018;25(1):19-24. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2017.25.1.19

- 668 View

- 3 Download

-

Abstract

Abstract

PDF

PDF Cu-Fe alloys (CFAs) are much anticipated for use in electrical contacts, magnetic recorders, and sensors. The low cost of Fe has inspired the investigation of these alloys as possible replacements for high-cost Cu-Nb and Cu-Ag alloys. Here, alloys of Cu and Fe having compositions of Cu100-xFex (x = 10, 30, and 50 wt.%) are prepared by gas atomization and characterized microstructurally and structurally based on composition and powder size with scanning electron microscopy (SEM) and X-ray diffraction (XRD). Grain sizes and Fe-rich particle sizes are measured and relationships among composition, powder size, and grain size are established. Same-sized powders of different compositions yield different microstructures, as do differently sized powders of equal composition. No atomic-level alloying is observed in the CFAs under the experimental conditions.

- [Korean]

- Effect of Deposition Parameter and Mixing Process of Raw Materials on the Phase and Structure of Ytterbium Silicate Environmental Barrier Coatings by Suspension Plasma Spray Method

- Ho-lim Ryu, Seon-A Choi, Sung-Min Lee, Yoon-Soo Han, Kyun Choi, Sahn Nahm, Yoon-Suk Oh

- J Korean Powder Metall Inst. 2017;24(6):437-443. Published online December 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.6.437

- 819 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF SiC-based composite materials with light weight, high durability, and high-temperature stability have been actively studied for use in aerospace and defense applications. Moreover, environmental barrier coating (EBC) technologies using oxide-based ceramic materials have been studied to prevent chemical deterioration at a high temperature of 1300°C or higher. In this study, an ytterbium silicate material, which has recently been actively studied as an environmental barrier coating because of its high-temperature chemical stability, is fabricated on a sintered SiC substrate. Yb2O3 and SiO2 are used as the raw starting materials to form ytterbium disilicate (Yb2Si2O7). Suspension plasma spraying is applied as the coating method. The effect of the mixing method on the particle size and distribution, which affect the coating formation behavior, is investigated using a scanning electron microscope (SEM), an energy dispersive spectrometer (EDS), and X-ray diffraction (XRD) analysis. It is found that the originally designed compounds are not effectively formed because of the refinement and vaporization of the raw material particles, i.e., SiO2, and the formation of a porous coating structure. By changing the coating parameters such as the deposition distance, it is found that a denser coating structure can be formed at a closer deposition distance.

-

Citations

Citations to this article as recorded by- Fabrication, Microstructure and Adhesive Properties of BCuP-5 Filler Metal/Ag Plate Composite by using Plasma Spray Process

Seong-June Youn, Young-Kyun Kim, Jae-Sung Park, Joo-Hyun Park, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(4): 333. CrossRef

- Fabrication, Microstructure and Adhesive Properties of BCuP-5 Filler Metal/Ag Plate Composite by using Plasma Spray Process

- [Korean]

- Fabrication and Mechanical Property of Fe-20Cu-1C Compacts by SPS process with Different Heating Rate

- Jung-Han Ryu, Soo-Sik Shin, Byung-Rok Ryu, Kyung-Sik Kim, Jun-Ho Jang, Ik-Hyun Oh, Kap-Tae Kim, Hyun-Kuk Park

- J Korean Powder Metall Inst. 2017;24(4):302-307. Published online August 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.4.302

- 1,094 View

- 6 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, Fe-Cu-C alloy is sintered by spark plasma sintering (SPS). The sintering conditions are 60 MPa pressure with heating rates of 30, 60 and 9°C/min to determine the influence of heating rate on the mechanical and microstructure properties of the sintered alloys. The microstructure and mechanical properties of the sintered Fe-Cu-C alloy is investigated by X-ray diffraction (XRD) and field-emission scanning electron microscopy (FE-SEM). The temperature of shrinkage displacement is changed at 450°C with heating rates 30, 60, and 90°C/min. The temperature of the shrinkage displacement is finished at 650°C when heating rate 30°C/min, at 700°C when heating rate 60oC/min and at 800°C when heating rate 90oC/min. For the sintered alloy at heating rates of 30, 60, and 90oC/min, the apparent porosity is calculated to be 3.7%, 5.2%, and 7.7%, respectively. The hardness of the sintered alloys is investigated using Rockwell hardness measurements. The objective of this study is to investigate the densification behavior, porosity, and mechanical properties of the sintered Fe-Cu-C alloys depending on the heating rate.

-

Citations

Citations to this article as recorded by- Effect of Milling Time and Addition of PCA on Austenite Stability of Fe-7%Mn Alloy

Seung-Jin Oh, In-Jin Shon, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2018; 25(2): 126. CrossRef

- Effect of Milling Time and Addition of PCA on Austenite Stability of Fe-7%Mn Alloy

- [English]

- Fabrication of Sintered Compact of Fe-TiB2 Composites by Pressureless Sintering of (FeB+TiH2) Powder Mixture

- Xuan-Khoa Huynh, Ji Soon Kim

- J Korean Powder Metall Inst. 2016;23(4):282-286. Published online August 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.4.282

- 997 View

- 1 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF A sintered body of TiB2-reinforced iron matrix composite (Fe-TiB2) is fabricated by pressureless-sintering of a mixture of titanium hydride (TiH2) and iron boride (FeB) powders. The powder mixture is prepared in a planetary ball-mill at 700 rpm for 3 h and then pressurelessly sintered at 1300, 1350 and 1400°C for 0-2 h. The optimal sintering temperature for high densities (above 95% relative density) is between 1350 and 1400°C, where the holding time can be varied from 0.25 to 2 h. A maximum relative density of 96.0% is obtained from the (FeB+TiH2) powder compacts sintered at 1400°C for 2 h. Sintered compacts have two main phases of Fe and TiB2 along with traces of TiB, which seems to be formed through the reaction of TiB2 formed at lower temperatures during the heating stage with the excess Ti that is intentionally added to complete the reaction for TiB2 formation. Nearly fully densified sintered compacts show a homogeneous microstructure composed of fine TiB2 particulates with submicron sizes and an Fe-matrix. A maximum hardness of 71.2 HRC is obtained from the specimen sintered at 1400°C for 0.5 h, which is nearly equivalent to the HRC of conventional WC-Co hardmetals containing 20 wt% Co.

-

Citations

Citations to this article as recorded by- Optimizing the Microstructure and Properties of Fe–Ni–Cu–Mo–C Sintered Steel by TiB2

Zenglin Liu, Yankang Wang, Weilong Lu, Feng Liu, Wei Han, Wuqiang He

Science of Advanced Materials.2024; 16(6): 707. CrossRef - Effect of Ce Addition on the As-Cast and As-Forged Microstructure of Fe-TiB2 Composites

Lin Zhang, Jianwen Gao, Minghao Huang, Engang Wang

JOM.2019; 71(11): 4144. CrossRef - Microstructure, mechanical, and tribological properties of pressureless sintered and spark plasma sintered Fe TiB2 nanocomposites

Hak-Rae Cho, Ji-Soon Kim, Koo-Hyun Chung

Tribology International.2019; 131: 83. CrossRef

- Optimizing the Microstructure and Properties of Fe–Ni–Cu–Mo–C Sintered Steel by TiB2

- [Korean]

- Spindle-shaped Fe2O3 Nanoparticle Coated Carbon Nanofiber Composites for Low-cost Dye-sensitized Solar Cells

- Dong-Hyeun Oh, HyeLan An, Bon-Ryul Koo, Hyo-Jin Ahn

- J Korean Powder Metall Inst. 2016;23(2):95-101. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.95

- 1,033 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Carbon nanofiber (CNF) composites coated with spindle-shaped Fe2O3 nanoparticles (NPs) are fabricated by a combination of an electrospinning method and a hydrothermal method, and their morphological, structural, and chemical properties are measured by field-emission scanning electron microscopy, transmission electron microscopy, Xray diffraction, and X-ray photoelectron spectroscopy. For comparison, CNFs and spindle-shaped Fe2O3 NPs are prepared by either an electrospinning method or a hydrothermal method, respectively. Dye-sensitized solar cells (DSSCs) fabricated with the composites exhibit enhanced open circuit voltage (0.70 V), short-circuit current density (12.82 mA/cm2), fill factor (61.30%), and power conversion efficiency (5.52%) compared to those of the CNFs (0.66 V, 11.61 mA/cm2, 51.96%, and 3.97%) and spindle-shaped Fe2O3 NPs (0.67 V, 11.45 mA/cm2, 50.17%, and 3.86%). This performance improvement can be attributed to a synergistic effect of a superb catalytic reaction of spindle-shaped Fe2O3 NPs and efficient charge transfer relative to the one-dimensional nanostructure of the CNFs. Therefore, spindle-shaped Fe2O3-NPcoated CNF composites may be proposed as a potential alternative material for low-cost counter electrodes in DSSCs.

-

Citations

Citations to this article as recorded by- Ni Nanoparticles-Graphitic Carbon Nanofiber Composites for Pt-Free Counter Electrode in Dye-Sensitized Solar Cells

Dong-Hyeun Oh, Bon-Ryul Koo, Yu-Jin Lee, HyeLan An, Hyo-Jin Ahn

Korean Journal of Materials Research.2016; 26(11): 649. CrossRef

- Ni Nanoparticles-Graphitic Carbon Nanofiber Composites for Pt-Free Counter Electrode in Dye-Sensitized Solar Cells

- [English]

- Environment Emission and Material Flow Analysis of Chromium in Korea

- Dong-won Shin, Jeong-gon Kim

- J Korean Powder Metall Inst. 2015;22(3):187-196. Published online June 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.3.187

- 651 View

- 1 Download

-

Abstract

Abstract

PDF

PDF With the stabilization of Korea’s industrialization, it has become interested in the efficient use of rare metals, climate change and industrial environment and safety etc. It is thus making efforts to implement economic policies that address such issues. Therefore it is necessary to understand the demand, supply and use of metal materials. Since 2010, the Korean government has developed the integrated material flow methodology and has been trying to examine the demand, supply and use of metal materials. In 2013, the Korean government surveyed the material flow of chromium. Material flow analysis and environment emission of chromium were investigated 8 steps; (1) raw material, (2) first process, (3) Intermediate product, (4) End product, (5) Use/accumulation, (6) Collection, (7) Recycling, (8) Disposal. Chromium was used for stainless steel, alloy steel, coated sheets, refractory material and coating materials. Recycling was done mainly in use of stainless steel scrap. To ensure efficient use of chromium, process improvement is required to reduce the scrap in the intermediate product stage. In the process of producing of the products using chromium, it was confirmed that chromium was exposed to the environment. It requires more attention and protection against environment emission of chromium.

- [Korean]

- Hydrogen Reduction Behavior of Oxide Scale in Water-atomized Iron Powder

- Hea-Min Shin, Kyeong-Ho Baik

- J Korean Powder Metall Inst. 2014;21(6):422-428. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.422

- 1,131 View

- 6 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, the reduction kinetics and behaviors of oxides in the water-atomized iron powder have been evaluated as a function of temperature ranging 850-1000°C in hydrogen environment, and compared to the reduction behaviors of individual iron oxides including Fe2O3, Fe3O4 and FeO. The water-atomized iron powder contained a significant amount of iron oxides, mainly Fe3O4 and FeO, which were formed as a partially-continuous surface layer and an inner inclusion. During hydrogen reduction, a significant weight loss in the iron powder occurred in the initial stage of 10 min by the reduction of surface oxides, and then further reduction underwent slowly with increasing time. A higher temperature in the hydrogen reduction promoted a high purity of iron powder, but no significant change in the reduction occurred above 950°C. Sequence reduction process by an alternating environment of hydrogen and inert gases effectively removed the oxide scale in the iron powder, which lowered reduction temperature and/or shortened reduction time.

-

Citations

Citations to this article as recorded by- Carbon Co-Deposition During Gas Reduction of Water-Atomized Fe-Cr-Mo Powder

B. Ali, S.H. Choi, S.J. Seo, D.Y. Maeng, C.G. Lee, T.S. Kim, K.T. Park

Archives of Metallurgy and Materials.2017; 62(2): 1119. CrossRef

- Carbon Co-Deposition During Gas Reduction of Water-Atomized Fe-Cr-Mo Powder

TOP

KPMI

KPMI

First

First Prev

Prev