Search

- Page Path

- HOME > Search

- [English]

- Recent Advances in Thermoelectric Materials and Devices: Improving Power Generation Performance

- Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Kwi-Il Park

- J Powder Mater. 2025;32(1):1-15. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00395

- 8,946 View

- 194 Download

- 3 Citations

-

Abstract

Abstract

PDF

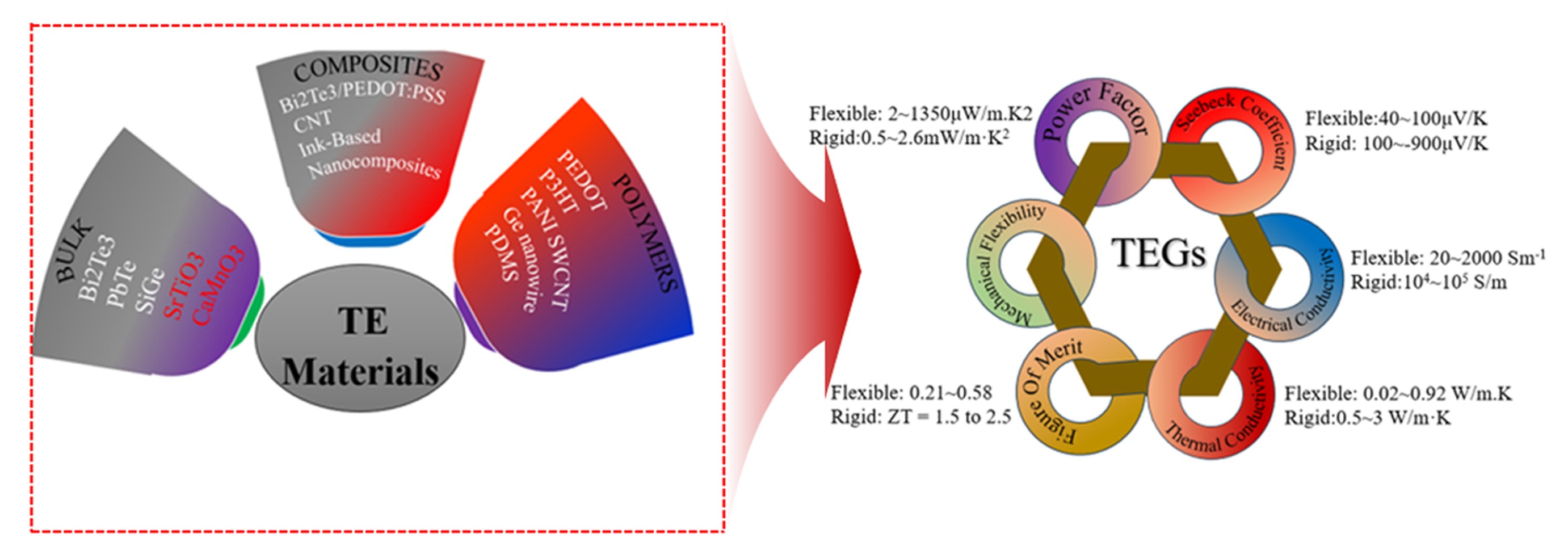

PDF - Thermoelectric materials have been the focus of extensive research interest in recent years due to their potential in clean power generation from waste heat. Their conversion efficiency is primarily reflected by the dimensionless figure of merit, with higher values indicating better performance. There is a pressing need to discover materials that increase output power and improve performance, from the material level to device fabrication. This review provides a comprehensive analysis of recent advancements, such as Bi2Te3-based nanostructures that reduce thermal conductivity while maintaining electrical conductivity, GeTe-based high entropy alloys that utilize multiple elements for improved thermoelectric properties, porous metal-organic frameworks offering tunable structures, and organic/hybrid films that present low-cost, flexible solutions. Innovations in thermoelectric generator designs, such as asymmetrical geometries, segmented modules, and flexible devices, have further contributed to increased efficiency and output power. Together, these developments are paving the way for more effective thermoelectric technologies in sustainable energy generation.

-

Citations

Citations to this article as recorded by- Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

Muhammad Sohaib Tahir, Xue Dong, Muhammad Mansoor Khan

Results in Engineering.2025; 27: 106344. CrossRef - Summary of Publications in the Special Issue: Advances in Corrosion Resistant Coatings

Yong X. Gan

Coatings.2025; 15(11): 1350. CrossRef - Standard Reference Thermoelectric Modules Based on Metallic Combinations and Geometric Design

EunA Koo, Hanhwi Jang, SuDong Park, Sang Hyun Park, Sae-byul Kang

Applied Sciences.2025; 15(18): 10273. CrossRef

- Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

- [English]

- Investigation of the Thermal-to-Electrical Properties of Transition Metal-Sb Alloys Synthesized for Thermoelectric Applications

- Jong Min Park, Seungki Jo, Sooho Jung, Jinhee Bae, Linh Ba Vu, Kwi-Il Park, Kyung Tae Kim

- J Powder Mater. 2024;31(3):236-242. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00031

- 1,512 View

- 43 Download

- 2 Citations

-

Abstract

Abstract

PDF

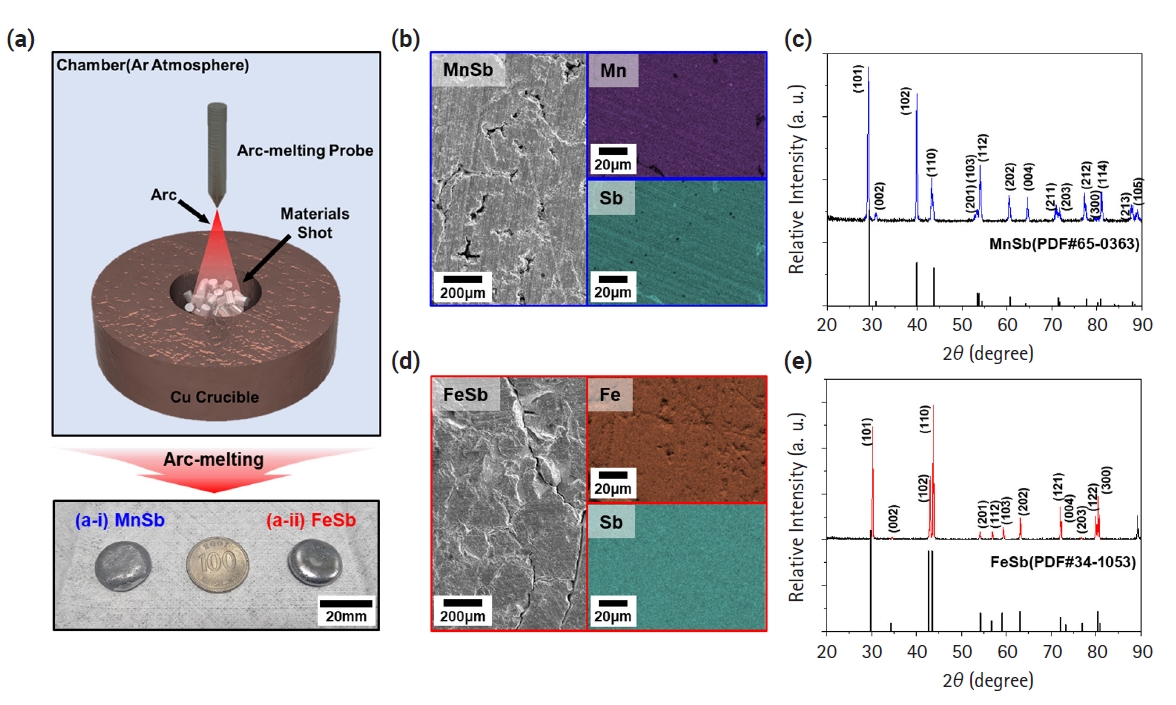

PDF - The development of thermoelectric (TE) materials to replace Bi2Te3 alloys is emerging as a hot issue with the potential for wider practical applications. In particular, layered Zintl-phase materials, which can appropriately control carrier and phonon transport behaviors, are being considered as promising candidates. However, limited data have been reported on the thermoelectric properties of metal-Sb materials that can be transformed into layered materials through the insertion of cations. In this study, we synthesized FeSb and MnSb, which are used as base materials for advanced thermoelectric materials. They were confirmed as single-phase materials by analyzing X-ray diffraction patterns. Based on electrical conductivity, the Seebeck coefficient, and thermal conductivity of both materials characterized as a function of temperature, the zT values of MnSb and FeSb were calculated to be 0.00119 and 0.00026, respectively. These properties provide a fundamental data for developing layered Zintl-phase materials with alkali/alkaline earth metal insertions.

-

Citations

Citations to this article as recorded by- Improving thermoelectric properties of CuMnSb alloys via strategic alloying with magnetic MnSb and Cu

Jong Min Park, Seungki Jo, Soo-ho Jung, Jinhee Bae, Linh Ba Vu, Jihun Yu, Kyung Tae Kim

Materials Letters.2025; 381: 137796. CrossRef - Highly deformable and hierarchical 3D composite sponge for versatile thermoelectric energy conversion

Jong Min Park, Changyeon Baek, Min-Ku Lee, Nagamalleswara Rao Alluri, Gyoung-Ja Lee, Kyung Tae Kim, Kwi-Il Park

Applied Surface Science.2025; 692: 162730. CrossRef

- Improving thermoelectric properties of CuMnSb alloys via strategic alloying with magnetic MnSb and Cu

- [English]

- Enhancing Electrical Properties of N-type Bismuth Telluride Alloys through Graphene Oxide Incorporation in Extrusion 3D Printing

- Jinhee Bae, Seungki Jo, Kyung Tae Kim

- J Powder Mater. 2023;30(4):318-323. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.318

- 1,523 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The thermoelectric effect, which converts waste heat into electricity, holds promise as a renewable energy technology. Recently, bismuth telluride (Bi2Te3)-based alloys are being recognized as important materials for practical applications in the temperature range from room temperature to 500 K. However, conventional sintering processes impose limitations on shape-changeable and tailorable Bi2Te3 materials. To overcome these issues, three-dimensional (3D) printing (additive manufacturing) is being adopted. Although some research results have been reported, relatively few studies on 3D printed thermoelectric materials are being carried out. In this study, we utilize extrusion 3D printing to manufacture n-type Bi1.7Sb0.3Te3 (N-BST). The ink is produced without using organic binders, which could negatively influence its thermoelectric properties. Furthermore, we introduce graphene oxide (GO) at the crystal interface to enhance the electrical properties. The formed N-BST composites exhibit significantly improved electrical conductivity and a higher Seebeck coefficient as the GO content increases. Therefore, we propose that the combination of the extrusion 3D printing process (Direct Ink Writing, DIW) and the incorporation of GO into N-BST offers a convenient and effective approach for achieving higher thermoelectric efficiency.

-

Citations

Citations to this article as recorded by- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

journal of Korean Powder Metallurgy Institute.2024; 31(2): 119. CrossRef

- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

- [Korean]

- Enhancement of Thermoelectric Performance in Spark Plasma Sintered p-Type Bi0.5Sb1.5Te3.0 Compound via Hot Isostatic Pressing (HIP) Induced Reduction of Lattice Thermal Conductivity

- Soo-Ho Jung, Ye Jin Woo, Kyung Tae Kim, Seungki Jo

- J Powder Mater. 2023;30(2):123-129. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.123

- 1,461 View

- 8 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF High-temperature and high-pressure post-processing applied to sintered thermoelectric materials can create nanoscale defects, thereby enhancing their thermoelectric performance. Here, we investigate the effect of hot isostatic pressing (HIP) as a post-processing treatment on the thermoelectric properties of

p -type Bi0.5Sb1.5Te3.0 compounds sintered via spark plasma sintering. The sample post-processed via HIP maintains its electronic transport properties despite the reduced microstructural texturing. Moreover, lattice thermal conductivity is significantly reduced owing to activated phonon scattering, which can be attributed to the nanoscale defects created during HIP, resulting in an ~18% increase in peakzT value, which reaches ~1.43 at 100°C. This study validates that HIP enhances the thermoelectric performance by controlling the thermal transport without having any detrimental effects on the electronic transport properties of thermoelectric materials.-

Citations

Citations to this article as recorded by- Enhanced Electrical Properties of 3D Printed Bi2Te3-Based Thermoelectric Materials via Hot Isostatic Pressing

Seungki Jo

Ceramist.2025; 28(1): 126. CrossRef - Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

journal of Korean Powder Metallurgy Institute.2024; 31(2): 119. CrossRef - Investigation of the Thermal-to-Electrical Properties of Transition Metal-Sb Alloys Synthesized for Thermoelectric Applications

Jong Min Park, Seungki Jo, Sooho Jung, Jinhee Bae, Linh Ba Vu, Kwi-Il Park, Kyung Tae Kim

journal of Korean Powder Metallurgy Institute.2024; 31(3): 236. CrossRef - Enhancing Electrical Properties of N-type Bismuth Telluride Alloys through Graphene Oxide Incorporation in Extrusion 3D Printing

Jinhee Bae, Seungki Jo, Kyung Tae Kim

journal of Korean Powder Metallurgy Institute.2023; 30(4): 318. CrossRef

- Enhanced Electrical Properties of 3D Printed Bi2Te3-Based Thermoelectric Materials via Hot Isostatic Pressing

- [Korean]

- Recent Studies on Performance Enhancement of Polycrystal SnSe Thermoelectric Materials

- Myeong Jun Jung, Byung Joon Choi

- J Powder Mater. 2022;29(2):152-158. Published online April 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.2.152

- 1,018 View

- 7 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Thermoelectric materials can reversely convert heat and electricity into each other; therefore, they can be very useful for energy harvesting from heat waste. Among many thermoelectrical materials, SnSe exhibits outstanding thermoelectric performance along the particular direction of a single crystal. However, single-crystal SnSe has poor mechanical properties and thus it is difficult to apply for mass production. Therefore, polycrystalline SnSe materials may be used to replace single-crystal SnSe by overcoming its inferior thermoelectric performance owing to surface oxidation. Considerable efforts are currently focused on enhancing the thermoelectric performance of polycrystalline SnSe. In this study, we briefly review various enhancement methods for SnSe thermoelectric materials, including doping, texturing, and nano-structuring. Finally, we discuss the future prospects of SnSe thermoelectric powder materials.

-

Citations

Citations to this article as recorded by- The Mechanism Behind the High zT of SnSe2 Added SnSe at High Temperatures

JunSu Kim, Seong-Mee Hwang, Hyunjin Park, Yinglu Tang, Won-Seon Seo, Chae Woo Ryu, Heesun Yang, Weon Ho Shin, Hyun-Sik Kim

Korean Journal of Metals and Materials.2023; 61(11): 857. CrossRef

- The Mechanism Behind the High zT of SnSe2 Added SnSe at High Temperatures

- [Korean]

- Recent progress on Performance Improvements of Thermoelectric Materials using Atomic Layer Deposition

- Seunghyeok Lee, Tae Joo Park, Seong Keun Kim

- J Powder Mater. 2022;29(1):56-62. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.56

- 1,400 View

- 29 Download

-

Abstract

Abstract

PDF

PDF Atomic layer deposition (ALD) is a promising technology for the uniform deposition of thin films. ALD is based on a self-limiting mechanism, which can effectively deposit thin films on the surfaces of powders of various sizes. Numerous studies are underway to improve the performance of thermoelectric materials by forming core-shell structures in which various materials are deposited on the powder surface using ALD. Thermoelectric materials are especially relevant as clean energy storage materials due to their ability to interconvert between thermal and electrical energy by the Seebeck and Peltier effects. Herein, we introduce a surface and interface modification strategy based on ALD to control the performance of thermoelectric materials. We also discuss the properties of the interface between various deposition materials and thermoelectric materials.

- [Korean]

- Rotation Speed Dependence of ZnO Coating Layer on SnSe powders by Rotary Atomic Layer Deposition Reactor

- Myeong Jun Jung, Ye Jun Yun, Jongmin Byun, Byung Joon Choi

- J Korean Powder Metall Inst. 2021;28(3):239-245. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.239

- 544 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The SnSe single crystal shows an outstanding figure of merit (

ZT ) of 2.6 at 973 K; thus, it is considered to be a promising thermoelectric material. However, the mass production of SnSe single crystals is difficult, and their mechanical properties are poor. Alternatively, we can use polycrystalline SnSe powder, which has better mechanical properties. In this study, surface modification by atomic layer deposition (ALD) is chosen to increase theZT value of SnSe polycrystalline powder. SnSe powder is ground by a ball mill. An ALD coating process using a rotary-type reactor is adopted. ZnO thin films are grown by 100 ALD cycles using diethylzinc and H2O as precursors at 100°C. ALD is performed at rotation speeds of 30, 40, 50, and 60 rpm to examine the effects of rotation speed on the thin film characteristics. The physical and chemical properties of ALD-coated SnSe powders are characterized by scanning and tunneling electron microscopy combined with energy-dispersive spectroscopy. The results reveal that a smooth oxygenrich ZnO layer is grown on SnSe at a rotation speed of 30 rpm. This result can be applied for the uniform coating of a ZnO layer on various powder materials.-

Citations

Citations to this article as recorded by- Thermal Confinement and Filtering Effect of SnSe by Insertion of Atomic-Layer-Deposited ZnO Interfacial Layer

Myeong Jun Jung, Su Min Eun, Hogyoung Kim, Seong Keun Kim, Jongmin Byun, Byung Joon Choi

Korean Journal of Chemical Engineering.2025; 42(14): 3545. CrossRef

- Thermal Confinement and Filtering Effect of SnSe by Insertion of Atomic-Layer-Deposited ZnO Interfacial Layer

- [English]

- Optimization of Spark Plasma Sintering Temperature Conditions for Enhancement of Thermoelectric Performance in Gas-Atomized Bi0.5Sb1.5Te3 Compound

- Kwang-yong Jeong, Chul Hee Lee, Peyala Dharmaiah, Soon-Jik Hong

- J Korean Powder Metall Inst. 2017;24(2):108-114. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.108

- 1,106 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF We fabricate fine (<20 μm) powders of Bi0.5Sb1.5Te3 alloys using a large-scale production method and subsequently consolidate them at temperatures of 573, 623, and 673 K using a spark plasma sintering process. The microstructure, mechanical properties, and thermoelectric properties are investigated for each sintering temperature. The microstructural features of both the powders and bulks are characterized by scanning electron microscopy, and the crystal structures are analyzed by X-ray diffraction analysis. The grain size increases with increasing sintering temperature from 573 to 673 K. In addition, the mechanical properties increase significantly with decreasing sintering temperature owing to an increase in grain boundaries. The results indicate that the electrical conductivity and Seebeck coefficient (217 μV/K) of the sample sintered at 673 K increase simultaneously owing to decreased carrier concentration and increased mobility. As a result, a high

ZT value of 0.92 at 300 K is achieved. According to the results, a sintering temperature of 673 K is preferable for consolidation of fine (<20 μm) powders.-

Citations

Citations to this article as recorded by- Complex microstructure induced high thermoelectric performances of p-type Bi–Sb–Te alloys

Eun-Ha Go, Babu Madavali, Min-Woo Shin, Sung Ho Song, Soon-Jik Hong

Materials Chemistry and Physics.2023; 307: 128156. CrossRef - Role of sintering temperature on electronic and mechanical properties of thermoelectric material: A theoretical and experimental study of TiCoSb half-Heusler alloy

Ajay Kumar Verma, Kishor Kumar Johari, Kriti Tyagi, Durgesh Kumar Sharma, Pawan Kumar, Sudhir Kumar, Sivaiah Bathula, S.R. Dhakate, Bhasker Gahtori

Materials Chemistry and Physics.2022; 281: 125854. CrossRef - Enhanced thermoelectric properties of Li and Mg co−substituted Bi2Sr2Co2O fabricated by combined conventional sintering and spark plasma sintering

K. Park, H.Y. Hong, S.Y. Gwon

Inorganic Chemistry Communications.2022; 145: 110005. CrossRef

- Complex microstructure induced high thermoelectric performances of p-type Bi–Sb–Te alloys

- [Korean]

- Thermoelectric Properties in the Cu Doping Effects of the n-type Bi-Te Powders

- Min Soo Park, Hye Young Koo, Gook Hyun Ha, Yong Ho Park

- J Korean Powder Metall Inst. 2015;22(4):254-259. Published online August 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.4.254

- 733 View

- 5 Download

-

Abstract

Abstract

PDF

PDF Bi2Te3 related compounds show the best thermoelectric properties at room temperature. However, n-type Bi2Te2.7Se0.3 showed no improvement on ZT values. To improve the thermolectric propterties of n-type Bi2Te2.7Se0.3, this research has Cu-doped n-type powder. This study focused on effects of Cu-doping method on the thermoelectric properties of n-type materials, and evaluated the comparison between the Cu chemical and mechanical doping. The synthesized powder was manufactured by the spark plasma sintering(SPS). The thermoelectric properties of the sintered body were evaluated by measuring their Seebeck coefficient, electrical resistivity, thermal conductivity, and hall coefficient. An introduction of a small amount of Cu reduced the thermal conductivity and improved the electrical properties with Seebeck coefficient. The authors provided the optimal concentration of Cu0.1Bi1.99Se0.3Te2.7. A figure of merit (ZT) value of 1.22 was obtained for Cu0.1Bi1.9Se0.3Te2.7 at 373K by Cu chemical doping, which was obviously higher than those of Cu0.1Bi1.9Se0.3Te2.7 at 373K by Cu mechanical doping (ZT=0.56) and Cu-free Bi2Se0.3Te2.7 (ZT=0.51).

TOP

KPMI

KPMI

First

First Prev

Prev