Current issue

- Page Path

- HOME > Browse Articles > Current issue

Research Articles

- [English]

- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

- Eunbi Park, Jongwon Bae, Sera Kang, Minsu Kang, Suseong Lee, Kun-Jae Lee

- J Powder Mater. 2025;32(5):375-382. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00248

- 743 View

- 11 Download

-

Abstract

Abstract

PDF

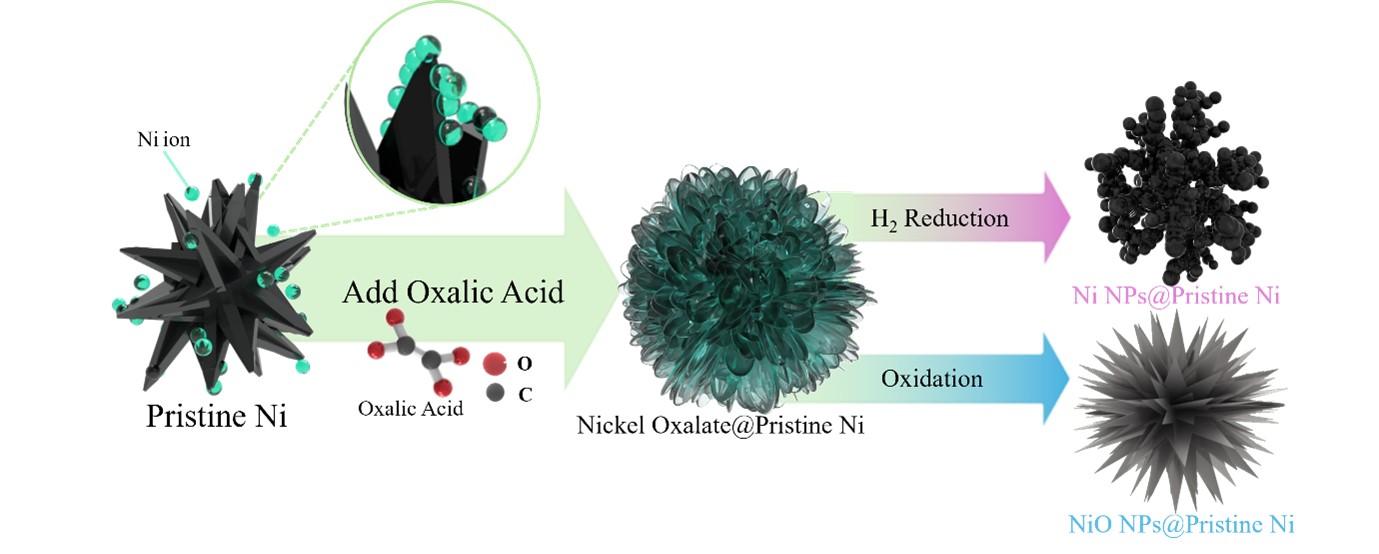

PDF - Nickel is widely used in industrial fields such as electrocatalysis and energy storage devices. Although micron-sized nickel particles exhibit excellent mechanical durability, their low specific surface area limits their reactivity. We modified the surface of micron-sized nickel particles with nanostructured nickel oxalate and investigated the effects of the solvent dielectric constant, surfactant, and thermal treatment atmosphere on the resulting particle morphology and phase transformation. Rietveld refinement analysis confirmed that changes in the solvent dielectric constant led to increased or diminished crystallinity of specific planes in nickel oxalate, resulting in diffraction patterns distinct from standard JCPDS data. These structural changes were also found to influence the morphology of the synthesized nickel oxalate. The results demonstrate that nickel oxalate serves as an effective precursor for producing Ni and NiO phases, and shape control of the final product can increase the surface reactivity of micron-sized nickel materials.

- [English]

- Preparation of Flake-shape Cobalt Powders by High-Energy Ball Milling for rSOC Current Collectors

- Poong-Yeon Kim, Min-Jeong Lee, Hyeon Ju Kim, Su-Jin Yun, Si Young Chang, Jung-Yeul Yun

- J Powder Mater. 2025;32(5):383-389. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00241

- 227 View

- 10 Download

-

Abstract

Abstract

PDF

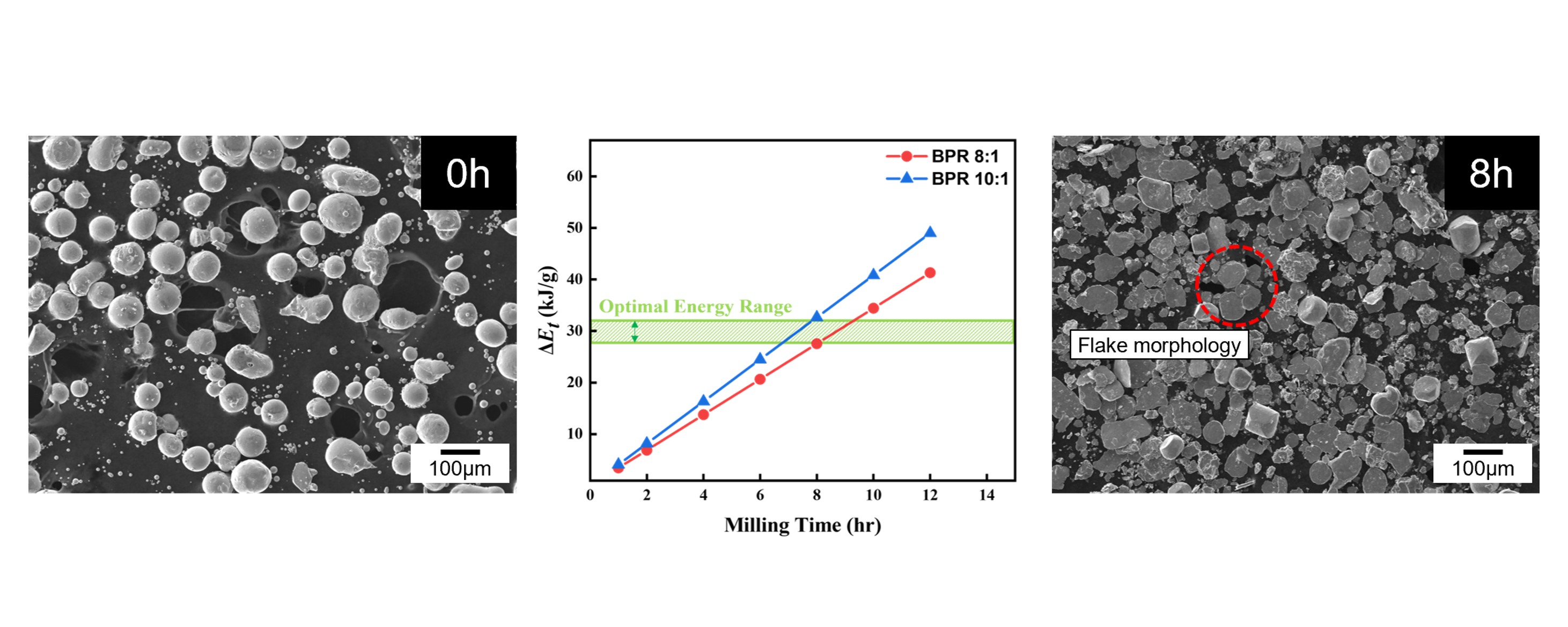

PDF - Reversible solid oxide cells (rSOCs), which enable two-way conversion between electricity and hydrogen, have gained attention with the rise of hydrogen energy. However, foam-type current collectors in rSOC stacks exhibit poor structural controllability and limited electrode contact area. To address these limitations, this study aimed to convert spherical cobalt powders into flake-type morphology via high-energy ball milling, as a preliminary step toward fabricating flake-based current collectors. Milling parameters—specifically, the ball-to-powder ratio (BPR), milling time, and process control agent (PCA) content—were varied. At an 8:1 BPR, over 90% of the powder became flake-shaped after 8 hours, while extended milling caused cold welding. In contrast, a 10:1 BPR resulted in dominant fragmentation. The Burgio–Rojac model quantified energy input and defined the optimal range for flake formation. Increasing the PCA to 4 wt% delayed flake formation to 16 hours and induced cold welding, as shown by bimodal particle size distributions. These results support the development of Co-based current collectors for use in rSOCs.

- [English]

- Enhancing the Dispersion Stability of Exfoliated MoS2 Nanoflakes for Na⁺ Intercalation

- Jae Min Sung, Dong-Won Kyung, Ammad Ali, Kee-Ryung Park, Mi Hye Lee, Da-Woon Jeong, Bum Sung Kim, Haejin Hwang, Leeseung Kang, Yoseb Song

- J Powder Mater. 2025;32(5):390-398. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00255

- 209 View

- 4 Download

-

Abstract

Abstract

PDF

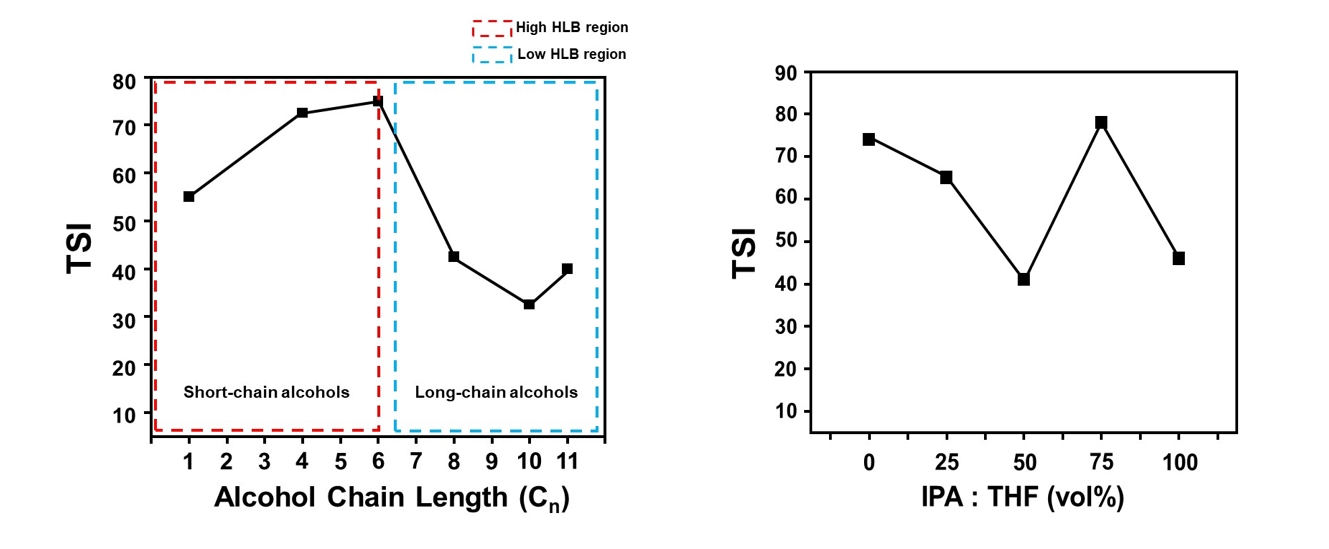

PDF - This study investigated the dispersion stability of exfoliated MoS₂ nanoflakes in various organic solvents and binary mixtures using a Turbiscan optical analyzer. Sedimentation behavior was quantitatively evaluated via transmittance variation (ΔT), backscattering variation (ΔBS), and the Turbiscan stability index (TSI). Alcohol-based solvents were categorized by hydrophilic-lipophilic balance values. Long-chain alcohols, such as 1-undecanol, showed increased stability due to high viscosity and strong hydrophobic affinity with MoS2 basal planes, while short-chain alcohols exhibited poor stabilization. Binary mixtures of isopropanol (IPA) and tetrahydrofuran (THF) were also assessed, with the 5:5 volume ratio showing the best stability profile, including the lowest TSI and minimal ΔT and ΔBS values. This improvement is attributed to synergistic interactions, as IPA stabilizes hydrophilic edge sites, while THF engages with hydrophobic basal surfaces. These findings highlight the importance of balancing physicochemical properties when selecting solvents to improve MoS2 dispersion for structural modification and electrocatalytic applications.

- [Korean]

- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

- Jiyeon Kim, HyunSeung Shim, Seong-Ju Hwang, YooJin Kim

- J Powder Mater. 2025;32(5):399-405. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00227

- 203 View

- 2 Download

-

Abstract

Abstract

PDF

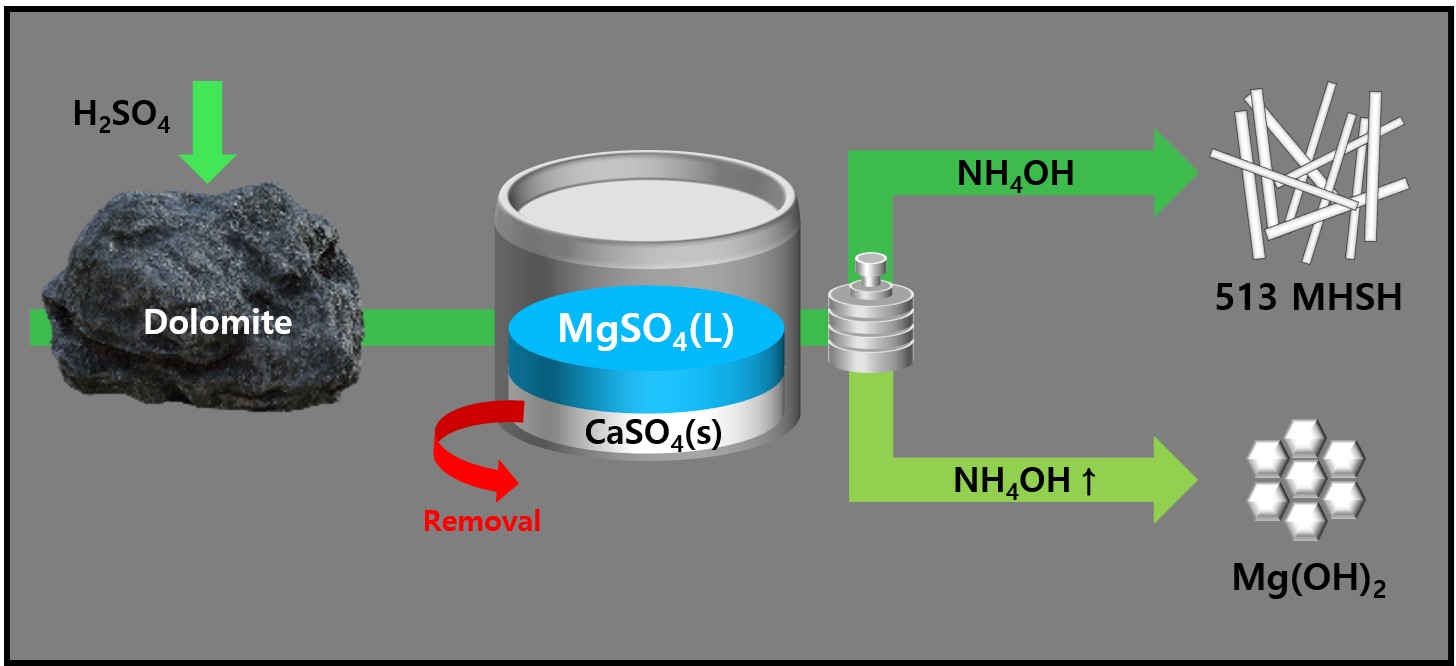

PDF - 513 magnesium hydroxide sulfate hydrate (MHSH) and Mg(OH)₂ were synthesized by controlling the pH and concentration using a domestic resource, dolomite (CaMg(CO3)2), as the raw material. The MgSO₄ was extracted by treating dolomite with sulfuric acid under various conditions. Hexagonal plate-shaped Mg(OH)₂ and needle-like 513 MHSH were synthesized under the hydrothermal condition. The morphology of the synthesized materials was controlled by adjusting the pH (SO42-/OH- ratio) and hydrothermal reaction time. As the pH of the solution increased, the formation of plate-like structures became dominant, whereas lower pH values (higher SO42- concentration) led to needle-like forms. The results of the 513 MHSH, which was synthesized using reagents and sea bittern, are consistent with the synthesis conditions, and we observed changes in the length and aspect ratio of the needle-shaped structure in response to adjusting the hydrothermal reaction time.

- [Korean]

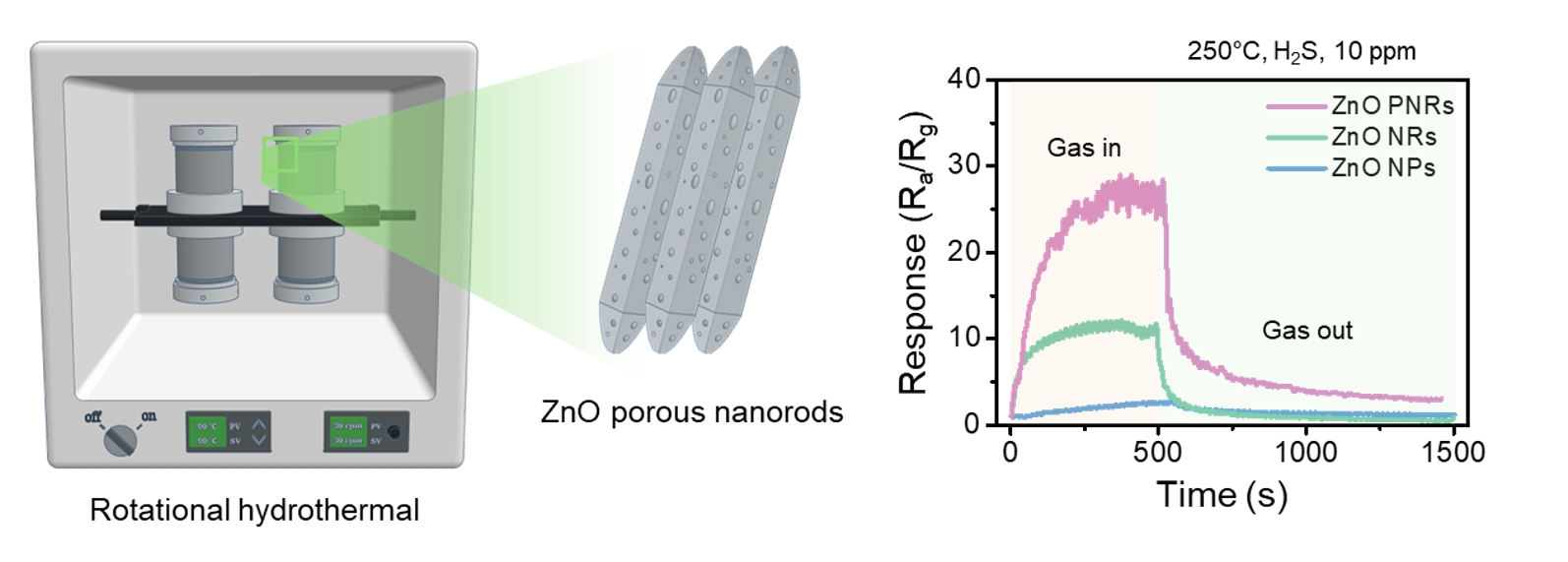

- Enhanced H2S Gas Sensing Using ZnO Porous Nanorod Synthesized via a Rotational Hydrothermal Method

- Jimyeong Park, Changyu Kim, Minseo Kim, Jiyeon Shin, Jae-Hyoung Lee, Myung Sik Choi

- J Powder Mater. 2025;32(5):406-415. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00262

- 201 View

- 5 Download

-

Abstract

Abstract

PDF

PDF - In this study, ZnO porous nanorods were synthesised using a rotational hydrothermal process, and their performance as hydrogen sulphide (H2S) gas sensors was analysed. Compared to commercial ZnO nanoparticles and conventionally hydrothermally synthesised ZnO nanorods, the ZnO porous nanorods exhibited a more uniform structure and improved crystal growth in the (002) plane, with surfaces rich in porosity and oxygen vacancies. These structural and chemical characteristics significantly improved the sensitivity toward H2S, showing high detection performance at 250°C across various concentrations of H2S gas. Additionally, the sensor demonstrated excellent selectivity against other gases such as C2H5OH, C6H6, C7H8, and NH3. This study indicated that the rotational hydrothermal process is an effective method for developing high-performance ZnO-based gas sensors and suggests its applicability to other metal oxide materials.

- [Korean]

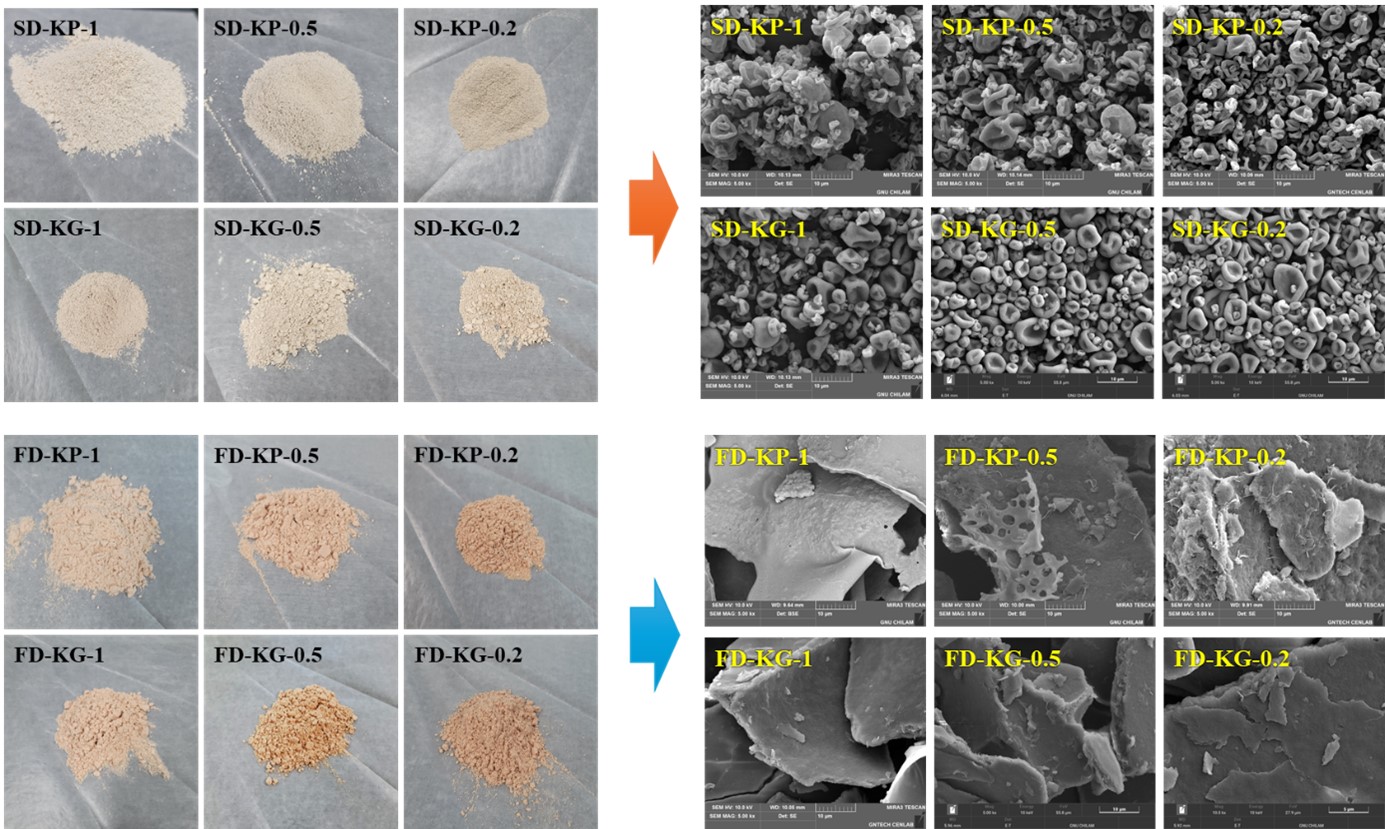

- Powderization Strategy for Porcine Organ By-Products: A Comparative Study on the Effects of Drying Method and Polymer Additives

- Seo Wan Yun, Eun Ju Jeong, Eui-Cheol Shin, Hyun-Wook Kim, Kyeong Soo Kim

- J Powder Mater. 2025;32(5):416-427. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00269

- 286 View

- 6 Download

-

Abstract

Abstract

PDF

PDF - This study aimed to develop a powderization strategy using porcine by-products (kidney, liver, and heart) by evaluating the effects of raw material type, pretreatment, and additives (hydroxypropyl methyl cellulose P645 and gelatin) on powder characteristics. Powders from kidney tissue were analyzed for yield, particle structure, compressibility, and size distribution, based on the drying method and additive composition. The spray-dried sample with gelatin at 1:0.5 (w/w) showed 20.4% compressibility and the smallest, most uniform particles, indicating excellent flowability. Due to its superior structural stability, gelatin was selected over HPMC P645. Liver and heart samples that underwent enzymatic hydrolysis and the Maillard reaction were spray-dried with gelatin and assessed for yield and microstructure. The Alcalase-treated liver sample showed the highest yield. Surface analysis confirmed that gelatin formed a protective film enhancing particle stability. These findings suggest gelatin-based spray drying is effective for producing high-quality powders from protein-rich by-products.

- [Korean]

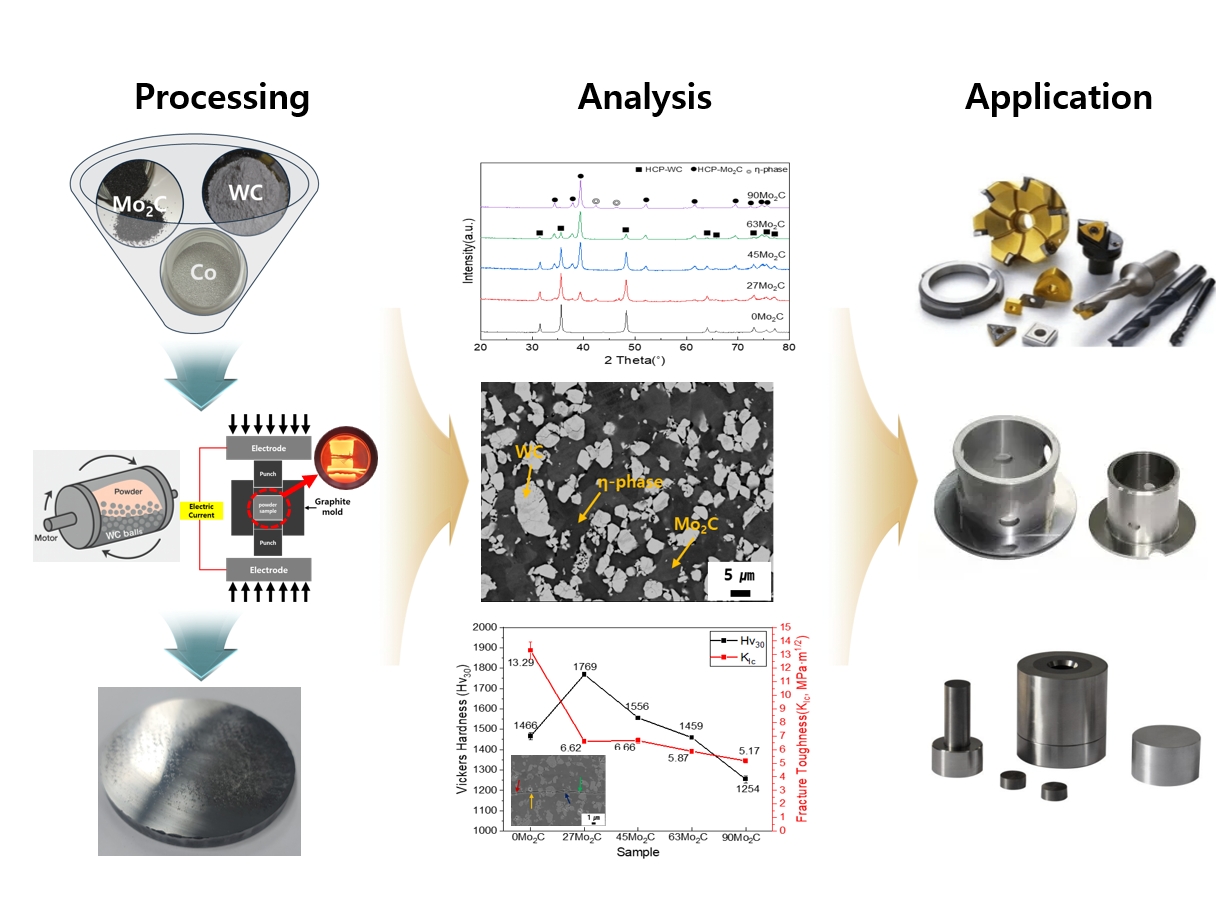

- Optimization of Mechanical Properties in WC–Mo₂C–Co Cemented Carbides via Dual Hard-Phase Based Heterogeneous Microstructure Design

- Jinwoo Seok, Jong Tae Kim, Juree Jung, SongYi Kim, Bin Lee, Junhee Han, Leeseung Kang

- J Powder Mater. 2025;32(5):428-436. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00297

- 259 View

- 12 Download

-

Abstract

Abstract

PDF

PDF - WC–Mo₂C–Co cemented carbides were fabricated to investigate the effects of Mo₂C addition on microstructure and mechanical properties. Dual hard-phase design using WC and Mo₂C was employed to optimize the balance between hardness and toughness. Spark plasma sintering (SPS) was conducted at various temperatures after ball milling, and 1300 °C for 5 min was identified as the optimized sintering condition, achieving complete densification and phase stability. The addition of Mo₂C refined the microstructure by suppressing abnormal WC grain growth through preferential dissolution of Mo₂C into the Co binder. Hardness increased up to 1769 Hv30 due to grain refinement and solid-solution strengthening, while promoted η-phase formation and reduced fracture toughness.The 27Mo₂C composition exhibited the most balanced combination of hardness and toughness. These results demonstrate that controlled Mo₂C addition enables dual hard-phase strengthening and microstructure optimization in WC–Mo₂C–Co carbides for advanced cutting and forming applications.

TOP

KPMI

KPMI

First

First Prev

Prev