Search

- Page Path

- HOME > Search

- [English]

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,526 View

- 118 Download

- 4 Citations

-

Abstract

Abstract

PDF

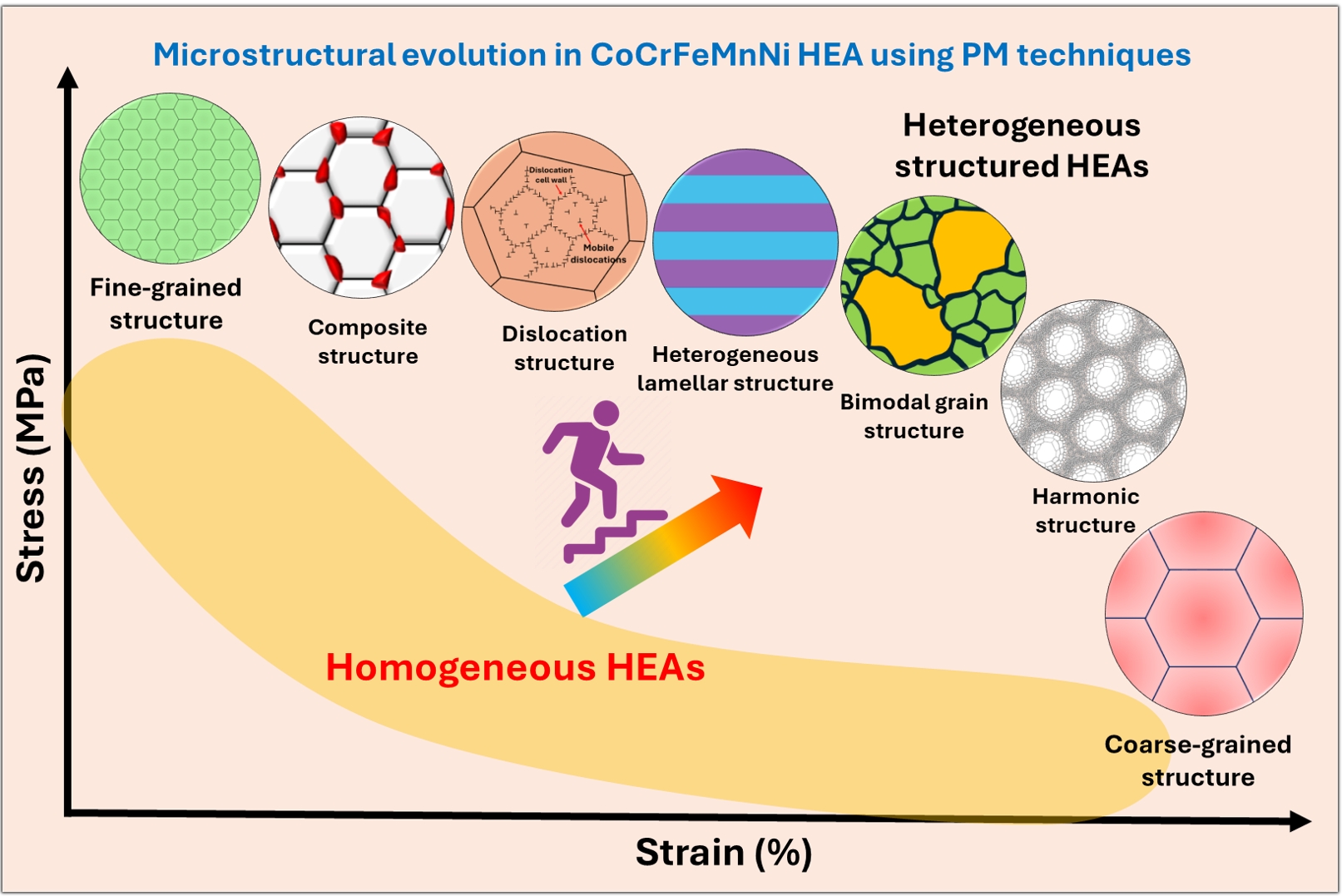

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

- The Use of TiH2 to Refine Y2Ti2O7 in a Nano Mo-ODS Alloy

- Yuncheol Ha, Chun Woong Park, Won Hee Lee, Jongmin Byun, Young Do Kim

- J Powder Mater. 2024;31(5):399-405. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00178

- 835 View

- 26 Download

-

Abstract

Abstract

PDF

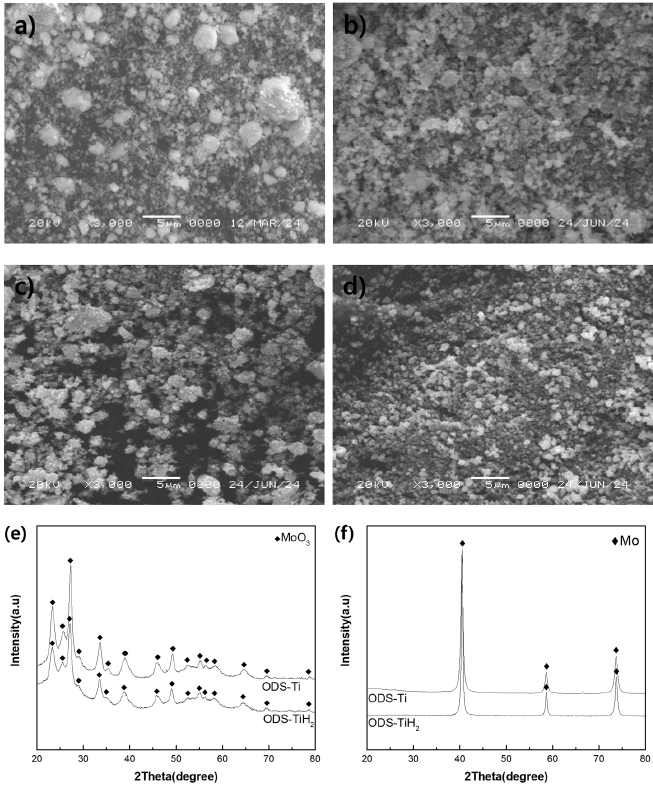

PDF - Mo-ODS alloys have excellent mechanical properties, including an improved recrystallization temperature, greater strength due to dispersed oxides, and the ability to suppress grain growth at high temperatures. In ODS alloys, the dispersed Y2O3 and added Ti form Y-Ti-O complex oxides, producing finer particles than those in the initial Y2O3. The complex oxides increase high-temperature stability and improve the mechanical properties of the alloy. In particular, the use of TiH2 powder, which is more brittle than conventional Ti, can enable the distribution of finer oxides than is possible with conventional Ti powder during milling. Moreover, dehydrogenation leads to a more refined powder size in the reduction process. This study investigated the refinement of Y2Ti2O7 in a nano Mo-ODS alloy using TiH2. The alloy compositions were determined to be Mo-0.5Ti-0.5Y2O3 and Mo-1.0Ti-0.5Y2O3. The nano Mo-ODS alloys were fabricated using Ti and TiH2 to explore the effects of adding different forms of Ti. The sintered specimens were analyzed through X-ray diffraction for phase analysis, and the microstructure of the alloys was analyzed using scanning electron microscopy and transmission electron microscopy. Vickers hardness tests were conducted to determine the effect of the form of Ti added on the mechanical properties, and it was found that using TiH2 effectively improved the mechanical properties.

- [Korean]

- Development of High-strength, High-temperature Nb-Si-Ti Alloys through Mechanical Alloying

- Jung-Joon Kim, Sang-Min Yoon, Deok-Hyun Han, Jongmin Byun, Young-Kyun Kim

- J Powder Mater. 2024;31(1):30-36. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.30

- 2,102 View

- 51 Download

- 1 Citations

-

PDF

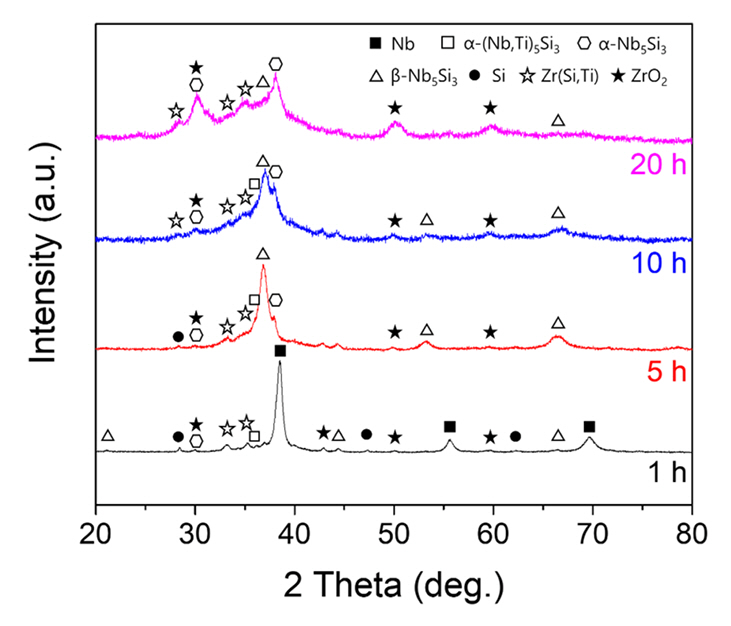

PDF -

Citations

Citations to this article as recorded by- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef

- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

- [Korean]

- Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

- Minsu Kim, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2023;30(6):478-483. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.478

- 1,224 View

- 15 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF High-entropy alloys (HEAs) are characterized by having five or more main elements and forming simple solids without forming intermetallic compounds, owing to the high entropy effect. HEAs with these characteristics are being researched as structural materials for extreme environments. Conventional refractory alloys have excellent hightemperature strength and stability; however, problems occur when they are used extensively in a high-temperature environment, leading to reduced fatigue properties due to oxidation or a limited service life. In contrast, refractory entropy alloys, which provide refractory properties to entropy alloys, can address these issues and improve the hightemperature stability of the alloy through phase control when designed based on existing refractory alloy elements. Refractory high-entropy alloys require sufficient milling time while in the process of mechanical alloying because of the brittleness of the added elements. Consequently, the high-energy milling process must be optimized because of the possibility of contamination of the alloyed powder during prolonged milling. In this study, we investigated the hightemperature oxidation behavior of refractory high-entropy alloys while optimizing the milling time.

-

Citations

Citations to this article as recorded by- Tailored high-temperature oxidation behavior and nanomechanical properties of Al0.75VCrZrNb lightweight refractory high-entropy alloys

Hansung Lee, Hwi Geun Yu, Reliance Jain, Man Mohan, Younggeon Lee, Sheetal Kumar Dewangan, Byungmin Ahn

International Journal of Refractory Metals and Hard Materials.2026; 135: 107507. CrossRef - Simultaneous enhancement of strength and ductility of Al matrix composites enabled by submicron-sized high-entropy alloy phases

Chahee Jung, Seungin Nam, Hansol Son, Juyeon Han, Jaewon Jeong, Hyokyung Sung, Hyoung Seop Kim, Seok Su Sohn, Hyunjoo Choi

Journal of Materials Research and Technology.2024; 33: 1470. CrossRef

- Tailored high-temperature oxidation behavior and nanomechanical properties of Al0.75VCrZrNb lightweight refractory high-entropy alloys

- [Korean]

- Evolution on Microstructures and Tensile Properties of 10Cr-1Mo ODS Steel with Different Lengths of Mechanical Alloying Process Times

- Sanghoon Noh, Tae Kyu Kim

- J Korean Powder Metall Inst. 2021;28(5):375-380. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.375

- 922 View

- 6 Download

-

Abstract

Abstract

PDF

PDF In this study, we investigate the effect of the duration of mechanical alloying on the microstructures and mechanical properties of ODS ferritic/martensitic steel. The Fe(bal.)-10Cr-1Mo pre-alloyed powder and Y2O3 powder are mechanically alloyed for the different mechanical alloying duration (0 to 40 h) and then constantly fabricated using a uniaxial hot pressing process. Upon increasing the mechanical alloying time, the average powder diameter and crystallite size increased dramatically. In the initial stages within 5 h of mechanical alloying, inhomogeneous grain morphology is observed along with coarsened carbide and oxide distributions; thus, precipitate phases are temporarily observed between the two powders because of insufficient collision energy to get fragmented. After 40 h of the MA process, however, fine martensitic grains and uniformly distributed oxide particles are observed. This led to a favorable tensile strength and elongation at room temperature and 650°C.

- [English]

- Effects of Precipitates and Oxide Dispersion on the High-temperature Mechanical Properties of ODS Ni-Based Superalloys

- GooWon Noh, Young Do Kim, Kee-Ahn Lee, Hwi-Jun Kim

- J Korean Powder Metall Inst. 2020;27(1):8-13. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.8

- 1,855 View

- 36 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, we investigated the effects of precipitates and oxide dispersoids on the high-temperature mechanical properties of oxide dispersion-strengthened (ODS) Ni-based super alloys. Two ODS Ni-based super alloy rods with different chemical compositions were fabricated by high-energy milling and hot extrusion process at 1150 °C to investigate the effects of precipitates on high-temperature mechanical properties. Further, the MA6000N alloy is an improvement over the commercial MA6000 alloy, and the KS6000 alloy has the same chemical composition as the MA6000 alloy. The phase and microstructure of Ni-based super alloys were investigated by X-ray diffraction and scanning electron microscopy. It was found that MC carbide precipitates and oxide dispersoids in the ODS Ni-based super alloys developed in this study may effectively improve high-temperature hardness and creep resistance.

-

Citations

Citations to this article as recorded by- Mechanical Properties and Residual Stress Analysis of ODS Ni Superalloy Fabricated by Laser Powder Bed Fusion Process

Dong Wan Lee, Su Gwan Lee, Cong Dhin Van, Cae Ryeong Kim, Jin Chun Kim, Hwi Jun Kim, Joong Gyeong Lim, Tae Sik Yoon

Journal of the Japan Society of Powder and Powder Metallurgy.2025; 72(Supplement): S453. CrossRef - Additive manufacturing of oxide-dispersion strengthened alloys: Materials, synthesis and manufacturing

Markus B. Wilms, Silja-Katharina Rittinghaus, Mareen Goßling, Bilal Gökce

Progress in Materials Science.2023; 133: 101049. CrossRef

- Mechanical Properties and Residual Stress Analysis of ODS Ni Superalloy Fabricated by Laser Powder Bed Fusion Process

- [Korean]

- Effect of Milling Time on the Microstructure and Mechanical Properties of Ta20Nb20V20W20Ti20 High Entropy Alloy

- Da Hye Song, Yeong Gyeom Kim, Jin Kyu Lee

- J Korean Powder Metall Inst. 2020;27(1):52-57. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.52

- 893 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, we report the microstructure and characterization of Ta20Nb20V20W20Ti20 high-entropy alloy powders and sintered samples. The effects of milling time on the microstructure and mechanical properties were investigated in detail. Microstructure and structural characterization were performed by scanning electron microscopy and X-ray diffraction. The mechanical properties of the sintered samples were analyzed through a compressive test at room temperature with a strain rate of 1 × 10−4 s−1. The microstructure of sintered Ta20Nb20V20W20Ti20 high-entropy alloy is composed of a BCC phase and a TiO phase. A better combination of compressive strength and strain was achieved by using prealloyed Ta20Nb20V20W20Ti20 powder with low oxygen content. The results suggest that the oxide formed during the sintering process affects the mechanical properties of Ta20Nb20V20W20Ti20 high-entropy alloys, which are related to the interfacial stability between the BCC matrix and TiO phase.

-

Citations

Citations to this article as recorded by- Mechanisms of high-entropy carbide formation (TiVTaNbW)C via high-energy milling: structural, chemical, and spectroscopic analysis

Anderson C. Marques, Thalita Q. Silva, Pâmala S. Vieira, Celmo Hudson Reis Paula, Maria J.S. Lima, Rubens M. Nascimento, Marcello Filgueira, Uílame U. Gomes, Meysam Mashhadikarimi

Materials Science and Engineering: B.2026; 323: 118787. CrossRef

- Mechanisms of high-entropy carbide formation (TiVTaNbW)C via high-energy milling: structural, chemical, and spectroscopic analysis

- [English]

- Fabrication of FeCuNi alloy by mechanical alloying followed by consolidation using high-pressure torsion

- Peyman Asghari-Rad, Yongju Kim, Nhung Thi-Cam Nguyen, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2020;27(1):1-7. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.1

- 1,501 View

- 9 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this research, a new medium-entropy alloy with an equiatomic composition of FeCuNi was designed using a phase diagram (CALPHAD) technique. The FeCuNi MEA was produced from pure iron, copper, and nickel powders through mechanical alloying. The alloy powders were consolidated via a high-pressure torsion process to obtain a rigid bulk specimen. Subsequently, annealing treatment at different conditions was conducted on the four turn HPT-processed specimen. The microstructural analysis indicates that an ultrafine-grained microstructure is achieved after post-HPT annealing, and microstructural evolutions at various stages of processing were consistent with the thermodynamic calculations. The results indicate that the post-HPT-annealed microstructure consists of a dual-phase structure with two FCC phases: one rich in Cu and the other rich in Fe and Ni. The kernel average misorientation value decreases with the increase in the annealing time and temperature, indicating the recovery of HPT-induced dislocations.

-

Citations

Citations to this article as recorded by- High-pressure torsion of face-centered cubic multi-principal element alloys: Nanostructuring and its influence on properties

Avanish Kumar Chandan, Kaushal Kishore, Megumi Kawasaki, Terence G. Langdon, Jenő Gubicza

Progress in Materials Science.2026; 158: 101620. CrossRef - Effects of nickel content and annealing temperature on the magnetic characteristics of nanostructured FeCu alloys

Abderrahmane Younes

Journal of Materials Science: Materials in Electronics.2024;[Epub] CrossRef

- High-pressure torsion of face-centered cubic multi-principal element alloys: Nanostructuring and its influence on properties

- [Korean]

- Prediction the Phase Transformation Time of Binary Alloy System by calculating the Input Energy of Mechanical Alloying

- Dong-Kyu Park, In-Shup Ahn

- J Korean Powder Metall Inst. 2019;26(2):107-111. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.107

- 613 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The activation energy to create a phase transformation or for the reaction to move to the next stage in the milling process can be calculated from the slop of the DSC plot, obtained at the various heating rates for mechanically activated Al-Ni alloy systems by using Kissinger’s equation. The mechanically activated material has been called “the driven material” as it creates new phases or intermetallic compounds of AlNi in Al-Ni alloy systems. The reaction time for phase transformation by milling can be calculated using the activation energy obtained from the above mentioned method and from the real required energy. The real required energy (activation energy) could be calculated by subtracting the loss energy from the total input energy (calculated input energy from electric motor). The loss energy and real required energy divided by the reaction time are considered the “metabolic energy” and “the effective input energy”, respectively. The milling time for phase transformation at other Al-Co alloy systems from the calculated data of Al-Ni systems can be predicted accordingly.

- [Korean]

- Analysis on Milling Behavior of Oxide Dispersion Strengthened Ni-based Atomizing Powder with Ni5Y Intermetallic Phase

- Chun Woong Park, Jong Min Byun, Won June Choi, Young Do Kim

- J Korean Powder Metall Inst. 2019;26(2):101-106. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.101

- 990 View

- 3 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Ni-based oxide dispersion strengthened (ODS) alloys have a higher usable temperature and better hightemperature mechanical properties than conventional superalloys. They are therefore being explored for applications in various fields such as those of aerospace and gas turbines. In general, ODS alloys are manufactured from alloy powders by mechanical alloying of element powders. However, our research team produces alloy powders in which the Ni5Y intermetallic phase is formed by an atomizing process. In this study, mechanical alloying was performed using a planetary mill to analyze the milling behavior of Ni-based oxide dispersions strengthened alloy powder in which the Ni5Y is the intermetallic phase. As the milling time increased, the Ni5Y intermetallic phase was refined. These results are confirmed by SEM and EPMA analysis on microstructure. In addition, it is confirmed that as the milling increased, the mechanical properties of Ni-based ODS alloy powder improve due to grain refinement by plastic deformation.

-

Citations

Citations to this article as recorded by- Efficient prediction of corrosion behavior in ternary Ni-based alloy systems: Theoretical calculations and experimental verification

Xuelian Xiao, Keke Chang, Kai Xu, Ming Lou, Liping Wang, Qunji Xue

Journal of Materials Science & Technology.2023; 167: 94. CrossRef - Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

Chun Woong Park, Won June Choi, Jongmin Byun, Young Do Kim

Journal of Materials Science.2022; 57(38): 18195. CrossRef

- Efficient prediction of corrosion behavior in ternary Ni-based alloy systems: Theoretical calculations and experimental verification

- [Korean]

- Microstructure and Mechanical Properties of Oxide Dispersion Strengthened alloy Based on Commercially Pure Titanium

- Taesung Park, Jeoung Han Kim

- J Korean Powder Metall Inst. 2018;25(4):327-330. Published online August 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.4.327

- 992 View

- 9 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF This study is conducted as a preliminary research to verify the feasibility of Ti-based Oxide dispersion strengthened (ODS) alloy. Pure-Ti powder is mixed with Y2O3 powder and subsequently, mechanically alloyed at -150°C. The Ti-based ODS powder is hot-isostatically pressed and subsequently hot-rolled for recrystallization. The microstructure consists of elongated grains and Y excess fine particles. The oxide particle size is larger than that of the typical Febased ODS steel. Tensile test shows that the tensile ductility is approximately 25%, while the strength is significantly higher than that of pure Ti. The high-temperature hardness of the Ti-ODS alloy is also significantly higher than that of pure Ti at all temperatures, while being lower than that of Ti-6Al-4V. The dimple structure is well developed, and no evidence of cleavage fracture surface is observed in the fracture surface of the tensile specimen.

-

Citations

Citations to this article as recorded by- Additive manufacturing of Ti-6Al-4V based oxide dispersion strengthened alloy using in-situ oxide-dispersed powders and bound metal deposition

Woo Hyeok Kim, Raj Narayan Hajra, Hyung-Ki Park, Jung-Yeul Yun, Jeoung Han Kim

Journal of Alloys and Compounds.2026; 1050: 185574. CrossRef - Experimental and Numerical Evaluation of Rockwell Hardness at High Temperatures

NamSeok Lee

Journal of the Korean Society of Manufacturing Technology Engineers.2025; 34(3): 165. CrossRef - Spheroidization of Pure-vanadium Powder using Radio Frequency Thermal Plasma Process

Nana Kwabena Adomako, Seungmin Yang, Min Gyu Lee, N. S. Reddy, Jeoung-Han Kim

Journal of Korean Powder Metallurgy Institute.2019; 26(4): 305. CrossRef - Microstructure and Mechanical Properties of Friction-Welded Alloy 718 and SNCRW Stainless Steel After Post-Weld Heat-Treatment

Jeoung Han Kim, Nam-Yong Kim, Yu Sik Kong, Nho Kwang Park

Journal of Welding and Joining.2019; 37(4): 313. CrossRef

- Additive manufacturing of Ti-6Al-4V based oxide dispersion strengthened alloy using in-situ oxide-dispersed powders and bound metal deposition

- [Korean]

- New Co10Fe10Mn35Ni35Zn10 high-entropy alloy Fabricated by Powder Metallurgy

- Dami Yim, Hyung Keun Park, Antonio Joao Seco Ferreira Tapia, Byeong-Joo Lee, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2018;25(3):208-212. Published online June 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.3.208

- 1,037 View

- 5 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this paper, a new Co10Fe10Mn35Ni35Zn10 high entropy alloy (HEA) is identified as a strong candidate for the single face-centered cubic (FCC) structure screened using the upgraded TCFE2000 thermodynamic CALPHAD database. The Co10Fe10Mn35Ni35Zn10 HEA is fabricated using the mechanical (MA) procedure and pressure-less sintering method. The Co10Fe10Mn35Ni35Zn10 HEA, which consists of elements with a large difference in melting point and atomic size, is successfully fabricated using powder metallurgy techniques. The MA behavior, microstructure, and mechanical properties of the Co10Fe10Mn35Ni35Zn10 HEA are systematically studied to understand the MA behavior and develop advanced techniques for fabricating HEA products. After MA, a single FCC phase is found. After sintering at 900°C, the microstructure has an FCC single phase with an average grain size of 18 μm. Finally, the Co10Fe10Mn35Ni35Zn10 HEA has a compressive yield strength of 302 MPa.

-

Citations

Citations to this article as recorded by- Composites of equiatomic Y, La, Ce, Nd, and Gd rare earth oxides: Chemical-shift effects and valence spectra

Jungsu Bin, Hyunbae Gee, Taesung Park, UiJun Go, Jeoung Han Kim, Youn-Seoung Lee

Current Applied Physics.2024; 59: 85. CrossRef - Fabrication, microstructure and mechanical property of a novel Nb-rich refractory high-entropy alloy strengthened by in-situ formation of dispersoids

Byungchul Kang, Taeyeong Kong, Ahmad Raza, Ho Jin Ryu, Soon Hyung Hong

International Journal of Refractory Metals and Hard Materials.2019; 81: 15. CrossRef

- Composites of equiatomic Y, La, Ce, Nd, and Gd rare earth oxides: Chemical-shift effects and valence spectra

- [English]

- A Study on Synthesis of Ni-Ti-B Alloy by Mechanical Alloying from Elemental Component Powder

- Jung Geun Kim, Yong Ho Park

- J Korean Powder Metall Inst. 2016;23(3):202-206. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.3.202

- 1,524 View

- 3 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF A Ni-Ti-B alloy powder prepared by mechanical alloying (MA) of individual Ni, Ti, and B components is examined with the aim of elucidating the phase transitions and crystallization during heat treatment. Ti and B atoms penetrating into the Ni lattice result in a Ni (Ti, B) solid solution and an amorphous phase. Differential thermal analysis (DTA) reveals peaks related to the decomposition of the metastable Ni (Ti, B) solid solution and the separation of equilibrium Ni3Ti, TiB2, and τ-Ni20Ti3B6 phases. The exothermal effects in the DTA curves move to lower temperatures with increasing milling time. The formation of a TiB2 phase by annealing indicates that the mechanochemical reaction of the Ni-Ti-B alloy does not comply with the alloy composition in the ternary phase diagram, and Ti-B bonds are found to be more preferable than Ni-B bonds.

-

Citations

Citations to this article as recorded by- Solid‐State Synthesis and Characterization of the Stable Nanostructured Ni21Ti2B6 Phase

Tuncay Simsek, Baris Avar, Sadan Ozcan, Arun K. Chattopadhyay, Bora Kalkan

physica status solidi (b).2021;[Epub] CrossRef - Synthesis and analysis of nanocrystalline β1-Cu3Al and β2-NiAl intermetallic-reinforced aluminum matrix composite by high energy ball milling

Hong-Hai Nguyen, Minh-Thuyet Nguyen, Won Joo Kim, Jin-Chun Kim

Metals and Materials International.2017; 23(1): 202. CrossRef

- Solid‐State Synthesis and Characterization of the Stable Nanostructured Ni21Ti2B6 Phase

- [English]

- Investigation of Ball Size Effect on Microstructure and Thermoelectric Properties of

p -type BiSbTe by Mechanical Alloying - May Likha Lwin, Sang-min Yoon, Babu Madavali, Chul-Hee Lee, Soon-Jik Hong

- J Korean Powder Metall Inst. 2016;23(2):120-125. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.120

- 1,467 View

- 5 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF P -type ternary Bi0.5Sb1.5Te3 alloys are fabricated via mechanical alloying (MA) and spark plasma sintering (SPS). Different ball sizes are used in the MA process, and their effect on the microstructure; hardness, and thermoelectric properties of thep -type BiSbTe alloys are investigated. The phases of milled powders and bulks are identified using an X-ray diffraction technique. The morphology of milled powders and fracture surface of compacted samples are examined using scanning electron microscopy. The morphology, phase, and grain structures of the samples are not altered by the use of different ball sizes in the MA process. Measurements of the thermoelectric (TE) transport properties including the electrical conductivity, Seebeck coefficient, and power factor are measured at temperatures of 300- 400 K for samples treated by SPS. The TE properties do not depend on the ball size used in the MA process.-

Citations

Citations to this article as recorded by- Investigation of Spark Plasma Sintering Temperature on Microstructure and Thermoelectric Properties of p-type Bi-Sb-Te alloys

Jin-Koo Han, Dong-won Shin, Babu Madavali, Soon-Jik Hong

Journal of Korean Powder Metallurgy Institute.2017; 24(2): 115. CrossRef - Flexible Thermoelectric Device Using Thick Films for Energy Harvesting from the Human Body

Han Ki Cho, Da Hye Kim, Hye Sun Sin, Churl-Hee Cho, Seungwoo Han

Journal of the Korean Ceramic Society.2017; 54(6): 518. CrossRef - Investigation of the Microstructure and Thermoelectric Properties of P-Type BiSbTe Alloys by Usage of Different Revolutions Per Minute (RPM) During Mechanical Milling

S.-M. Yoon, B. Madavali, Y.-N. Yoon, S.-J. Hong

Archives of Metallurgy and Materials.2017; 62(2): 1167. CrossRef - Mechanical and thermoelectric properties of Bi2−xSbxTe3 prepared by using encapsulated melting and hot pressing

Woo-Jin Jung, Il-Ho Kim

Journal of the Korean Physical Society.2016; 69(8): 1328. CrossRef

- Investigation of Spark Plasma Sintering Temperature on Microstructure and Thermoelectric Properties of p-type Bi-Sb-Te alloys

- [Korean]

- Powder Sintering Characteristics of Carbon Nanotubes Reinforced SKD11 Tool Steel Sintered by Spark Plasma Sintering

- Je-Se Moon, Sung-Sil Jung, Dae-Yeol Lee, Young-Keun Jeong, Myung Chang Kang, Chun-Dal Park, Kook-Tae Youn

- J Korean Powder Metall Inst. 2015;22(3):157-162. Published online June 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.3.157

- 903 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF SKD11 (ASTM D2) tool steel is a versatile high-carbon, high-chromium, air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous, large, chromium rich alloy carbide in the microstructure. SKD11 tool steel provides an effective combination of wear resistance and toughness, tool performance, price, and a wide variety of product forms. Adding of CNTs increased the performance of mechanical properties more. 1, 3 vol% CNTs was dispersed in SKD11 matrix by mechanical alloying. SKD11 carbon nanocomposite powder was sintered by spark plasma sintering process. FE-SEM, HR-TEM and Raman analysis were carried out for the SKD11 carbon nanocomposites.

-

Citations

Citations to this article as recorded by- Study on Effects of Mold Temperature on the Injection Molded Article

J.-H. Han, Y.-C. Kim

Archives of Metallurgy and Materials.2017; 62(2): 1271. CrossRef

- Study on Effects of Mold Temperature on the Injection Molded Article

- [Korean]

- A Precipitation Behavior of Nano-Oxide Particles in Mechanically Alloyed Fe-5Y2O3 Powders

- Ga Eon Kim, Sanghoon Noh, Ji Eun Choi, Young Do Kim, Tae Kyu Kim

- J Korean Powder Metall Inst. 2015;22(1):46-51. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.46

- 905 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF A precipitation behavior of nano-oxide particle in Fe-5Y2O3 alloy powders is studied. The mechanically alloyed Fe-5Y2O3 powders are pressed at 750°C for 1h, 850°C for 1h and 1150°C for 1h, respectively. The results of Xray diffraction pattern analysis indicate that the Y2O3 diffraction peak disappear after mechanically alloying process, but Y2O3 and YFe2O4 complex oxide precipitates peak are observed in the powders pressed at 1150°C. The differential scanning calorimetry study results reveal that the formation of precipitates occur at around 1054°C. Based on the transmission electron microscopy analysis result, the oxide particles with a composition of Y-Fe-O are found in the Fe-5Y2O3 alloy powders pressed at 1150°C. It is thus conclude that the mechanically alloyed Fe-5Y2O3 powders have no precipitates and the oxide particles in the powders are formed by a high temperature heat-treatment.

-

Citations

Citations to this article as recorded by- Mechanical properties of Mo-Si-B alloys fabricated by using core-shell powder with dispersion of yttria nanoparticles

Jong Min Byun, Su-Ryong Bang, Won June Choi, Min Sang Kim, Goo Won Noh, Young Do Kim

Metals and Materials International.2017; 23(1): 170. CrossRef

- Mechanical properties of Mo-Si-B alloys fabricated by using core-shell powder with dispersion of yttria nanoparticles

- [Korean]

- Mechanical Alloying of GaSe and GaTe Systems

- Jung Bo Choi, Jung-Ho Ahn

- J Korean Powder Metall Inst. 2014;21(5):338-342. Published online October 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.5.338

- 721 View

- 0 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In the present work, we investigated the mechanical alloying of binary Ga-Se(1:1) and Ga-Te(1;1) sysyems. The high-energy ball-milling was performed at 40°C where one of constituents (Ga) is molten state. The purpose of the work was to see whether reactions between constituent elements are accelerated by the presence of a liquid phase. During the ball-milling, the liquid Ga phase completely disappeared and the resulting powders consist of nanocrystalline grain of ~20 nm with partly amorphized phases. However, no intermetallic compounds formed in spite of the presence of the liquid phases which has much higher diffusivity than solid constituents. By subsequent heat-treatments, the inter-metallic compounds such as GaSe and GaTe formed at relatively low temperatures. The formation temperature of theses compound was much lower than those predicted by equilibrium phase diagram. The comparison of the ball-milled powders with un-milled ones indicated that the easy formation of intermetallic compound or allying occurs at low temperatures.

-

Citations

Citations to this article as recorded by- A Study on Synthesis of Ni-Ti-B Alloy by Mechanical Alloying from Elemental Component Powder

Jung Geun Kim, Yong Ho Park

Journal of Korean Powder Metallurgy Institute.2016; 23(3): 202. CrossRef

- A Study on Synthesis of Ni-Ti-B Alloy by Mechanical Alloying from Elemental Component Powder

TOP

KPMI

KPMI

First

First Prev

Prev